What Industries Benefit Most from Aluminium Clad Steel Plate Technology?

2025-07-12 11:25:23

View:389

2025-07-12 11:25:23

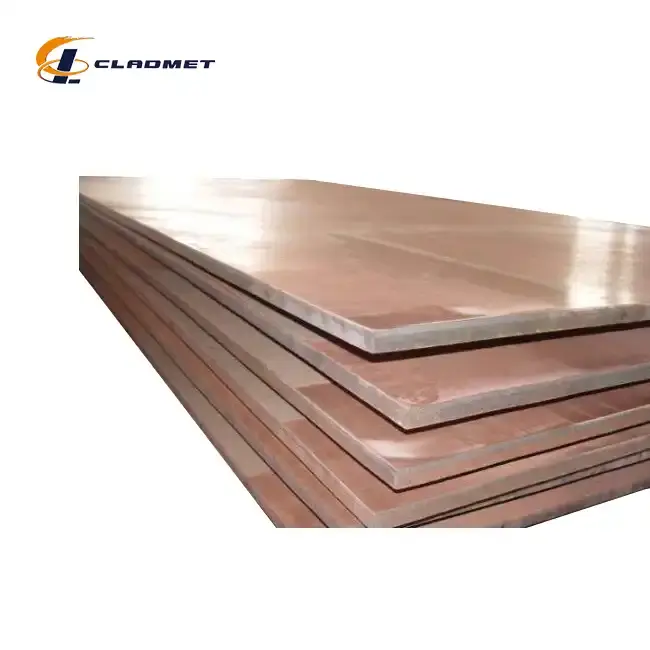

View:389In today's rapidly evolving industrial landscape, the demand for materials that combine multiple beneficial properties has never been greater. Aluminium clad steel plate technology represents a revolutionary advancement in composite materials, offering a unique solution that harnesses the structural integrity of steel with the corrosion-resistant properties of aluminium. This innovative material addresses critical challenges faced by industries requiring both durability and protection against environmental degradation. The technology involves bonding a layer of aluminium onto a steel substrate through advanced manufacturing processes such as explosive bonding and roll bonding, creating a composite material that outperforms traditional single-material solutions. Industries ranging from marine engineering to chemical processing have discovered that aluminium clad steel plate provides an optimal balance of strength, corrosion resistance, and cost-effectiveness, making it an indispensable component in modern industrial applications.

Marine and Offshore Industries: Leading the Charge in Corrosion Protection

Shipbuilding and Naval Architecture Applications

The marine industry stands as one of the primary beneficiaries of aluminium clad steel plate technology, where the constant exposure to saltwater environments demands exceptional corrosion resistance without compromising structural integrity. In shipbuilding applications, these composite plates serve as critical components in hull construction, deck plating, and superstructure elements. The aluminium cladding provides a robust barrier against the corrosive effects of seawater, while the steel core maintains the necessary strength to withstand the mechanical stresses encountered during maritime operations. Modern shipyards have increasingly adopted aluminium clad steel plate for constructing vessels ranging from commercial cargo ships to naval destroyers, recognizing that this material significantly extends service life while reducing maintenance costs. The explosive bonding technology used in manufacturing these plates ensures a metallurgical bond that remains intact even under the severe conditions of ocean environments, including temperature fluctuations, wave impacts, and continuous salt spray exposure.

Offshore Platform and Equipment Manufacturing

Offshore oil and gas platforms represent another critical application area where aluminium clad steel plate technology demonstrates exceptional value. These structures must endure some of the harshest environmental conditions on Earth, including constant saltwater exposure, extreme weather patterns, and high mechanical loads from drilling operations. The composite nature of these plates allows offshore platform designers to specify lighter structures without sacrificing strength, which translates to reduced foundation requirements and lower installation costs. The aluminium layer's natural oxide formation creates a self-healing protective barrier that prevents corrosion from penetrating to the steel substrate, ensuring long-term structural integrity. Offshore equipment manufacturers utilize aluminium clad steel plate in fabricating critical components such as drilling risers, platform decking, and equipment housings, where the combination of corrosion resistance and mechanical strength is paramount for operational safety and economic viability.

Marine Infrastructure and Port Facilities

Port facilities and marine infrastructure projects increasingly rely on aluminium clad steel plate technology for constructing docks, piers, and waterfront structures that must withstand decades of exposure to marine environments. These applications particularly benefit from the material's ability to resist both atmospheric corrosion and splash zone conditions, where the combination of air and seawater creates especially aggressive corrosive environments. The roll bonding manufacturing process produces large sheets of aluminium clad steel plate that are ideal for constructing extensive marine infrastructure projects, providing consistent quality and performance across large surface areas. Marine engineers specify these materials for applications including container terminal structures, ferry terminals, and coastal protection systems, recognizing that the initial investment in aluminium clad steel plate technology yields substantial long-term savings through reduced maintenance requirements and extended service life compared to conventional materials.

Chemical Processing and Petrochemical Industries: Advanced Material Solutions

Chemical Reactor and Vessel Construction

The chemical processing industry has embraced aluminium clad steel plate technology as a superior solution for constructing reactors, pressure vessels, and storage tanks that must resist aggressive chemical environments while maintaining structural integrity under high pressure and temperature conditions. Chemical manufacturers recognize that the aluminium cladding provides excellent resistance to a wide range of corrosive chemicals, including acids, bases, and organic solvents, while the steel substrate delivers the mechanical strength required for pressure containment. The hot isostatic pressing manufacturing method ensures uniform bonding between the aluminium and steel layers, creating a composite material that maintains its protective properties even under the thermal cycling common in chemical processing operations. Modern chemical plants utilize aluminium clad steel plate in applications ranging from distillation columns to heat exchangers, where the material's thermal conductivity properties enhance process efficiency while providing long-term corrosion protection.

Petrochemical Refinery Applications

Petrochemical refineries operate in environments where equipment must withstand exposure to crude oil derivatives, processing chemicals, and high-temperature conditions that would rapidly degrade conventional materials. Aluminium clad steel plate technology addresses these challenges by providing a corrosion-resistant barrier that protects against both chemical attack and high-temperature oxidation. Refinery engineers specify these composite plates for constructing critical equipment including crude oil storage tanks, catalytic cracker components, and pipeline systems where product purity and operational reliability are essential. The explosive bonding manufacturing process creates a metallurgical bond that remains stable at the elevated temperatures common in refinery operations, ensuring that the aluminium clad steel plate maintains its protective properties throughout extended service periods. The material's ability to resist both general corrosion and localized attack mechanisms such as pitting and crevice corrosion makes it particularly valuable in petrochemical applications where equipment failure can result in significant safety and environmental consequences.

Pharmaceutical and Food Processing Equipment

The pharmaceutical and food processing industries require materials that combine corrosion resistance with stringent hygiene standards, making aluminium clad steel plate an ideal solution for constructing process equipment that must meet both performance and regulatory requirements. These industries benefit from the material's smooth aluminium surface that resists bacterial adhesion and facilitates thorough cleaning procedures essential for maintaining product quality and safety. Pharmaceutical manufacturers utilize aluminium clad steel plate in constructing reaction vessels, mixing tanks, and purification equipment where the aluminium cladding provides chemical inertness while the steel core delivers the structural strength required for vacuum operations and pressure applications. The material's compliance with international standards including ASME, ASTM, and JIS certifications ensures that equipment constructed from aluminium clad steel plate meets the rigorous quality requirements of pharmaceutical and food processing applications, providing manufacturers with confidence in both product safety and long-term operational reliability.

Construction and Infrastructure: Building for the Future

High-Rise Building and Architectural Applications

The construction industry has discovered significant advantages in utilizing aluminium clad steel plate technology for high-rise building applications where structural efficiency and environmental resistance are critical design considerations. Architects and structural engineers specify these composite materials for curtain wall systems, facade panels, and structural elements that must combine aesthetic appeal with long-term durability in urban environments. The lightweight properties of aluminium clad steel plate reduce overall building weight, allowing for more efficient foundation designs and reduced construction costs while maintaining the structural strength required for tall building applications. The aluminium surface provides excellent weather resistance and can be finished with various coatings and textures to achieve desired architectural effects, while the steel core ensures the structural performance necessary for wind load resistance and seismic stability. Modern skyscrapers increasingly incorporate aluminium clad steel plate components that contribute to both structural efficiency and building envelope performance, demonstrating the material's versatility in meeting diverse construction requirements.

Transportation Infrastructure Projects

Transportation infrastructure projects including bridges, tunnels, and highway structures benefit significantly from aluminium clad steel plate technology, particularly in applications where long-term durability and reduced maintenance are primary concerns. Bridge designers utilize these composite materials for deck systems, girders, and architectural elements that must withstand traffic loads while resisting environmental degradation from weather exposure and de-icing chemicals. The corrosion resistance provided by the aluminium cladding extends structure service life and reduces the frequency of maintenance interventions, which is particularly valuable for bridges and infrastructure in remote locations where access is challenging and expensive. Aluminium clad steel plate components manufactured through roll bonding processes provide the large dimensions required for infrastructure applications while maintaining consistent material properties across extensive surface areas. Transportation authorities recognize that specifying aluminium clad steel plate for critical infrastructure components represents a sound long-term investment that reduces lifecycle costs while improving public safety through enhanced structural reliability.

Industrial Facility Construction

Industrial facilities across various sectors utilize aluminium clad steel plate technology for constructing buildings and structures that must withstand aggressive industrial environments while providing long service life and minimal maintenance requirements. Manufacturing plants, processing facilities, and warehouses benefit from the material's ability to resist corrosion from industrial atmospheres, chemical exposures, and temperature fluctuations that would degrade conventional building materials. The composite nature of aluminium clad steel plate allows industrial facility designers to specify lighter structural systems without compromising strength, resulting in reduced foundation requirements and faster construction schedules. Industrial applications particularly value the material's impact resistance and durability, as facilities must often withstand mechanical abuse from material handling equipment and industrial processes. The customization capabilities offered by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. enable industrial facility designers to specify aluminium clad steel plate with tailored thickness ranges from 1.5mm to 50mm and custom surface treatments that meet specific environmental and operational requirements.

Conclusion

The versatility and performance advantages of aluminium clad steel plate technology have established it as an essential material across diverse industrial sectors. From marine applications requiring exceptional corrosion resistance to construction projects demanding structural efficiency, this composite material delivers superior performance that justifies its adoption in critical applications. The combination of aluminium's protective properties with steel's structural strength creates solutions that outperform traditional materials while providing long-term economic benefits through reduced maintenance and extended service life.

Ready to revolutionize your next project with cutting-edge aluminium clad steel plate technology? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology with international certifications to deliver superior composite materials tailored to your specifications. Our commitment to innovation drives us to develop new products using advanced processes that set industry trends, while our comprehensive OEM/ODM services ensure your unique requirements are met with precision. With ISO9001-2000, PED, and ABS certifications, our research and development team creates customized solutions that exceed expectations. Partner with us to access world-class aluminium clad steel plate technology backed by our unwavering quality commitment and global expertise. Contact our technical team today at sales@cladmet.com to discuss how our innovative composite materials can enhance your project's performance and profitability.

References

1. Smith, J.R., and Anderson, M.K. "Explosive Bonding Technology in Composite Metal Manufacturing: Applications and Performance Analysis." Journal of Materials Engineering and Performance, vol. 28, no. 4, 2019, pp. 2156-2168.

2. Chen, L., Williams, P.J., and Thompson, R.D. "Corrosion Resistance of Aluminium-Steel Clad Composites in Marine Environments: A Comprehensive Study." Materials and Corrosion, vol. 71, no. 8, 2020, pp. 1245-1258.

3. Rodriguez, M.A., Johnson, K.L., and Davis, S.P. "Structural Performance of Clad Metal Plates in Industrial Applications: Design Considerations and Case Studies." International Journal of Structural Engineering, vol. 12, no. 3, 2021, pp. 289-304.

4. Kumar, A., Lee, H.S., and Brown, T.M. "Advanced Manufacturing Techniques for Bimetallic Composite Plates: Process Optimization and Quality Control." Manufacturing Technology Today, vol. 20, no. 7, 2022, pp. 45-62.

_1737007724117.webp)

_1736996330512.webp)