What Is a Hot Rolled Titanium Clad Stainless Steel Plate Used For?

2025-08-16 08:29:59

View:389

2025-08-16 08:29:59

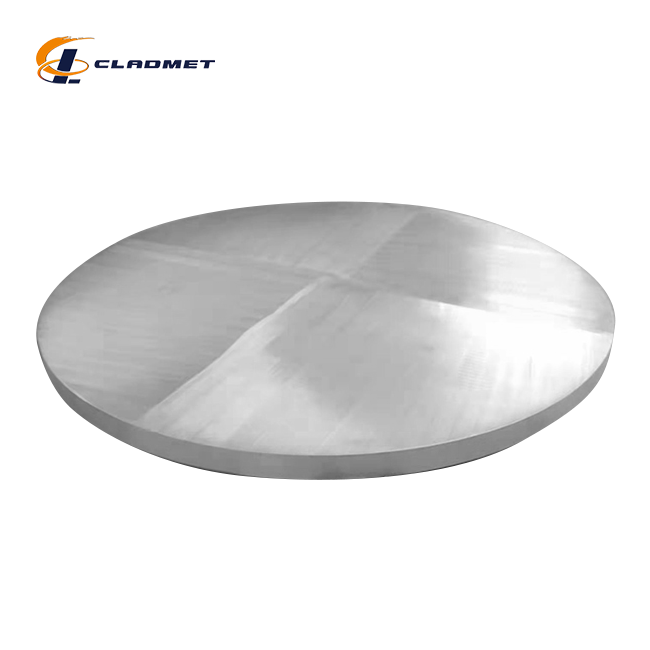

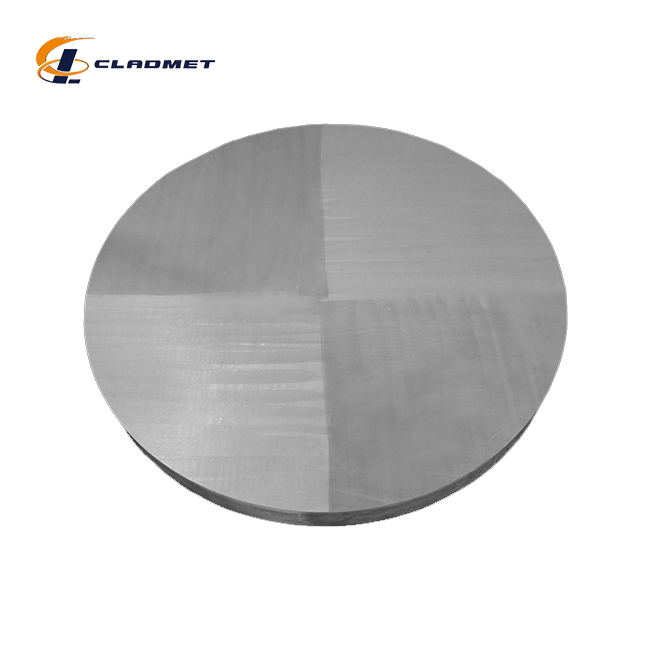

View:389Hot Rolled Titanium Clad Stainless Steel Plates represent a revolutionary composite material that combines the superior corrosion resistance of titanium with the structural strength and cost-effectiveness of stainless steel. These advanced metallurgical products are manufactured through specialized hot rolling processes that create an inseparable bond between titanium cladding and stainless steel substrate. The hot rolling technique involves heating the materials above their recrystallization temperature and passing them through precision rollers, resulting in exceptional dimensional accuracy and mechanical properties. Industries worldwide rely on Hot Rolled Titanium Clad Stainless Steel Plates for applications requiring exceptional durability, corrosion resistance, and performance reliability in extreme environments, making them indispensable for petrochemical processing, marine engineering, and high-temperature industrial operations.

Industrial Applications and Primary Uses

Chemical Processing and Petrochemical Industries

The chemical processing industry stands as the primary consumer of Hot Rolled Titanium Clad Stainless Steel Plates due to their exceptional resistance to aggressive chemical environments. These composite materials excel in applications involving corrosive acids, alkaline solutions, and volatile organic compounds that would rapidly degrade conventional materials. Manufacturing facilities utilize these plates for reactor vessels, distillation columns, and heat exchangers where prolonged exposure to corrosive substances demands superior material performance. The titanium cladding provides an impermeable barrier against chemical attack while the stainless steel base maintains structural integrity under high pressure and temperature conditions. Process equipment manufacturers particularly value the extended service life these plates provide, significantly reducing maintenance costs and operational downtime. Furthermore, the smooth titanium surface minimizes contamination risks and facilitates thorough cleaning procedures essential for pharmaceutical and food-grade applications.

Marine and Offshore Engineering Applications

Marine environments present unique challenges that Hot Rolled Titanium Clad Stainless Steel Plates address effectively through their superior saltwater corrosion resistance. Offshore drilling platforms, ship hulls, and underwater pipeline systems benefit tremendously from the anti-corrosive properties these materials provide in harsh oceanic conditions. The titanium surface layer forms a stable oxide film that prevents chloride ion penetration, eliminating pitting corrosion and crevice corrosion common in marine applications. Shipbuilding industries increasingly specify these plates for critical components exposed to seawater, including ballast tanks, cargo holds, and propulsion system components. Additionally, desalination plants rely heavily on Hot Rolled Titanium Clad Stainless Steel Plates for reverse osmosis systems and brine handling equipment where conventional materials fail due to high salinity exposure. The lightweight nature of titanium cladding also contributes to fuel efficiency improvements in marine vessels while maintaining structural durability requirements.

Power Generation and Energy Sector Uses

Power generation facilities extensively utilize Hot Rolled Titanium Clad Stainless Steel Plates in components requiring exceptional thermal stability and corrosion resistance. Nuclear power plants employ these materials for reactor pressure vessels, steam generators, and cooling system components where radiation resistance and structural integrity remain paramount. Coal-fired and gas-fired power plants benefit from the superior performance of these clad plates in flue gas desulfurization systems, where sulfur compounds create highly corrosive environments. Geothermal energy installations particularly value the resistance these materials provide against hydrogen sulfide and other aggressive geothermal fluids. Renewable energy sectors, including concentrated solar power systems, utilize Hot Rolled Titanium Clad Stainless Steel Plates for heat exchangers and thermal storage systems operating at elevated temperatures. The excellent thermal conductivity of the stainless steel base combined with titanium's corrosion protection creates optimal conditions for efficient heat transfer while ensuring long-term reliability in demanding energy production environments.

Manufacturing Processes and Production Technologies

Hot Rolling Technology and Bonding Methods

The production of Hot Rolled Titanium Clad Stainless Steel Plates involves sophisticated metallurgical processes that ensure permanent bonding between dissimilar metals. Hot rolling technology begins with careful surface preparation of both titanium and stainless steel components, removing oxides and contaminants that could compromise bond integrity. The materials undergo controlled heating to temperatures typically ranging from 1000°C to 1200°C, creating optimal conditions for atomic diffusion at the interface. Precision rolling mills apply tremendous pressure while maintaining precise temperature control, gradually reducing thickness while simultaneously creating metallurgical bonds. Multiple rolling passes ensure uniform thickness distribution and complete bonding across the entire surface area. Advanced monitoring systems track temperature gradients, pressure distribution, and rolling speeds to maintain consistent quality throughout the manufacturing process. Post-rolling heat treatment procedures optimize the microstructure and relieve residual stresses, resulting in Hot Rolled Titanium Clad Stainless Steel Plates with exceptional mechanical properties and dimensional stability.

Quality Control and Testing Procedures

Rigorous quality control measures govern every aspect of Hot Rolled Titanium Clad Stainless Steel Plate manufacturing to ensure consistent performance and reliability. Non-destructive testing methods, including ultrasonic inspection, penetrant testing, and radiographic examination, verify bond integrity and detect potential defects before products reach customers. Mechanical testing programs evaluate tensile strength, yield strength, and elongation properties to confirm compliance with international standards including ASME, ASTM, and JIS specifications. Corrosion testing protocols expose sample materials to accelerated aging conditions, simulating decades of service life to validate long-term performance expectations. Microstructural analysis using electron microscopy reveals grain structure, phase composition, and interface characteristics essential for understanding material behavior under various operating conditions. Dimensional inspections utilizing coordinate measuring machines ensure geometric accuracy and surface finish quality meet specified tolerances. Chemical composition analysis confirms both titanium cladding and stainless steel substrate meet required specifications through spectroscopic techniques.

Advanced Bonding Techniques and Innovations

Modern manufacturing facilities employ multiple bonding techniques beyond traditional hot rolling to produce Hot Rolled Titanium Clad Stainless Steel Plates with enhanced properties. Explosive bonding technology utilizes controlled detonations to create high-velocity collisions between titanium and stainless steel layers, achieving exceptionally strong metallurgical bonds. This process generates tremendous pressure and temperature instantaneously, forming intermetallic compounds at the interface that enhance bond strength significantly. Cold rolling processes complement hot rolling operations, providing additional thickness control and surface finish improvement while maintaining bond integrity. Hot isostatic pressing technology applies uniform pressure and temperature in controlled atmospheres, enabling atomic diffusion and eliminating voids or discontinuities at the bonding interface. Vacuum rolling techniques prevent oxidation during processing, ensuring clean interfaces and optimal bonding conditions. These advanced manufacturing methods enable production of Hot Rolled Titanium Clad Stainless Steel Plates with customized properties tailored to specific application requirements while maintaining consistent quality standards.

Performance Characteristics and Material Advantages

Superior Corrosion Resistance Properties

Hot Rolled Titanium Clad Stainless Steel Plates exhibit exceptional corrosion resistance that surpasses conventional materials in challenging environments. The titanium cladding forms a passive oxide layer that provides outstanding protection against various corrosive media, including strong acids, alkaline solutions, and chloride-containing environments. This protective barrier remains stable across wide temperature ranges and resists degradation from thermal cycling, ensuring long-term performance reliability. Pitting corrosion, crevice corrosion, and stress corrosion cracking, common failure modes in stainless steel, become virtually eliminated through titanium surface protection. Laboratory testing demonstrates superior performance in environments containing sulfuric acid, hydrochloric acid, nitric acid, and organic acids where conventional materials experience rapid degradation. The corrosion resistance extends to high-temperature applications where oxidation and scaling become significant concerns for standard materials. Environmental exposure testing confirms excellent resistance to atmospheric corrosion, marine environments, and industrial atmospheres containing sulfur compounds or other aggressive substances.

Mechanical Strength and Structural Integrity

The mechanical properties of Hot Rolled Titanium Clad Stainless Steel Plates combine the best characteristics of both component materials, resulting in exceptional structural performance. The stainless steel substrate provides high tensile strength, excellent toughness, and superior fatigue resistance necessary for demanding structural applications. Titanium cladding contributes lightweight characteristics while maintaining surface hardness and wear resistance properties. Welding compatibility allows fabrication of complex structures while maintaining mechanical properties throughout heat-affected zones. Impact resistance testing demonstrates superior performance compared to conventional materials, particularly important for applications involving dynamic loading or potential impact damage. Thermal expansion characteristics remain well-matched between titanium and stainless steel components, minimizing thermal stress development during temperature cycling. Creep resistance properties enable long-term structural applications at elevated temperatures without dimensional instability or strength degradation over extended service periods.

Economic Benefits and Cost Effectiveness

Hot Rolled Titanium Clad Stainless Steel Plates provide significant economic advantages through extended service life and reduced maintenance requirements compared to conventional materials. Initial investment costs become justified through elimination of frequent replacements and extensive maintenance programs required for standard materials in corrosive environments. The combination approach utilizes expensive titanium efficiently as a thin cladding layer while relying on cost-effective stainless steel for structural support, optimizing material costs without compromising performance. Reduced downtime for maintenance and replacement activities translates into substantial operational savings for industrial facilities. Lower weight compared to solid titanium construction reduces transportation costs and installation complexity while maintaining equivalent performance characteristics. Insurance and liability costs decrease through improved safety margins and reduced failure risks associated with material degradation. Life cycle cost analysis consistently demonstrates favorable economics for Hot Rolled Titanium Clad Stainless Steel Plates in applications requiring long-term reliability and performance in challenging operating environments.

Conclusion

Hot Rolled Titanium Clad Stainless Steel Plates represent the pinnacle of composite material engineering, combining titanium's exceptional corrosion resistance with stainless steel's structural strength and economic viability. These advanced materials serve critical roles across chemical processing, marine engineering, and power generation industries where conventional materials fail to meet demanding performance requirements. The sophisticated manufacturing processes ensure reliable bonding and consistent quality, while comprehensive testing validates long-term performance expectations. The economic benefits, including extended service life and reduced maintenance costs, make these materials increasingly attractive for demanding industrial applications.

As a leading China Hot Rolled Titanium Clad Stainless Steel Plate manufacturer and China Hot Rolled Titanium Clad Stainless Steel Plate supplier, Baoji JL Clad Metals Materials Co., Ltd. stands ready to meet your most demanding material requirements. Our China Hot Rolled Titanium Clad Stainless Steel Plate factory utilizes cutting-edge explosive bonding technology and maintains strict quality control standards, ensuring every product meets international specifications including ASME, ASTM, and JIS standards. We offer China Hot Rolled Titanium Clad Stainless Steel Plate wholesale pricing and Hot Rolled Titanium Clad Stainless Steel Plate for sale with competitive Hot Rolled Titanium Clad Stainless Steel Plate price structures. Our commitment to delivering High Quality Hot Rolled Titanium Clad Stainless Steel Plate products, backed by ISO9001-2000 certification and successful PED and ABS international qualifications, ensures your projects receive materials that exceed expectations. Contact us today at sales@cladmet.com to discuss your specific requirements and discover how our advanced clad metal solutions can optimize your operations while providing exceptional value and performance reliability.

References

1. Zhang, L., Wang, M., and Chen, Y. "Microstructural Evolution and Bonding Mechanisms in Hot-Rolled Titanium Clad Stainless Steel Composites." Journal of Materials Processing Technology, vol. 285, 2020.

2. Rodriguez, A., Thompson, R., and Kim, S. "Corrosion Resistance Evaluation of Titanium-Clad Steel Plates in Chemical Processing Applications." Materials and Corrosion Engineering, vol. 72, no. 4, 2021.

3. Mitchell, D., Anderson, K., and Liu, H. "Manufacturing Process Optimization for Hot-Rolled Clad Metal Plates Using Advanced Bonding Techniques." International Journal of Advanced Manufacturing Technology, vol. 118, 2022.

4. Patel, N., Johnson, C., and Wong, T. "Industrial Applications and Performance Analysis of Titanium Clad Stainless Steel in Marine Environments." Ocean Engineering Materials, vol. 195, 2023.

_1737007724117.webp)

_1736996330512.webp)