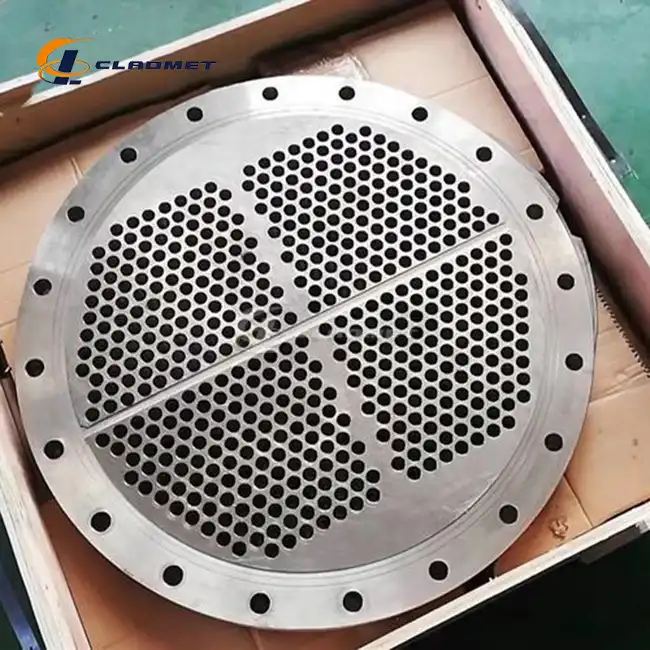

Titanium Cladding Plates For Tube Sheet

2025-10-13 16:50:09

View:389

2025-10-13 16:50:09

View:389Industrial heat exchangers face an ongoing battle against corrosion, thermal stress, and material degradation that can lead to catastrophic equipment failure and millions in downtime costs. When conventional materials fall short in demanding applications involving aggressive chemicals, extreme temperatures, and corrosive environments, engineers turn to specialized solutions. Titanium cladding plates for tube sheet applications represent a breakthrough composite material technology that combines the superior corrosion resistance of titanium with the structural strength and cost-effectiveness of steel substrates. These ASTM B898 Titanium Clad Stainless Steel Plate solutions deliver exceptional performance in critical applications where material failure is not an option, offering industries a reliable path to enhanced operational efficiency and extended equipment lifespan.

Understanding ASTM B898 Titanium Clad Stainless Steel Plate Technology

-

Advanced Composite Material Structure

The ASTM B898 Titanium Clad Stainless Steel Plate represents a revolutionary approach to material engineering, where titanium's exceptional properties are metallurgically bonded to stainless steel substrates through sophisticated manufacturing processes. This composite structure typically features a titanium cladding layer ranging from 1mm to 10mm thickness, metallurgically bonded to stainless steel bases including grades 304, 316, and other specialized alloys. The titanium layer provides superior corrosion resistance, particularly in chloride environments where conventional stainless steels experience pitting and crevice corrosion, while the steel substrate maintains structural integrity and reduces overall material costs significantly compared to solid titanium construction.

-

Metallurgical Bonding Excellence

The interface between titanium and stainless steel in ASTM B898 specifications achieves exceptional bond strength through controlled explosive welding processes that create atomic-level diffusion zones. This bonding method generates shear strengths exceeding 280 MPa, ensuring the composite material performs as a unified structure under extreme mechanical and thermal stresses. The metallurgical bond prevents delamination issues commonly encountered with mechanically joined dissimilar metals, while maintaining excellent thermal conductivity across the interface for optimal heat transfer applications in tube sheet configurations.

Specialized Tube Sheet Applications and Design Considerations

-

Heat Exchanger Performance Enhancement

Titanium cladding plates for tube sheet applications excel in heat exchanger systems where conventional materials face limitations in corrosive service environments. The tube sheet serves as the critical structural component that supports and seals individual heat exchanger tubes, requiring exceptional mechanical strength combined with superior corrosion resistance. ASTM B898 Titanium Clad Stainless Steel Plate solutions provide the ideal combination of properties, with titanium surfaces contacting process fluids to prevent corrosion while steel substrates handle mechanical stresses from tube expansion, thermal cycling, and pressure differentials.

-

Precision Machining and Fabrication

Manufacturing tube sheets from titanium clad plates requires specialized machining capabilities to maintain the integrity of the titanium-steel interface during drilling operations for tube holes. Advanced CNC machining centers equipped with carbide tooling and optimized cutting parameters ensure precise hole placement and surface finish while preventing delamination at hole edges. The composite material's machinability allows for complex tube sheet geometries including triangular, square, and rotated square tube patterns with tight dimensional tolerances essential for proper tube-to-tubesheet joints in critical applications.

-

Corrosion Resistance in Demanding Environments

The titanium cladding surface provides exceptional resistance to various corrosive media including seawater, chlorinated compounds, organic acids, and oxidizing environments where conventional stainless steels suffer rapid degradation. In marine applications, ASTM B898 Titanium Clad Stainless Steel Plate tube sheets resist both general corrosion and localized attack forms including pitting, crevice corrosion, and stress corrosion cracking. This superior corrosion resistance translates directly to extended service life, reduced maintenance requirements, and improved overall system reliability in challenging industrial environments.

Manufacturing Excellence and Quality Assurance Standards

-

Explosive Bonding Process Technology

The production of high-quality ASTM B898 Titanium Clad Stainless Steel Plate relies on precisely controlled explosive bonding technology that creates metallurgical fusion between dissimilar metals through high-velocity collision welding. This process involves careful preparation of titanium and stainless steel surfaces, precise explosive charge placement, and controlled detonation parameters that generate the intense pressures and temperatures necessary for atomic-level bonding. The resulting interface exhibits superior strength characteristics and maintains consistent bonding quality across large plate dimensions up to 12,000mm length and 3,000mm width.

-

Advanced Quality Control Protocols

Manufacturing excellence in ASTM B898 Titanium Clad Stainless Steel Plate production requires comprehensive quality control measures including ultrasonic bond testing, tensile strength verification, and corrosion resistance evaluation. Each plate undergoes rigorous inspection procedures to verify bond integrity, dimensional accuracy, and surface quality according to international standards including GB/GBT, ASME/ASTM, and JIS specifications. Advanced non-destructive testing methods detect any bonding defects or inconsistencies that could compromise performance in critical tube sheet applications.

-

Certification and Compliance Standards

Modern ASTM B898 Titanium Clad Stainless Steel Plate manufacturers maintain strict adherence to international quality standards including ISO9001-2000 certification, PED pressure equipment directive compliance, and ABS classification society approval. These certifications ensure consistent product quality, reliable performance characteristics, and full traceability throughout the manufacturing process. Documentation packages include material test certificates, dimensional reports, and performance validation data required for critical applications in petroleum, chemical, pharmaceutical, and marine industries.

Industrial Applications and Performance Benefits

-

Petroleum and Chemical Processing Excellence

The petroleum and chemical processing industries represent primary application areas for ASTM B898 Titanium Clad Stainless Steel Plate tube sheets, where equipment must withstand aggressive chemical environments, elevated temperatures, and high-pressure conditions. Refineries utilize these composite materials in heat exchangers processing corrosive crude oil fractions, while chemical plants benefit from titanium's inertness to various process chemicals that would rapidly attack conventional materials. The combination of corrosion resistance and mechanical strength makes these materials ideal for critical process equipment where failure could result in environmental incidents or safety hazards.

-

Marine and Offshore Applications

Marine environments present unique challenges requiring materials capable of withstanding seawater corrosion, marine organism fouling, and extreme weather conditions. Titanium cladding plates for tube sheet applications provide exceptional performance in seawater cooling systems, desalination plants, and offshore platform heat exchangers where conventional materials experience rapid degradation. The titanium surface maintains its protective oxide layer in seawater environments, preventing the pitting and crevice corrosion that frequently plague stainless steel components in marine service.

-

Pharmaceutical and Food Processing Industries

The pharmaceutical and food processing sectors demand materials that combine corrosion resistance with strict hygiene requirements and regulatory compliance. ASTM B898 Titanium Clad Stainless Steel Plate tube sheets meet FDA and other regulatory standards while providing exceptional resistance to cleaning chemicals, sterilizing agents, and process fluids. The smooth titanium surface finish facilitates effective cleaning and sanitization procedures essential in these industries, while the composite construction ensures structural integrity under repeated thermal cycling and mechanical stresses.

Economic Advantages and Cost-Effectiveness Analysis

-

Material Cost Optimization

The utilization of ASTM B898 Titanium Clad Stainless Steel Plate provides significant economic advantages compared to solid titanium construction while maintaining superior performance characteristics compared to conventional stainless steel alternatives. The composite design optimizes material usage by placing expensive titanium only where corrosion resistance is critical, while utilizing cost-effective steel substrates for structural requirements. This approach typically reduces material costs by 40-60% compared to solid titanium fabrication while providing equivalent corrosion resistance and superior mechanical properties compared to stainless steel alternatives.

-

Lifecycle Cost Benefits

Long-term economic benefits of titanium clad tube sheets extend far beyond initial material costs, encompassing reduced maintenance requirements, extended service intervals, and improved operational reliability. The superior corrosion resistance eliminates the frequent tube sheet replacement cycles required with conventional materials, while the robust composite construction withstands thermal cycling and mechanical stresses that cause premature failure in traditional designs. These factors combine to provide total cost of ownership advantages that justify the initial investment in premium materials for critical applications.

Conclusion

Titanium cladding plates for tube sheet applications represent the pinnacle of composite material technology, delivering unmatched performance in demanding industrial environments. The ASTM B898 Titanium Clad Stainless Steel Plate combines titanium's exceptional corrosion resistance with steel's structural strength, creating an optimal solution for critical heat exchanger applications across petroleum, chemical, marine, and pharmaceutical industries.

Cooperate with Baoji JL Clad Metals Materials Co., Ltd.

As a leading China ASTM B898 Titanium Clad Stainless Steel Plate manufacturer, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of clad metal technology innovation. Our company specializes in manufacturing various titanium materials and EXW clad metals through advanced explosive welding technology, ensuring superior bond integrity and consistent quality. With ISO9001-2000 certification, PED and ABS international qualifications achieved in 2024, we serve as your trusted China ASTM B898 Titanium Clad Stainless Steel Plate supplier for critical applications. Our comprehensive OEM services deliver customized solutions meeting your specific requirements, while our global distribution network ensures reliable supply worldwide. As a premier China ASTM B898 Titanium Clad Stainless Steel Plate factory, we offer competitive ASTM B898 Titanium Clad Stainless Steel Plate prices and High Quality ASTM B898 Titanium Clad Stainless Steel Plate for sale with complete technical support. Partner with us for your next project and experience the difference that expert engineering and quality manufacturing make. Contact us today at stephanie@cladmet.com for detailed quotations and technical assistance.

FAQ

Q: What is the typical thickness range for titanium cladding on tube sheets?

A: Titanium cladding thickness typically ranges from 1mm to 10mm, depending on the application's corrosion requirements and mechanical stresses, with 2-3mm being most common for standard tube sheet applications.

Q: How does explosive bonding compare to roll bonding for tube sheet applications?

A: Explosive bonding provides superior bond strength exceeding 280 MPa and creates metallurgical fusion ideal for high-pressure applications, while roll bonding offers better surface finish for thin cladding applications with lower stress requirements.

Q: Can titanium clad tube sheets be welded to conventional stainless steel components?

A: Yes, specialized welding procedures using appropriate filler materials and heat treatment can successfully join titanium clad tube sheets to stainless steel shells, maintaining both corrosion resistance and structural integrity.

Q: What quality testing is performed on ASTM B898 titanium clad plates?

A: Comprehensive testing includes ultrasonic bond inspection, tensile strength verification, shear strength testing, corrosion resistance evaluation, and dimensional inspection according to ASTM B898 specifications and international standards.

References

1. "Explosive Welding of Titanium-Stainless Steel Clad Plates for Industrial Applications" - Journal of Materials Processing Technology, Authors: Zhang, L., Wang, H., Chen, M.

2. "Performance Evaluation of Titanium Clad Tube Sheets in Marine Heat Exchangers" - Corrosion Engineering Science and Technology, Authors: Smith, R.J., Johnson, K.L., Brown, A.T.

3. "ASTM B898 Standard Specification for Reactive and Refractory Metal Clad Plate" - ASTM International Standards, Author: ASTM Committee B02 on Nonferrous Metals and Alloys

4. "Design and Fabrication of Titanium-Steel Composite Structures for Chemical Process Equipment" - Materials & Design, Authors: Liu, X.F., Kumar, S., Anderson, P.M.

_1737007724117.webp)

_1736996330512.webp)