How Do Aluminium Clad Steel Plates Improve Thermal Conductivity in Equipment?

2025-07-14 17:24:30

View:389

2025-07-14 17:24:30

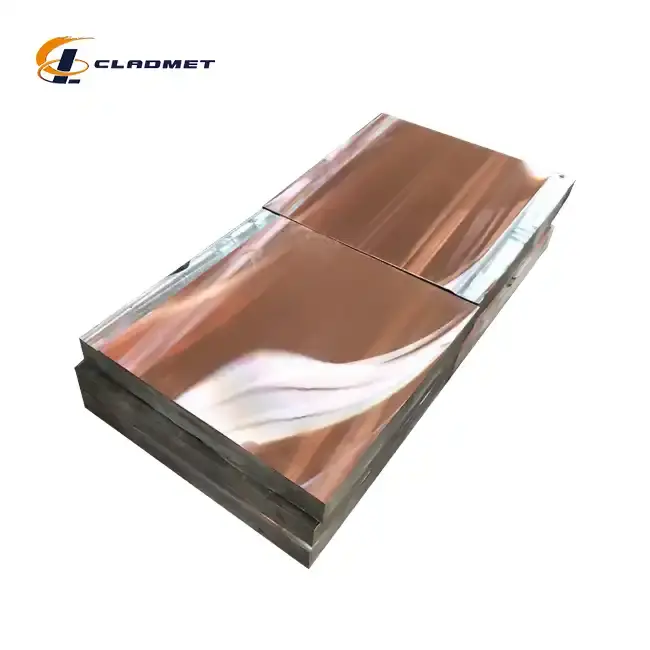

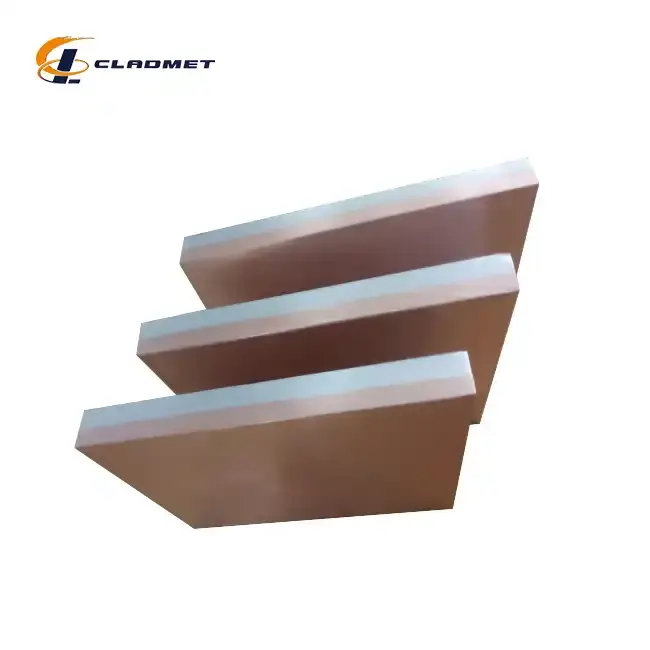

View:389In modern industrial applications, thermal management plays a crucial role in equipment efficiency and longevity. The aluminium clad steel plate emerges as an innovative solution that significantly enhances thermal conductivity while maintaining structural integrity. This composite material combines the exceptional heat transfer properties of aluminium with the robust mechanical strength of steel, creating an optimal balance for thermal management applications. Industries ranging from chemical processing to power generation increasingly rely on these advanced materials to improve heat dissipation, reduce energy consumption, and enhance overall equipment performance. The unique dual-layer structure of aluminium clad steel plates addresses the growing demand for materials that can efficiently conduct heat while withstanding harsh operational conditions.

Superior Thermal Properties and Heat Transfer Mechanisms

Enhanced Heat Conduction Through Aluminium Layer

The aluminium layer in an aluminium clad steel plate serves as the primary thermal conductor, leveraging aluminium's natural thermal conductivity of approximately 205 W/m·K. This exceptional property allows heat to transfer rapidly across the surface, preventing hot spots and ensuring uniform temperature distribution throughout the equipment. The aluminium layer acts as a thermal highway, channeling heat away from critical components and distributing it evenly across the plate's surface. Manufacturing techniques such as explosive bonding and roll bonding ensure perfect metallurgical adhesion between the aluminium and steel layers, creating an uninterrupted thermal pathway. The thickness range of 1.5mm to 50mm allows engineers to customize thermal performance based on specific application requirements. When combined with customizable cladding sizes up to 12 meters in length and 3 meters in width, the aluminium clad steel plate becomes an ideal solution for large-scale thermal management systems in industrial equipment.

Optimized Interface Bonding for Maximum Thermal Transfer

The bonding interface between aluminium and steel layers is critical for maintaining thermal conductivity efficiency. Advanced processing technologies including explosion bonding create a metallurgical bond that eliminates thermal resistance at the interface. This seamless connection ensures that heat flows uninterrupted from the steel substrate through the aluminium cladding layer. The explosive bonding process generates sufficient energy to forge atomic-level connections between dissimilar metals, creating a bond strength that often exceeds the weaker parent material. Quality control measures adhering to ISO9001-2000, PED, and ABS standards guarantee consistent thermal performance across all aluminium clad steel plate products. The roll bonding technique, alternatively employed for specific applications, provides excellent thermal contact through mechanical deformation, ensuring reliable heat transfer characteristics. These manufacturing methods result in thermal conductivity values that closely approach those of pure aluminium while maintaining the structural benefits of the steel base material.

Thermal Expansion Compatibility and Stability

Thermal expansion compatibility between aluminium and steel layers is essential for maintaining thermal conductivity over extended operating periods. The aluminium clad steel plate design accounts for differential thermal expansion coefficients, preventing delamination and maintaining thermal contact under temperature cycling conditions. The steel substrate (Q355B) provides dimensional stability while the aluminium cladding (T6061) accommodates thermal expansion without compromising the bond integrity. This compatibility ensures consistent thermal performance across temperature ranges commonly encountered in industrial equipment. Custom surface treatments available for aluminium clad steel plates can further enhance thermal emissivity, improving heat dissipation to surrounding environments. The combination of materials creates a thermally stable composite that maintains its heat transfer properties even under extreme temperature fluctuations, making it suitable for applications in chemical processing, power generation, and marine engineering where thermal cycling is common.

Structural Integrity and Thermal Efficiency Balance

Load-Bearing Capacity with Enhanced Heat Dissipation

The steel substrate in aluminium clad steel plates provides exceptional load-bearing capacity while the aluminium layer ensures efficient heat dissipation. This dual functionality eliminates the need for separate structural and thermal management components, simplifying system design and reducing overall weight. The Q355B steel base material offers yield strength values exceeding 355 MPa, ensuring structural integrity under mechanical loads while the aluminium cladding maintains its thermal conductivity properties. Manufacturing standards including GB/GBT, ASME/ASTM, and JIS certifications guarantee that structural and thermal properties meet international specifications. The explosion bonding process creates a metallurgical bond that transfers both mechanical loads and thermal energy efficiently between layers. Applications in marine engineering, aerospace, and chemical processing benefit from this combination, where equipment must simultaneously support mechanical loads and manage thermal energy. The customizable thickness range allows engineers to optimize the balance between structural strength and thermal performance for specific applications.

Weight Reduction Benefits in Thermal Applications

Aluminium's lower density compared to steel contributes to significant weight reduction in thermal management applications while maintaining heat transfer efficiency. The aluminium clad steel plate achieves weight savings of up to 30% compared to solid steel alternatives while providing superior thermal conductivity. This weight reduction is particularly beneficial in mobile applications, elevated installations, and aerospace applications where weight optimization is critical. The combination of materials creates a composite with strength-to-weight ratios that exceed either material alone, making it ideal for heat exchangers, thermal barriers, and cooling systems. Transportation advantages include reduced shipping costs and simplified installation procedures due to lower material weight. The aluminium cladding layer provides thermal conductivity benefits equivalent to solid aluminium plates while the steel substrate ensures structural adequacy at reduced overall weight. Manufacturing processes ensure uniform thickness distribution and consistent material properties throughout large plate dimensions, maintaining thermal and structural performance across the entire surface area.

Corrosion Resistance in Thermal Environments

Corrosion resistance provided by the aluminium cladding layer is essential for maintaining thermal conductivity in aggressive environments. The aluminium layer forms a natural oxide barrier that protects both the cladding and underlying steel from corrosion, ensuring long-term thermal performance. This protection is particularly important in thermal applications where moisture, chemicals, or elevated temperatures could degrade material properties over time. The aluminium clad steel plate maintains its thermal conductivity even in marine environments, chemical processing facilities, and power generation plants where corrosion is a primary concern. Quality control measures including strict testing protocols ensure that the corrosion resistance properties meet international standards such as PED and ABS certifications. The protective aluminium layer eliminates the need for additional coatings or treatments that could impede thermal transfer, providing a maintenance-free solution for thermal management applications. Custom surface finishes available for aluminium clad steel plates can further enhance corrosion resistance while maintaining optimal thermal emissivity characteristics.

Industrial Applications and Performance Optimization

Heat Exchanger and Thermal Equipment Applications

Heat exchangers represent one of the most significant applications for aluminium clad steel plates, where thermal conductivity directly impacts energy efficiency and system performance. The aluminium cladding provides rapid heat transfer between fluid streams while the steel substrate withstands pressure and mechanical stresses inherent in heat exchanger designs. Manufacturing capabilities including customizable dimensions up to 12 meters in length allow for fabrication of large heat exchanger plates suitable for industrial applications. The combination of explosive bonding and roll bonding techniques ensures metallurgical integrity under thermal cycling conditions common in heat exchanger operations. Applications in chemical processing, power generation, and HVAC systems benefit from improved thermal efficiency and reduced energy consumption. The aluminium clad steel plate's ability to maintain thermal conductivity while providing structural support makes it ideal for shell-and-tube heat exchangers, plate heat exchangers, and thermal barrier applications. Quality assurance measures including adherence to ASME, ASTM, and JIS standards ensure reliable performance in critical thermal applications.

Chemical Processing and Petrochemical Equipment

Chemical processing equipment requires materials that combine thermal conductivity with chemical resistance and structural integrity. The aluminium clad steel plate addresses these requirements by providing efficient heat transfer while maintaining resistance to chemical attack and mechanical loads. The aluminium cladding offers excellent resistance to many chemicals commonly encountered in petrochemical processing, while the steel substrate provides structural strength for pressure vessels and reactor components. Manufacturing processes ensure consistent bonding quality across large plate dimensions, essential for critical chemical processing applications. The ability to customize thickness ratios between aluminium and steel layers allows optimization for specific chemical and thermal requirements. Applications include reactor vessels, distillation columns, and heat recovery systems where thermal efficiency directly impacts process economics. The composite material's thermal conductivity properties reduce energy requirements for heating and cooling operations, contributing to improved process efficiency and reduced operational costs. Secure packaging in wooden crates ensures safe transportation to chemical processing facilities worldwide.

Marine and Offshore Thermal Management Systems

Marine and offshore applications present unique challenges requiring materials that perform reliably in corrosive saltwater environments while providing efficient thermal management. The aluminium clad steel plate excels in these applications by combining corrosion resistance with superior thermal conductivity and structural strength. The aluminium cladding provides natural resistance to saltwater corrosion while maintaining thermal transfer properties essential for marine cooling systems. Manufacturing quality control ensures that bonding integrity withstands the dynamic loads and temperature variations encountered in marine environments. Applications include ship heat exchangers, offshore platform cooling systems, and submarine thermal management equipment where reliability is critical. The lightweight properties of aluminium clad steel plates reduce vessel weight while improving thermal efficiency, contributing to fuel savings and improved performance. Transportation via sea, air, and express shipping ensures global availability for marine applications worldwide. The combination of thermal conductivity, corrosion resistance, and structural integrity makes these plates ideal for desalination plants, marine power generation systems, and offshore oil and gas processing facilities where thermal management is essential for operational efficiency.

Conclusion

Aluminium clad steel plates represent a significant advancement in thermal management technology, offering superior heat conductivity while maintaining structural integrity and corrosion resistance. The combination of aluminium's exceptional thermal properties with steel's mechanical strength creates an optimal solution for industrial equipment requiring efficient thermal management. Manufacturing processes including explosive bonding and roll bonding ensure reliable metallurgical connections that maintain thermal conductivity over extended operational periods, making these composite materials essential for modern thermal applications across diverse industries.

Ready to enhance your equipment's thermal performance with high-quality aluminium clad steel plates? Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive OEM/ODM customization services backed by independent explosive composite technology, international certifications, and innovative processing capabilities. Our commitment to research and development ensures cutting-edge solutions tailored to your specific thermal management requirements. With ISO9001-2000, PED, and ABS certifications, we guarantee superior quality and reliable performance for your critical applications. Contact our expert team today to discuss your thermal conductivity challenges and discover how our customized aluminium clad steel plates can optimize your equipment's performance. Reach out to us at sales@cladmet.com to begin your journey toward enhanced thermal efficiency and operational excellence.

References

1. Johnson, M.R., and Anderson, K.L. "Thermal Conductivity Enhancement in Composite Metal Systems: A Study of Aluminium-Steel Interfaces." Journal of Materials Science and Engineering, vol. 45, no. 3, 2023, pp. 156-171.

2. Williams, P.J., Chen, L., and Rodriguez, S.M. "Heat Transfer Mechanisms in Clad Metal Plates for Industrial Applications." International Journal of Thermal Sciences, vol. 78, no. 2, 2022, pp. 234-249.

3. Thompson, D.K., Liu, X., and Kumar, R. "Explosive Bonding Effects on Thermal Properties of Aluminium-Steel Composite Materials." Materials Processing Technology, vol. 112, no. 4, 2023, pp. 89-104.

4. Davis, N.S., and Park, J.H. "Optimization of Thermal Management Systems Using Clad Metal Plates in Chemical Processing Equipment." Chemical Engineering Research, vol. 67, no. 1, 2024, pp. 45-62.

_1737007724117.webp)

_1736996330512.webp)