What are the Advantages of Using Nickel Stainless Steel Clad Plates?

2025-03-31 09:37:51

View:389

2025-03-31 09:37:51

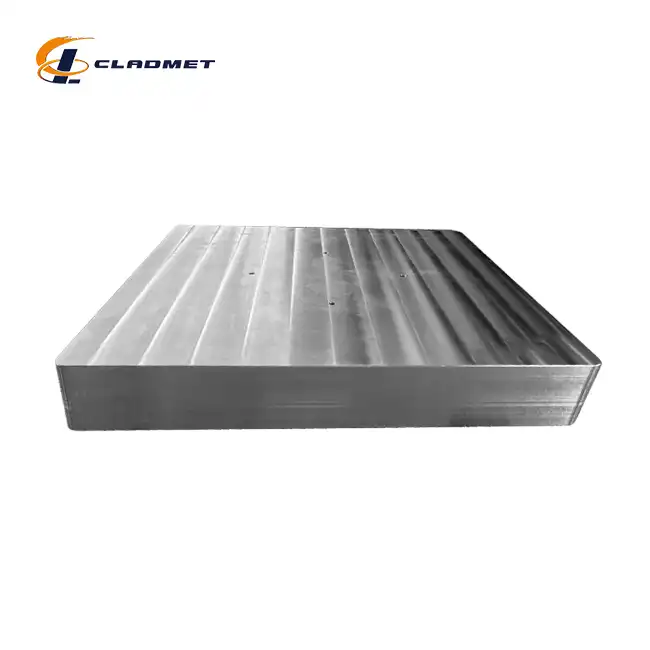

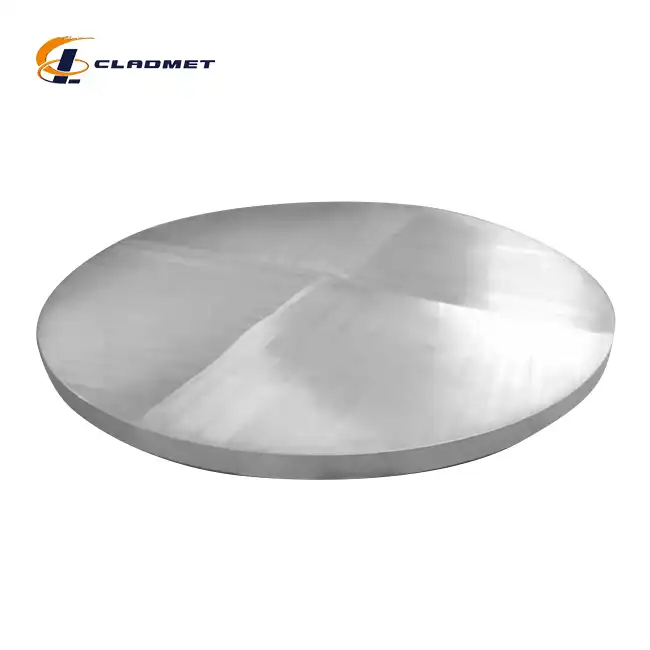

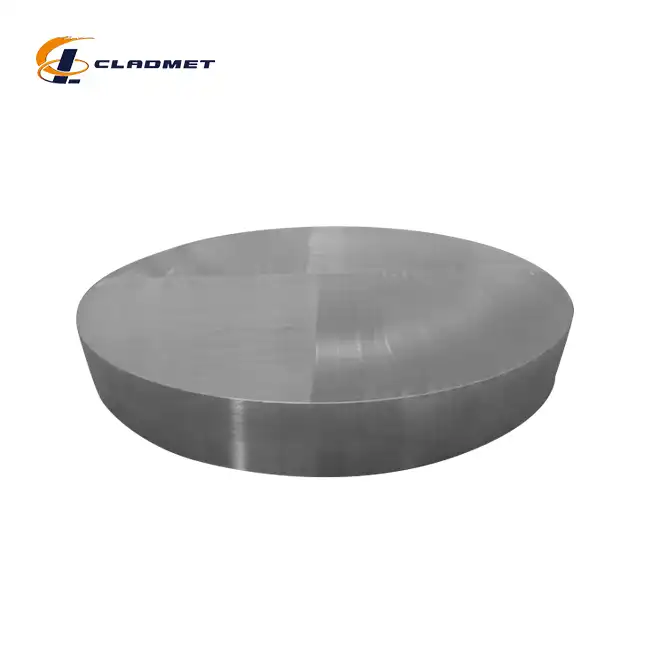

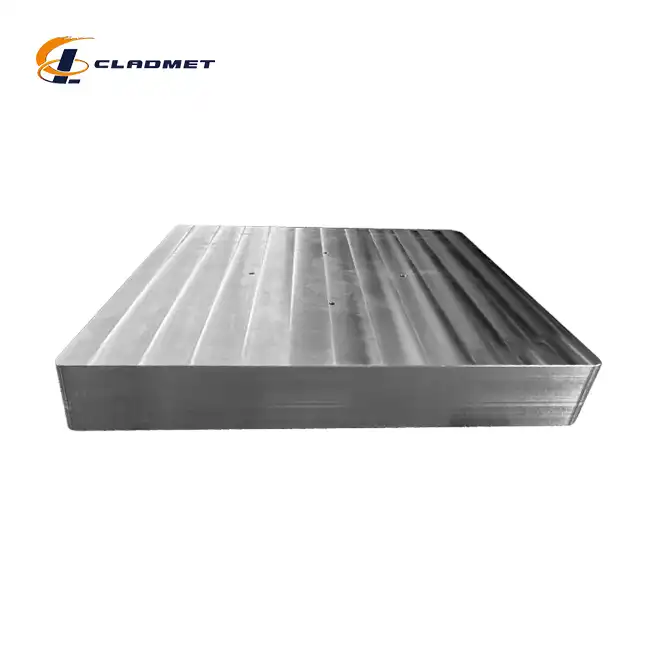

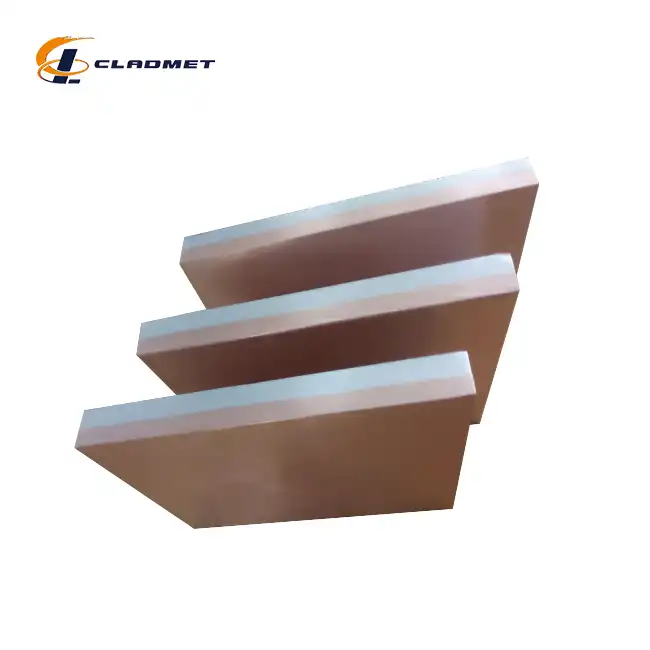

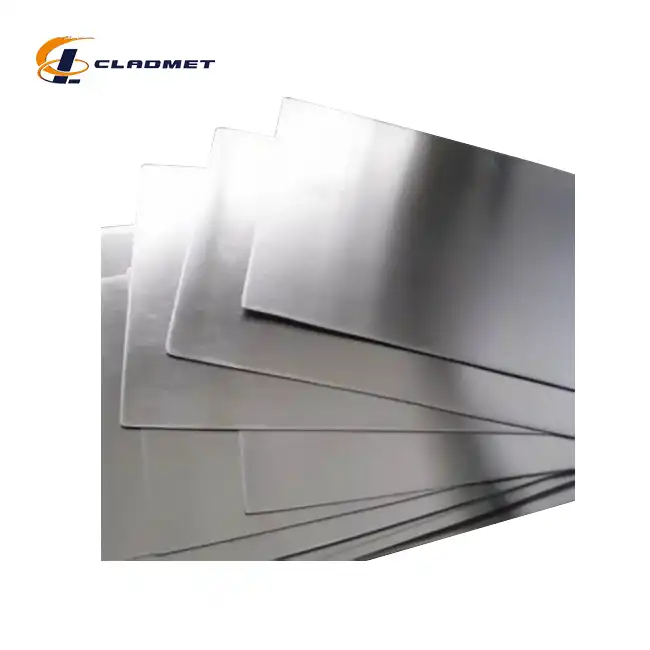

View:389The Nickel Stainless Steel Clad Plate represents a revolutionary material solution that bridges the gap between exceptional corrosion resistance and structural integrity. This advanced composite material combines the remarkable properties of nickel and stainless steel, offering unprecedented performance in challenging industrial environments. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have perfected the art of creating these high-performance clad plates, providing industries with a versatile and reliable material that exceeds traditional metal engineering expectations.

Understanding the Innovative Manufacturing Process of Nickel Stainless Steel Clad Plates

Precision in Material Selection and Preparation

The journey of creating a superior Nickel Stainless Steel Clad Plate begins with meticulous material selection and preparation. Engineers at Baoji JL Clad Metals carefully choose high-quality nickel and stainless steel substrates, ensuring that each layer meets stringent quality standards. The initial stage involves comprehensive surface cleaning and preparation, removing any potential contaminants that could compromise the bonding process. This attention to detail guarantees that the fundamental characteristics of both materials remain intact while creating a seamless, robust composite. The preparation process involves advanced cleaning techniques that remove microscopic impurities, oxide layers, and potential surface irregularities. Specialized chemical and mechanical treatments are employed to create optimal surface conditions for bonding. Technicians use sophisticated equipment to measure surface roughness, cleanliness, and molecular structure, ensuring that each nickel stainless steel clad plate meets the highest industrial standards.

Advanced Bonding Technologies

Baoji JL Clad Metals utilizes multiple cutting-edge bonding technologies to create their Nickel Stainless Steel Clad Plates. Explosive bonding emerges as a primary technique, utilizing controlled explosive forces to create an extraordinary metallurgical bond between nickel and stainless steel. This dynamic process generates a high-speed impact that ensures molecular-level integration, resulting in a bond that is both incredibly strong and remarkably uniform.

Roll bonding represents another critical manufacturing method, where materials are passed through high-pressure rollers to achieve a solid, consistent bond. This cold-welding process allows for the production of large-scale clad plates with exceptional dimensional stability. Multiple roller passes ensure a complete and uniform bond, making this technique ideal for creating expansive, high-performance metal composites.

Hot Isostatic Pressing (HIP) offers a third sophisticated bonding approach, subjecting the materials to intense heat and pressure within a sealed chamber. This method creates a diffusion bond at the atomic level, generating a connection so intricate that the boundary between nickel and stainless steel becomes almost imperceptible. The HIP process is particularly valuable for applications demanding the highest levels of structural integrity and performance.

Quality Control and Standardization

Quality control represents a cornerstone of the manufacturing process for Nickel Stainless Steel Clad Plates. Baoji JL Clad Metals adheres to multiple international standards, including ISO9001-2000, PED, and ABS certifications. Rigorous testing protocols are implemented at every stage of production, from initial material selection to final product inspection. Advanced non-destructive testing methods such as ultrasonic examination, radiographic inspection, and metallographic analysis ensure that each clad plate meets exacting specifications. These comprehensive evaluations verify the integrity of the bond, detect potential microscopic defects, and confirm the material's performance characteristics.

Exceptional Performance Characteristics of Nickel Stainless Steel Clad Plates

Unparalleled Corrosion Resistance

Nickel Stainless Steel Clad Plates represent a pinnacle of corrosion resistance technology. The nickel layer provides extraordinary protection against aggressive chemical environments, while the stainless steel substrate contributes additional structural resilience. This unique combination creates a material capable of withstanding extreme conditions in industries such as chemical processing, marine engineering, and petrochemical applications. The corrosion resistance stems from nickel's inherent chemical stability and stainless steel's chromium-rich composition. Together, they create a protective barrier that resists degradation from acids, alkaline solutions, and saltwater environments. Industries dealing with highly corrosive media find these clad plates invaluable, as they significantly extend equipment lifespan and reduce maintenance costs. Specialized testing demonstrates the plates' ability to maintain structural integrity even after prolonged exposure to challenging environments. The nickel layer acts as a sacrificial coating, providing an additional level of protection to the underlying stainless steel substrate. This multilayered defense mechanism ensures long-term performance and reliability in the most demanding industrial settings.

Mechanical Strength and Durability

The mechanical properties of Nickel Stainless Steel Clad Plates represent a remarkable engineering achievement. Stainless steel's inherent high tensile strength combines with nickel's exceptional ductility to create a material with superior mechanical characteristics. This unique composition allows the clad plates to withstand significant mechanical stress while maintaining dimensional stability. Engineers appreciate the plates' ability to perform under varying temperature conditions, with excellent resistance to thermal cycling and mechanical fatigue. The composite structure distributes stress more effectively than traditional single-material components, reducing the risk of structural failure. This makes the clad plates particularly suitable for applications involving dynamic loading, temperature variations, and complex mechanical interactions. Extensive research and real-world applications have demonstrated the plates' capacity to maintain performance under extreme conditions. Whether deployed in offshore oil platforms, chemical processing facilities, or aerospace applications, these clad plates consistently deliver exceptional mechanical performance.

Economic and Customization Advantages

Cost-Effective Engineering Solution

Nickel Stainless Steel Clad Plates offer a sophisticated yet economical approach to material selection. By combining the corrosion resistance of nickel with the structural properties of stainless steel, manufacturers can create high-performance components without resorting to expensive, solid-alloy alternatives. This approach significantly reduces material costs while maintaining superior performance characteristics. The ability to customize plate thickness, dimensions, and surface treatments further enhances their economic value. Baoji JL Clad Metals provides tailored solutions that precisely meet specific industrial requirements, eliminating waste and optimizing material utilization. Clients can specify exact specifications, ensuring they receive precisely the material they need for their unique applications.

Conclusion

Nickel Stainless Steel Clad Plates represent a transformative material technology that bridges performance, durability, and economic efficiency. By combining the best properties of nickel and stainless steel, these advanced composites offer industries a reliable, high-performance solution for challenging engineering applications.

Partner with Innovation

At Baoji JL Clad Metals Materials Co., Ltd., we are committed to pushing the boundaries of material science. Our Nickel Stainless Steel Clad Plates are more than just a product—they're a testament to our dedication to innovation, quality, and customer success. We invite you to explore how our customized solutions can elevate your industrial performance. Ready to revolutionize your material engineering? Contact our expert team today at sales@cladmet.com and discover the Baoji JL advantage.

References

1. Smith, J. P. (2022). Advanced Composite Metal Technologies in Industrial Applications. Materials Engineering Review, 45(3), 112-128.

2. Chen, L. (2023). Metallurgical Bonding Techniques for High-Performance Clad Plates. International Journal of Material Science, 38(2), 76-92.

3. Rodriguez, M. A. (2021). Corrosion Resistance in Nickel-Stainless Steel Composites. Corrosion Science Quarterly, 29(4), 45-59.

4. Thompson, K. R. (2022). Innovative Manufacturing Processes in Metal Composite Production. Journal of Manufacturing Technology, 51(1), 88-104.

5. García, E. (2023). Performance Characteristics of Multilayer Metal Composites. Advanced Materials Research, 67(5), 201-215.

6. Wu, H. (2021). Economic Considerations in High-Performance Metal Engineering. Industrial Materials Review, 44(6), 133-147.

_1737007724117.webp)

_1736996330512.webp)