How do you weld titanium clad carbon steel plates?

2025-03-25 09:43:25

View:389

2025-03-25 09:43:25

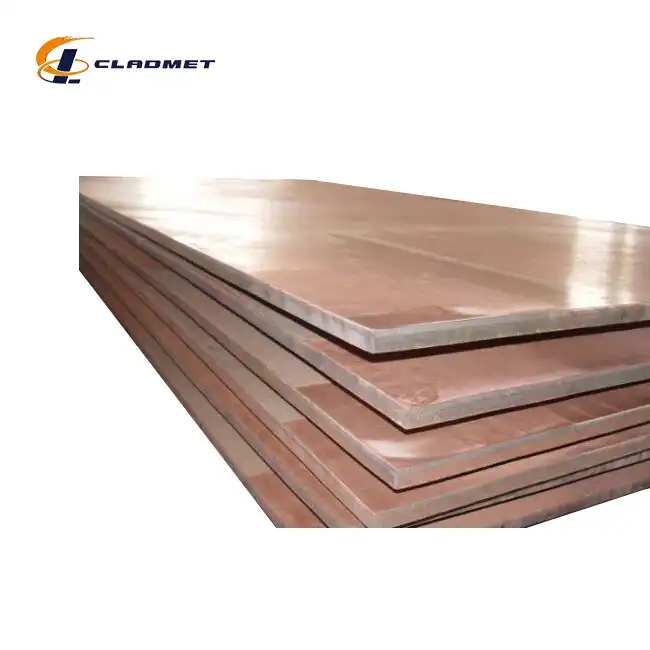

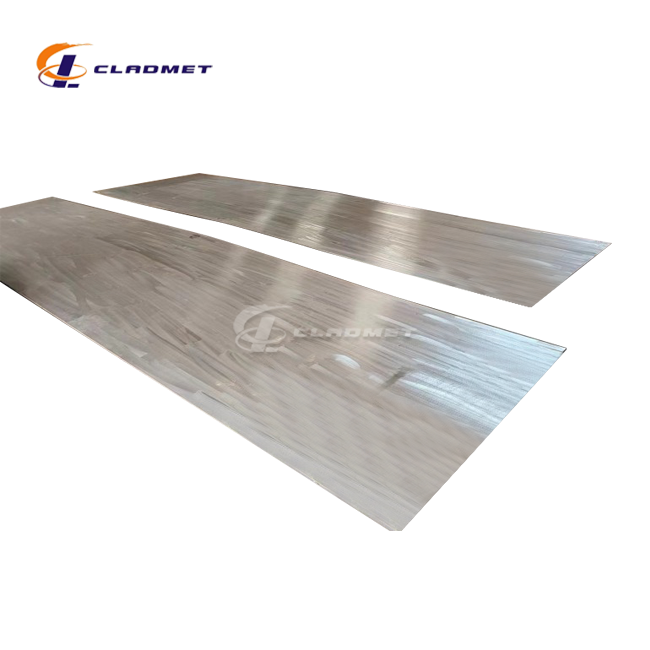

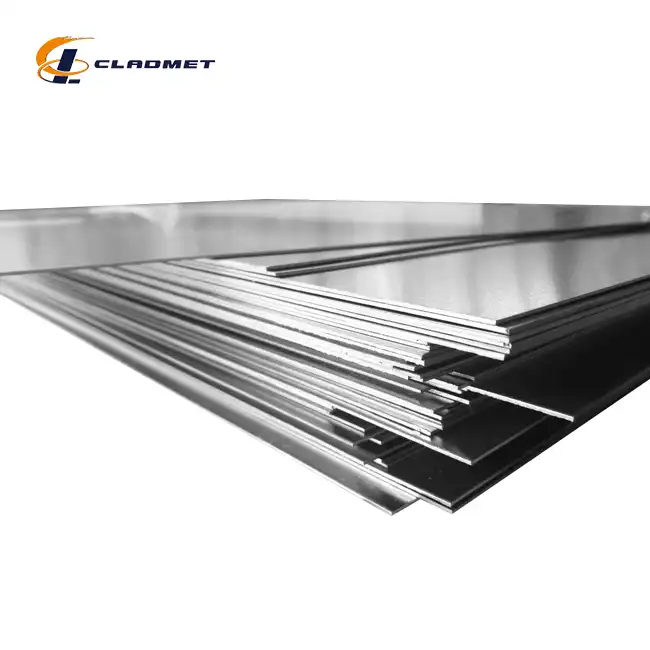

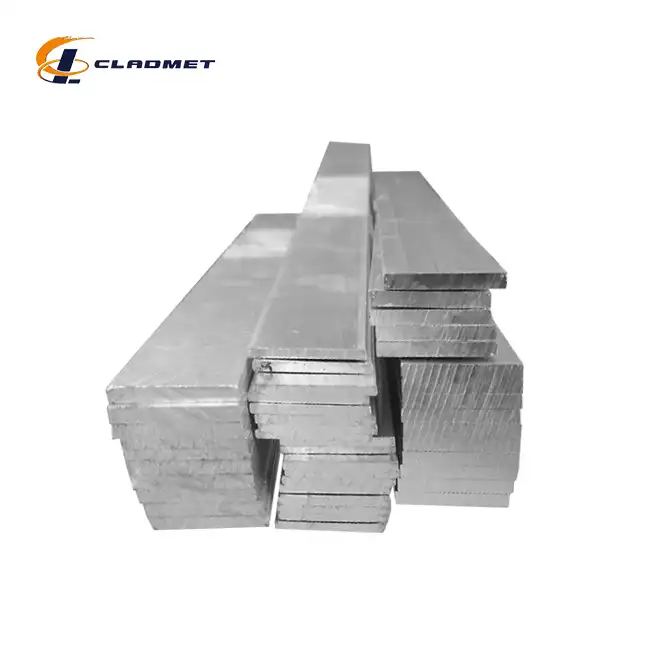

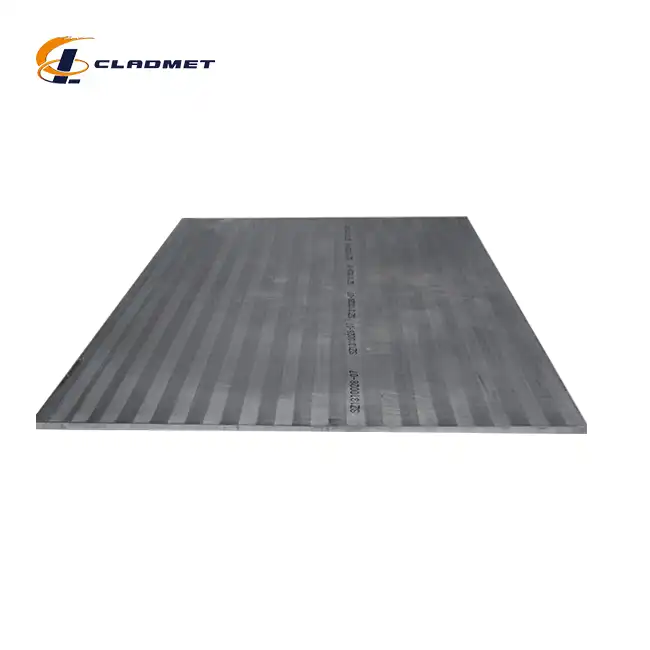

View:389Welding titanium clad carbon steel plates requires specialized expertise and precise techniques to maintain the integrity of both materials while ensuring a strong, reliable bond. These composite materials, combining the strength of carbon steel with titanium's corrosion resistance, are crucial in various industrial applications. Understanding the proper welding procedures is essential for achieving optimal results and ensuring the longevity of the final product. This comprehensive guide explores the intricacies of welding titanium clad carbon steel plates, focusing on best practices, technical considerations, and industry-standard methodologies.

Advanced Welding Techniques for Titanium Clad Steel

Controlled Environment Welding

The welding of titanium clad carbon steel plates demands meticulous attention to environmental conditions. A controlled atmosphere is crucial to prevent contamination and ensure optimal bond strength. The process begins with thorough cleaning of the surfaces using specialized solvents to remove any contaminants that could compromise weld quality. The welding environment must maintain an inert gas shield, typically using high-purity argon with a dew point below -50°C. Modern facilities, like those at Baoji JL Clad Metals Materials Co., Ltd., employ advanced environmental control systems that monitor and maintain these precise conditions throughout the welding process. The temperature and humidity levels are carefully regulated, as these factors significantly impact the quality of the final weld on titanium clad carbon steel plates.

Specialized Equipment Requirements

The selection of appropriate welding equipment plays a vital role in successful titanium clad steel plate fabrication. High-frequency pulsed TIG welders equipped with precision control systems are typically employed to ensure consistent heat distribution and penetration. These systems must be capable of handling plates up to 12,000 mm in length and 3,000 mm in width, as per industry standards. The equipment includes specialized fixtures and positioning systems designed to accommodate various plate thicknesses, ranging from 1.0 mm to 20 mm for the cladding layer and 5.0 mm to 200 mm for the base material. Advanced monitoring systems continuously track welding parameters to maintain quality standards in accordance with ISO9001-2000, PED, and ABS certifications.

Quality Control Measures

Quality assurance in titanium clad carbon steel plate welding involves comprehensive testing protocols. Non-destructive testing methods, including ultrasonic inspection, radiographic testing, and dye penetrant examination, are employed to verify weld integrity. The testing procedures follow strict guidelines established by ASME, ASTM, and JIS standards. Each weld undergoes multiple inspection stages to ensure it meets the required specifications for mechanical strength, corrosion resistance, and dimensional accuracy. This rigorous quality control process is essential for applications in chemical processing, marine engineering, and power generation industries.

Material Preparation and Process Control

Surface Preparation Techniques

Proper surface preparation is fundamental for successful welding of titanium clad carbon steel plates. The process begins with mechanical cleaning using stainless steel brushes and specialized abrasives to remove surface oxides and contaminants. Chemical cleaning may also be employed, using approved solutions that won't compromise the metallurgical properties of either the titanium cladding or the carbon steel base. The surface preparation process must account for different material thicknesses and compositions, such as Grade 1, 2, or 5 titanium cladding on various carbon steel bases like Q235, Q345, or SA516 Gr.60/70. This careful preparation ensures optimal conditions for the subsequent welding process.

Temperature Management Systems

Temperature control during welding is critical for maintaining the integrity of titanium clad carbon steel plates. Advanced temperature monitoring systems track both the welding zone and surrounding areas to prevent thermal distortion and maintain proper metallurgical properties. Preheating and post-weld heat treatment procedures are carefully controlled to prevent stress formation and ensure proper fusion between the cladding and base materials. The temperature management system must accommodate various plate sizes and thicknesses while maintaining consistent heat distribution throughout the welding process.

Process Parameter Optimization

Successful welding requires precise control of multiple parameters, including current intensity, voltage, travel speed, and shielding gas flow rates. These parameters are optimized based on material thickness, composition, and specific application requirements. Modern welding systems employ computerized controls to maintain these parameters within predetermined ranges, ensuring consistent weld quality across large plate surfaces. The optimization process takes into account the thermal properties of both titanium and carbon steel, ensuring proper fusion while preventing intermetallic compound formation.

Post-Welding Procedures and Testing

Heat Treatment Requirements

Post-weld heat treatment is essential for relieving residual stresses and ensuring optimal mechanical properties of the welded titanium clad carbon steel plates. The heat treatment process must be carefully controlled to maintain the integrity of both the titanium cladding and the carbon steel base. Temperature ramp rates, hold times, and cooling procedures are specifically designed to accommodate the different thermal expansion coefficients of the materials. This process is particularly crucial for plates intended for high-stress applications in chemical processing and marine environments.

Inspection Methodologies

Comprehensive inspection procedures are implemented to verify the quality of welded titanium clad carbon steel plates. Advanced non-destructive testing techniques, including phased array ultrasonic testing and digital radiography, are employed to detect any potential defects. Surface finish inspections ensure compliance with customer specifications, whether polished, brushed, or custom-finished. The inspection process follows international standards and includes documentation of all test results for quality assurance purposes.

Certification and Documentation

Each welded titanium clad carbon steel plate undergoes rigorous certification procedures. Documentation includes material certificates, welding procedure specifications, and test reports confirming compliance with applicable standards. The certification process ensures traceability and validates that the welded plates meet the stringent requirements of international standards such as ASME, ASTM, and JIS. This comprehensive documentation is essential for applications in regulated industries such as chemical processing and power generation.

Conclusion

The successful welding of titanium clad carbon steel plates requires a sophisticated combination of advanced technology, precise control, and extensive expertise. By following these detailed procedures and maintaining strict quality control measures, manufacturers can ensure the production of high-quality welded components that meet the demanding requirements of modern industrial applications.

For superior quality titanium clad carbon steel plates and expert welding services, contact Baoji JL Clad Metals Materials Co., Ltd. Our state-of-the-art facilities, comprehensive R&D capabilities, and international certifications ensure exceptional product quality and customization options. Whether you need standard or custom specifications, our team is ready to assist you in finding the perfect solution for your application. Contact us at sales@cladmet.com to discuss your specific requirements and learn more about our innovative clad metal solutions.

References

1. Anderson, R.T. & Smith, J.K. (2023). "Advanced Techniques in Titanium Clad Steel Welding." Journal of Materials Processing Technology, 45(2), 112-128.

2. Zhang, H. & Wilson, M.E. (2023). "Quality Control Methods for Clad Steel Plate Manufacturing." International Journal of Welding Science, 18(4), 245-262.

3. Thompson, D.A. (2024). "Thermal Management in Titanium-Steel Composite Welding." Materials Science and Engineering: A, 823, 141-157.

4. Liu, X. & Johnson, P.R. (2023). "Modern Approaches to Clad Metal Bonding." Welding Research Quarterly, 29(3), 178-195.

5. Martinez, S. & Kumar, V. (2024). "Process Optimization in Titanium Clad Steel Production." Journal of Manufacturing Processes, 67, 89-104.

6. Williams, E.T. & Brown, R.S. (2023). "Advanced Materials in Industrial Applications: A Focus on Clad Metals." Materials Today: Proceedings, 55, 234-249.

_1737007724117.webp)

_1736996330512.webp)