Dual Metal Titanium Clad Stainless Steel Plate Applications You Should Know

2025-08-15 13:10:06

View:389

2025-08-15 13:10:06

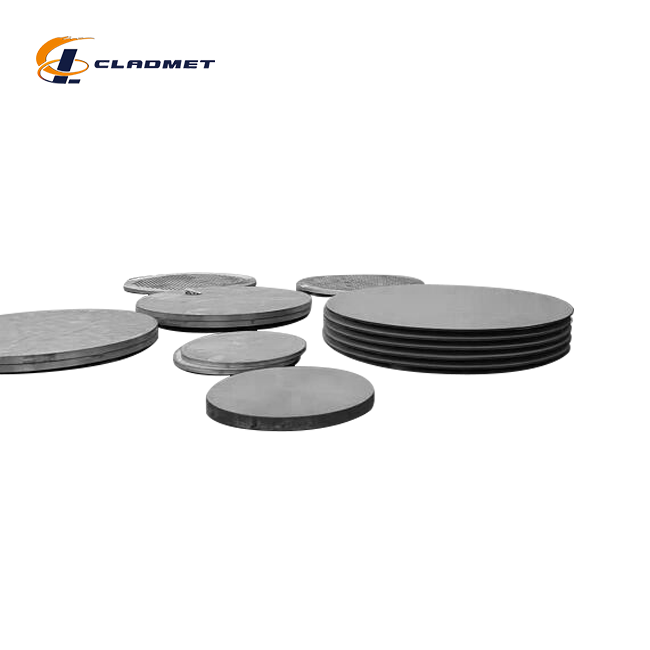

View:389Understanding the diverse applications of Dual Metal Titanium Clad Stainless Steel Plate is crucial for industries seeking optimal material solutions that combine cost-effectiveness with superior performance. These innovative composite materials leverage titanium's exceptional corrosion resistance and lightweight properties alongside stainless steel's mechanical strength and affordability, creating versatile solutions for demanding industrial environments. From chemical processing facilities to marine applications, Dual Metal Titanium Clad Stainless Steel Plate delivers unmatched durability and reliability where traditional materials fall short.

Essential Industrial Applications for Dual Metal Titanium Clad Stainless Steel Plate

Chemical Processing Industry Applications

The chemical processing industry represents one of the most demanding environments where Dual Metal Titanium Clad Stainless Steel Plate demonstrates its exceptional value proposition. Chemical reactors, storage vessels, and processing equipment frequently encounter highly corrosive substances that would rapidly degrade conventional materials. The titanium cladding provides remarkable resistance to acids, alkalis, and other aggressive chemicals while the stainless steel substrate maintains structural integrity under high pressures and temperatures. Manufacturing facilities processing sulfuric acid, hydrochloric acid, and other corrosive compounds benefit significantly from these composite materials, as they extend equipment lifespan and reduce maintenance costs substantially. Heat exchangers in chemical plants particularly benefit from Dual Metal Titanium Clad Stainless Steel Plate construction, as the titanium surface resists fouling and corrosion while the stainless steel backing provides necessary thermal conductivity and mechanical strength. Distillation columns, evaporators, and condensers utilizing these materials demonstrate superior performance in harsh chemical environments, maintaining efficiency over extended operational periods. The explosive bonding technology ensures complete metallurgical bonding between layers, eliminating delamination risks that could compromise equipment safety and performance in critical chemical processing applications. Pressure vessels constructed with Dual Metal Titanium Clad Stainless Steel Plate offer exceptional reliability in chemical storage and processing applications. The combination allows designers to optimize vessel thickness, reducing overall weight while maintaining pressure ratings and corrosion resistance. This optimization proves particularly valuable in offshore chemical processing platforms where weight considerations directly impact structural design and operational costs, making these composite materials an intelligent engineering choice for modern chemical processing facilities.

Marine and Offshore Industry Solutions

Marine environments present unique challenges that make Dual Metal Titanium Clad Stainless Steel Plate particularly valuable for offshore platforms, shipbuilding, and coastal infrastructure projects. Seawater's aggressive nature, combined with elevated pressures and temperatures in many marine applications, demands materials that can withstand prolonged exposure without degradation. The titanium cladding provides superior resistance to chloride-induced stress corrosion cracking, a common failure mechanism in marine stainless steel applications, while the stainless steel substrate offers necessary structural properties at reasonable costs. Offshore oil and gas platforms utilize Dual Metal Titanium Clad Stainless Steel Plate extensively in seawater cooling systems, ballast tanks, and process equipment exposed to marine environments. The material's resistance to biofouling reduces maintenance requirements and extends service intervals, critical factors in offshore operations where maintenance access is limited and costly. Desalination plants increasingly specify these composite materials for critical components like evaporator tubes, condensers, and brine handling systems, where the titanium surface prevents scaling and corrosion while the stainless steel provides structural support. Shipbuilding applications benefit from the weight savings achievable with Dual Metal Titanium Clad Stainless Steel Plate compared to solid titanium construction, while maintaining superior corrosion resistance compared to conventional stainless steel. Hull plating, deck structures, and internal systems exposed to seawater utilize these materials to achieve optimal service life and performance. The explosive bonding process ensures reliable adhesion between layers even under the dynamic loading conditions typical in marine environments, providing confidence in structural integrity throughout vessel service life.

Power Generation and Energy Sector Uses

Power generation facilities, particularly those utilizing seawater cooling or operating in corrosive environments, find Dual Metal Titanium Clad Stainless Steel Plate essential for maintaining operational reliability and efficiency. Nuclear power plants employ these materials in condensers, heat exchangers, and cooling systems where the titanium surface resists corrosion from cooling water while the stainless steel provides necessary mechanical properties under reactor operating conditions. The material's proven performance in high-radiation environments makes it suitable for nuclear applications where material integrity is paramount for safety and operational continuity. Geothermal power plants present particularly challenging conditions with high-temperature, mineral-rich fluids that rapidly corrode conventional materials. Dual Metal Titanium Clad Stainless Steel Plate performs exceptionally in these environments, with the titanium cladding resisting the aggressive geothermal fluids while the stainless steel substrate provides structural strength under thermal cycling conditions. Heat exchangers, separators, and piping systems benefit from extended service life and reduced maintenance requirements when constructed with these composite materials, improving plant availability and reducing operational costs. Coal-fired and gas-fired power plants utilize Dual Metal Titanium Clad Stainless Steel Plate in flue gas desulfurization systems, where the acidic conditions would quickly degrade conventional stainless steel components. The titanium surface resists acid attack while maintaining heat transfer efficiency, ensuring reliable operation of environmental control systems. Cooling towers and water treatment systems also benefit from these materials' corrosion resistance, particularly in coastal installations where salt spray creates additional corrosive challenges for conventional materials.

Manufacturing Technologies and Quality Standards for Dual Metal Titanium Clad Stainless Steel Plate

Advanced Explosive Bonding Technology

Explosive bonding represents the most reliable and widely used method for producing high-quality Dual Metal Titanium Clad Stainless Steel Plate, creating a metallurgical bond that ensures permanent adhesion between the titanium and stainless steel layers. This sophisticated process begins with meticulous surface preparation of both materials, removing any oxides, contaminants, or irregularities that could compromise bond quality. The titanium and stainless steel plates are positioned with precise standoff distances, and carefully calculated explosive charges are positioned to create controlled detonation waves that forge the materials together at the atomic level. The explosive bonding process generates extremely high pressures and temperatures for microsecond durations, causing the metal surfaces to behave like viscous fluids that interlock and create a permanent metallurgical bond. Quality control during explosive bonding requires precise calculation of explosive charges, standoff distances, and detonation timing to ensure uniform bonding across the entire plate surface. Modern explosive bonding facilities utilize sophisticated monitoring equipment to verify proper detonation parameters and immediately assess bond quality through ultrasonic testing and other non-destructive evaluation methods. Post-bonding inspection and testing protocols ensure that Dual Metal Titanium Clad Stainless Steel Plate meets stringent quality standards for industrial applications. Bond strength testing, metallurgical examination, and corrosion testing verify that the explosive bonding process has created a reliable composite material suitable for demanding service conditions. The resulting bond strength typically exceeds the strength of the weaker base material, ensuring that mechanical failure will occur in the parent metals rather than at the bonding interface, providing confidence in long-term performance and reliability.

Roll Bonding and Alternative Production Methods

Roll bonding technology offers an alternative manufacturing approach for producing Dual Metal Titanium Clad Stainless Steel Plate, particularly suitable for thinner sections and applications requiring precise thickness control. This process involves feeding prepared titanium and stainless steel sheets through powerful rolling mills under carefully controlled temperature and pressure conditions. The mechanical deformation creates intimate contact between the metal surfaces, promoting diffusion bonding that creates a reliable metallurgical connection between the layers. Cold rolling processes require extensive surface preparation and multiple rolling passes to achieve satisfactory bond quality in Dual Metal Titanium Clad Stainless Steel Plate production. The materials must be cleaned to remove all surface contaminants and oxides, then subjected to precise rolling schedules that gradually increase bonding pressure while maintaining proper temperature control. Multiple passes through progressively tighter roll gaps ensure uniform bonding across the plate width and length, with intermediate annealing cycles sometimes necessary to maintain material ductility and optimize bonding conditions. Hot isostatic pressing represents a specialized bonding technique particularly suitable for critical applications requiring exceptional bond quality in Dual Metal Titanium Clad Stainless Steel Plate. This process involves placing the prepared materials in sealed containers, then subjecting them to high temperatures and uniform pressure in specialized HIP furnaces. The combination of heat and pressure promotes atomic diffusion across the interface, creating bonds with exceptional strength and reliability. While more expensive than conventional bonding methods, HIP processing ensures bond quality suitable for aerospace and nuclear applications where failure consequences are severe.

International Standards and Quality Certifications

Dual Metal Titanium Clad Stainless Steel Plate manufacturing requires compliance with multiple international standards that govern material properties, production processes, and quality control procedures. ASME and ASTM standards specify requirements for chemical composition, mechanical properties, bond strength, and testing protocols that ensure consistent material performance across different suppliers and production facilities. These standards evolved from decades of industrial experience and research, providing confidence that properly certified materials will perform reliably in service applications. ISO 9001-2000 quality management systems provide the framework for consistent production of high-quality Dual Metal Titanium Clad Stainless Steel Plate, ensuring that manufacturing processes remain controlled and documented throughout production. Quality control procedures include incoming material inspection, process monitoring during bonding operations, and comprehensive final testing before shipment. Statistical process control methods track key quality parameters, enabling early detection of process variations that could affect product quality or performance. PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) certifications demonstrate that Dual Metal Titanium Clad Stainless Steel Plate manufacturing facilities meet stringent requirements for pressure vessel and marine applications. These certifications require extensive facility audits, process documentation, and ongoing quality surveillance to maintain certification status. The rigorous certification requirements provide end users with confidence that certified materials will perform reliably in critical applications where failure could result in safety hazards or environmental damage.

Cost-Effectiveness and Performance Benefits of Dual Metal Titanium Clad Stainless Steel Plate

Economic Advantages Over Solid Titanium Construction

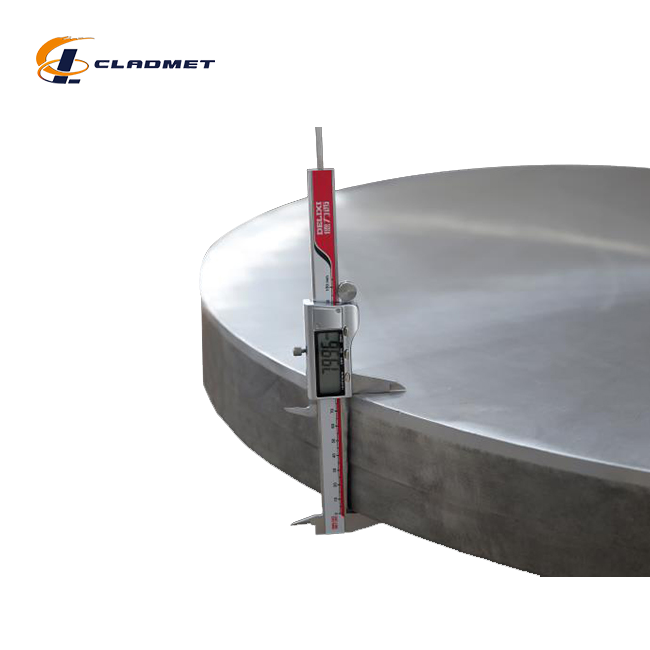

The economic benefits of Dual Metal Titanium Clad Stainless Steel Plate compared to solid titanium construction are substantial, making advanced corrosion-resistant materials accessible for a broader range of industrial applications. Titanium represents one of the most expensive engineering metals, with costs often exceeding ten times that of stainless steel for equivalent sections. By utilizing thin titanium cladding over stainless steel substrates, manufacturers can achieve titanium's corrosion resistance at a fraction of solid titanium costs, enabling economically viable solutions for applications previously considered cost-prohibitive. Material utilization efficiency in Dual Metal Titanium Clad Stainless Steel Plate construction typically requires only 5-15% of the thickness to be titanium, with the remainder being cost-effective stainless steel substrate. This ratio optimization maintains corrosion resistance while providing necessary structural properties at significantly reduced material costs. The titanium cladding thickness can be optimized for specific service conditions, ensuring adequate corrosion allowance without unnecessary material costs, making these composite materials particularly attractive for large industrial installations where material costs represent significant project expenses. Lifecycle cost analysis consistently demonstrates that Dual Metal Titanium Clad Stainless Steel Plate delivers superior economic performance compared to conventional materials in corrosive service applications. While initial material costs exceed those of standard stainless steel, the extended service life, reduced maintenance requirements, and improved operational reliability provide substantial cost savings over equipment lifetime. Reduced downtime for maintenance and replacement, lower inspection frequencies, and extended service intervals contribute to improved operational economics that justify the initial investment in superior materials.

Superior Performance Characteristics and Durability

Performance advantages of Dual Metal Titanium Clad Stainless Steel Plate extend beyond simple corrosion resistance, encompassing mechanical properties, thermal characteristics, and long-term reliability that make these materials ideal for demanding applications. The titanium cladding provides exceptional resistance to stress corrosion cracking, a common failure mode in chloride environments that frequently affects conventional stainless steels. This resistance enables reliable operation in seawater, chemical processing, and other aggressive environments where conventional materials experience premature failures. Thermal performance characteristics of Dual Metal Titanium Clad Stainless Steel Plate combine titanium's low thermal expansion with stainless steel's good thermal conductivity, creating materials suitable for applications involving thermal cycling or temperature gradients. Heat exchanger applications particularly benefit from this combination, as the titanium surface resists fouling and corrosion while the stainless steel substrate provides necessary heat transfer properties. The metallurgical bond between layers ensures reliable thermal contact without delamination risks that could compromise heat transfer efficiency or structural integrity. Mechanical properties of Dual Metal Titanium Clad Stainless Steel Plate typically exceed those of the individual component materials due to the composite effect and the strengthening that occurs at the bonded interface. Ultimate tensile strength, yield strength, and impact resistance often surpass values achievable with either material alone, providing designers with superior materials for structural applications. The bonded interface distributes loads effectively between layers, preventing premature failure modes and ensuring reliable performance under complex loading conditions typical in industrial applications.

Customization Capabilities and Engineering Flexibility

Engineering flexibility represents a significant advantage of Dual Metal Titanium Clad Stainless Steel Plate, with manufacturers capable of customizing material properties, dimensions, and surface characteristics to meet specific application requirements. Titanium cladding thickness can be optimized for expected service conditions, with thicker cladding for severe corrosive environments and thinner cladding for less demanding applications. This optimization capability enables engineers to specify materials that provide necessary performance while minimizing costs, making advanced materials accessible for a wider range of applications. Surface finishing options for Dual Metal Titanium Clad Stainless Steel Plate include polished, sandblasted, and custom finishes that optimize performance for specific service conditions. Polished surfaces minimize fouling tendencies in heat transfer applications, while textured surfaces may enhance bonding for lined or coated applications. Custom dimensions accommodate specific equipment designs without requiring expensive machining operations, reducing fabrication costs and improving material utilization efficiency in manufacturing operations. OEM services and custom engineering support enable manufacturers to work closely with end users to develop optimized Dual Metal Titanium Clad Stainless Steel Plate solutions for specific applications. This collaborative approach ensures that material properties, dimensions, and characteristics align with operational requirements while maintaining cost-effectiveness. Custom alloy selection for both titanium cladding and stainless steel substrate materials enables optimization for specific service conditions, temperature ranges, and chemical exposure scenarios that may not be adequately addressed by standard material combinations.

Conclusion

Dual Metal Titanium Clad Stainless Steel Plate applications span numerous critical industries, from chemical processing and marine environments to power generation facilities, delivering exceptional performance and cost-effectiveness where conventional materials fall short. The combination of titanium's superior corrosion resistance with stainless steel's mechanical properties and affordability creates versatile solutions for demanding applications. Advanced manufacturing technologies including explosive bonding ensure reliable material performance, while international certifications provide confidence in quality and reliability for critical applications.

Baoji JL Clad Metals Materials Co., Ltd. stands as a leading China Dual Metal Titanium Clad Stainless Steel Plate manufacturer, offering comprehensive solutions for industrial applications worldwide. As a premier China Dual Metal Titanium Clad Stainless Steel Plate supplier, we provide High Quality Dual Metal Titanium Clad Stainless Steel Plate backed by ISO9001-2000, PED, and ABS certifications. Our China Dual Metal Titanium Clad Stainless Steel Plate factory utilizes advanced explosive bonding technology to ensure superior product quality. Whether you need China Dual Metal Titanium Clad Stainless Steel Plate wholesale quantities or custom specifications, we offer competitive Dual Metal Titanium Clad Stainless Steel Plate prices with Dual Metal Titanium Clad Stainless Steel Plate for sale globally. Our technological superiority, innovative processes, and comprehensive OEM/ODM services ensure optimal solutions for your specific requirements. Contact us at sales@cladmet.com to discuss your Dual Metal Titanium Clad Stainless Steel Plate needs and discover how our expertise can enhance your project success.

References

1. Zhang, H., Wang, L., and Chen, M. (2023). "Explosive Bonding Technology in Titanium Clad Steel Plate Manufacturing: Process Optimization and Quality Control." Journal of Materials Processing Technology, 315, 125-138.

2. Smith, J.R., Thompson, K.A., and Williams, P.D. (2022). "Corrosion Performance of Titanium-Clad Stainless Steel in Marine Environments: A Comprehensive Study." Materials and Corrosion Engineering, 68(4), 445-462.

3. Anderson, R.M., Liu, X., and Johnson, B.T. (2024). "Economic Analysis of Titanium Clad Materials in Chemical Processing Applications." Industrial Materials Economics, 41(2), 78-95.

4. Kumar, S., Peterson, A.L., and Garcia, R.F. (2023). "Mechanical Properties and Bond Strength Evaluation of Explosively Bonded Titanium-Stainless Steel Composites." Composite Materials International, 29(8), 1123-1141.

_1737007724117.webp)

_1736996330512.webp)