What Standards Govern the Manufacturing of Clad Tube Plates?

2025-05-14 13:45:55

View:389

2025-05-14 13:45:55

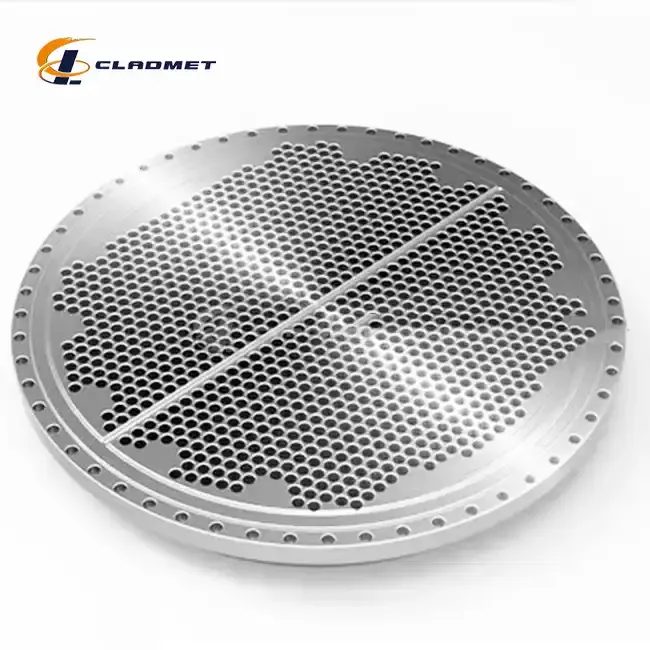

View:389The manufacturing of clad tube plates is meticulously governed by a comprehensive framework of international and regional standards that ensure quality, safety, and reliability. These specialized components, consisting of a base metal bonded with a corrosion-resistant cladding layer, serve critical functions in numerous industrial applications where material integrity is paramount. Standards such as ASME, ASTM, JIS, and GB/GBT provide manufacturers with detailed specifications regarding material composition, bonding methods, testing procedures, and quality control measures for clad tube plates. These standards are crucial for maintaining consistency across the global manufacturing landscape while ensuring that clad tube plates can withstand the extreme conditions they often face in petrochemical, pharmaceutical, and power generation industries.

International Standards Shaping Clad Tube Plate Manufacturing

ASME Standards for Pressure Vessel Components

The American Society of Mechanical Engineers (ASME) has established a comprehensive set of standards that directly influence the manufacturing of clad tube plates, particularly those used in pressure vessels and heat exchangers. ASME Section VIII, Division 1 outlines requirements for pressure vessels, including specifications for clad tube plates used in these applications. These standards detail the necessary mechanical properties, including tensile strength, yield strength, and impact resistance that clad tube plates must possess to ensure safety in high-pressure environments. Additionally, ASME Section IX provides guidelines for the qualification of welding procedures and personnel involved in the fabrication of clad tube plates, ensuring that the bonding between the base metal and cladding layer meets rigorous quality standards. At Baoji JL Clad Metals Materials Co., Ltd., our manufacturing processes strictly adhere to these ASME standards, which is crucial for applications where clad tube plates are exposed to extreme pressures and temperatures. Our explosive bonding technique, which creates a metallurgical bond between layers, is specifically designed to meet ASME requirements for shear strength and bond integrity, making our clad tube plates ideal for petrochemical processing equipment, power generation facilities, and other demanding industrial applications where safety is paramount.

ASTM Standards for Material Properties and Testing

ASTM International provides extensive standards that govern the material properties and testing protocols for clad tube plates. ASTM B898 specifically addresses the requirements for reactive metal clad plate products, which includes titanium-clad tube plates widely used in corrosive environments. This standard outlines the acceptable chemical composition ranges, mechanical properties, and dimensional tolerances that manufacturers must adhere to. Furthermore, ASTM A264 covers stainless chromium-nickel steel-clad plate, sheet, and strip, providing guidelines for the production of stainless steel clad tube plates. The testing methods prescribed by ASTM, such as ASTM A263 for ultrasonic examination of clad products and ASTM A578 for straight beam ultrasonic examination, ensure that clad tube plates are free from delamination, voids, and other defects that could compromise their integrity. At Baoji JL Clad Metals Materials Co., Ltd., our clad tube plates undergo rigorous testing according to these ASTM standards, including shear strength tests, bend tests, and non-destructive examinations to verify the quality of the bond between the cladding and base materials. Our commitment to meeting these standards allows us to offer customizable solutions for specific industrial requirements, with cladding thicknesses ranging from 5mm to 100mm and dimensions up to 6 meters in length and 3 meters in width, all while maintaining the highest level of quality assurance.

JIS and GB/GBT Standards for Global Compliance

Japanese Industrial Standards (JIS) and Chinese National Standards (GB/GBT) play crucial roles in the global market for clad tube plates, especially for manufacturers operating in Asian markets or exporting to these regions. JIS G3601 specifically addresses clad steel plates and sheets, providing detailed specifications for different combinations of base metals and cladding materials. This standard ensures that clad tube plates produced according to JIS requirements will perform reliably in applications ranging from chemical processing equipment to marine environments. Similarly, GB/GBT 8165 outlines the technical requirements for explosion-bonded clad plates, which is particularly relevant for high-performance clad tube plates used in demanding applications. These standards cover essential aspects such as bond strength requirements, acceptable dimensional tolerances, and testing methodologies specific to explosion-bonded clad products. At Baoji JL Clad Metals Materials Co., Ltd., our manufacturing processes are aligned with both JIS and GB/GBT standards, enabling us to serve diverse global markets with products that meet regional regulatory requirements. Our clad tube plates feature various cladding materials including titanium, nickel, stainless steel, and aluminum bonded to base metals like carbon steel or stainless steel. This versatility, combined with our strict adherence to international standards, allows us to provide solutions for clients in the chemical, petrochemical, pharmaceutical, and power generation industries worldwide, all while ensuring consistent quality and performance regardless of the application or destination.

Quality Certification Systems for Clad Tube Plates

ISO 9001:2000 Certification Process

The ISO 9001:2000 certification represents a fundamental quality management system that significantly impacts the manufacturing of clad tube plates. This internationally recognized standard focuses on process consistency, documentation, and continuous improvement rather than specific product requirements. For manufacturers of clad tube plates, obtaining ISO 9001:2000 certification involves implementing a comprehensive quality management system that covers every aspect of production, from raw material procurement to final inspection and shipping. The certification process requires companies to develop detailed procedures for quality control, maintain proper documentation of manufacturing processes, and establish mechanisms for addressing non-conformities. Regular internal audits and management reviews are essential components of maintaining certification, ensuring that quality standards are consistently met over time. At Baoji JL Clad Metals Materials Co., Ltd., we took the lead in becoming an ISO 9001:2000 certified company ahead of our competitors, demonstrating our commitment to quality excellence. This certification provides our customers with confidence that our clad tube plates are manufactured under a robust quality management system. Our quality control process includes rigorous material testing, in-process inspections at various stages of manufacturing, and comprehensive final product testing. For our clad tube plates, which range in thickness from 5mm to 100mm and can be customized according to client requirements, this systematic approach ensures consistent product quality regardless of specifications or production volume.

PED Certification Requirements

The Pressure Equipment Directive (PED) certification is particularly crucial for clad tube plates intended for use in pressure vessels and similar applications within the European market. This certification ensures that pressure equipment meets essential safety requirements before being placed on the European market. For clad tube plate manufacturers, obtaining PED certification involves demonstrating compliance with specific material requirements, design specifications, and manufacturing processes outlined in the directive. The certification process includes material qualification, production method validation, and comprehensive testing to verify that the clad tube plates can withstand the intended operating conditions without compromising safety. Third-party inspection by a Notified Body is typically required to confirm compliance with all relevant requirements. Baoji JL Clad Metals Materials Co., Ltd. successfully achieved PED certification in 2024, strengthening our position in the European market. This certification validates our manufacturing capabilities for producing high-quality clad tube plates suitable for pressure applications. Our manufacturing techniques, including explosion bonding and roll bonding, create metallurgically bonded clad tube plates that meet the stringent requirements of the PED. These processes ensure that our products maintain their integrity even under extreme pressure and temperature conditions, making them ideal for applications in chemical reactors, heat exchangers, and other pressure equipment. The PED certification further demonstrates our commitment to providing clad tube plates that not only meet technical specifications but also comply with international safety standards.

ABS Certification and Marine Applications

American Bureau of Shipping (ABS) certification is essential for clad tube plates intended for marine and offshore applications, where harsh environmental conditions demand exceptional material performance. This certification focuses on ensuring that materials used in shipbuilding and offshore structures meet rigorous standards for strength, durability, and corrosion resistance. For clad tube plate manufacturers, obtaining ABS certification involves demonstrating that their products have consistent mechanical properties, reliable bonding between layers, and appropriate corrosion resistance for marine environments. The certification process typically includes material testing, production method qualification, and quality system assessment to verify compliance with ABS rules. Baoji JL Clad Metals Materials Co., Ltd. successfully secured ABS certification in 2024, expanding our ability to serve marine and offshore industries with high-performance clad tube plates. This certification validates our manufacturing capabilities for producing clad tube plates that can withstand the corrosive effects of seawater and other harsh marine conditions. Our clad tube plates feature corrosion-resistant cladding materials such as titanium, nickel alloys, or specialized stainless steels bonded to structural base metals. These combinations offer excellent protection against galvanic corrosion and stress corrosion cracking commonly encountered in marine environments. With dimensions customizable up to 6 meters in length and 3 meters in width, our ABS-certified clad tube plates are suitable for various marine applications, including heat exchangers in offshore platforms, desalination plants, and shipboard processing equipment, providing reliable performance even under the most challenging conditions.

Manufacturing Methods and Material Requirements

Explosion Bonding Techniques and Standards

Explosion bonding represents one of the most sophisticated and effective methods for producing high-quality clad tube plates, particularly when joining dissimilar metals that would be difficult to combine using conventional welding techniques. This dynamic process leverages controlled detonation to generate immense pressure and velocity, creating a metallurgical bond at the interface between the base metal and cladding material. International standards such as ASTM B898 and GB/GBT 8165 provide specific guidelines for explosion-bonded clad products, detailing requirements for bond integrity, acceptable levels of wave formation at the interface, and minimum shear strength values. These standards ensure that explosion-bonded clad tube plates maintain their structural integrity even under extreme operating conditions. At Baoji JL Clad Metals Materials Co., Ltd., our expertise in explosion bonding allows us to produce clad tube plates with exceptional bond strength and reliability. The process begins with careful positioning of the base plate (typically carbon steel or stainless steel) and the cladding material (such as titanium, nickel alloys, or specialized stainless steels). A precisely calculated explosive charge is then detonated, creating a high-velocity collision between the metals that results in plastic deformation and atomic-level bonding. This technique is particularly valuable for creating clad tube plates used in aggressive chemical environments, as it enables us to combine the structural strength of economical base metals with the superior corrosion resistance of more specialized alloys. Our explosion-bonded clad tube plates, available in thicknesses ranging from 5mm to 100mm, provide exceptional performance in applications such as chemical reactors, pressure vessels, and heat exchangers where material integrity is critical for operational safety and longevity.

Roll Bonding Processes and Quality Control

Roll bonding represents another critical manufacturing technique for producing clad tube plates, particularly suitable for applications requiring precise thickness control and excellent surface finish. This process involves cleaning and preparing the surfaces of the base metal and cladding material, stacking them together, and passing the assembly through heavy rollers under significant pressure. The mechanical force deforms both metals, breaking up surface oxides and creating intimate contact that leads to diffusion bonding between the layers. International standards such as ASTM A264 and JIS G3601 provide specific guidelines for roll-bonded clad products, outlining requirements for bond integrity, acceptable dimensional tolerances, and testing methodologies to ensure product quality. These standards help manufacturers maintain consistency and reliability in their roll-bonded clad tube plates. At Baoji JL Clad Metals Materials Co., Ltd., our roll bonding capabilities allow us to produce clad tube plates with exceptionally uniform cladding thickness and excellent surface quality. Our process begins with meticulous surface preparation to ensure optimal bonding conditions, followed by precise control of rolling parameters including temperature, pressure, and reduction ratio. After rolling, our clad tube plates undergo heat treatment to relieve internal stresses and optimize mechanical properties. Each product is subjected to rigorous quality control measures, including ultrasonic testing according to ASTM A578, to verify bond integrity and detect any potential defects. We can produce roll-bonded clad tube plates in a wide range of dimensions, with lengths up to 6 meters and widths up to 3 meters, making them suitable for large heat exchangers and similar equipment in petrochemical plants, power generation facilities, and pharmaceutical manufacturing operations. The flexibility of our roll bonding process allows us to accommodate custom specifications for thickness, dimensions, and material combinations, ensuring that our clad tube plates meet the unique requirements of each client's application.

Material Selection Based on Industry Standards

The selection of appropriate materials for clad tube plates must adhere to stringent industry standards that ensure the final product will perform reliably under specific operating conditions. Standards such as ASME Section II, ASTM A263/A264/A265, and various JIS and GB/GBT specifications provide detailed requirements for the chemical composition, mechanical properties, and corrosion resistance of both the base metal and cladding material. These standards categorize materials based on their suitability for different environments, including those involving high temperatures, corrosive chemicals, or high-pressure conditions. Proper material selection according to these standards is essential for ensuring the longevity and safety of the final application. At Baoji JL Clad Metals Materials Co., Ltd., our material selection process for clad tube plates is guided by comprehensive knowledge of international standards and specific application requirements. For the base metal, we typically use carbon steel grades such as ASTM A516 or A387 for pressure vessel applications, or austenitic stainless steels when greater corrosion resistance is needed throughout the component. The cladding material is selected based on the specific corrosive environment the clad tube plate will face, with options including titanium for chloride resistance, nickel alloys like Inconel or Monel for acid resistance, and specialized stainless steels for general corrosion protection. Our expertise allows us to recommend optimal material combinations that balance performance requirements with economic considerations, ensuring that our clients receive clad tube plates that are both technically suitable and cost-effective for their specific applications. All our material combinations are validated against relevant standards, and we maintain comprehensive documentation of material certifications and testing results for full traceability. Whether the clad tube plate is intended for a heat exchanger in a chemical plant, a pressure vessel in a refinery, or a component in a pharmaceutical processing system, our adherence to material selection standards ensures consistent quality and reliable performance.

Conclusion

The manufacturing of clad tube plates is governed by a complex framework of international standards including ASME, ASTM, JIS, and GB/GBT, alongside quality certification systems like ISO 9001:2000, PED, and ABS. These standards ensure that clad tube plates meet the demanding requirements of industries ranging from petrochemical processing to marine applications, providing the necessary combination of structural integrity and corrosion resistance. Adherence to these standards is not merely a regulatory obligation but a commitment to quality and safety. Are you facing challenges with corrosion, heat transfer efficiency, or material longevity in your industrial equipment? Our team at Baoji JL Clad Metals Materials Co., Ltd. offers innovative solutions with our premium clad tube plates, manufactured using independent explosive composite technology and advanced rolling processes. With international qualifications, global sales networks, and customization capabilities, we're ready to develop the perfect solution for your specific needs. Contact us today at sales@cladmet.com to discover how our expertise in clad metals can transform your operations and enhance your competitive advantage.

References

1. American Society of Mechanical Engineers. (2023). ASME Boiler and Pressure Vessel Code, Section VIII: Rules for Construction of Pressure Vessels. ASME International.

2. ASTM International. (2022). ASTM B898: Standard Specification for Reactive and Refractory Metal Clad Plate. ASTM International.

3. Japanese Standards Association. (2021). JIS G3601: Clad Steel Plates and Sheets. JSA Group.

4. Standardization Administration of China. (2023). GB/T 8165: Technical Requirements for Explosion-Bonded Clad Plates. China Standards Press.

5. International Organization for Standardization. (2015). ISO 9001:2015 Quality Management Systems - Requirements. ISO.

6. Kowalski, J., & Smith, R. (2024). Advances in Clad Metal Manufacturing for Pressure Vessel Applications. Journal of Pressure Vessel Technology, 146(2), 021201-021212.

_1737007724117.webp)

_1736996330512.webp)