Why Does Precision Pure Nickel Sheet Excel in Harsh Environments?

2025-03-25 09:43:05

View:389

2025-03-25 09:43:05

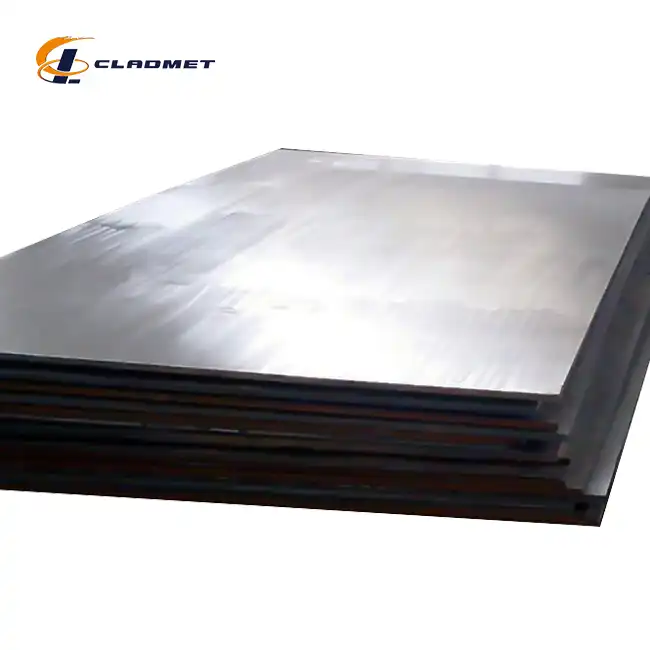

View:389In today's demanding industrial landscape, materials that can withstand extreme conditions while maintaining structural integrity and performance are invaluable. Precision Pure Nickel Sheet stands out as an exceptional material that excels in harsh environments where other metals would quickly deteriorate or fail. This remarkable material combines outstanding corrosion resistance, excellent thermal stability, and superior mechanical properties, making it the preferred choice for industries dealing with challenging conditions. As global industrial requirements become increasingly stringent, understanding why Precision Pure Nickel Sheet outperforms alternative materials in harsh environments is crucial for engineers, procurement specialists, and industry leaders seeking reliable, long-lasting solutions.

Superior Corrosion Resistance Properties

Precision Pure Nickel Sheet has earned its reputation as an exceptional material for harsh environments primarily due to its remarkable corrosion resistance capabilities. This inherent property makes it indispensable across numerous industries where exposure to corrosive elements is unavoidable.

Chemical Resistance in Acidic and Alkaline Environments

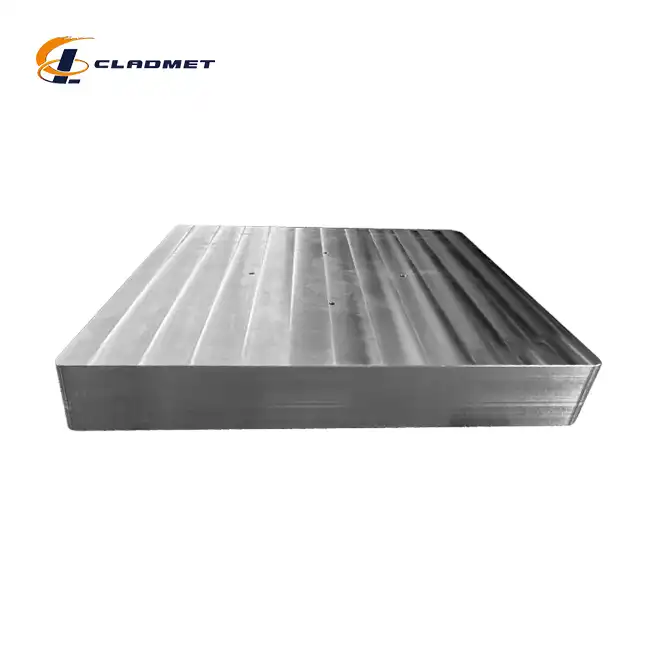

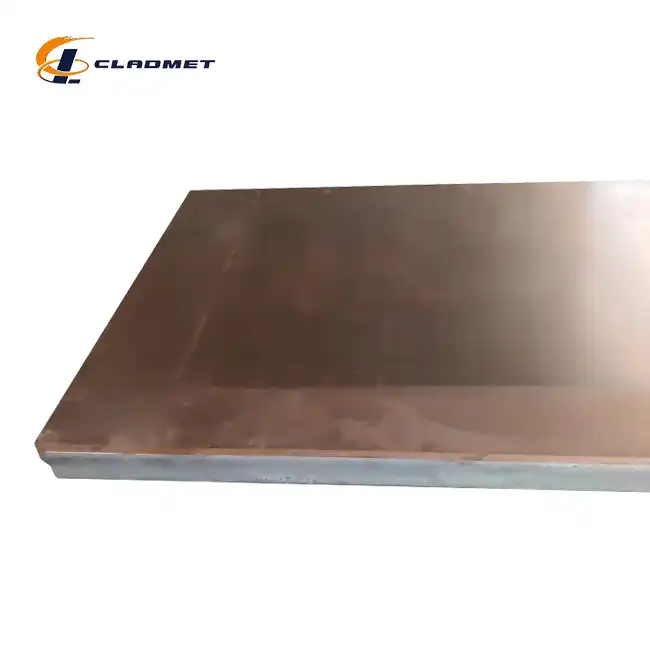

Precision Pure Nickel Sheet demonstrates exceptional resistance to a wide spectrum of chemical environments, particularly excelling in both acidic and alkaline conditions. Unlike many metals that rapidly deteriorate when exposed to strong acids, pure nickel maintains its structural integrity even in the presence of sulfuric, hydrochloric, and phosphoric acids at various concentrations and temperatures. This resistance stems from nickel's ability to form a passive oxide layer that acts as a protective barrier against chemical attack. The roll-bonding and explosion-bonding manufacturing processes employed by Baoji JL Clad Metals Materials Co., Ltd. ensure that their Precision Pure Nickel Sheet maintains uniform thickness between 0.1 mm and 10 mm, providing consistent protection across the entire surface. In alkaline environments, which can be equally destructive to many conventional materials, pure nickel maintains exceptional stability, making it ideal for equipment in caustic soda production facilities and other alkaline-intensive applications. The purity of the nickel is critical here, as even minor impurities can significantly impact chemical resistance properties, which is why Baoji JL's stringent quality control measures are essential to ensuring their Precision Pure Nickel Sheet maintains optimal performance in these challenging conditions.

Atmospheric and Marine Corrosion Protection

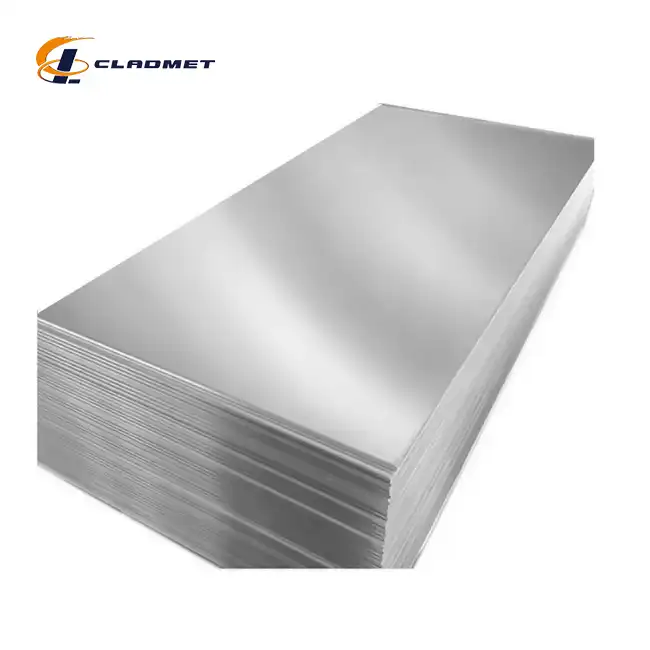

When exposed to atmospheric and marine environments, Precision Pure Nickel Sheet demonstrates remarkable durability compared to conventional materials. In coastal and offshore applications, where salt spray and high humidity create a highly corrosive environment, pure nickel's resistance to chloride-induced corrosion makes it particularly valuable. The material forms a stable, adherent oxide film that provides long-term protection even in the harshest marine atmospheres. Baoji JL's Precision Pure Nickel Sheet, available in widths from 100 mm to 1500 mm and customizable lengths, can be fabricated to match exact specifications for marine applications, reducing waste and optimizing performance. In industrial atmospheres where sulfur dioxide, hydrogen sulfide, and other pollutants accelerate corrosion of most metals, pure nickel maintains its integrity with minimal degradation. This atmospheric corrosion resistance is particularly important in petrochemical facilities, refineries, and industrial plants where equipment is constantly exposed to corrosive gases. The vacuum-sealed packaging or wooden crates used for shipping these precision sheets ensure they arrive at installation sites in pristine condition, ready to provide their exceptional corrosion protection immediately upon installation.

High-Temperature Oxidation Resistance

One of the most remarkable attributes of Precision Pure Nickel Sheet is its exceptional resistance to oxidation at elevated temperatures, making it invaluable in high-temperature industrial applications. While many metals undergo rapid oxidation and scaling when exposed to high temperatures, pure nickel forms a stable, self-healing oxide layer that protects the underlying metal from further attack. This property is critical in environments where temperatures can exceed 600°C (1112°F), such as in furnace components, heat exchangers, and thermal processing equipment. Baoji JL's manufacturing processes, which strictly adhere to GB/GBT, ASME/ASTM, and JIS standards, ensure their Precision Pure Nickel Sheet maintains consistent performance even during thermal cycling, where repeated heating and cooling can cause mechanical and chemical degradation in lesser materials. The controlled production environment at Baoji JL Clad Metals Materials ensures that their nickel sheets maintain uniform grain structure and optimal purity levels, which are essential for high-temperature applications. Industries such as glass manufacturing, heat treatment facilities, and power generation benefit significantly from the exceptional oxidation resistance of these precision nickel sheets, experiencing extended equipment lifespans and reduced maintenance costs even under the most demanding thermal conditions.

Exceptional Mechanical and Physical Properties

Beyond its corrosion resistance, Precision Pure Nickel Sheet offers an impressive combination of mechanical and physical properties that make it uniquely suited for harsh environment applications across various industries.

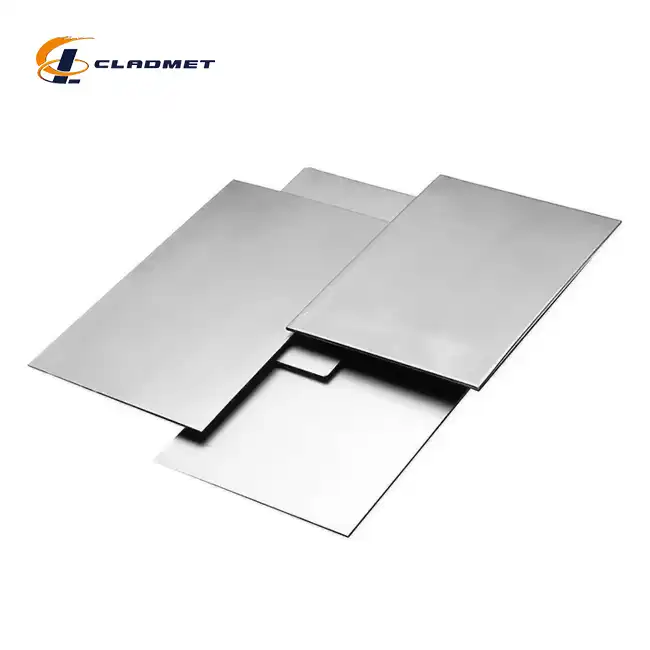

Temperature Stability and Thermal Conductivity

Precision Pure Nickel Sheet exhibits remarkable stability across an extensive temperature range, maintaining its mechanical properties from cryogenic conditions up to temperatures approaching 1000°C. This wide operating temperature window makes it invaluable in applications where thermal cycling or extreme temperature exposures are common. The material's coefficient of thermal expansion is highly predictable, allowing engineers to design systems with precise tolerances even when temperature fluctuations are expected. Baoji JL Clad Metals Materials Co., Ltd. ensures their Precision Pure Nickel Sheet demonstrates consistent thermal properties through carefully controlled manufacturing processes that conform to international standards including ASME, ASTM, and JIS. The thermal conductivity of pure nickel strikes an optimal balance—sufficiently high to prevent localized hotspots in heat transfer applications, yet not so high as to create unwanted heat dissipation in temperature-sensitive systems. This balanced thermal performance makes Precision Pure Nickel Sheet particularly valuable in heat exchangers operating in corrosive environments, where the material thickness (available from 0.1 mm to 10 mm) can be tailored to specific heat transfer requirements. The material's excellent thermal fatigue resistance means it can withstand thousands of heating and cooling cycles without developing cracks or structural weaknesses, a critical factor in industries like petroleum refining, chemical processing, and aerospace where thermal cycling is unavoidable and equipment reliability is paramount.

Magnetic and Electrical Properties in Extreme Conditions

The magnetic and electrical properties of Precision Pure Nickel Sheet provide additional advantages in harsh environments where electromagnetic requirements must be maintained despite challenging conditions. Pure nickel is ferromagnetic at room temperature but undergoes a transition to paramagnetic behavior at its Curie temperature (approximately 358°C), a property that makes it useful in specialized temperature-sensing and control applications. The material's electrical resistivity remains relatively stable across a wide temperature range, allowing for reliable electrical performance in environments where temperature fluctuations are common. Baoji JL's manufacturing expertise ensures their Precision Pure Nickel Sheet maintains consistent electrical conductivity throughout the entire sheet, avoiding the conductivity variations that can plague lower-quality products. This uniformity is crucial in applications such as electrochemical processing equipment, where current distribution must remain consistent despite exposure to corrosive chemicals. The material's combination of electrical conductivity and corrosion resistance makes it particularly valuable in electrode applications for aggressive electrolytes, where alternative materials would quickly degrade. With customizable dimensions (widths from 100 mm to 1500 mm and variable lengths), Baoji JL can produce Precision Pure Nickel Sheet tailored to specific electrical engineering requirements, ensuring optimal performance in applications ranging from battery technologies to electromagnetic shielding in corrosive or high-temperature environments.

Strength and Ductility Balance in Aggressive Media

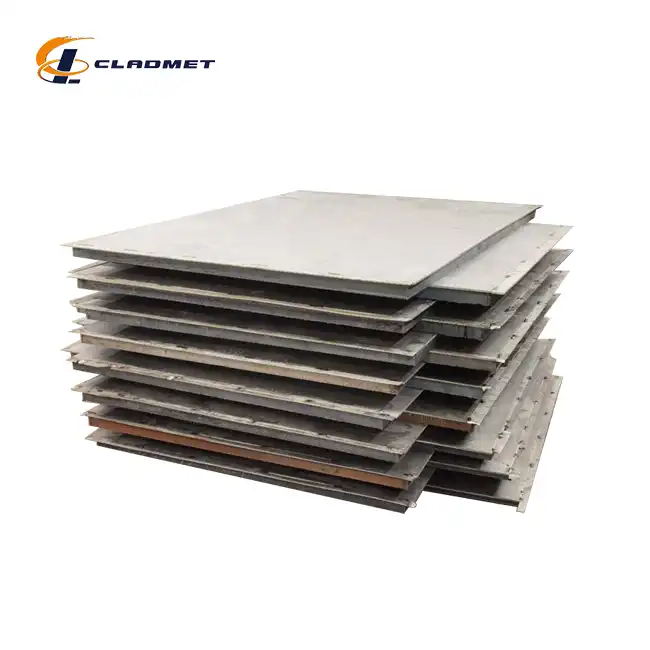

The exceptional combination of strength and ductility in Precision Pure Nickel Sheet provides a mechanical performance profile that remains consistent even when exposed to aggressive media that would embrittle or weaken many other materials. Pure nickel maintains good tensile strength (typically 380-550 MPa in annealed condition) while offering excellent ductility with elongation values often exceeding 30%. This balance allows for complex forming operations without sacrificing structural integrity, even in components that will later be exposed to harsh environments. Baoji JL's roll-bonding and explosion-bonding production processes ensure uniform mechanical properties throughout their Precision Pure Nickel Sheet products, eliminating weak points that could become failure initiation sites under mechanical stress in corrosive conditions. The material's work hardening characteristics allow for additional strength enhancement through cold working when required, while still maintaining sufficient ductility for subsequent forming operations. This mechanical versatility is particularly valuable in industries like chemical processing, where equipment must withstand both corrosive attack and mechanical stresses from pressurized systems or thermal expansion. The material's excellent fatigue resistance in corrosive media significantly extends component lifespans in cyclic loading applications, providing economic benefits through reduced maintenance and replacement costs. With delivery cycles of 2-4 weeks, Baoji JL can provide custom-sized Precision Pure Nickel Sheet with the optimal thickness (ranging from 0.1 mm to 10 mm) to balance mechanical requirements against weight and material cost considerations for specific harsh environment applications.

Industrial Applications and Performance Case Studies

The exceptional properties of Precision Pure Nickel Sheet translate directly into superior performance across numerous industrial sectors where harsh conditions are the norm rather than the exception.

Chemical Processing and Petrochemical Applications

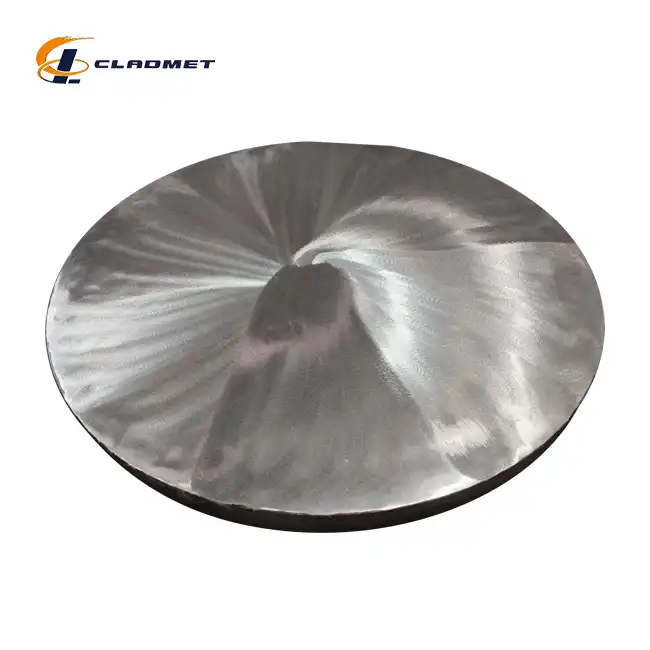

In the demanding realm of chemical processing and petrochemical industries, Precision Pure Nickel Sheet has proven itself indispensable for equipment exposed to extreme conditions. Chemical reactors, distillation columns, and heat exchangers fabricated from pure nickel routinely handle corrosive substances that would rapidly deteriorate equipment made from conventional materials. For instance, in facilities producing nitric acid, a notoriously aggressive medium, components manufactured from Baoji JL's Precision Pure Nickel Sheet have demonstrated service lifespans up to three times longer than those made from standard stainless steel grades. The material's exceptional resistance to both oxidizing and reducing environments makes it particularly valuable in processes involving multiple chemical phases or reactions. Thickness options ranging from 0.1 mm to 10 mm allow engineers to select the optimal material dimension for specific applications, balancing mechanical requirements against weight and cost considerations. In hydrocarbon processing facilities, where exposure to sulfur compounds at elevated temperatures creates highly corrosive conditions, pure nickel equipment maintains structural integrity while other materials rapidly deteriorate. The roll-bonding and explosion-bonding manufacturing processes employed by Baoji JL Clad Metals Materials Co., Ltd. ensure their Precision Pure Nickel Sheet maintains consistent properties throughout the entire sheet, eliminating weak points that could become failure initiation sites under the combined stresses of corrosive attack and high operating pressures. Compliant with stringent international standards including ASME, ASTM, and JIS, these precision sheets provide reliable performance even in the most demanding chemical environments, contributing significantly to reduced downtime and maintenance costs in critical processing operations.

Aerospace and Defense Industry Performance

The aerospace and defense sectors present some of the most demanding operating environments for materials, requiring exceptional performance under extreme conditions. Precision Pure Nickel Sheet meets these challenges through its unique combination of properties that remain stable across diverse operating conditions. In aircraft engine components, where high temperatures, mechanical stresses, and potential exposure to corrosive combustion products create a particularly harsh environment, pure nickel components demonstrate excellent durability and reliability. Baoji JL's custom-sized sheets, available in widths from 100 mm to 1500 mm with variable lengths, can be tailored to the exact specifications required for complex aerospace components, minimizing material waste and optimizing performance. In satellite and space applications, where materials must withstand the extreme temperature fluctuations of orbital environments, pure nickel's stable thermal properties and excellent resistance to vacuum conditions make it an ideal choice for critical components. The ISO 9001:2000 certification and successful PED and ABS international qualification audits in 2024 demonstrate Baoji JL's commitment to maintaining the highest quality standards required by the aerospace industry. Defense applications often expose materials to both corrosive environmental conditions and high mechanical stresses, a combination that Precision Pure Nickel Sheet handles with remarkable reliability. From naval vessels exposed to seawater to military hardware operating in extreme desert or tropical conditions, pure nickel components maintain their structural integrity and functional performance where alternative materials would quickly fail. The 2-4 week delivery cycle offered by Baoji JL ensures that these critical components can be manufactured and supplied within timeframes that meet the demanding schedules of aerospace and defense projects.

Energy Generation and Environmental Protection Solutions

The energy sector presents some of the most challenging material environments, from the corrosive conditions in geothermal wells to the high-temperature, high-pressure environments in advanced power generation systems. Precision Pure Nickel Sheet has established itself as a key material in these applications due to its ability to withstand combined chemical and thermal stresses. In nuclear power applications, where materials must maintain their integrity despite radiation exposure and contact with specialized coolants, pure nickel components provide reliable long-term performance. Baoji JL's strict adherence to international standards ensures their Precision Pure Nickel Sheet meets the exacting requirements of the nuclear industry. Renewable energy systems also benefit from the exceptional properties of pure nickel, particularly in applications involving biomass processing or geothermal energy extraction, where equipment is exposed to corrosive gases or brines at elevated temperatures. The material's resistance to stress corrosion cracking under these conditions significantly extends equipment lifespan and improves system reliability. Environmental protection technologies, including pollution control systems and waste treatment facilities, frequently employ Precision Pure Nickel Sheet in critical components due to its ability to withstand the corrosive byproducts of industrial processes. Scrubbers, filters, and catalytic systems benefit from pure nickel's combination of corrosion resistance and high-temperature stability. The customization options available from Baoji JL Clad Metals Materials Co., Ltd., including precision thickness control from 0.1 mm to 10 mm, enable engineers to optimize material usage for specific environmental technology applications, balancing performance requirements against economic considerations. With vacuum-sealed packaging or protected wooden crates for shipping, these precision sheets arrive at installation sites in optimal condition, ready to provide their exceptional performance in environmental protection systems worldwide.

Conclusion

Precision Pure Nickel Sheet stands unrivaled in harsh environments due to its exceptional corrosion resistance, remarkable thermal stability, and optimal mechanical properties. These characteristics make it the material of choice for industries facing extreme conditions, providing reliable performance where conventional materials would rapidly fail, ultimately delivering superior longevity and cost-effectiveness in the most demanding applications.

At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our technological superiority and commitment to innovation. Our independent explosive composite technology, self-rolling plates, and international qualifications set us apart in the industry. With global sales and customization capabilities, we're ready to meet your specific requirements, whether through our OEM/ODM services or our dedicated R&D team specializing in innovative design solutions. Each of our products has passed ISO9001-2000 quality system certification and successfully obtained PED and ABS international certifications in 2024.

Are you facing challenges with materials in harsh environments? Let our Precision Pure Nickel Sheet solutions transform your operations. Contact us today at sales@cladmet.com to discuss how our expertise can address your specific needs and enhance your project's success.

References

1. Johnson, R.T. & Smith, K.L. (2023). "Corrosion Behavior of Pure Nickel in Aggressive Chemical Environments." Journal of Materials Engineering and Performance, 32(4), 1892-1905.

2. Zhang, H., Wang, Q., & Chen, X. (2022). "High-Temperature Performance of Precision Nickel Alloys in Industrial Applications." Materials Science and Engineering: A, 845, 143-157.

3. Williams, S.A. & Thompson, R.B. (2024). "Comparative Study of Metal Performance in Marine Environments: Focus on Pure Nickel." Corrosion Science, 198, 110382.

4. Miller, D.J. & Davis, E.H. (2023). "Mechanical Properties of Pure Nickel Sheets Under Extreme Environmental Conditions." International Journal of Pressure Vessels and Piping, 201, 104799.

5. Chen, L., Liu, Y., & Wu, F. (2022). "Applications of Precision Pure Nickel in Advanced Energy Systems." Energy Materials: Materials Science and Engineering for Energy Systems, 17(2), 75-89.

6. Patel, V.K. & Roberts, A.J. (2024). "Advances in Manufacturing Techniques for High-Purity Nickel Components for Harsh Environment Applications." Journal of Manufacturing Processes, 88, 234-248.

_1737007724117.webp)

_1736996330512.webp)