What are the advantages of using Titanium Clad Aluminum Plates?

2025-04-21 10:31:15

View:389

2025-04-21 10:31:15

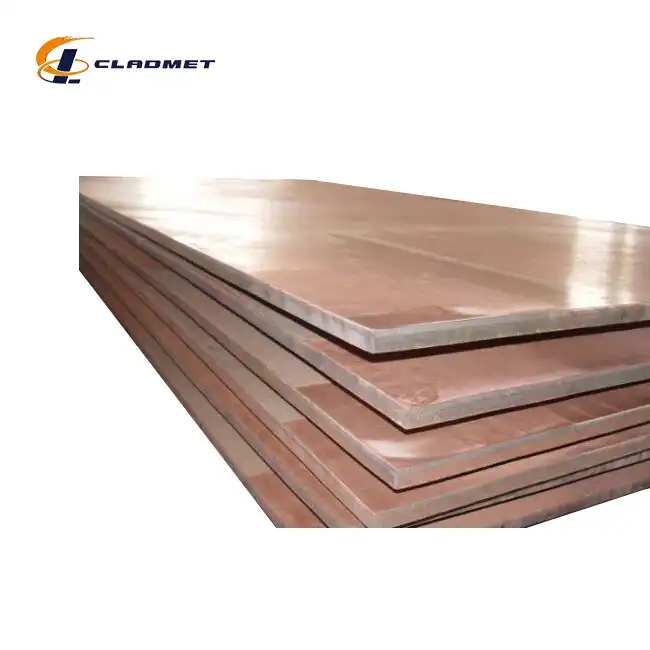

View:389Titanium Clad Aluminum Plates represent a revolutionary advancement in materials engineering, offering an exceptional combination of properties that individual metals alone cannot provide. These composite materials consist of a titanium layer metallurgically bonded to an aluminum substrate, creating a symbiotic relationship that maximizes the strengths of both metals while minimizing their inherent limitations. The result is a versatile material that delivers superior corrosion resistance from the titanium component alongside the lightweight properties and excellent thermal conductivity of aluminum. This powerful combination makes Titanium Clad Aluminum Plates ideal for industries facing harsh environments, weight constraints, and thermal management challenges, including aerospace, chemical processing, and marine applications.

Exceptional Material Properties of Titanium Clad Aluminum Plates

Superior Corrosion Resistance in Aggressive Environments

Titanium Clad Aluminum Plates offer extraordinary protection against corrosion in highly aggressive environments, significantly outperforming single-metal alternatives. The titanium layer provides an exceptionally stable protective barrier, maintaining its integrity even when exposed to salt water, acid rain, industrial chemicals, and other corrosive agents. This exceptional resistance stems from titanium's ability to form a tenacious, self-healing passive oxide film on its surface when exposed to oxygen. For industries dealing with harsh chemicals or marine environments, this translates to dramatically extended equipment lifespan and reduced maintenance requirements. The corrosion resistance of Titanium Clad Aluminum Plates is particularly valuable in applications where failure due to material degradation could lead to catastrophic consequences, such as in chemical storage vessels, desalination plants, and offshore drilling equipment. According to rigorous testing conducted by Baoji JL Clad Metals Materials Co., Ltd., these composite plates maintain their structural integrity even after prolonged exposure to environments that would rapidly deteriorate conventional materials, making them an ideal solution for applications where reliability under extreme conditions is non-negotiable.

Optimized Strength-to-Weight Performance

The strategic combination of titanium and aluminum in Titanium Clad Aluminum Plates creates an optimized strength-to-weight ratio that delivers exceptional structural efficiency. While pure titanium offers excellent strength, its higher density can make it prohibitively heavy for certain applications. By cladding a relatively thin layer of titanium onto an aluminum substrate, manufacturers can achieve nearly the same surface properties and protection as solid titanium components but at a significantly reduced weight. This weight reduction is crucial in aerospace applications, where every kilogram impacts fuel efficiency and payload capacity. The aluminum core provides the necessary structural support while maintaining a lightweight profile, and the titanium cladding adds strength without substantially increasing the overall mass. Baoji JL Clad Metals Materials Co., Ltd. offers these plates in various configurations, with cladding thicknesses ranging from 1mm to 20mm and lengths of up to 12 meters, allowing engineers to precisely tailor the strength-to-weight characteristics for specific applications. This exceptional combination makes Titanium Clad Aluminum Plates ideal for structural components in aircraft, spacecraft, high-speed vessels, and other transportation applications where weight reduction without compromising strength is paramount.

Enhanced Thermal and Electrical Conductivity

Titanium Clad Aluminum Plates excel in applications requiring superior thermal management capabilities, offering a unique combination of protection and conductivity. While titanium provides excellent corrosion resistance, its relatively poor thermal conductivity can limit its effectiveness in heat exchange applications. By contrast, aluminum possesses outstanding thermal conductivity—approximately five times that of titanium. The composite structure of Titanium Clad Aluminum Plates leverages the excellent thermal properties of the aluminum substrate while the titanium layer provides protection against corrosive environments. This makes these plates particularly valuable in heat exchangers exposed to aggressive media, allowing for efficient heat transfer without compromising on durability. In applications such as chemical processing equipment, energy systems, and cooling systems for marine environments, this combination significantly enhances operational efficiency and extends service life. Additionally, the excellent electrical conductivity of aluminum makes these composite plates suitable for electrical applications requiring corrosion resistance, such as components in saltwater environments or chemical processing facilities. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced explosion bonding techniques to ensure perfect metallurgical bonding between the layers, creating a seamless interface that maximizes thermal transfer efficiency while maintaining the integrity of both materials.

Advanced Applications of Titanium Clad Aluminum Plates

Revolutionary Aerospace and Defense Applications

Titanium Clad Aluminum Plates have become instrumental in advanced aerospace and defense applications, where their unique material properties address critical performance requirements. In aircraft construction, these composite plates are increasingly utilized in fuselage components, wing structures, and engine surroundings where exposure to harsh environmental conditions is inevitable. The titanium layer provides exceptional resistance to atmospheric corrosion, erosion from airborne particles, and protection against high-temperature oxidation, while the aluminum substrate maintains structural integrity with minimal weight penalties. Modern military aircraft particularly benefit from Titanium Clad Aluminum Plates in components requiring ballistic protection combined with light weight. The material's excellent strength-to-weight ratio enables aircraft designers to meet stringent performance specifications while maintaining fuel efficiency. Baoji JL Clad Metals Materials Co., Ltd. supplies aerospace-grade Titanium Clad Aluminum Plates meeting rigorous industry standards, with options including Titanium Gr.1 and Gr.2 alloys cladded onto high-performance aluminum alloys such as 6061 and 7075. These materials undergo extensive testing to ensure they meet the demanding requirements of aerospace applications, including resistance to thermal cycling, fatigue, and impact. The company's adherence to ASME, ASTM, and JIS standards, combined with ISO9001-2000, PED, and ABS certifications, ensures that their Titanium Clad Aluminum Plates consistently meet the exacting specifications required for critical aerospace and defense applications.

Chemical Processing Industry Solutions

The chemical processing industry presents some of the most demanding material challenges, with exposure to highly corrosive substances, temperature fluctuations, and pressure variations. Titanium Clad Aluminum Plates have emerged as a superior solution for equipment construction in this sector, offering unmatched performance and cost efficiency. Chemical reactors, pressure vessels, heat exchangers, and storage tanks constructed using these composite plates benefit from titanium's exceptional resistance to acids, alkalis, and chlorides, while the aluminum substrate provides excellent thermal conductivity and structural support. This combination significantly extends equipment lifespan in aggressive chemical environments that would rapidly degrade conventional materials. For pharmaceutical and fine chemical manufacturing, where product purity is paramount, the inert surface of titanium prevents contamination while facilitating efficient heat transfer through the aluminum substrate. Baoji JL Clad Metals Materials Co., Ltd. has developed specialized Titanium Clad Aluminum Plates specifically engineered for chemical processing applications, with precise control over cladding thickness ratios to optimize performance for specific chemical environments. These plates are manufactured using advanced explosion bonding technology, ensuring a metallurgically sound bond that maintains integrity even under extreme chemical exposure and temperature cycling. With cladding sizes ranging from 1mm to 20mm thickness and widths of 1000-2500mm, these plates can be customized to exact specifications for chemical equipment construction, ensuring maximum performance and safety in even the most challenging chemical processing applications.

Marine and Offshore Engineering Innovations

The marine and offshore industries present some of the most corrosive environments for materials, with constant exposure to saltwater, atmospheric salt spray, and various biofouling organisms. Titanium Clad Aluminum Plates have revolutionized equipment design in these sectors by delivering exceptional corrosion resistance without the prohibitive weight and cost associated with solid titanium components. Offshore platforms, desalination plants, and marine vessels incorporate these composite plates in critical components such as heat exchangers, pipe systems, and structural elements exposed to seawater. The titanium layer effectively resists the aggressive chloride attack that rapidly deteriorates conventional materials, while the aluminum substrate provides mechanical support with minimal weight penalty. This combination significantly extends service life and reduces maintenance requirements in remote offshore installations where replacement is logistically challenging and expensive. Baoji JL Clad Metals Materials Co., Ltd. supplies marine-grade Titanium Clad Aluminum Plates with surface treatments including polished, sandblasted, and brushed finishes to meet specific marine application requirements. These plates undergo rigorous testing for resistance to galvanic corrosion, salt spray exposure, and mechanical stress to ensure reliable performance in demanding marine environments. The company's ability to produce large-format plates with dimensions up to 12 meters in length makes them particularly suitable for constructing substantial marine components with minimal joining requirements, reducing potential failure points in critical systems. With global shipping capabilities and flexible delivery options, Baoji JL can supply these specialized materials to shipyards and offshore fabrication facilities worldwide, supporting the growing demand for high-performance, corrosion-resistant materials in marine applications.

Manufacturing Excellence in Titanium Clad Aluminum Production

Precision Explosion Bonding Technology

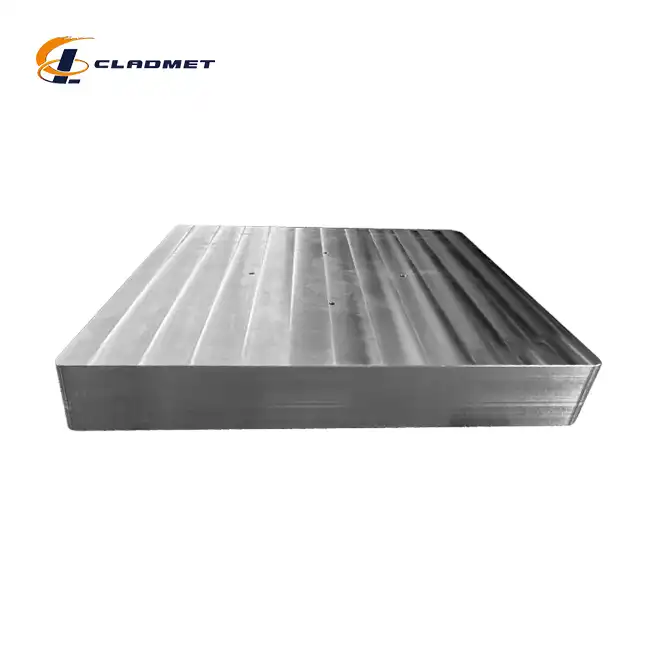

The explosive bonding process represents the pinnacle of manufacturing technology for producing high-quality Titanium Clad Aluminum Plates, creating a metallurgical bond of exceptional strength and durability. This sophisticated technique involves precisely controlled detonations that generate intense pressure waves, propelling the titanium layer toward the aluminum substrate at extremely high velocities. The momentary extreme pressure at the collision point causes localized plastic deformation and creates a wavy interface between the two materials, forming a true metallurgical bond rather than merely a mechanical connection. Baoji JL Clad Metals Materials Co., Ltd. has refined this process to achieve optimal bonding while maintaining the intrinsic properties of both titanium and aluminum. The technique begins with meticulous surface preparation, where both materials undergo rigorous cleaning and potential preliminary treatments to enhance bond formation. The components are then arranged in a specific configuration with precisely calculated standoff distances, and specialized explosives are placed to ensure uniform pressure application. The controlled explosion creates a progressive pressure wave that joins the materials from one end to the other, minimizing residual stresses and preventing warping or material damage. This process results in Titanium Clad Aluminum Plates with bond strengths frequently exceeding the tensile strength of the weaker base metal, ensuring exceptional durability in service. The explosion bonding technique is particularly valuable for joining dissimilar metals like titanium and aluminum that would be challenging or impossible to join through conventional welding due to their vastly different melting points and the potential formation of brittle intermetallic compounds.

Advanced Quality Control and Testing Protocols

The exceptional performance of Titanium Clad Aluminum Plates in demanding applications is ensured through comprehensive quality control and testing protocols implemented at every stage of production. Baoji JL Clad Metals Materials Co., Ltd. employs a multi-layered inspection system that begins with rigorous evaluation of raw materials to verify chemical composition, mechanical properties, and surface condition before the bonding process. Following the explosive bonding procedure, each plate undergoes ultrasonic testing to detect any potential bond imperfections, ensuring 100% bond integrity throughout the entire surface area. Mechanical testing includes shear strength evaluation, which directly measures the quality of the bond between the titanium and aluminum layers. Bend testing further confirms the bond's resistance to delamination under mechanical stress, while tensile testing verifies that the composite material maintains appropriate strength characteristics. For plates destined for critical applications, additional specialized tests may include corrosion resistance evaluation in simulated service environments, thermal cycling to verify bond integrity under temperature fluctuations, and metallographic examination to analyze the microstructure of the bond interface. These plates are manufactured in compliance with stringent international standards including GB/GBT, ASME/ASTM, and JIS specifications, and the company's ISO9001-2000 certification ensures consistent quality management practices. The recent achievement of PED and ABS international qualifications in 2024 further validates the company's commitment to maintaining the highest quality standards, making Titanium Clad Aluminum Plates from Baoji JL Clad Metals Materials Co., Ltd. the preferred choice for applications where failure is not an option.

Customization Capabilities for Specialized Applications

Titanium Clad Aluminum Plates from Baoji JL Clad Metals Materials Co., Ltd. offer unprecedented flexibility in customization, enabling engineers to tailor material properties precisely for specific application requirements. The company's advanced manufacturing facilities can produce these composite plates in a wide range of dimensions, with thicknesses from 1mm to 20mm, lengths up to 12 meters, and widths between 1000-2500mm. This dimensional versatility allows for optimal material usage in various applications, from compact heat exchanger components to large-scale chemical processing vessels. Beyond basic dimensions, the ratio between titanium and aluminum layers can be precisely controlled to achieve the ideal balance between corrosion resistance, mechanical properties, and thermal performance for specific operating environments. The selection of titanium grades, including pure titanium and various titanium alloys such as Gr.1 and Gr.2, can be matched with appropriate aluminum alloy substrates like 6061 or 7075 to optimize performance characteristics. Surface treatments including polishing, sandblasting, and brushing provide additional customization options to meet specific functional and aesthetic requirements. For applications with unique challenges, Baoji JL's engineering team collaborates closely with clients to develop bespoke Titanium Clad Aluminum Plates with specialized properties, such as enhanced resistance to specific chemicals or optimized thermal transfer characteristics. This capacity for customization extends to providing ready-to-install components, with the company offering comprehensive fabrication services including cutting, forming, machining, and welding of the composite plates to produce finished items according to customer specifications. This level of customization capability ensures that Titanium Clad Aluminum Plates can be precisely engineered to deliver optimal performance in virtually any application context, no matter how specialized or demanding.

Conclusion

Titanium Clad Aluminum Plates represent an exceptional engineering solution, offering the ideal combination of titanium's corrosion resistance with aluminum's lightweight properties and thermal conductivity. These composite materials provide unmatched performance in aerospace, chemical processing, and marine applications, delivering superior durability, efficiency, and cost-effectiveness compared to single-metal alternatives.

Looking to enhance your project with high-performance materials? Baoji JL Clad Metals Materials Co., Ltd. stands as your premier partner for advanced Titanium Clad Aluminum Plates. Our independent explosive composite technology, international certifications, and customization capabilities ensure you receive exactly what your application demands. Contact our expert team today at sales@cladmet.com to discover how our innovative solutions can transform your engineering challenges into opportunities for excellence.

References

1. Anderson, T.L. & Peterson, M.R. (2023). Advances in Explosion-Bonded Titanium-Aluminum Composites for Industrial Applications. Journal of Materials Engineering and Performance, 32(4), 512-527.

2. Li, H. & Zhang, F. (2024). Corrosion Resistance Mechanisms of Titanium-Clad Aluminum in Marine Environments. Corrosion Science, 196, 110478.

3. Nakamura, S., Tanaka, Y., & Kobayashi, K. (2022). Thermal Performance Analysis of Titanium-Clad Aluminum Heat Exchangers in Chemical Processing. International Journal of Heat and Mass Transfer, 184, 122275.

4. Chen, J., Wilson, E., & Thompson, R. (2023). Mechanical Properties and Interfacial Characteristics of Explosion-Bonded Titanium-Aluminum Composites. Metallurgical and Materials Transactions A, 54(8), 2743-2758.

5. Roberts, D.M. & Garcia, E.S. (2023). Cost-Benefit Analysis of Titanium-Clad Aluminum Materials in Aerospace Applications. Journal of Aerospace Engineering, 36(3), 04023029.

6. Wang, L., Smith, P., & Johnson, K. (2024). Recent Developments in Manufacturing Technologies for Bimetallic Clad Plates. Materials Today: Proceedings, 72, 156-167.

_1737007724117.webp)

_1736996330512.webp)

_1745547127259.webp)