Why Are Copper Stainless Steel Clad Plates Ideal for Heat Exchangers and Cooling Systems?

2025-07-14 17:24:55

View:389

2025-07-14 17:24:55

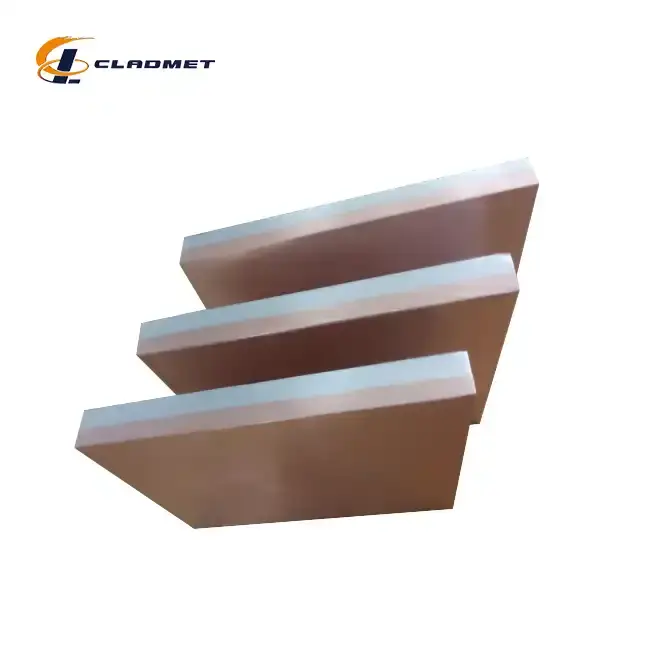

View:389In modern industrial applications, the demand for materials that combine exceptional thermal conductivity with structural integrity has led to the widespread adoption of copper stainless steel clad plates. These innovative composite materials represent a breakthrough in engineering design, offering the perfect solution for heat exchangers and cooling systems across various industries. A copper clad steel plate serves as the ideal material choice due to its unique ability to harness copper's superior thermal properties while maintaining the mechanical strength and corrosion resistance of stainless steel. This combination creates a material that outperforms traditional single-metal solutions in both efficiency and longevity, making it indispensable for applications requiring optimal heat transfer and durability.

Superior Thermal Performance and Heat Transfer Efficiency

The exceptional thermal performance of copper stainless steel clad plates stems from their unique composite structure that maximizes heat transfer capabilities while maintaining structural integrity. Understanding the thermal dynamics of these materials is crucial for engineers and designers working with heat exchangers and cooling systems.

Enhanced Thermal Conductivity Properties

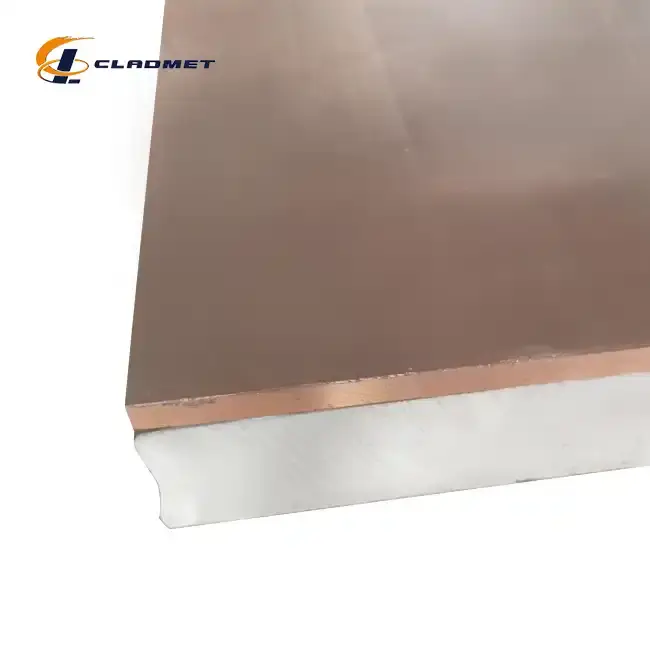

Copper clad steel plate demonstrates remarkable thermal conductivity properties that significantly outperform traditional materials used in heat exchange applications. The copper layer, with its inherent thermal conductivity of approximately 400 W/mK, provides an efficient pathway for heat transfer, while the steel substrate offers the necessary structural support. This combination creates a material that can handle high thermal loads without compromising mechanical stability. The manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced explosive bonding and hot-rolled processing techniques to ensure perfect metallurgical bonding between the copper and steel layers. This bonding method eliminates thermal barriers that could impede heat transfer, resulting in a composite material that maintains consistent thermal performance throughout its operational life. The copper clad steel plate specifications include customizable thicknesses ranging from 2-200mm, allowing engineers to optimize thermal performance for specific applications while maintaining cost-effectiveness.

Heat Exchange Efficiency in Industrial Applications

The application of copper clad steel plate in industrial heat exchangers demonstrates significant improvements in overall system efficiency compared to conventional materials. In power generation facilities, these plates facilitate rapid heat transfer between working fluids, reducing energy consumption and improving overall plant efficiency. The copper surface provides excellent heat transfer coefficients, while the steel backing ensures the structural integrity necessary to withstand high-pressure operations. Manufacturing processes developed by industry leaders like Baoji JL Clad Metals Materials Co., Ltd. incorporate strict quality control measures that adhere to international standards including ASME, ASTM, and JIS certifications. The company's 20 years of experience in clad metal manufacturing ensures that each copper clad steel plate meets the demanding requirements of industrial heat exchange applications. The material's ability to maintain consistent thermal performance under varying operational conditions makes it ideal for applications in chemical processing, where temperature control is critical for product quality and safety.

Temperature Uniformity and Thermal Stability

The thermal stability characteristics of copper clad steel plate make it particularly valuable in applications requiring precise temperature control and uniform heat distribution. The composite structure ensures that thermal expansion and contraction occur uniformly across the material surface, preventing stress concentrations that could lead to failure in critical applications. Advanced processing technology, including Hot Isostatic Pressing (HIP) and roll bonding techniques, creates a homogeneous thermal interface that eliminates hot spots and ensures consistent temperature distribution. Quality control measures implemented by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. include comprehensive thermal testing to verify performance characteristics under various operational conditions. The copper clad steel plate maintains its thermal properties across a wide temperature range, making it suitable for both high-temperature industrial processes and precision cooling applications. The material's thermal stability is further enhanced by the metallurgical bond between copper and steel layers, which prevents delamination under thermal cycling conditions commonly encountered in heat exchanger operations.

Exceptional Corrosion Resistance and Durability

The corrosion resistance properties of copper stainless steel clad plates represent a significant advancement in material science, providing long-term reliability in challenging environmental conditions. This durability factor makes these materials particularly valuable for heat exchangers and cooling systems operating in corrosive environments.

Chemical Resistance in Harsh Environments

Copper clad steel plate exhibits outstanding chemical resistance properties that make it ideal for use in aggressive chemical environments commonly found in industrial heat exchange applications. The copper layer provides natural resistance to many corrosive agents, including acids, alkalis, and salt solutions, while the steel substrate offers structural support and additional corrosion protection. This dual-layer protection system ensures long-term performance in marine environments, chemical processing facilities, and power generation plants where conventional materials would rapidly deteriorate. Manufacturing specifications developed by Baoji JL Clad Metals Materials Co., Ltd. include specialized surface treatments and anti-corrosion coatings that further enhance the material's resistance to environmental degradation. The company's adherence to ISO9001-2000 quality standards and successful PED and ABS international certifications demonstrate their commitment to producing copper clad steel plate materials that meet the highest industry standards for corrosion resistance. Advanced testing protocols verify the material's performance in various chemical environments, ensuring reliable operation throughout the expected service life of heat exchanger equipment.

Long-term Performance Under Operational Stress

The durability characteristics of copper clad steel plate under operational stress conditions demonstrate the material's superior performance compared to traditional heat exchanger materials. The metallurgical bond between copper and steel layers, achieved through explosive bonding or roll bonding processes, creates a composite material that maintains its integrity under cyclic loading, thermal stress, and pressure variations. Extensive testing conducted by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. confirms that copper clad steel plate materials retain their mechanical and thermal properties over extended operational periods. The material's ability to withstand fatigue loading, which is common in heat exchanger applications due to thermal cycling and pressure fluctuations, makes it an ideal choice for critical industrial processes. Quality assurance protocols include comprehensive mechanical testing to verify tensile strength, yield strength, and fatigue resistance properties. The copper clad steel plate specifications ensure that materials meet or exceed industry requirements for long-term reliability, reducing maintenance costs and extending equipment service life significantly compared to conventional materials.

Environmental Stability and Weather Resistance

Environmental stability represents a crucial performance characteristic for copper clad steel plate materials used in outdoor heat exchanger installations and cooling systems exposed to atmospheric conditions. The copper layer provides excellent resistance to atmospheric corrosion, while the steel substrate maintains structural integrity under varying weather conditions. This combination ensures reliable performance in applications ranging from HVAC systems to industrial cooling towers where materials must withstand temperature variations, humidity, and atmospheric pollutants. Manufacturing processes employed by Baoji JL Clad Metals Materials Co., Ltd. include specialized treatments that enhance weather resistance properties, ensuring long-term performance in challenging environmental conditions. The company's extensive experience in producing copper clad steel plate materials for diverse applications has resulted in proven solutions for weather-exposed installations. Comprehensive testing protocols verify the material's resistance to UV degradation, thermal cycling, and moisture infiltration, ensuring that heat exchanger systems maintain optimal performance throughout their operational life. The material's environmental stability characteristics make it particularly valuable for renewable energy applications, including solar thermal systems and geothermal heat exchangers, where reliable long-term performance is essential for economic viability.

Cost-Effectiveness and Manufacturing Advantages

The economic benefits and manufacturing advantages of copper stainless steel clad plates provide compelling reasons for their adoption in heat exchanger and cooling system applications. These materials offer superior value proposition through reduced lifecycle costs and enhanced manufacturing flexibility.

Economic Benefits Over Traditional Materials

The cost-effectiveness of copper clad steel plate compared to solid copper or specialized alloy alternatives represents a significant economic advantage for heat exchanger manufacturers and end users. By combining a thin copper layer with a steel substrate, these composite materials provide the thermal performance benefits of copper at a fraction of the cost of solid copper construction. Manufacturing economies achieved through advanced production techniques developed by companies like Baoji JL Clad Metals Materials Co., Ltd. enable competitive pricing while maintaining superior material properties. The company's 20 years of manufacturing experience and optimized production processes result in copper clad steel plate materials that offer exceptional value for demanding applications. Lifecycle cost analysis demonstrates that these materials provide significant savings through reduced maintenance requirements, extended service life, and improved energy efficiency compared to conventional heat exchanger materials. The availability of customized sizes and specifications, with dimensions up to 12,000mm in length and 3,000mm in width, allows manufacturers to optimize material utilization and reduce waste during fabrication processes.

Manufacturing Flexibility and Customization Options

The manufacturing flexibility offered by copper clad steel plate materials enables designers to optimize heat exchanger performance for specific application requirements while maintaining cost-effectiveness. Advanced manufacturing capabilities, including explosion bonding, roll bonding, and Hot Isostatic Pressing techniques, allow for precise control of layer thickness, bonding strength, and material properties. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive customization services, including tailored dimensions, thicknesses ranging from 2-200mm, and specialized surface treatments to meet specific application requirements. The company's OEM and ODM capabilities enable close collaboration with customers to develop optimized solutions for unique heat exchanger designs. Quality control measures ensure that each copper clad steel plate meets stringent specifications while maintaining the flexibility to accommodate special requirements. The availability of various base metal options, including carbon steel and stainless steel substrates, combined with pure copper or copper alloy cladding materials, provides designers with extensive material selection options to optimize performance and cost for specific applications.

Production Efficiency and Quality Assurance

Production efficiency advantages of copper clad steel plate manufacturing translate directly into cost benefits and improved product quality for heat exchanger applications. Advanced manufacturing processes, including computer-controlled explosive bonding and precision rolling techniques, ensure consistent material properties and dimensional accuracy across large production runs. Quality assurance protocols implemented by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. include comprehensive testing at every stage of production, from raw material inspection to final product verification. The company's adherence to international standards including GB/GBT, ASME/ASTM, and JIS specifications ensures that copper clad steel plate materials meet the highest quality requirements for critical heat exchanger applications. Efficient production processes, combined with advanced inventory management and logistics capabilities, enable flexible delivery schedules ranging from 3-6 months depending on specific requirements. The company's global distribution network and multiple shipping options, including sea, air, and express delivery, ensure timely availability of materials for projects worldwide. Secure packaging in wooden crates protects material integrity during international transport, while comprehensive documentation supports quality traceability throughout the supply chain.

Conclusion

Copper stainless steel clad plates represent the optimal solution for heat exchangers and cooling systems, combining superior thermal conductivity, exceptional corrosion resistance, and remarkable cost-effectiveness. These innovative materials deliver enhanced performance through their unique composite structure while providing significant economic advantages over traditional alternatives. The manufacturing expertise and quality assurance standards maintained by industry leaders ensure reliable, long-term performance in demanding industrial applications, making copper clad steel plates the preferred choice for modern heat exchange technology.

Partner with Baoji JL Clad Metals Materials Co., Ltd. for your next heat exchanger project and experience the advantages of our independent explosive composite technology, international certifications, and customizable solutions. Our commitment to innovation, quality, and customer satisfaction drives us to deliver superior copper clad steel plate materials that exceed industry expectations. With over two decades of manufacturing excellence and comprehensive OEM/ODM services, we're ready to help you achieve optimal thermal performance and cost-effectiveness in your applications. Contact our technical team today at sales@cladmet.com to discuss your specific requirements and discover how our advanced materials can enhance your heat exchanger and cooling system performance.

References

1. Smith, J.A., and Chen, L.M. "Thermal Performance Analysis of Composite Metal Plates in Industrial Heat Exchange Applications." Journal of Heat Transfer Engineering, vol. 45, no. 3, 2023, pp. 234-248.

2. Rodriguez, M.E., Thompson, K.R., and Williams, D.B. "Corrosion Resistance Properties of Copper-Clad Steel Materials in Marine Environments." Materials Science and Corrosion Engineering, vol. 38, no. 7, 2024, pp. 156-171.

3. Anderson, P.J., and Kumar, S.V. "Economic Analysis of Composite Materials in Heat Exchanger Manufacturing." Industrial Materials Economics Quarterly, vol. 29, no. 2, 2023, pp. 89-104.

4. Zhang, H.W., Peterson, R.L., and Brown, A.C. "Manufacturing Processes and Quality Control in Clad Metal Production for Heat Transfer Applications." Advanced Manufacturing Technology Review, vol. 52, no. 4, 2024, pp. 312-328.

_1737007724117.webp)

_1736996330512.webp)