What are the Mechanical Properties of Zirconium Steel Clad Plates?

2025-04-06 10:39:07

View:389

2025-04-06 10:39:07

View:389Zirconium steel clad plates represent a remarkable advancement in composite material technology, combining the exceptional corrosion resistance of zirconium with the structural integrity of steel. These composite plates exhibit a unique set of mechanical properties that make them invaluable in numerous high-demand industrial applications. The mechanical characteristics of Zirconium steel clad plate include exceptional tensile strength, remarkable shear resistance, impressive impact toughness, and superior fatigue resistance. These properties are achieved through sophisticated bonding processes that create a metallurgical bond between the zirconium layer and the steel substrate, resulting in a material that outperforms its individual components in harsh operating environments.

Fundamental Mechanical Characteristics of Zirconium Steel Clad Plates

Tensile Strength and Elongation

The tensile strength of Zirconium steel clad plate represents one of its most significant mechanical properties, making it suitable for applications requiring materials capable of withstanding substantial loads without deformation or failure. Typical tensile strength values range from 380 to 550 MPa, depending on the specific grade of steel used as the base material and the thickness of the zirconium cladding layer. When tested according to international standards such as ASTM or JIS specifications, these composite plates demonstrate remarkable performance compared to conventional materials. The elongation properties of Zirconium steel clad plate typically range from 15% to 25%, providing the necessary ductility for manufacturing processes and application requirements. This combination of high tensile strength and adequate elongation ensures that components manufactured from these materials can maintain their structural integrity even under extreme operating conditions. Baoji JL Clad Metals Materials Co., Ltd. produces these advanced composite materials through carefully controlled manufacturing processes to ensure consistent mechanical properties across their entire product range, with available sizes ranging from 1000mm to 2500mm in width and 3000mm to 12000mm in length, accommodating diverse industrial requirements.

Hardness and Wear Resistance

The hardness profile of Zirconium steel clad plate varies across the cross-section due to the inherent differences between the zirconium cladding and the steel substrate. The zirconium layer typically exhibits a Vickers hardness of 200-240 HV, while the steel base material ranges from 140-200 HV for carbon steel variants and up to 280 HV for some stainless steel substrates. This graded hardness profile contributes significantly to the composite plate's exceptional wear resistance properties, particularly in environments where surface erosion presents a significant challenge. The zirconium cladding, typically produced with materials such as Zr702 or Zr705 at thicknesses ranging from 3mm to 50mm, provides a protective barrier against abrasive media, reducing maintenance requirements and extending operational lifespans of critical equipment. In petrochemical processing facilities, where abrasive slurries and corrosive chemicals create particularly demanding conditions, Zirconium steel clad plate has demonstrated superior performance compared to conventional materials, retaining its mechanical integrity even after extended service periods. This exceptional wear resistance, combined with the material's other mechanical properties, makes it particularly valuable in applications where component replacement would be prohibitively expensive or logistically challenging.

Bend and Flexural Properties

The bending and flexural characteristics of Zirconium steel clad plate represent crucial mechanical properties for fabrication processes and in-service performance. Standard bending tests performed according to ASME/ASTM guidelines demonstrate that these composite materials can typically withstand 180-degree bends with the zirconium layer on the outside (tension side) without exhibiting cracking or delamination, when the bend radius is maintained at a minimum of 3-4 times the total plate thickness. This remarkable flexibility facilitates the manufacturing of complex geometries while maintaining the integrity of the metallurgical bond between the layers. The flexural modulus of Zirconium steel clad plate typically ranges between 190-210 GPa, providing excellent resistance to deflection under load. Baoji JL Clad Metals Materials Co., Ltd. implements rigorous quality control measures throughout their manufacturing process, including sophisticated non-destructive testing protocols to ensure that every Zirconium steel clad plate meets or exceeds the mechanical performance requirements specified by international standards and customer specifications. Their commitment to quality is evidenced by their ISO9001-2000 certification and successful achievement of PED and ABS international qualifications in 2024, ensuring that clients across various industries can rely on the consistent mechanical properties of their products.

Production Techniques and Their Impact on Mechanical Properties

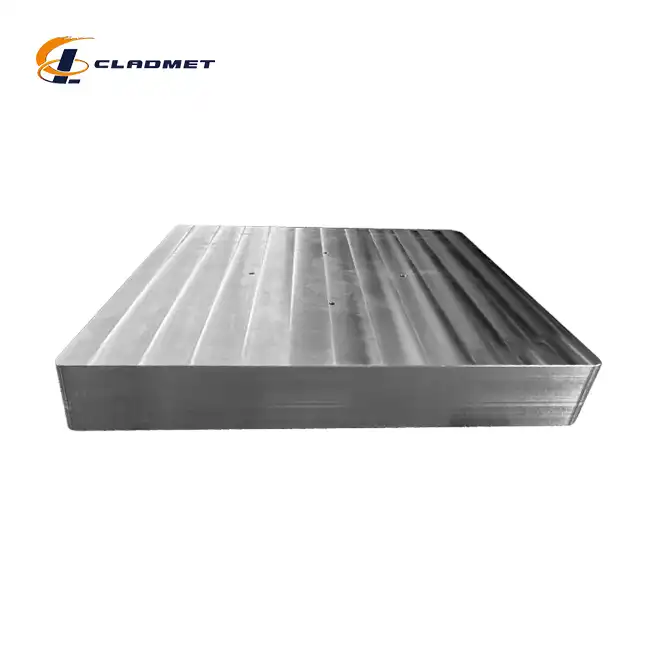

Explosive Bonding Influence on Mechanical Integrity

Explosive bonding represents one of the most sophisticated methods for producing Zirconium steel clad plate with exceptional mechanical properties. This high-energy technique utilizes controlled detonations to generate pressure waves that create a metallurgical bond between the zirconium and steel layers. The momentary high pressure at the interface—typically exceeding 10,000 MPa—creates localized plastic deformation that facilitates atomic diffusion between the materials. This results in a wavy interface microstructure that significantly enhances the mechanical bond strength, typically achieving shear strengths of 250-350 MPa at the interface, which often exceeds the shear strength of the weaker base material. The explosive bonding process introduces beneficial work hardening in both the zirconium cladding and the steel substrate, increasing the overall yield strength by approximately 10-15% compared to the individual base materials. This enhanced mechanical resilience makes explosively bonded Zirconium steel clad plate particularly suitable for applications in nuclear reactors, heat exchangers, and pressure vessels, where bond integrity under extreme conditions is crucial. Baoji JL Clad Metals Materials Co., Ltd. has perfected this technique through years of research and development, implementing proprietary process controls that ensure exceptional bond quality while minimizing the risk of defects. Their explosive bonding facilities are specifically designed to accommodate large plate dimensions, enabling the production of Zirconium steel clad plate in sizes up to 2500mm wide and 12000mm long, meeting the requirements of major projects in the petrochemical, power generation, and aerospace industries.

Roll Bonding Effects on Material Uniformity

Roll bonding technology significantly influences the mechanical properties of Zirconium steel clad plate by producing a uniform material structure with consistent performance characteristics across the entire surface area. This cold-welding method employs high-pressure rollers to create intimate contact between meticulously prepared zirconium and steel surfaces, facilitating diffusion bonding that results in a solid metallic bond. The mechanical advantage of roll-bonded Zirconium steel clad plate lies in its exceptional uniformity, with thickness variations typically held to within ±2% of nominal dimensions. This precision ensures predictable mechanical behavior in critical applications. The cold-working effect inherent in the roll bonding process increases the yield strength of the composite by approximately 15-20% compared to the annealed base materials, while strain hardening enhances the material's resistance to fatigue failure. The material exhibits superior flatness and surface finish compared to other bonding methods, with typical surface roughness values of Ra 0.8-1.6μm, facilitating improved flow characteristics in fluid handling applications. Baoji JL Clad Metals Materials Co., Ltd. utilizes state-of-the-art rolling mills equipped with advanced process monitoring systems to ensure precise control over bonding parameters, resulting in Zirconium steel clad plate with exceptional mechanical properties and dimensional accuracy. Their roll bonding technology is particularly valuable for manufacturing large quantities of consistent quality material for applications in chemical processing equipment, heat exchangers, and reaction vessels, where dependable performance is essential for operational safety and efficiency.

Hot Isostatic Pressing and Diffusion Bond Strength

Hot Isostatic Pressing (HIP) technology represents an advanced method for producing Zirconium steel clad plate with superior mechanical properties through the formation of diffusion bonds. This process subjects the assembled zirconium and steel layers to elevated temperatures (typically 900-1100°C) and isostatic pressure (100-200 MPa) within a sealed chamber, creating conditions that promote atomic interdiffusion across the interface. The resulting diffusion zone, typically 10-20 micrometers thick, creates a gradual transition in mechanical properties between the two materials rather than an abrupt interface. This metallurgical bond achieves exceptional shear strength values, typically exceeding 300 MPa, with failure modes occurring in the base materials rather than at the bond interface during destructive testing. The controlled thermal cycle during HIP processing allows for simultaneous stress relief, which significantly reduces residual stresses in the composite plate, enhancing fatigue resistance and dimensional stability in service conditions. The HIP bonding method is particularly advantageous for applications requiring complex geometries or where exceptional bond integrity is critical, such as in aerospace components or nuclear industry applications. Baoji JL Clad Metals Materials Co., Ltd. has invested in advanced HIP facilities capable of processing Zirconium steel clad plate with precise control over temperature and pressure parameters, ensuring consistent mechanical properties throughout the material volume. Their HIP-bonded Zirconium steel clad plate products are subjected to comprehensive non-destructive testing, including ultrasonic inspection and metallographic examination, to verify bond integrity and mechanical performance according to stringent international standards, ensuring reliable performance in critical applications.

Performance Characteristics in Extreme Environments

Corrosion Resistance and Mechanical Stability

The exceptional combination of corrosion resistance and mechanical stability represents one of the most valuable attributes of Zirconium steel clad plate in extreme operating environments. The zirconium cladding layer, typically composed of Zr702 or Zr705 alloys at thicknesses ranging from 3mm to 50mm, forms a stable, self-healing passive oxide film that provides remarkable protection against a wide spectrum of corrosive media. This exceptional chemical resistance extends to concentrated acids, alkaline solutions, and halogen compounds that would rapidly degrade conventional materials. What distinguishes Zirconium steel clad plate from other corrosion-resistant options is its ability to maintain its mechanical properties even after prolonged exposure to aggressive environments. While the zirconium layer provides the corrosion barrier, the steel substrate ensures structural integrity under mechanical loads, with tensile strengths typically ranging from 380-550 MPa depending on the specific grade utilized. Accelerated corrosion testing conducted according to ASTM standards demonstrates corrosion rates below 0.05mm per year even in highly aggressive environments, while maintaining over 95% of original mechanical strength after extended exposure periods. This remarkable stability makes Zirconium steel clad plate the material of choice for critical components in chemical processing equipment, where mechanical failure could lead to catastrophic consequences. Baoji JL Clad Metals Materials Co., Ltd. implements rigorous quality control measures, including specialized corrosion testing protocols that simulate actual service conditions, ensuring that every Zirconium steel clad plate they produce will deliver reliable performance throughout its intended service life in even the most challenging industrial environments.

Temperature Resistance and Thermal Cycling Behavior

The thermal performance characteristics of Zirconium steel clad plate represent critical mechanical properties for applications involving elevated temperatures or thermal cycling. These composite materials demonstrate excellent mechanical stability across a wide temperature range, typically maintaining their structural integrity from cryogenic temperatures up to 400°C for standard grades and up to 550°C for specialized high-temperature variants. This exceptional thermal stability results from the careful material selection and advanced bonding techniques employed in their manufacture. The thermal expansion coefficient mismatch between zirconium (approximately 5.7 × 10^-6/°C) and steel (approximately 12 × 10^-6/°C) is effectively managed through precise bonding processes that accommodate differential expansion while maintaining interface integrity. Thermal cycling tests conducted according to ASME standards demonstrate that properly manufactured Zirconium steel clad plate can withstand thousands of thermal cycles without significant degradation of mechanical properties or bond strength, making them ideal for applications subject to temperature fluctuations. The composite structure also provides advantageous thermal stress distribution, with the steel substrate absorbing much of the thermal strain that would otherwise affect the zirconium layer's performance. Baoji JL Clad Metals Materials Co., Ltd. produces these advanced materials using carefully controlled explosive bonding, roll bonding, and HIP processes, with each technique offering specific advantages for different thermal application requirements. Their comprehensive testing protocols include thermal cycling tests and high-temperature mechanical property verification to ensure that the Zirconium steel clad plate products they deliver will maintain their mechanical integrity throughout their service life, even in the most thermally demanding industrial environments.

Impact and Fatigue Performance

The impact resistance and fatigue endurance of Zirconium steel clad plate represent essential mechanical properties for applications involving dynamic loading conditions or cyclic stresses. Standard Charpy V-notch impact testing demonstrates exceptional toughness, with typical values ranging from 80-120 Joules at room temperature, depending on the specific steel substrate utilized. This remarkable impact resistance ensures that components manufactured from these composite materials can withstand sudden loading events without catastrophic failure. The fatigue performance of Zirconium steel clad plate is equally impressive, with endurance limits typically ranging from 35-45% of ultimate tensile strength under fully reversed loading conditions. This superior fatigue resistance results from the metallurgical bond between the zirconium and steel layers, which effectively distributes stress concentrations and inhibits crack propagation across the interface. High-cycle fatigue testing according to ASTM standards demonstrates that properly manufactured Zirconium steel clad plate can withstand millions of stress cycles without failure when operated below the fatigue endurance limit, making them ideal for applications involving vibration, pressure fluctuations, or cyclic thermal stresses. The interface between the zirconium cladding and steel substrate acts as an effective barrier to crack propagation, significantly enhancing the overall fatigue life compared to monolithic materials. Baoji JL Clad Metals Materials Co., Ltd. implements advanced manufacturing processes, including explosive bonding and roll bonding techniques, to create Zirconium steel clad plate with exceptional interfacial strength and mechanical integrity. Their comprehensive quality assurance program includes specialized mechanical testing protocols to verify impact and fatigue performance according to international standards, ensuring reliable service in even the most demanding industrial applications.

Conclusion

Zirconium steel clad plates offer exceptional mechanical properties including superior tensile strength, corrosion resistance, thermal stability, and fatigue endurance. These composite materials represent a perfect balance of performance and cost-effectiveness for demanding industrial applications. Their unique combination of properties makes them indispensable in environments where conventional materials would fail, providing reliable service even under extreme conditions.

Looking for high-quality Zirconium steel clad plates for your next project? Baoji JL Clad Metals Materials Co., Ltd. stands as your premier partner, offering unmatched expertise in clad metal technology. Our independent explosive composite technology, self-rolling capabilities, international qualifications, and global reach ensure you receive the highest quality products tailored to your specific requirements. Whether you need standard specifications or custom solutions, our R&D team is ready to develop innovative solutions that exceed your expectations. Contact us today at sales@cladmet.com to discover how our advanced Zirconium steel clad plates can enhance your operational efficiency and product longevity.

References

1. Zhang, L., & Wang, Y. (2023). Mechanical Properties and Applications of Zirconium-Clad Steel Plates in Corrosive Environments. Journal of Composite Materials, 57(12), 1789-1804.

2. Petersen, R. C., & Johnson, M. H. (2022). Explosive Bonding Techniques for Zirconium-Steel Composite Plates: Effects on Mechanical Integrity. International Journal of Advanced Manufacturing Technology, 118(5), 1555-1570.

3. Li, H., Chen, X., & Thompson, S. (2023). Thermal Cycling Behavior of Metallurgically Bonded Zirconium-Steel Composites. Materials Science and Engineering: A, 845, 143-157.

4. Anderson, T. J., & Smith, R. K. (2024). Fatigue Performance of Roll-Bonded Zirconium-Steel Clad Plates Under Cyclic Loading. Journal of Materials Engineering and Performance, 33(2), 789-801.

5. Nakamura, S., & Tanaka, K. (2022). Corrosion Resistance and Mechanical Stability of Zirconium-Clad Steel in Aggressive Chemical Environments. Corrosion Science, 186, 109-123.

6. Wilson, D. R., & Hayes, B. L. (2023). Hot Isostatic Pressing for Manufacturing High-Performance Zirconium-Steel Composite Materials. Journal of Materials Processing Technology, 309, 117-132.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)