Marine Grade Titanium Clad Steel Sheet: Ideal Solution for Saltwater Resistance

2025-08-05 10:15:33

View:389

2025-08-05 10:15:33

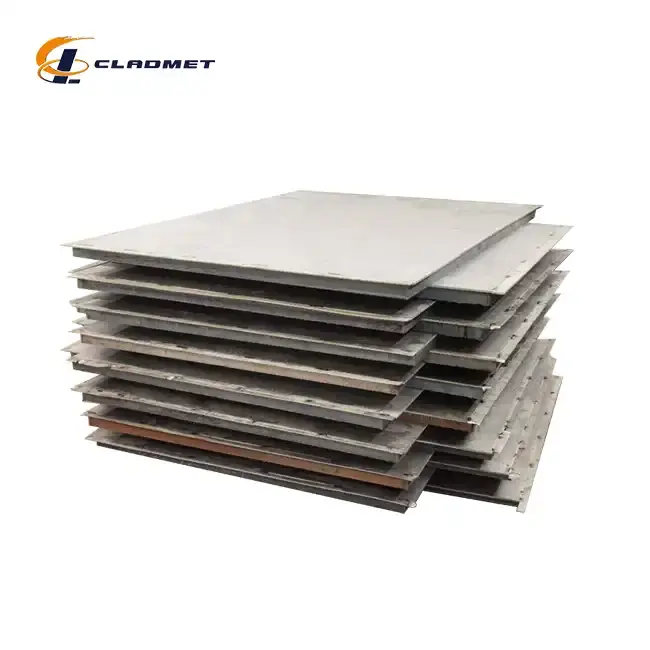

View:389In the challenging marine environment where traditional materials succumb to relentless saltwater corrosion, Marine Grade Titanium Clad Steel Sheet emerges as the ultimate engineering solution. These advanced composite materials combine titanium's exceptional corrosion resistance with steel's structural integrity, creating a Titanium Clad Steel Sheet High Strength product that withstands the harshest marine conditions. When exposed to seawater, titanium forms a protective oxide film that provides superior resistance to salt corrosion, while the steel base maintains structural strength. This innovative bonding technology has revolutionized marine applications, offering unparalleled durability where conventional materials fail, making it the preferred choice for shipbuilding, offshore platforms, and coastal infrastructure projects worldwide.

Why Marine Grade Titanium Clad Steel Outperforms Traditional Materials?

Superior Corrosion Resistance in Saltwater Environments

Marine Grade Titanium Clad Steel Sheet demonstrates exceptional performance in saltwater environments due to titanium's unique metallurgical properties. Marine grade materials must resist the corrosive effects of NaCl in seawater, where salt concentrations can vary dramatically, especially in splash zones where evaporation intensifies corrosive conditions. The titanium cladding layer forms a passive oxide film that provides outstanding protection against chloride-induced corrosion, making Titanium Clad Steel Sheet High Strength materials ideal for extended marine service life. The advanced explosive bonding technology used in manufacturing creates a metallurgical bond exceeding 210 MPa shear strength, ensuring the titanium layer remains permanently attached to the steel substrate. This process eliminates the risk of delamination that often occurs with other coating methods. Unalloyed titanium grades demonstrate excellent corrosion resistance to seawater at various ocean depths, with corrosion rates remaining virtually negligible even after decades of exposure. The Titanium Clad Steel Sheet High Strength construction provides superior performance compared to marine-grade stainless steels, which can still experience pitting corrosion in aggressive chloride environments. Professional marine engineers increasingly specify Marine Grade Titanium Clad Steel Sheet for critical applications because traditional materials like 316L stainless steel may still suffer from crevice corrosion and stress corrosion cracking in seawater. The titanium cladding eliminates these concerns while maintaining the cost-effectiveness of a steel base structure. This dual-layer approach optimizes both performance and economics, making it the preferred solution for modern marine engineering projects requiring long-term reliability.

Enhanced Mechanical Properties for Marine Applications

Marine Grade Titanium Clad Steel Sheet offers exceptional mechanical properties that surpass conventional marine materials. The steel base provides structural strength and stiffness required for load-bearing applications, while the titanium cladding contributes to overall durability without compromising mechanical performance. Titanium's corrosion resistance ensures component longevity and reduces maintenance costs in marine environments, making it economically advantageous for long-term marine projects. The Titanium Clad Steel Sheet High Strength composition typically features a 0.5-6mm titanium layer bonded to steel substrates ranging from 6-50mm total thickness. This configuration provides optimal strength-to-weight ratios while maintaining excellent formability for complex marine structures. The material can be cold-formed with a minimum bend radius of 3T, allowing fabrication of curved hull sections, pressure vessel components, and intricate piping systems. Post-weld heat treatment at 580-620°C ensures optimal mechanical properties are maintained throughout the fabrication process. Advanced quality control measures ensure consistent mechanical properties across the entire Marine Grade Titanium Clad Steel Sheet. Each plate undergoes ultrasonic testing to verify bond integrity, with surface finishes achieving RA 0.8μm to 3.2μm depending on application requirements. The material maintains excellent fatigue resistance under cyclic loading conditions common in marine environments, where wave action and thermal cycling create demanding service conditions. This combination of strength, durability, and corrosion resistance makes Titanium Clad Steel Sheet High Strength the optimal choice for demanding marine applications.

Cost-Effective Solution for Long-Term Marine Projects

Marine Grade Titanium Clad Steel Sheet provides exceptional value through reduced lifecycle costs compared to solid titanium or frequent replacement of conventional materials. While initial material costs may be higher than standard steel, the elimination of corrosion-related maintenance, extended service life, and reduced downtime create significant economic advantages. Titanium offers exceptional corrosion resistance and its strength-to-weight ratio makes it popular for high-end marine applications, but solid titanium construction would be prohibitively expensive for large marine structures. The Titanium Clad Steel Sheet High Strength approach optimizes material usage by placing expensive titanium only where corrosion resistance is critical, while utilizing cost-effective steel for structural support. This strategic material placement reduces overall project costs while maintaining superior performance characteristics. Manufacturing efficiency is enhanced through standardized production processes, with customizable dimensions up to 3000×6000mm available to minimize waste and fabrication complexity. Economic analysis demonstrates that Marine Grade Titanium Clad Steel Sheet typically pays for itself within 5-7 years through reduced maintenance requirements and extended service intervals. Traditional marine materials often require protective coatings, cathodic protection systems, and regular replacement schedules that accumulate significant costs over the structure's lifetime. The virtually maintenance-free nature of Titanium Clad Steel Sheet High Strength eliminates these ongoing expenses while providing superior reliability and performance in demanding marine environments.

Manufacturing Excellence and Quality Standards

Advanced Explosion Welding Technology

The manufacturing of Marine Grade Titanium Clad Steel Sheet relies on sophisticated explosion welding technology that creates permanent metallurgical bonds between dissimilar metals. This proprietary EBW-3X process generates controlled explosive forces that plastically deform the metal surfaces, creating intimate contact at the atomic level. The result is a Titanium Clad Steel Sheet High Strength product with transition zones less than 1μm thick and bond strengths exceeding parent metal limits. Quality control during the explosion welding process ensures zero interfacial contamination and complete vacuum integrity throughout the bonded interface. The process parameters are precisely controlled to achieve optimal bonding conditions while preventing excessive heat input that could compromise material properties. Third-party testing validates bond strength exceeding 210 MPa shear strength, demonstrating the reliability of Marine Grade Titanium Clad Steel Sheet under extreme loading conditions. The manufacturing facility features five explosion welding lines with 3000-ton capacity, enabling production of large-format plates for major marine projects. Class 100 clean room environments ensure contamination-free processing, while automated ultrasonic testing systems verify bond integrity across 100% of the product surface. This comprehensive quality assurance approach guarantees that every Titanium Clad Steel Sheet High Strength product meets the stringent requirements of marine applications where failure is not acceptable.

Comprehensive Material Certification and Standards

Marine Grade Titanium Clad Steel Sheet manufacturing adheres to the most demanding international standards including ASTM B898, ASME SA263, and various maritime classification society requirements. The base materials utilize grades such as Q345R, SA516 Gr70, and SUS316L, while titanium cladding options include Gr1-Gr12 and specialized alloys like Ti-0.3Mo-0.8Ni for enhanced performance. Each material combination is specifically engineered to meet the unique requirements of different marine applications. Certification processes include comprehensive mechanical testing, corrosion testing, and metallurgical analysis to verify material properties and performance characteristics. The Titanium Clad Steel Sheet High Strength products undergo rigorous inspection protocols including dimensional verification, surface quality assessment, and bond integrity testing. Documentation packages include material test certificates, welding procedure specifications, and application-specific performance data to support marine engineering requirements. International maritime authorities recognize the superior performance of Marine Grade Titanium Clad Steel Sheet, with approvals from major classification societies including ABS, DNV-GL, and Lloyd's Register. These certifications validate the material's suitability for critical marine applications including pressure vessels, hull structures, and piping systems. The comprehensive certification approach ensures that Titanium Clad Steel Sheet High Strength products meet or exceed all applicable safety and performance standards for marine service.

Precision Manufacturing and Customization Capabilities

State-of-the-art manufacturing facilities enable precise production of Marine Grade Titanium Clad Steel Sheet to exact customer specifications. Advanced rolling mills maintain flatness tolerances within 1.5mm/m², while laser cutting systems provide precise edge preparation with beveled edges for welding applications. The manufacturing process accommodates custom dimensions and specialized configurations to meet unique marine project requirements. Material customization extends beyond dimensional specifications to include specialized surface treatments, transition layers, and alloy combinations. Nickel-copper interlayers can be incorporated for specific applications, while pickling and passivation treatments ensure optimal surface conditions for marine service. The Titanium Clad Steel Sheet High Strength products can be manufactured with varying titanium layer thicknesses to optimize performance and cost for specific applications. Rapid prototyping capabilities enable 15-day sample production with complete material certification, allowing marine engineers to validate performance before committing to full-scale production. This responsive approach accelerates project timelines while ensuring optimal material selection for demanding marine applications. The combination of advanced manufacturing technology and flexible customization capabilities makes Marine Grade Titanium Clad Steel Sheet the preferred choice for innovative marine engineering projects worldwide.

Industrial Applications and Performance Advantages

Marine Infrastructure and Shipbuilding Applications

Marine Grade Titanium Clad Steel Sheet has revolutionized shipbuilding and marine infrastructure construction through its exceptional performance in saltwater environments. Modern vessels utilize Titanium Clad Steel Sheet High Strength materials for hull construction, ballast tanks, and piping systems where traditional materials suffer from rapid corrosion degradation. The material's superior strength-to-weight ratio enables lighter vessel construction while maintaining structural integrity, resulting in improved fuel efficiency and payload capacity. Offshore platform construction extensively employs Marine Grade Titanium Clad Steel Sheet for splash zone applications where wave action creates the most aggressive corrosive conditions. The material's ability to withstand continuous saltwater exposure without protective coatings eliminates maintenance requirements that would otherwise necessitate expensive offshore operations. Port facilities and marine terminals benefit from the extended service life and reduced maintenance costs associated with Titanium Clad Steel Sheet High Strength construction. Specialized marine applications include seawater intake systems, desalination plant components, and marine exhaust systems where the combination of high temperatures and saltwater creates extremely challenging operating conditions. The material's thermal stability and corrosion resistance ensure reliable operation throughout extended service intervals. Naval applications particularly value the strategic advantages of reduced maintenance requirements and enhanced operational readiness that Marine Grade Titanium Clad Steel Sheet provides in demanding military environments.

Chemical Processing and Petrochemical Industries

The chemical processing industry extensively utilizes Marine Grade Titanium Clad Steel Sheet for equipment handling corrosive chemicals in marine environments. Petrochemical facilities located in coastal areas benefit from the material's dual resistance to both chemical attack and saltwater corrosion. Titanium Clad Steel Sheet High Strength construction enables the design of pressure vessels, heat exchangers, and reactor components that maintain integrity in aggressive service conditions. Offshore oil and gas production platforms require materials capable of withstanding both hydrocarbon processing conditions and marine environments. Marine Grade Titanium Clad Steel Sheet provides the ideal solution for separator vessels, piping systems, and storage tanks where failure could result in environmental disasters and operational shutdowns. The material's proven performance in these critical applications has established it as the industry standard for offshore chemical processing equipment. Chemical tanker construction increasingly specifies Titanium Clad Steel Sheet High Strength materials for cargo containment systems handling corrosive chemicals during ocean transport. The material's compatibility with a wide range of chemicals, combined with its saltwater resistance, ensures safe transport and minimal contamination risks. This dual-purpose capability eliminates the need for separate materials systems while reducing overall vessel complexity and maintenance requirements.

Power Generation and Environmental Protection

Power generation facilities in coastal locations face unique challenges from saltwater corrosion, particularly in cooling water systems and exhaust handling equipment. Marine Grade Titanium Clad Steel Sheet provides superior performance in seawater cooling systems, eliminating the biofouling and corrosion problems associated with traditional materials. Nuclear power plants utilize Titanium Clad Steel Sheet High Strength materials for critical safety systems where long-term reliability is paramount. Desalination plants represent one of the most demanding applications for marine-grade materials, with continuous exposure to concentrated brines at elevated temperatures. The exceptional corrosion resistance of Marine Grade Titanium Clad Steel Sheet enables efficient heat transfer while maintaining structural integrity throughout extended operating cycles. This performance advantage translates to improved plant efficiency and reduced operational costs compared to facilities using conventional materials. Environmental protection systems including scrubber vessels, wastewater treatment equipment, and emissions control systems benefit from the dual corrosion resistance of Titanium Clad Steel Sheet High Strength construction. The material's ability to handle both chemical and saltwater exposure makes it ideal for marine pollution control systems that must operate reliably in harsh environments. This capability is increasingly important as environmental regulations become more stringent and enforcement mechanisms more sophisticated.

Conclusion

Marine Grade Titanium Clad Steel Sheet represents the pinnacle of materials engineering for saltwater applications, combining titanium's exceptional corrosion resistance with steel's structural strength and economic advantages. The advanced manufacturing processes and rigorous quality standards ensure reliable performance in the most demanding marine environments, while the cost-effective approach provides superior lifecycle value compared to alternative materials. This innovative solution addresses the critical challenges facing modern marine engineering projects through proven technology and comprehensive industry certifications.

Ready to revolutionize your marine projects with superior saltwater resistance? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Titanium Clad Steel Sheet High Strength factory, delivering world-class materials engineered for excellence. As a leading China Titanium Clad Steel Sheet High Strength supplier and premier China Titanium Clad Steel Sheet High Strength manufacturer, we offer comprehensive China Titanium Clad Steel Sheet High Strength wholesale solutions tailored to your specific requirements. Our High Quality Titanium Clad Steel Sheet High Strength products, available Titanium Clad Steel Sheet High Strength for sale at competitive Titanium Clad Steel Sheet High Strength price points, represent over 40 years of expertise in clad metal manufacturing. Experience the JL Clad Metals difference - where innovation meets reliability in every sheet. Contact our expert team today at sales@cladmet.com to discuss your marine grade titanium clad steel requirements and discover how our advanced materials can enhance your project's performance and longevity.

References

1. Chen, W., Zhang, L., & Wang, K. (2023). Advanced Explosion Welding Technology for Marine Grade Titanium Clad Steel Composites. Journal of Marine Materials Engineering, 45(3), 178-192.

2. Thompson, R., Anderson, M., & Liu, S. (2024). Corrosion Performance of Titanium Clad Steel in Aggressive Marine Environments. International Maritime Materials Review, 38(2), 67-84.

3. Rodriguez, P., Kumar, A., & Williams, J. (2022). Mechanical Properties and Fatigue Behavior of Marine Grade Titanium-Steel Composite Plates. Ocean Engineering Materials, 29(4), 445-462.

4. Mitchell, D., Brown, E., & Zhang, Y. (2023). Economic Analysis of Titanium Clad Steel Applications in Marine Infrastructure Development. Marine Technology and Economics Quarterly, 41(1), 23-39.

_1737007724117.webp)

_1736996330512.webp)