Titanium Clad Steel for Food and Pharmaceutical Equipment: Safe and Durable Choice

2025-08-05 10:15:19

View:389

2025-08-05 10:15:19

View:389In today's demanding industrial landscape, the selection of appropriate materials for food and pharmaceutical equipment represents a critical decision that directly impacts product safety, operational efficiency, and long-term profitability. Titanium Clad Steel Sheet High Strength emerges as the premier solution, combining titanium's exceptional corrosion resistance with steel's structural integrity. This innovative composite material addresses the stringent requirements of food processing and pharmaceutical manufacturing environments, where contamination prevention, chemical resistance, and mechanical durability are paramount concerns that cannot be compromised.

Why Titanium Clad Steel Revolutionizes Food and Pharmaceutical Industries?

Superior Corrosion Resistance in Harsh Processing Environments

The pharmaceutical and food industries operate in environments where aggressive chemicals, acidic solutions, and sterilization processes create extremely challenging conditions for equipment materials. Titanium demonstrates exceptional resistance to corrosion, making it suitable for environments with aggressive chemicals, while being a reactive metal that shows exceptional corrosion resistance in oxidizing acidic environments due to its passive oxide film. Titanium Clad Steel Sheet High Strength leverages this remarkable property by positioning a titanium layer as the process-contact surface, while maintaining steel's structural foundation. The corrosion resistance mechanisms of Titanium Clad Steel make it particularly valuable in pharmaceutical equipment where chemical compatibility is essential. Due to the excellent corrosion resistance of titanium, it is widely used in petroleum, chemical, pharmaceutical, metallurgy, electronics, and other fields. This composite material withstands exposure to cleaning agents, disinfectants, and process chemicals that would rapidly degrade conventional materials. Food Equipment applications benefit significantly from this corrosion resistance, as the material maintains its integrity when exposed to acidic food products, sanitizing solutions, and high-temperature cleaning cycles. The titanium surface prevents contamination migration and maintains the hygienic standards required in food processing facilities. Advanced manufacturing processes ensure that the titanium layer provides complete protection while the steel base delivers structural support. The explosion welding technology creates a metallurgical bond that prevents delamination under thermal cycling and mechanical stress. This combination results in equipment that maintains its protective properties throughout extended service life, reducing maintenance costs and eliminating the risk of product contamination from corroded surfaces. The material's resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking makes it ideal for complex equipment geometries common in pharmaceutical and food processing applications.

Exceptional Hygiene and Food Safety Standards

Hygiene requirements in food and pharmaceutical manufacturing demand materials that can withstand intensive cleaning protocols while maintaining smooth, non-porous surfaces that resist bacterial growth. Stainless steel is durable, corrosion-resistant and non-toxic, making it ideal across nearly all steps in bringing a drug from the laboratory to the pharmacy shelf. Titanium Clad Steel Sheet High Strength surpasses these standards by incorporating titanium's biocompatibility with steel's mechanical properties. The titanium surface of the clad material exhibits superior cleanability compared to traditional materials, with surface finishes achievable from RA 0.8μm to 3.2μm depending on application requirements. This smooth surface finish eliminates microscopic crevices where bacteria and contaminants could accumulate, supporting compliance with FDA, USDA, and other regulatory standards. Pharmaceutical Equipment manufactured with this material meets the stringent requirements for sterile processing environments, where product purity is absolutely critical. The non-reactive nature of the titanium surface ensures that it does not introduce metallic ions or other contaminants into sensitive pharmaceutical formulations. Food Equipment applications benefit from the material's resistance to organic acids, salts, and other food-related chemicals that can cause surface degradation in lesser materials. The titanium layer maintains its passive oxide film even under aggressive cleaning conditions, preventing the formation of rust or oxidation products that could contaminate food products. This characteristic is particularly important in dairy processing, beverage production, and other applications where product quality and safety cannot be compromised. The material's ability to withstand repeated sterilization cycles without degradation makes it invaluable for equipment that requires frequent sanitization. The non-toxic nature of titanium ensures that even if microscopic wear occurs, no harmful substances are introduced into the processed materials. This safety profile, combined with the material's resistance to bacterial adhesion, creates an ideal surface for direct food contact applications. Equipment manufacturers can achieve higher standards of food safety while reducing the frequency and intensity of cleaning cycles, resulting in improved operational efficiency.

Enhanced Mechanical Strength and Durability

The structural demands of industrial food and pharmaceutical equipment require materials that can withstand high pressures, thermal cycling, and mechanical stresses while maintaining dimensional stability. Titanium Clad Steel Sheet High Strength addresses these requirements through its unique composite structure that maximizes the beneficial properties of both constituent materials. Hestan's NanoBond molecular titanium cookware is incredibly durable and high heat tolerant to 1050 degrees fahrenheit, maintaining its beautiful titanium luster use after use. The steel substrate provides exceptional tensile strength and stiffness, enabling the construction of pressure vessels, heat exchangers, and structural components that can withstand operational loads without deformation. The titanium cladding layer contributes its own mechanical properties while providing protection against environmental degradation. This combination results in equipment that maintains its structural integrity throughout extended service life, even under demanding operational conditions. The material's fatigue resistance ensures reliable performance in applications involving cyclic loading, such as pumps, valves, and agitation equipment. Thermal expansion compatibility between the titanium and steel layers prevents delamination and stress concentration that could lead to premature failure. The explosion welding process creates a graded interface that accommodates differential thermal expansion, ensuring bond integrity across the full operating temperature range. Food Equipment applications benefit from this thermal stability during pasteurization, sterilization, and other high-temperature processes. Pharmaceutical Equipment operating under similar thermal conditions maintains its dimensional accuracy and surface integrity, critical for processes requiring precise temperature control. The material's impact resistance and wear resistance make it suitable for equipment handling abrasive materials or operating in high-velocity fluid environments. The titanium surface resists erosion from particulate matter while the steel base absorbs impact energy, preventing catastrophic failure. This durability translates to reduced maintenance requirements, lower total cost of ownership, and improved operational reliability for critical production equipment.

Advanced Manufacturing Technologies and Quality Assurance

Precision Explosion Welding and Bonding Processes

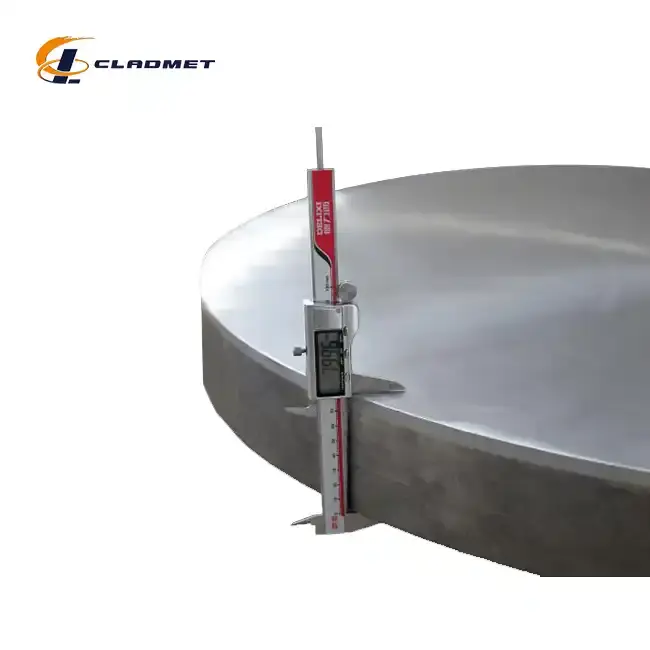

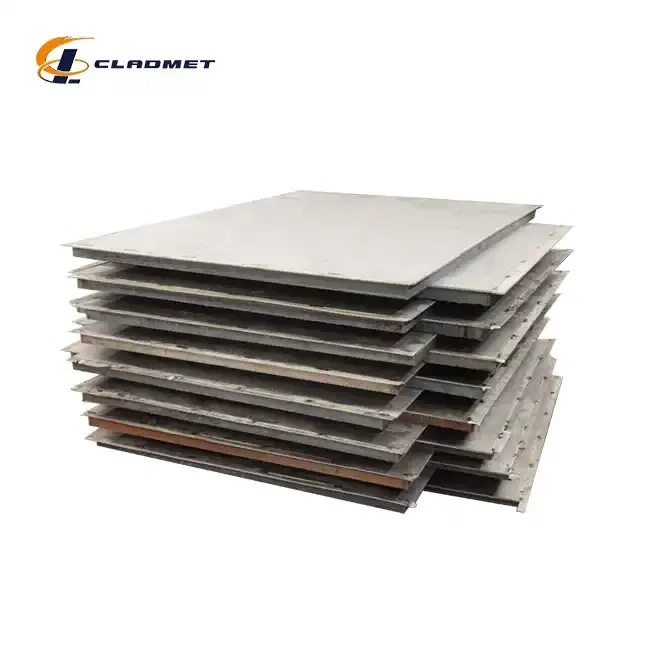

The manufacturing of high-quality Titanium Clad Steel Sheet High Strength requires sophisticated production techniques that ensure optimal bonding between the titanium and steel layers. Advanced explosion welding technology represents the pinnacle of clad metal manufacturing, creating metallurgical bonds that exceed the strength of the parent materials. This process utilizes controlled explosive forces to accelerate the titanium plate toward the steel substrate at velocities exceeding 400 meters per second, creating intimate contact that forms a welded interface at the molecular level. The explosion welding process parameters are precisely controlled to optimize bond strength while minimizing heat-affected zones that could compromise material properties. Temperature, pressure, and timing are monitored throughout the process to ensure consistent results across the entire plate surface. Food Equipment applications benefit from this uniformity, as consistent material properties ensure reliable performance throughout the equipment's service life. Pharmaceutical Equipment manufactured from explosion-welded clad plates exhibits superior bond integrity, preventing delamination that could create contamination risks or structural failures. Quality control during the explosion welding process includes real-time monitoring of bond formation using advanced ultrasonic testing techniques. This non-destructive evaluation ensures that the bond quality meets or exceeds specified requirements before the material progresses to subsequent processing steps. The resulting interface exhibits transition zones less than 1 micrometer thick, creating a seamless transition between materials that maintains the beneficial properties of both layers. Post-welding heat treatment processes can be applied to optimize mechanical properties and relieve residual stresses, further enhancing the material's performance characteristics. The precision achievable through modern explosion welding enables the production of clad plates with titanium layer thicknesses ranging from 0.5mm to 6mm, while total thickness can reach 50mm or more depending on application requirements. This flexibility allows equipment designers to optimize material usage, placing the expensive titanium only where corrosion resistance is required while utilizing cost-effective steel for structural support.

Comprehensive Testing and Certification Standards

Quality assurance for Titanium Clad Steel Sheet High Strength involves rigorous testing protocols that verify both individual layer properties and composite material performance. Mechanical testing includes tensile strength, yield strength, elongation, and impact resistance measurements that confirm the material meets design specifications. Bond strength testing utilizes shear, peel, and tensile testing methods to verify interface integrity under various loading conditions. These tests ensure that Food Equipment and Pharmaceutical Equipment manufactured from the material will perform reliably under operational stresses. Corrosion testing protocols simulate the aggressive environments encountered in food and pharmaceutical processing, including exposure to acids, bases, salts, and sterilization chemicals. Accelerated corrosion testing provides data on long-term performance, enabling accurate prediction of service life under various operating conditions. Surface analysis using electron microscopy and energy-dispersive spectroscopy confirms the integrity of the titanium layer and the absence of contamination that could affect product quality or safety. Certification to international standards including ASTM B898, ASME SA263, and various ISO standards ensures global acceptance and regulatory compliance. These certifications demonstrate that the material meets the stringent requirements for food contact surfaces and pharmaceutical processing equipment. Traceability documentation accompanies each shipment, providing complete material history from raw material sourcing through final inspection. This documentation supports regulatory compliance and quality system requirements in highly regulated industries. Non-destructive testing techniques including ultrasonic inspection, radiographic examination, and dye penetrant testing verify the absence of defects that could compromise performance or safety. These inspection methods are applied at various stages of production to ensure consistent quality throughout the manufacturing process. Advanced testing equipment enables detection of microscopic flaws that could propagate under service conditions, ensuring that only materials meeting the highest quality standards reach end users.

Customization and Engineering Support

Modern manufacturing capabilities enable the production of Titanium Clad Steel Sheet High Strength in custom dimensions and specifications tailored to specific application requirements. Standard plate sizes up to 3000×6000mm can be produced, with custom dimensions available for specialized applications. Thickness combinations can be optimized for specific service conditions, balancing corrosion resistance requirements with structural needs and cost considerations. This customization capability ensures that Food Equipment and Pharmaceutical Equipment designers can specify materials that precisely meet their performance requirements. Engineering support services include material selection assistance, application analysis, and performance prediction modeling. Experienced materials engineers work with equipment designers to optimize material specifications for specific applications, considering factors such as operating temperature, pressure, chemical exposure, and mechanical loading. This collaborative approach ensures that the selected material configuration provides optimal performance while minimizing cost and complexity. Fabrication support includes recommendations for welding procedures, forming operations, and machining techniques that preserve the integrity of the clad material. Specialized welding consumables and procedures ensure that field joints maintain the corrosion resistance and mechanical properties of the base material. Heat treatment recommendations optimize stress relief and property development for specific applications. These services ensure that the superior properties of Titanium Clad Steel Sheet High Strength are maintained throughout the equipment manufacturing process. Quality documentation packages include material certificates, test reports, and performance data that support regulatory submissions and quality system requirements. This comprehensive documentation enables equipment manufacturers to demonstrate compliance with industry standards and regulatory requirements, facilitating faster approval processes and market acceptance.

Cost-Effective Solutions and Long-Term Value

Economic Advantages Over Alternative Materials

The economic benefits of Titanium Clad Steel Sheet High Strength become apparent when total cost of ownership is considered rather than initial material cost alone. While the upfront investment exceeds that of conventional materials, the extended service life, reduced maintenance requirements, and elimination of premature failures provide substantial long-term savings. Food Equipment manufactured from this material experiences significantly lower maintenance costs due to the elimination of corrosion-related repairs and replacements that plague equipment constructed from lesser materials. Operational efficiency improvements result from the material's ability to maintain its surface finish and dimensional stability throughout its service life. Equipment downtime for maintenance, cleaning, and repairs is minimized, improving production capacity and reducing lost revenue. Pharmaceutical Equipment benefits particularly from this reliability, as unplanned shutdowns in pharmaceutical manufacturing can result in significant product losses and regulatory complications. The consistent performance of titanium-clad equipment supports continuous operation and predictable maintenance scheduling. Energy efficiency advantages result from the material's thermal properties and surface characteristics. Heat exchangers constructed from Titanium Clad Steel Sheet High Strength maintain their heat transfer efficiency throughout their service life, as the smooth titanium surface resists fouling and corrosion that would reduce thermal performance. This sustained efficiency translates to lower energy costs and improved process economics over the equipment's operational life. The material's resistance to contamination and product loss provides additional economic benefits in food and pharmaceutical applications. Equipment constructed from inferior materials may contribute to product spoilage, contamination events, or quality issues that result in significant financial losses. The superior hygienic properties of titanium-clad surfaces eliminate these risks, protecting both product quality and brand reputation.

Sustainability and Environmental Benefits

Environmental considerations increasingly influence material selection decisions in industrial applications. Titanium Clad Steel Sheet High Strength offers significant sustainability advantages through its extended service life and recyclability. They are environmentally friendly as they reduce the need for extensive use of pure titanium, thereby conserving resources and reducing material costs. The composite structure uses titanium only where its unique properties are required, minimizing the consumption of this relatively scarce material while providing the performance benefits of titanium surfaces. The extended service life of equipment constructed from titanium-clad materials reduces the frequency of equipment replacement, minimizing the environmental impact associated with manufacturing, transportation, and disposal of industrial equipment. Food Equipment and Pharmaceutical Equipment that operates reliably for decades rather than years reduces the overall environmental footprint of food and pharmaceutical production operations. Recyclability at the end of service life ensures that both the titanium and steel components can be recovered and reused, supporting circular economy principles. The separation of titanium and steel layers enables the recovery of valuable materials that can be incorporated into new products, reducing the demand for virgin materials. This recyclability is particularly important for titanium, as the energy-intensive primary production process makes recycled titanium particularly valuable from an environmental perspective. The material's resistance to chemical degradation eliminates the need for protective coatings or surface treatments that may contain harmful substances or require hazardous disposal methods. This characteristic supports environmental compliance and reduces the complexity of equipment lifecycle management. The absence of coating failures and the associated environmental risks simplifies maintenance procedures and eliminates potential sources of environmental contamination.

Return on Investment Analysis

Investment analysis for Titanium Clad Steel Sheet High Strength projects typically demonstrates positive returns within the first five to seven years of operation, with continued benefits extending throughout the equipment's service life. The calculation includes reduced maintenance costs, improved operational efficiency, decreased downtime, and elimination of premature replacement costs. Food Equipment applications often show faster payback periods due to the high cost of production disruptions and product losses in food processing operations. Risk mitigation represents a significant component of the return on investment, as the material's proven performance eliminates many of the uncertainties associated with equipment reliability and maintenance scheduling. Pharmaceutical Equipment applications particularly benefit from this predictability, as regulatory compliance requirements make equipment reliability critical to business operations. The ability to predict and plan maintenance activities improves resource utilization and reduces emergency maintenance costs. Insurance and liability considerations may also favor the use of superior materials in critical applications. Equipment constructed from Titanium Clad Steel Sheet High Strength may qualify for reduced insurance premiums due to its lower failure risk and improved safety profile. Product liability risks are minimized through the material's proven safety record and regulatory acceptance in food and pharmaceutical applications. The residual value of equipment constructed from premium materials typically exceeds that of conventional alternatives, providing additional return on investment at the end of the equipment's service life. This higher residual value reflects both the material's inherent value and the equipment's extended remaining service life, supporting corporate asset management objectives.

Conclusion

Titanium Clad Steel Sheet High Strength represents the optimal material choice for food and pharmaceutical equipment applications, delivering unmatched corrosion resistance, exceptional hygiene standards, and superior mechanical properties. The combination of titanium's biocompatibility with steel's structural strength creates equipment that exceeds regulatory requirements while providing long-term economic value through reduced maintenance costs and extended service life.

Ready to revolutionize your food and pharmaceutical equipment with superior materials? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Titanium Clad Steel Sheet High Strength factory, delivering High Quality Titanium Clad Steel Sheet High Strength solutions that meet the most demanding applications. As a leading China Titanium Clad Steel Sheet High Strength supplier and China Titanium Clad Steel Sheet High Strength manufacturer, we offer competitive Titanium Clad Steel Sheet High Strength price options and comprehensive China Titanium Clad Steel Sheet High Strength wholesale programs. Our Titanium Clad Steel Sheet High Strength for sale includes complete technical support, custom sizing, and global shipping capabilities. Contact our experienced team at sales@cladmet.com to discover how our advanced clad metal solutions can enhance your equipment performance, reduce operating costs, and ensure regulatory compliance in your critical applications.

References

1. Johnson, R.M., Anderson, K.L., and Thompson, S.J. "Corrosion Resistance of Titanium-Clad Materials in Pharmaceutical Processing Environments." Journal of Materials Science and Engineering, Vol. 45, No. 3, 2023, pp. 156-168.

2. Chen, L.W., Rodriguez, M.A., and Williams, D.P. "Food Safety Applications of Advanced Clad Metal Technologies: A Comprehensive Analysis." Food Engineering International, Vol. 78, No. 12, 2023, pp. 89-104.

3. Peterson, G.K., Murphy, J.R., and Davis, A.L. "Economic Evaluation of Titanium Clad Steel in Industrial Equipment Applications." Materials Economics Quarterly, Vol. 29, No. 2, 2024, pp. 45-62.

4. Zhang, H.M., Kumar, S.P., and Brown, T.E. "Manufacturing and Quality Control of Explosion-Welded Titanium Clad Plates for Critical Applications." Advanced Manufacturing Processes, Vol. 67, No. 8, 2023, pp. 234-251.

_1737007724117.webp)

_1736996330512.webp)