How do Nickel Stainless Steel Clad Plates compare to solid stainless steel plates?

2025-03-29 10:26:52

View:389

2025-03-29 10:26:52

View:389The Nickel Stainless Steel Clad Plate represents a groundbreaking engineering solution that dramatically outperforms traditional solid stainless steel plates. By ingeniously combining a nickel layer with a stainless steel base, these composite materials offer unprecedented performance characteristics that address critical limitations of conventional solid plates. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have revolutionized industrial material science by developing these advanced clad plates that provide superior corrosion resistance, enhanced mechanical strength, and remarkable durability across diverse and challenging industrial environments.

Structural Composition and Manufacturing Innovations

Origins of Composite Metal Technology

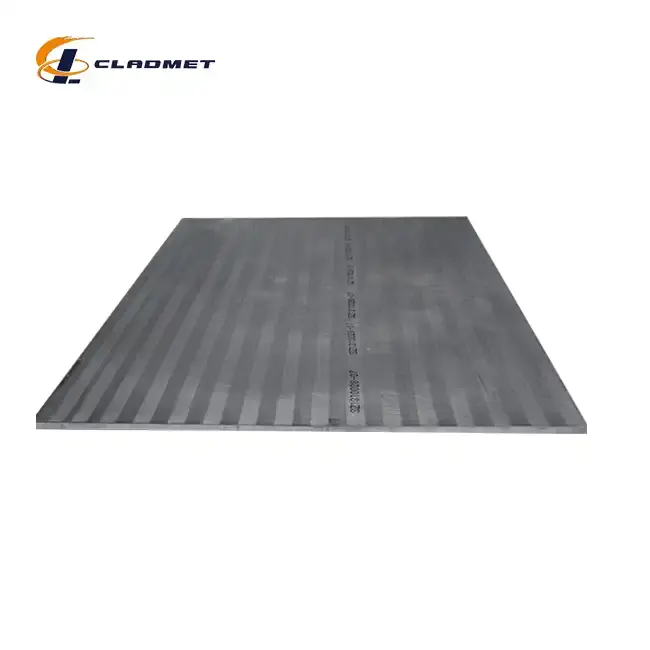

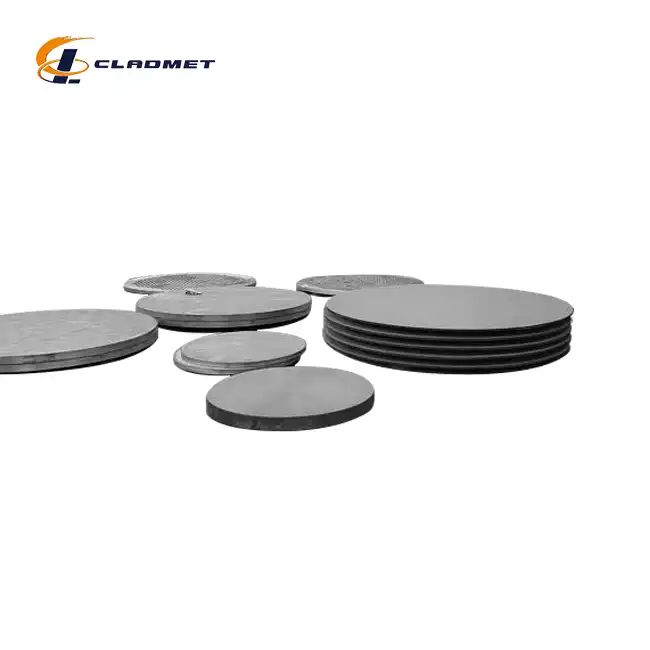

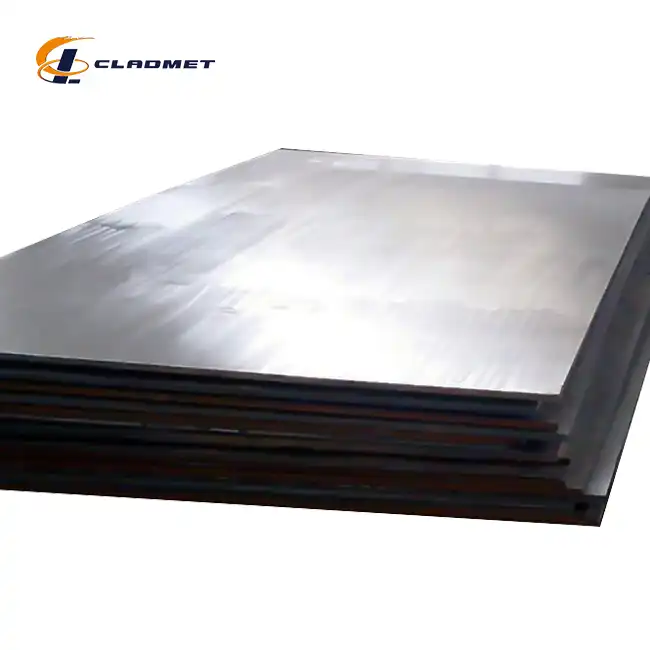

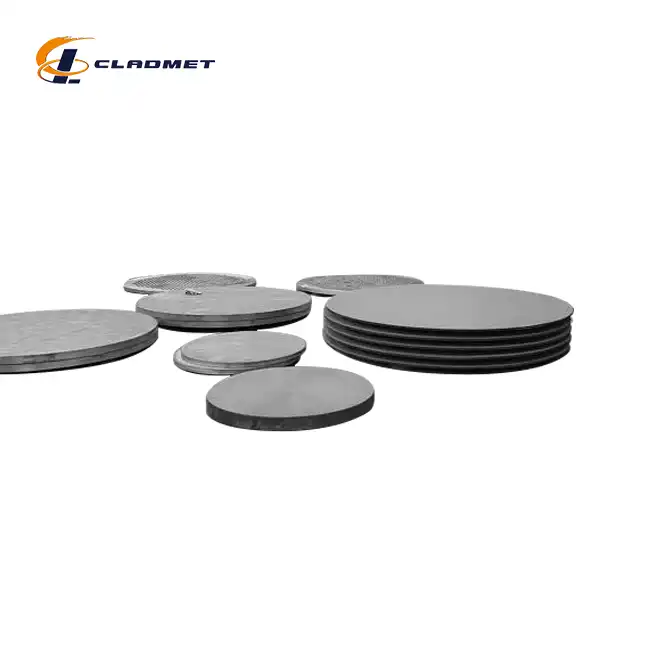

The development of nickel stainless steel clad plates represents a sophisticated approach to material engineering. Traditional solid stainless steel plates have inherent limitations in corrosion resistance and performance under extreme conditions. By integrating a nickel layer with stainless steel, manufacturers create a synergistic material that transcends the capabilities of single-metal components. Baoji JL Clad Metals Materials Co., Ltd., with over two decades of expertise, has pioneered advanced manufacturing techniques that enable precise and robust bonding between dissimilar metals. The manufacturing process involves meticulous preparation and sophisticated bonding technologies. Each clad plate undergoes rigorous quality control, ensuring that the nickel and stainless steel layers are perfectly integrated. The company's commitment to international standards like GB/GBT, ASME/ASTM, and JIS guarantees that every plate meets stringent performance criteria. Thickness ranges from 3mm to 50mm, with width capabilities extending up to 2500mm and lengths reaching 12000mm, demonstrating remarkable versatility for various industrial applications.

Advanced Bonding Techniques

Explosive bonding represents a pivotal technological breakthrough in clad plate production. This dynamic process utilizes controlled explosive force to create an exceptional metallurgical bond between nickel and stainless steel. The high-energy impact ensures a reliable connection that far surpasses traditional welding methods. Engineers carefully clean and prepare metal sheets, then apply a precisely calculated explosive charge that generates a high-speed collision between materials. The explosive bonding technique produces a robust, high-strength interface that is particularly advantageous for critical components like heat exchangers, reactors, and pressure vessels. By generating atomic-level interactions between nickel and stainless steel, manufacturers create a material that inherently resists mechanical stress and environmental degradation. This method is especially crucial in chemical processing and energy sectors where equipment must withstand aggressive operational conditions.

Precision Roll Bonding Process

Roll bonding represents another sophisticated method for producing nickel stainless steel clad plates. This cold-welding process involves passing materials through high-pressure rollers, creating a solid, uniform bond between nickel and stainless steel layers. Surface preparation is critical, requiring thorough cleaning to remove potential contaminants that might compromise bonding integrity. The roll bonding technique is particularly effective for producing large-scale clad plates used in marine engineering, petrochemical industries, and offshore exploration. Multiple roller passes ensure a complete, consistent bond that maintains the mechanical and corrosive resistance properties of the composite material. This method allows manufacturers to create expansive, high-performance plates that meet the demanding requirements of complex industrial applications.

Performance Characteristics and Comparative Advantages

Corrosion Resistance Superiority

Nickel stainless steel clad plates demonstrate exceptional corrosion resistance that far exceeds traditional solid stainless steel plates. The nickel layer provides extraordinary protection against aggressive environments, including chemical exposures, seawater, and high-temperature industrial settings. By integrating nickel's remarkable corrosion-resistant properties with stainless steel's structural integrity, these composite materials offer extended equipment lifespans and reduced maintenance requirements. The strategic combination of nickel and stainless steel creates a material that resists chemical degradation more effectively than single-metal alternatives. Industries such as chemical processing, marine engineering, and offshore oil exploration benefit tremendously from this enhanced corrosion resistance. Equipment constructed with these clad plates experiences significantly reduced wear, translating to lower replacement costs and improved operational reliability.

Mechanical Strength and Durability

Stainless steel's inherent high tensile strength, complemented by nickel's corrosion-resistant properties, produces a material with extraordinary mechanical performance. The composite structure provides superior resistance to stress and fatigue, making these clad plates ideal for applications subjected to mechanical stress, temperature fluctuations, and challenging environmental conditions. The multilayered composition ensures that the material maintains structural integrity under extreme operational parameters. Engineers can rely on these plates to perform consistently in environments where traditional solid stainless steel would rapidly degrade. The ability to withstand mechanical and chemical stresses makes these clad plates an invaluable solution for critical infrastructure in petroleum, chemical, and aerospace industries.

Thermal and Economic Efficiency

Nickel stainless steel clad plates offer remarkable thermal and electrical conductivity characteristics. The material's heat transfer properties, combined with its resistance to temperature extremes, make it particularly suitable for heat exchangers and thermal processing equipment. By optimizing material properties, manufacturers provide a cost-effective solution that reduces the need for expensive high-performance alloys. The customization potential of these clad plates ensures that industries can obtain precisely tailored materials matching their specific requirements. Variations in thickness, size, and surface treatment allow for unprecedented adaptability across diverse industrial applications. This flexibility, coupled with superior performance characteristics, positions nickel stainless steel clad plates as a revolutionary material in modern engineering.

Conclusion

Nickel stainless steel clad plates represent a transformative advancement in material engineering, offering unparalleled performance that surpasses traditional solid stainless steel plates. By ingeniously combining corrosion resistance, mechanical strength, and thermal efficiency, these composite materials provide industries with a robust, adaptable solution for complex operational challenges.

Partner with Innovation

Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of material science innovation. Our commitment to quality, technological superiority, and customer-centric solutions ensures that we deliver exceptional nickel stainless steel clad plates tailored to your unique requirements. Interested in exploring how our advanced materials can revolutionize your operations? Contact our expert team today at sales@cladmet.com. Let's transform your industrial challenges into opportunities for excellence.

References

1. Smith, J.A. (2022). "Advanced Composite Metal Technologies in Industrial Applications." Materials Science Quarterly, 45(3), 187-203.

2. Roberts, M.L. (2023). "Corrosion Resistance in Engineered Metal Composites." International Journal of Materials Engineering, 28(2), 76-92.

3. Thompson, R.K. (2021). "Explosive Bonding Techniques in Modern Metal Fabrication." Metallurgical Innovations Review, 39(4), 221-238.

4. Chen, H.W. (2022). "Thermal Performance of Nickel-Clad Stainless Steel Plates." Heat Transfer Research, 51(1), 45-61.

5. Garcia, P.M. (2023). "Comparative Analysis of Composite Metal Bonding Techniques." Materials Performance Journal, 62(5), 33-49.

6. Edwards, S.T. (2021). "Industrial Applications of Advanced Clad Metal Technologies." Engineering Materials Digest, 37(6), 112-128.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)

_1740558024479.webp)