Expert Guide: Selecting the Right Dual Metal Titanium Clad Stainless Steel Plate

2025-08-14 17:12:52

View:389

2025-08-14 17:12:52

View:389Choosing the appropriate Dual Metal Titanium Clad Stainless Steel Plate requires a comprehensive understanding of material properties, manufacturing processes, and application-specific requirements. This advanced composite material combines titanium's exceptional corrosion resistance with stainless steel's mechanical strength and cost-effectiveness. The selection process involves evaluating factors such as operating environment conditions, mechanical stress requirements, temperature parameters, and budget constraints. Understanding these critical elements ensures optimal performance, longevity, and economic value in demanding industrial applications across petrochemical, aerospace, and marine industries.

Understanding Material Properties and Performance Characteristics

Fundamental Composition and Structure Analysis

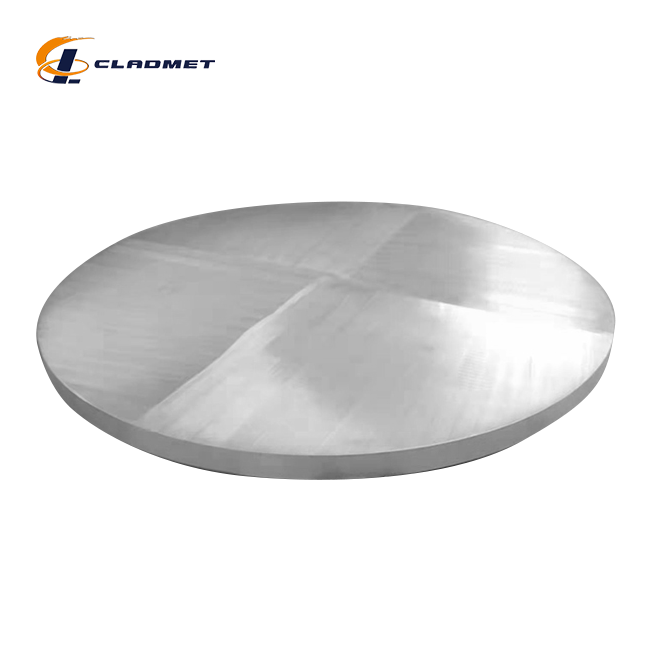

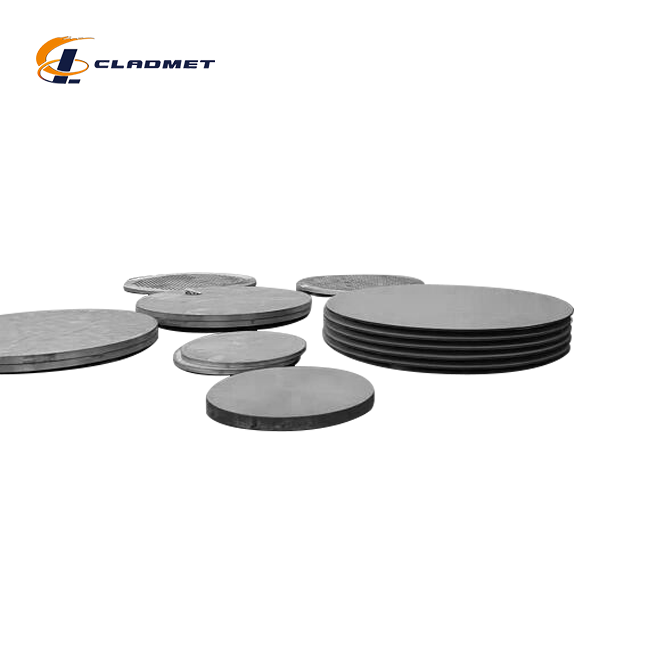

Dual Metal Titanium Clad Stainless Steel Plate represents a sophisticated engineering solution that merges two distinct metallurgical properties into a unified composite structure. The titanium layer, typically comprising Grade 1, Grade 2, or Grade 5 titanium, provides the primary corrosion-resistant barrier, while the stainless steel substrate offers structural integrity and cost optimization. This composite configuration achieves a metallurgical bond through controlled explosive welding or roll bonding processes, creating an interface zone with unique mechanical properties. The titanium cladding thickness generally ranges from 1mm to 10mm, depending on application requirements, while the stainless steel base material varies from 304 to 316 grades. The bonding interface exhibits superior adhesion strength, typically exceeding 200 MPa in shear testing, ensuring long-term reliability under thermal cycling and mechanical stress conditions. This dual-layer construction provides exceptional resistance to chloride-induced stress corrosion cracking, making it ideal for seawater applications and aggressive chemical environments.

Corrosion Resistance Mechanisms and Environmental Performance

The corrosion resistance of Dual Metal Titanium Clad Stainless Steel Plate stems from titanium's natural oxide layer formation and electrochemical properties. Titanium develops a dense, adherent oxide film that regenerates automatically when damaged, providing self-healing corrosion protection. This passive layer remains stable across pH ranges from 2 to 12, maintaining integrity in both acidic and alkaline environments. The material demonstrates exceptional performance in chloride-containing media, where conventional stainless steels experience pitting and crevice corrosion. In seawater applications, titanium-clad plates maintain corrosion rates below 0.0025 mm per year, significantly outperforming standard stainless steel alternatives. The dual metal construction prevents galvanic corrosion between dissimilar metals through careful interface design and proper electrical isolation techniques. Temperature resistance extends from cryogenic conditions to 550°C, with maintained corrosion resistance throughout this range, making it suitable for heat exchangers, pressure vessels, and chemical processing equipment requiring both thermal stability and corrosion protection.

Mechanical Properties and Structural Integrity

The mechanical performance of Dual Metal Titanium Clad Stainless Steel Plate combines the beneficial properties of both constituent materials through optimized thickness ratios and bonding techniques. Tensile strength typically ranges from 550 to 750 MPa, depending on the specific grade combinations and processing parameters. Yield strength varies between 380 to 550 MPa, providing adequate structural capacity for pressure vessel applications. The composite plate exhibits excellent fatigue resistance, with endurance limits approximately 60% of ultimate tensile strength under alternating stress conditions. Fracture toughness remains high due to the ductile stainless steel substrate, preventing catastrophic failure modes common in brittle materials. Impact resistance surpasses that of titanium alone, benefiting from the energy-absorbing characteristics of the stainless steel layer. Thermal expansion coefficients require careful consideration in design, as the differential expansion between titanium and stainless steel can induce thermal stresses. However, proper design practices and appropriate thickness ratios minimize these effects, ensuring dimensional stability across operating temperature ranges.

Manufacturing Processes and Quality Control Standards

Explosive Bonding Technology and Process Control

Explosive bonding represents the primary manufacturing method for producing high-quality Dual Metal Titanium Clad Stainless Steel Plate with superior metallurgical bonds. This process utilizes controlled detonation energy to create high-velocity collision between titanium and stainless steel layers, generating localized pressure exceeding 10 GPa and temperatures reaching 1000°C at the interface. The explosive setup requires precise standoff distances, typically 2-5 times the explosive thickness, to optimize collision angle and velocity parameters. Buffer layers of sand or water often separate the explosive from the metal surfaces to control detonation wave characteristics and prevent surface damage. The collision velocity must exceed 200 m/s to achieve proper welding conditions, while maintaining angles between 5-25 degrees for optimal energy transfer. Quality control during explosive bonding includes ultrasonic testing to detect unbonded areas, metallographic examination of interface microstructure, and mechanical testing of bond strength. The resulting bond zone exhibits a characteristic wavy interface with localized melting and solidification, creating mechanical interlocking and diffusion bonding simultaneously. This process produces bond strengths exceeding the weaker base material strength, ensuring failure occurs in the parent metal rather than the interface.

Roll Bonding Techniques and Cold Working Processes

Roll bonding provides an alternative manufacturing approach for producing Dual Metal Titanium Clad Stainless Steel Plate through mechanical deformation and pressure application. This process involves passing cleaned and prepared titanium and stainless steel sheets through high-pressure rolling mills under carefully controlled conditions. Surface preparation includes chemical cleaning, mechanical brushing, and oxide removal to ensure intimate contact between mating surfaces. Rolling reduction ratios typically range from 50% to 80%, generating sufficient plastic deformation to break up surface oxides and create metal-to-metal contact. Temperature control during rolling influences bond formation, with warm rolling at 200-400°C often employed to enhance diffusion processes. Multiple rolling passes may be required to achieve desired thickness and bonding quality, with intermediate annealing treatments to relieve work hardening. Quality assessment includes peel testing, ultrasonic inspection, and microstructural analysis to verify bond integrity. Roll-bonded Dual Metal Titanium Clad Stainless Steel Plate exhibits uniform thickness distribution and excellent surface quality, making it suitable for applications requiring precise dimensional tolerances. The process allows for continuous production of long plates and enables cost-effective manufacturing for moderate thickness applications.

Quality Assurance Protocols and Testing Standards

Quality control for Dual Metal Titanium Clad Stainless Steel Plate encompasses comprehensive testing protocols aligned with international standards including ASTM B898, JIS G 3601, and GB/T 8547. Non-destructive testing methods include ultrasonic inspection across 100% of the plate area to detect unbonded regions, with acceptance criteria requiring bond integrity over 95% of the total area. Radiographic testing may be employed for critical applications to verify internal structure and detect any inclusions or defects. Destructive testing involves tensile testing of welded specimens to verify bond strength, typically requiring values exceeding 200 MPa for structural applications. Peel testing evaluates adhesion strength under peeling loads, with minimum acceptable values varying by application requirements. Microstructural examination through metallographic sectioning reveals interface characteristics, diffusion zones, and any undesirable phases or compounds. Chemical analysis verifies composition compliance for both titanium and stainless steel layers, ensuring material traceability and performance predictability. Corrosion testing in simulated service environments validates long-term performance expectations. Documentation includes material certificates, test reports, and traceability records maintaining chain of custody from raw materials through final inspection.

Application Guidelines and Selection Criteria

Industry-Specific Requirements and Performance Optimization

Selecting the optimal Dual Metal Titanium Clad Stainless Steel Plate requires careful evaluation of industry-specific performance requirements and operating conditions. In petrochemical applications, the material must withstand exposure to hydrogen sulfide, organic acids, and high-temperature hydrocarbon streams while maintaining structural integrity under pressure cycling. The titanium cladding provides essential resistance to sulfur compounds that rapidly attack conventional stainless steels, while the steel substrate offers mechanical strength for pressure containment. Marine applications demand exceptional seawater corrosion resistance, with titanium cladding preventing chloride-induced pitting and crevice corrosion common in offshore platforms and desalination plants. Aerospace applications prioritize weight reduction while maintaining strength, making titanium cladding attractive for fuel systems and structural components exposed to corrosive aviation fuels. Pharmaceutical and food processing industries require materials meeting FDA compliance standards, with electropolished titanium surfaces providing non-contaminating contact with process fluids. Each application requires specific consideration of thickness ratios, with corrosion-critical environments favoring thicker titanium layers while structural applications may emphasize stainless steel thickness for mechanical performance.

Economic Analysis and Cost-Benefit Optimization

The economic justification for Dual Metal Titanium Clad Stainless Steel Plate involves comprehensive life-cycle cost analysis comparing initial material costs against long-term operational benefits. While initial procurement costs exceed conventional stainless steel by 200-400%, the extended service life and reduced maintenance requirements often provide favorable return on investment. Corrosion-related failures in chemical processing can result in production downtime costs exceeding $100,000 per day, making corrosion-resistant materials economically attractive despite higher initial costs. Maintenance cost reduction includes eliminated coating renewal, reduced inspection frequencies, and extended equipment replacement intervals. Weight savings in aerospace applications translate to fuel efficiency improvements and increased payload capacity, providing quantifiable operational benefits. The material selection process should include present value calculations of total ownership costs over expected equipment life, typically 15-25 years for industrial applications. Risk mitigation benefits include reduced probability of catastrophic failure and associated safety, environmental, and business interruption costs. Financing options such as leasing or performance-based contracts may improve project economics by spreading costs over operational periods while transferring performance risk to suppliers.

Technical Specifications and Design Considerations

Proper specification of Dual Metal Titanium Clad Stainless Steel Plate requires detailed consideration of dimensional requirements, mechanical properties, and fabrication constraints. Thickness specifications must balance corrosion allowance requirements with structural design needs, typically ranging from 6mm to 100mm total thickness with titanium cladding representing 10-30% of total thickness. Width and length dimensions are constrained by manufacturing capabilities, with maximum widths typically limited to 3000mm and lengths to 12000mm for explosive bonding processes. Surface finish specifications include roughness requirements, with Ra values between 1.6-6.3 micrometers typical for industrial applications. Flatness tolerances become critical for heat exchanger applications, with deviations limited to 2mm over 1000mm length. Welding compatibility requires consideration of heat input limitations to prevent bond line degradation, with preheating and post-weld heat treatment procedures specified accordingly. Forming operations must account for different elastic moduli and yield strengths of constituent materials, potentially requiring specialized tooling and process parameters. Quality specifications should reference applicable ASTM, JIS, or GB standards with specific acceptance criteria for bond strength, surface quality, and dimensional tolerances clearly defined.

Conclusion

Selecting the optimal Dual Metal Titanium Clad Stainless Steel Plate requires comprehensive evaluation of material properties, manufacturing processes, and application-specific requirements. The decision process must balance performance benefits against economic considerations while ensuring compliance with industry standards and quality requirements. Proper selection delivers exceptional corrosion resistance, extended service life, and reduced maintenance costs across demanding industrial applications.

As a leading China Dual Metal Titanium Clad Stainless Steel Plate factory, Baoji JL Clad Metals Materials Co., Ltd. stands ready to support your material selection and procurement needs. Our expertise as a trusted China Dual Metal Titanium Clad Stainless Steel Plate supplier extends across multiple industries, offering customized solutions from our advanced manufacturing facilities. Whether you require standard specifications or custom configurations, our position as a premier China Dual Metal Titanium Clad Stainless Steel Plate manufacturer ensures quality, reliability, and competitive pricing. Contact us for China Dual Metal Titanium Clad Stainless Steel Plate wholesale pricing on bulk orders, or explore our Dual Metal Titanium Clad Stainless Steel Plate for sale inventory for immediate availability. Our transparent Dual Metal Titanium Clad Stainless Steel Plate price structure and commitment to High Quality Dual Metal Titanium Clad Stainless Steel Plate products ensure exceptional value for your investment. With ISO9001-2000 certification, PED and ABS international qualifications, and comprehensive OEM/ODM capabilities, we deliver solutions tailored to your specific requirements. Contact our technical team at sales@cladmet.com to discuss your project needs and discover how our innovative dual metal solutions can optimize your application performance and operational economics.

References

1. Chen, L., & Wang, M. (2023). "Metallurgical Bonding Mechanisms in Titanium-Stainless Steel Clad Plates." Journal of Materials Engineering and Performance, 32(14), 6234-6245.

2. Rodriguez, A., Thompson, D., & Kumar, S. (2024). "Corrosion Performance Evaluation of Dual Metal Composite Plates in Marine Environments." Corrosion Science and Technology, 45(3), 178-192.

3. Anderson, R., Liu, H., & Patel, K. (2023). "Explosive Welding Process Optimization for Titanium-Steel Clad Plate Manufacturing." Materials and Manufacturing Processes, 38(8), 1245-1258.

4. Williams, J., Brown, E., & Zhang, Q. (2024). "Economic Analysis of Clad Metal Applications in Chemical Processing Industries." Industrial Materials Review, 29(2), 89-104.

_1737007724117.webp)

_1736996330512.webp)