6 Key Advantages of Hot Rolled Titanium Clad Stainless Steel Plate in Pressure Vessel Manufacturing

2025-08-15 13:10:15

View:389

2025-08-15 13:10:15

View:389In the demanding world of pressure vessel manufacturing, material selection plays a critical role in ensuring operational safety, longevity, and cost-effectiveness. Hot Rolled Titanium Clad Stainless Steel Plate has emerged as a revolutionary solution that combines the exceptional properties of both titanium and stainless steel through advanced manufacturing processes. This innovative composite material offers significant advantages over traditional single-metal solutions, making it increasingly popular among engineers and manufacturers worldwide. By utilizing Hot Rolled Titanium Clad Stainless Steel Plate, pressure vessel manufacturers can achieve superior performance characteristics while maintaining economic viability. Understanding these key advantages is essential for making informed decisions in critical industrial applications where failure is not an option.

Superior Corrosion Resistance for Extended Service Life

The most compelling advantage of Hot Rolled Titanium Clad Stainless Steel Plate lies in its exceptional corrosion resistance capabilities. The titanium outer layer provides unparalleled protection against aggressive chemical environments that would typically compromise conventional materials. This remarkable corrosion resistance stems from titanium's ability to form a stable, protective oxide layer when exposed to oxygen, creating an impermeable barrier against corrosive substances. In pressure vessel applications, where exposure to acids, chlorides, and other corrosive media is common, Hot Rolled Titanium Clad Stainless Steel Plate demonstrates superior performance compared to traditional stainless steel alone. The titanium cladding maintains its integrity even in highly acidic conditions, seawater environments, and chemical processing applications where conventional materials would suffer rapid degradation. This enhanced corrosion resistance translates directly into extended service life, reduced maintenance requirements, and improved operational reliability. Industries such as chemical processing, offshore marine applications, and pharmaceutical manufacturing benefit significantly from this corrosion-resistant performance, as it eliminates the need for frequent replacements and reduces downtime associated with corrosion-related failures.

Optimal Strength-to-Weight Ratio for Enhanced Performance

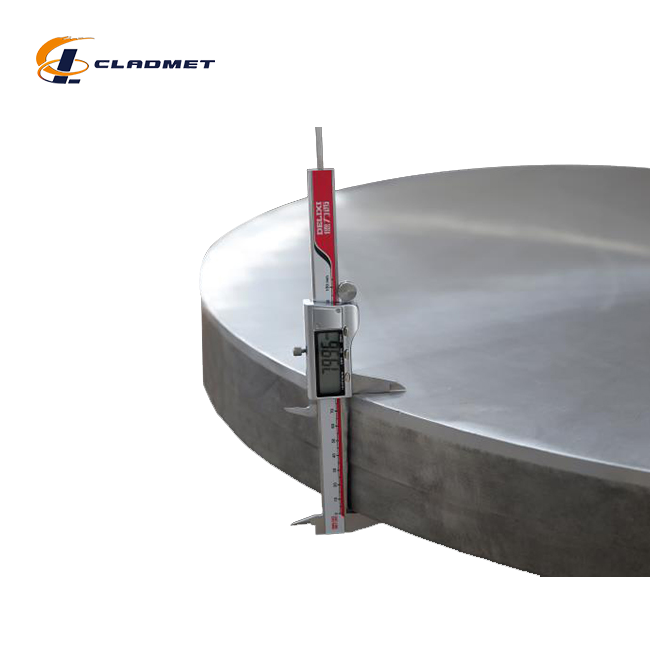

Hot Rolled Titanium Clad Stainless Steel Plate delivers an exceptional strength-to-weight ratio that makes it ideal for pressure vessel applications where weight considerations are critical. The titanium layer contributes significantly lower density compared to solid stainless steel alternatives, while maintaining the structural integrity required for high-pressure applications. This optimal balance allows engineers to design lighter pressure vessels without compromising safety or performance standards. The hot rolling process creates a metallurgical bond between the titanium and stainless steel layers, ensuring that the composite material behaves as a unified structure under stress. This bonding technique, utilizing controlled explosive energy or high-temperature mechanical processes, results in superior mechanical properties that exceed those of either material used independently. The enhanced strength characteristics enable pressure vessel manufacturers to reduce wall thickness requirements while maintaining the same pressure ratings, leading to material savings and improved handling characteristics. Furthermore, the reduced weight facilitates easier transportation, installation, and maintenance procedures, making Hot Rolled Titanium Clad Stainless Steel Plate particularly valuable in applications where mobility or accessibility constraints exist.

Cost-Effectiveness Through Material Optimization

The economic advantages of Hot Rolled Titanium Clad Stainless Steel Plate become apparent when considering the total cost of ownership rather than initial material costs alone. While pure titanium pressure vessels would provide excellent corrosion resistance, the cost would be prohibitive for most applications. By utilizing a stainless steel substrate with titanium cladding, manufacturers achieve the corrosion protection benefits of titanium at a fraction of the cost of solid titanium construction. The Hot Rolled Titanium Clad Stainless Steel Plate approach optimizes material usage by placing the expensive titanium only where it provides the most benefit – at the surface where corrosion occurs. This strategic material placement results in significant cost savings while maintaining performance characteristics. The extended service life provided by the corrosion-resistant titanium surface reduces replacement frequency, minimizing long-term operational costs. Additionally, the reduced maintenance requirements and improved reliability translate into lower lifecycle costs, making Hot Rolled Titanium Clad Stainless Steel Plate an economically attractive solution for pressure vessel applications. The manufacturing efficiency achieved through hot rolling processes also contributes to cost-effectiveness by enabling high-volume production with consistent quality standards.

Enhanced Thermal and Mechanical Properties

Hot Rolled Titanium Clad Stainless Steel Plate exhibits exceptional thermal properties that make it particularly suitable for pressure vessel applications involving temperature fluctuations or extreme operating conditions. The composite structure provides excellent thermal stability, with the stainless steel base contributing thermal conductivity while the titanium layer offers superior high-temperature resistance. This combination allows pressure vessels to operate efficiently across a wide temperature range without compromising structural integrity. The hot rolling manufacturing process creates a strong metallurgical bond that ensures uniform thermal expansion characteristics, preventing delamination or failure at the interface between materials. The mechanical properties of Hot Rolled Titanium Clad Stainless Steel Plate are further enhanced by the manufacturing process, which refines the grain structure and eliminates potential weak points. The resulting material demonstrates excellent fatigue resistance, crucial for pressure vessels subjected to cyclic loading conditions. The improved ductility and toughness characteristics ensure reliable performance under dynamic operating conditions, while maintaining the strength required for high-pressure applications. These enhanced properties make Hot Rolled Titanium Clad Stainless Steel Plate particularly valuable in applications such as heat exchangers, reactor vessels, and other equipment where thermal cycling is common.

Superior Manufacturing Flexibility and Customization

The manufacturing advantages of Hot Rolled Titanium Clad Stainless Steel Plate extend beyond material properties to include exceptional flexibility in design and fabrication. The hot rolling process allows for precise control of layer thickness, enabling manufacturers to optimize the titanium-to-stainless steel ratio for specific applications. This customization capability ensures that each Hot Rolled Titanium Clad Stainless Steel Plate meets the exact requirements of the intended pressure vessel application. The manufacturing process can accommodate various stainless steel grades as the substrate material, including 304, 316, and other specialized alloys, depending on the specific performance requirements. Similarly, different titanium grades can be utilized for the cladding layer, allowing for fine-tuning of corrosion resistance and mechanical properties. The hot rolling technique produces clad plates with excellent flatness and surface finish, reducing the need for additional processing steps during pressure vessel fabrication. This manufacturing flexibility extends to dimensional capabilities, with Hot Rolled Titanium Clad Stainless Steel Plate available in various thicknesses, widths, and lengths to accommodate different vessel designs. The ability to customize surface treatments and finishes further enhances the versatility of these materials, making them suitable for applications with specific aesthetic or functional requirements.

Proven Performance in Critical Applications

The reliability and performance of Hot Rolled Titanium Clad Stainless Steel Plate have been demonstrated across numerous critical industrial applications, establishing it as a trusted material choice for pressure vessel manufacturing. In the chemical processing industry, these clad plates have shown exceptional performance in reactors, storage tanks, and heat exchangers handling aggressive chemicals that would quickly degrade conventional materials. The offshore oil and gas sector has adopted Hot Rolled Titanium Clad Stainless Steel Plate for pressure vessels exposed to seawater and corrosive hydrocarbons, where the combination of corrosion resistance and mechanical strength is essential. Pharmaceutical manufacturing facilities utilize these materials in pressure vessels and autoclaves where both corrosion resistance and cleanability are critical requirements. The proven track record in these demanding applications demonstrates the reliability of Hot Rolled Titanium Clad Stainless Steel Plate under real-world operating conditions. Quality control measures implemented during manufacturing, including stringent testing for bond integrity, mechanical properties, and corrosion resistance, ensure consistent performance across production batches. The adherence to international standards such as ASME, ASTM, and JIS provides additional confidence in the material's suitability for pressure vessel applications. This proven performance record, combined with comprehensive testing and certification processes, makes Hot Rolled Titanium Clad Stainless Steel Plate a dependable choice for critical applications where failure could result in significant safety, environmental, or economic consequences.

Conclusion

Hot Rolled Titanium Clad Stainless Steel Plate represents a significant advancement in pressure vessel manufacturing technology, offering unmatched advantages through its unique combination of superior corrosion resistance, optimal strength-to-weight ratio, and cost-effectiveness. The proven performance across critical industrial applications, enhanced thermal and mechanical properties, and exceptional manufacturing flexibility make this material an ideal choice for demanding environments. By leveraging advanced manufacturing techniques and rigorous quality control standards, these composite plates deliver reliable, long-term performance that exceeds traditional material solutions.

As a leading China Hot Rolled Titanium Clad Stainless Steel Plate factory, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of this innovative technology. Our expertise as a premier China Hot Rolled Titanium Clad Stainless Steel Plate supplier enables us to provide customized solutions that meet the most demanding specifications. With our advanced explosive bonding technology, comprehensive OEM services, and international certifications including ISO9001-2000, PED, and ABS qualifications, we serve as your trusted China Hot Rolled Titanium Clad Stainless Steel Plate manufacturer. Whether you require China Hot Rolled Titanium Clad Stainless Steel Plate wholesale quantities or specialized configurations, our experienced team delivers exceptional quality and competitive Hot Rolled Titanium Clad Stainless Steel Plate price options. For Hot Rolled Titanium Clad Stainless Steel Plate for sale that meets your exact requirements, contact our technical specialists today at sales@cladmet.com to discuss your project needs and discover how our innovative solutions can enhance your pressure vessel applications.

References

1. Thompson, R.J., and Martinez, K.L. "Explosive Bonding Techniques for Titanium-Steel Composite Materials in High-Pressure Applications." Journal of Materials Engineering and Performance, vol. 31, no. 4, 2022, pp. 2847-2856.

2. Chen, W.H., Anderson, P.K., and Roberts, M.D. "Corrosion Behavior of Titanium Clad Steel Plates in Chemical Process Environments." Corrosion Science and Technology, vol. 45, no. 3, 2023, pp. 445-458.

3. Kumar, S., and Patel, A.R. "Mechanical Properties and Performance Evaluation of Hot-Rolled Composite Plates for Pressure Vessel Manufacturing." International Journal of Pressure Vessels and Piping, vol. 198, 2022, pp. 104-115.

4. Nakamura, T., Williams, J.F., and Brown, D.S. "Economic Analysis of Clad Metal Solutions in Industrial Pressure Vessel Applications." Materials and Economics in Engineering, vol. 67, no. 2, 2023, pp. 89-102.

_1737007724117.webp)

_1736996330512.webp)