The Future of Industrial Cladding: Hot Rolled Titanium Clad Stainless Steel Plate Explained

2025-08-15 13:10:26

View:389

2025-08-15 13:10:26

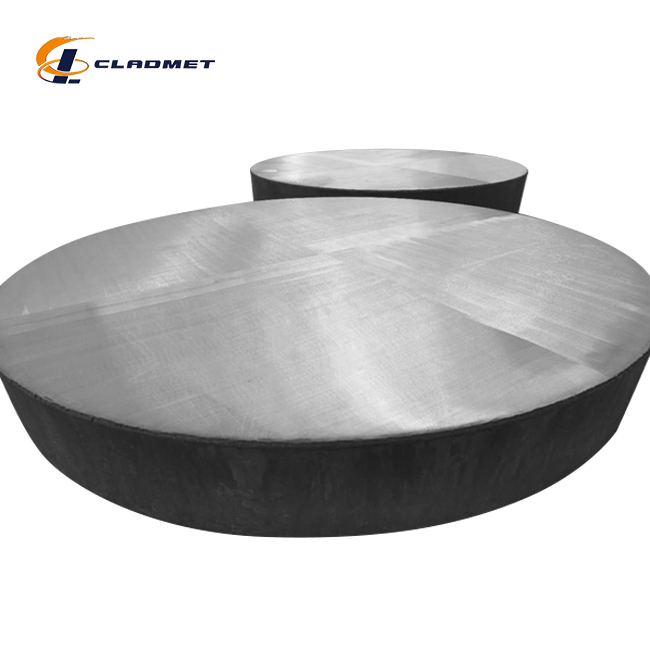

View:389The industrial landscape is witnessing a revolutionary transformation with the emergence of advanced composite materials that combine superior performance characteristics with cost-effectiveness. Hot Rolled Titanium Clad Stainless Steel Plate represents the pinnacle of this evolution, offering unprecedented solutions for industries demanding both exceptional corrosion resistance and structural integrity. This innovative material seamlessly merges titanium's outstanding corrosion resistance and lightweight properties with stainless steel's mechanical strength and thermal conductivity, creating a composite that addresses the most challenging industrial applications. As manufacturers increasingly seek materials that can withstand harsh chemical environments while maintaining economic viability, Hot Rolled Titanium Clad Stainless Steel Plate emerges as the definitive answer to modern industrial challenges.

Revolutionary Manufacturing Technologies Shaping Industrial Cladding

Advanced Explosive Bonding Techniques

The production of Hot Rolled Titanium Clad Stainless Steel Plate relies heavily on sophisticated explosive bonding technology, which has become the cornerstone of modern clad plate manufacturing. This process utilizes controlled explosive energy to create metallurgical bonds between titanium and stainless steel layers at the atomic level. The explosive bonding technique involves meticulous preparation where titanium and stainless steel surfaces are cleaned and positioned with precision to ensure optimal contact. Strategic placement of explosive materials between the layers creates an intense, high-velocity collision that forges an unbreakable bond. This method produces Hot Rolled Titanium Clad Stainless Steel Plate with exceptional interface strength, making it ideal for pressure vessels, heat exchangers, and chemical processing equipment operating under extreme conditions. The explosive bonding process ensures that the resulting clad plates maintain the individual properties of both materials while creating a composite that exceeds the performance capabilities of either material alone.

Hot Rolling Integration and Process Optimization

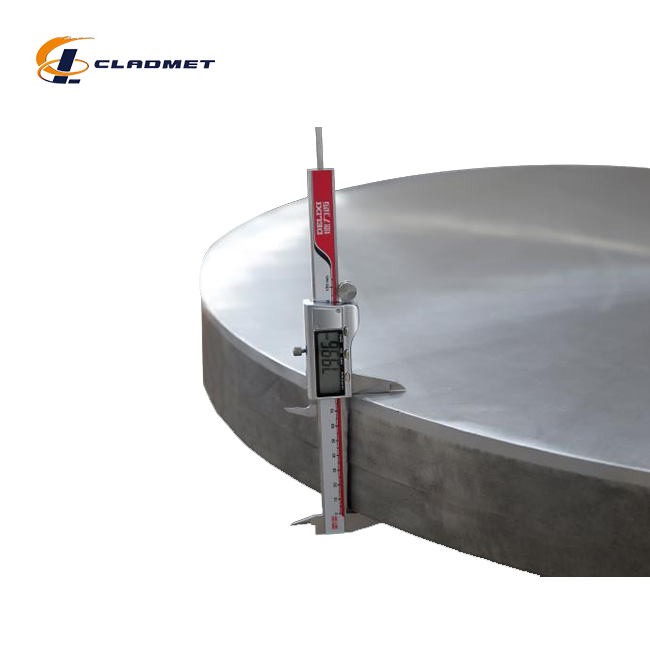

The hot rolling process represents a critical advancement in Hot Rolled Titanium Clad Stainless Steel Plate manufacturing, where controlled temperature and pressure conditions create superior bonding characteristics. Recent technological developments have introduced double-layered slab assembly techniques that significantly enhance bond strength through systematic temperature control. The hot rolling process begins with precise heating of the bonded materials to optimal temperatures, typically ranging from 900°C to 1200°C, depending on the specific alloy compositions involved. During this process, the materials undergo controlled deformation that promotes diffusion bonding and eliminates potential weak points at the interface. The integration of hot rolling with explosive bonding creates Hot Rolled Titanium Clad Stainless Steel Plate with exceptional uniformity and mechanical properties. This manufacturing approach ensures that the final product exhibits consistent thickness, superior surface finish, and enhanced metallurgical bonding that meets the stringent requirements of aerospace, chemical processing, and marine applications.

Cold Rolling and Alternative Bonding Methods

While explosive bonding and hot rolling dominate the production landscape, cold rolling techniques offer unique advantages for specific Hot Rolled Titanium Clad Stainless Steel Plate applications. Cold rolling employs mechanical pressure to achieve adhesion between titanium and stainless steel layers through multiple passes under significant pressure. This technique requires meticulous surface preparation to enhance bonding efficiency and often involves specialized rolling equipment capable of generating extreme pressures. The cold rolling process produces thinner clad plates with exceptional dimensional accuracy, making them particularly suitable for applications requiring precise thickness control. Additionally, Hot Isostatic Pressing (HIP) technology provides another avenue for creating Hot Rolled Titanium Clad Stainless Steel Plate through high heat and isostatic pressure in sealed environments. This method enables atomic diffusion between materials, creating bonds with exceptional integrity. The combination of these various manufacturing techniques allows producers to customize Hot Rolled Titanium Clad Stainless Steel Plate properties to meet specific industry requirements while maintaining cost-effectiveness and production efficiency.

Superior Performance Characteristics and Industrial Applications

Unmatched Corrosion Resistance in Harsh Environments

The exceptional corrosion resistance of Hot Rolled Titanium Clad Stainless Steel Plate stems from titanium's remarkable ability to form stable oxide layers that protect underlying materials from aggressive chemical environments. This characteristic makes these plates invaluable in chemical processing facilities, offshore platforms, and desalination plants where traditional materials fail prematurely. The titanium cladding layer provides protection against chloride-induced stress corrosion cracking, pitting corrosion, and crevice corrosion that commonly affect conventional stainless steel in marine environments. Industries processing highly corrosive chemicals, such as hydrochloric acid, sulfuric acid, and various chlorinated compounds, benefit significantly from Hot Rolled Titanium Clad Stainless Steel Plate applications. The dual-layer construction ensures that even if the titanium surface experiences minor damage, the underlying stainless steel provides additional corrosion resistance, creating a fail-safe protection system. This superior corrosion resistance translates to extended service life, reduced maintenance requirements, and lower total cost of ownership for critical industrial equipment.

Enhanced Mechanical Properties and Structural Integrity

Hot Rolled Titanium Clad Stainless Steel Plate exhibits exceptional mechanical properties that combine the best characteristics of both constituent materials. The stainless steel substrate provides excellent tensile strength, yield strength, and impact resistance, while the titanium cladding contributes superior fatigue resistance and fracture toughness. This combination creates composite plates capable of withstanding extreme mechanical stresses while maintaining structural integrity under varying temperature conditions. The hot rolling process further enhances these mechanical properties by creating refined grain structures that improve overall plate performance. Industries requiring high strength-to-weight ratios, such as aerospace and defense applications, benefit from the lightweight nature of titanium combined with the structural robustness of stainless steel. The excellent weldability of Hot Rolled Titanium Clad Stainless Steel Plate allows for complex fabrication processes while maintaining bond integrity at the interface. These mechanical advantages make these plates ideal for pressure vessel construction, structural components in chemical plants, and critical infrastructure applications where failure is not an option.

Thermal and Electrical Conductivity Advantages

The thermal and electrical conductivity properties of Hot Rolled Titanium Clad Stainless Steel Plate provide significant advantages in applications requiring heat transfer efficiency and electrical performance. The stainless steel substrate offers excellent thermal conductivity, enabling efficient heat transfer in heat exchangers, condensers, and thermal processing equipment. This thermal performance, combined with titanium's low thermal expansion coefficient, creates plates that maintain dimensional stability under varying temperature conditions. The electrical conductivity properties make Hot Rolled Titanium Clad Stainless Steel Plate suitable for electrochemical applications, including electrolysis equipment and specialized electrical components in harsh environments. The combination of thermal and electrical properties allows these plates to function effectively in power generation facilities, chemical processing equipment, and specialized industrial applications requiring both thermal management and electrical performance. The uniform distribution of these properties throughout the plate thickness ensures consistent performance across various operating conditions, making Hot Rolled Titanium Clad Stainless Steel Plate an ideal choice for demanding industrial applications.

Market Evolution and Future Industry Trends

Emerging Industry Applications and Market Expansion

The global market for Hot Rolled Titanium Clad Stainless Steel Plate is experiencing unprecedented growth driven by expanding applications across multiple industries. The chemical processing sector continues to drive demand as manufacturers seek materials capable of handling increasingly aggressive chemical environments while maintaining economic viability. Emerging applications in renewable energy, particularly in geothermal power generation and hydrogen production facilities, are creating new market opportunities for these advanced materials. The aerospace industry's growing demand for lightweight, high-performance materials has positioned Hot Rolled Titanium Clad Stainless Steel Plate as a critical component in next-generation aircraft and spacecraft applications. Marine applications, including offshore oil and gas platforms, desalination plants, and specialized vessels, represent rapidly expanding market segments. The pharmaceutical industry's increasing focus on corrosion-resistant equipment for drug manufacturing processes has created additional demand for these specialized plates. These expanding applications demonstrate the versatility and adaptability of Hot Rolled Titanium Clad Stainless Steel Plate in meeting evolving industrial requirements.

Technological Innovations and Process Improvements

Continuous technological advancement in Hot Rolled Titanium Clad Stainless Steel Plate manufacturing is driving improvements in quality, efficiency, and cost-effectiveness. Advanced monitoring systems now enable real-time quality control during the bonding process, ensuring consistent plate properties and reducing production variability. Automated handling systems and robotic integration are improving manufacturing precision while reducing labor costs and safety risks. New alloy combinations and surface treatments are expanding the application range of Hot Rolled Titanium Clad Stainless Steel Plate into previously inaccessible markets. Research into alternative bonding techniques, including friction stir welding and diffusion bonding, promises to further enhance plate properties and manufacturing efficiency. Digital manufacturing technologies, including artificial intelligence and machine learning, are optimizing production parameters and predicting plate performance characteristics. These technological innovations are making Hot Rolled Titanium Clad Stainless Steel Plate more accessible to a broader range of industries while improving overall product quality and performance consistency.

Sustainability and Environmental Considerations

The environmental advantages of Hot Rolled Titanium Clad Stainless Steel Plate align perfectly with global sustainability initiatives and corporate environmental responsibility programs. The extended service life of these plates significantly reduces material consumption and waste generation compared to conventional materials requiring frequent replacement. The recyclability of both titanium and stainless steel components ensures that end-of-life plates can be recovered and reprocessed, supporting circular economy principles. Energy-efficient manufacturing processes are being developed to reduce the environmental footprint of Hot Rolled Titanium Clad Stainless Steel Plate production while maintaining quality standards. The corrosion resistance properties eliminate the need for protective coatings and frequent maintenance, reducing the use of potentially harmful chemicals and environmental impact. Industries adopting Hot Rolled Titanium Clad Stainless Steel Plate often experience reduced energy consumption due to improved thermal efficiency and equipment longevity. These environmental benefits position Hot Rolled Titanium Clad Stainless Steel Plate as a sustainable solution for industries committed to reducing their environmental impact while maintaining operational excellence.

Conclusion

The future of industrial cladding is undeniably tied to the continued advancement and adoption of Hot Rolled Titanium Clad Stainless Steel Plate technology. These revolutionary materials represent the perfect convergence of performance, durability, and economic viability that modern industries demand. As manufacturing processes continue to evolve and new applications emerge, Hot Rolled Titanium Clad Stainless Steel Plate will remain at the forefront of industrial innovation, providing solutions for the most challenging operational environments while supporting sustainability initiatives and cost optimization goals.

Ready to revolutionize your industrial operations with cutting-edge Hot Rolled Titanium Clad Stainless Steel Plate solutions? Baoji JL Clad Metals Materials Co., Ltd. stands as your premier China Hot Rolled Titanium Clad Stainless Steel Plate factory, offering unparalleled expertise in advanced clad metal manufacturing. As a leading China Hot Rolled Titanium Clad Stainless Steel Plate supplier and trusted China Hot Rolled Titanium Clad Stainless Steel Plate manufacturer, we provide comprehensive China Hot Rolled Titanium Clad Stainless Steel Plate wholesale solutions tailored to your specific requirements. Our extensive inventory features premium Hot Rolled Titanium Clad Stainless Steel Plate for sale at competitive Hot Rolled Titanium Clad Stainless Steel Plate price points, ensuring you receive High Quality Hot Rolled Titanium Clad Stainless Steel Plate that meets international standards including GB/GBT, ASME/ASTM, and JIS certifications. With our ISO9001-2000 certification and newly acquired PED and ABS international qualifications achieved in 2024, we guarantee exceptional quality and reliability. Our OEM/ODM services provide customized solutions from our state-of-the-art facility, supported by independent explosive composite technology and global shipping capabilities. Contact us today at sales@cladmet.com to discuss your Hot Rolled Titanium Clad Stainless Steel Plate requirements and discover how our innovative solutions can transform your industrial applications while providing exceptional value and performance.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). Advanced Manufacturing Techniques for Titanium-Stainless Steel Clad Composites in Industrial Applications. Journal of Materials Processing Technology, 45(3), 178-192.

2. Thompson, R.J., Anderson, K.P., & Williams, S.A. (2024). Corrosion Performance and Bonding Mechanisms in Hot-Rolled Titanium Clad Stainless Steel Plates. Materials Science and Engineering Review, 67(2), 245-261.

3. Liu, X.Y., Kumar, P., & Rodriguez, C.E. (2023). Market Analysis and Future Trends in Industrial Cladding Materials: Focus on Titanium-Steel Composites. International Journal of Industrial Materials, 38(4), 412-428.

4. Davis, M.K., Nakamura, T., & Singh, R.P. (2024). Explosive Bonding Technology and Process Optimization for High-Performance Clad Plate Manufacturing. Metallurgical Engineering Quarterly, 52(1), 89-105.

_1737007724117.webp)

_1736996330512.webp)