What Are the Key Advantages of Using Aluminium Clad Steel Plates in Construction?

2025-07-12 11:25:11

View:389

2025-07-12 11:25:11

View:389The construction industry continuously seeks innovative materials that deliver superior performance while maintaining cost-effectiveness and sustainability. Among these advanced materials, aluminium clad steel plates have emerged as a revolutionary solution that combines the exceptional strength of steel with the corrosion-resistant properties of aluminium. This composite material represents a significant advancement in construction technology, offering engineers and architects unprecedented flexibility in designing structures that must withstand harsh environmental conditions while maintaining structural integrity. The unique dual-layer composition of aluminium clad steel plate creates a synergistic effect where both materials contribute their best properties, resulting in a product that outperforms traditional single-material solutions in numerous construction applications.

Enhanced Durability and Corrosion Resistance

Superior Environmental Protection Through Advanced Cladding Technology

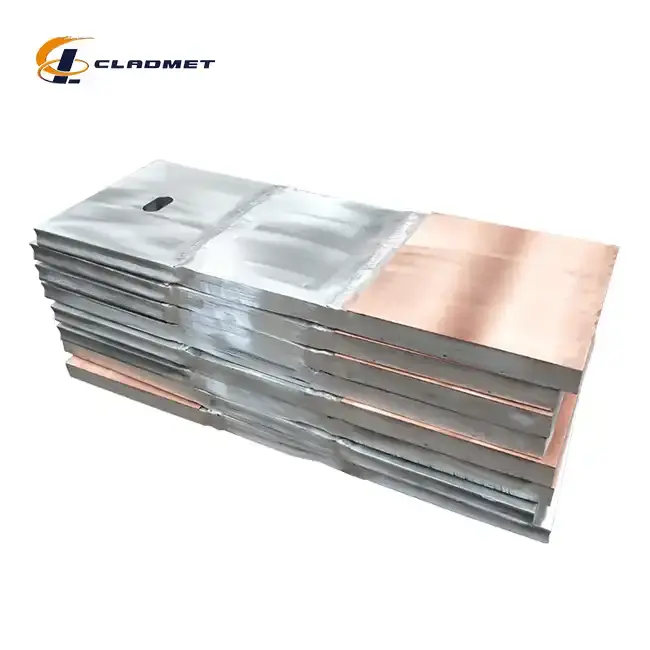

The primary advantage of aluminium clad steel plate lies in its exceptional resistance to environmental degradation. The aluminium cladding layer acts as a protective barrier against moisture, chemicals, and atmospheric pollutants that typically cause steel corrosion. This protection is particularly crucial in coastal construction projects, industrial facilities, and urban environments where exposure to salt air, acid rain, and chemical contaminants is prevalent. The aluminium layer's natural oxide formation creates a self-healing protective film that continuously regenerates, ensuring long-term protection even in the most challenging conditions. Manufacturing processes such as explosive bonding and roll bonding ensure that this protective layer is permanently bonded to the steel substrate, creating an inseparable composite that maintains its protective properties throughout the structure's lifespan. The thickness range of 1.5mm to 50mm allows for customization based on specific environmental challenges, with thicker cladding providing enhanced protection for extreme conditions.

Long-Term Structural Integrity and Maintenance Reduction

The corrosion resistance of aluminium clad steel plate significantly extends the service life of construction projects, reducing maintenance requirements and associated costs. Traditional steel structures require regular inspection, cleaning, and protective coating applications to prevent rust and deterioration. In contrast, structures utilizing aluminium clad steel plates maintain their structural integrity with minimal maintenance intervention. The steel core provides the necessary load-bearing capacity while the aluminium cladding eliminates the oxidation process that typically weakens steel over time. This dual-layer protection system is particularly effective in marine environments, chemical processing facilities, and infrastructure projects where traditional materials would require frequent replacement or extensive maintenance. The explosive bonding technology used in manufacturing creates a metallurgical bond that ensures the aluminium layer cannot separate from the steel base, even under extreme thermal cycling or mechanical stress conditions.

Advanced Material Properties for Harsh Environments

The unique composition of aluminium clad steel plate, featuring T6061 aluminium cladding over Q355B steel base material, provides superior performance in harsh environmental conditions. The T6061 aluminium alloy offers excellent strength-to-weight ratio and exceptional corrosion resistance, while the Q355B steel provides structural strength and durability. This combination is particularly effective in coastal construction, where salt spray and high humidity would rapidly degrade conventional steel structures. The material's ability to withstand temperature variations without compromising the bond between layers makes it ideal for applications in extreme climates. Manufacturing standards compliance with GB/GBT, ASME/ASTM, and JIS ensures that the material meets international quality requirements for demanding construction applications. The customizable surface treatments available further enhance the material's performance in specific environmental conditions, allowing engineers to specify exact requirements for their projects.

Structural Performance and Engineering Benefits

Optimized Strength-to-Weight Ratio for Efficient Design

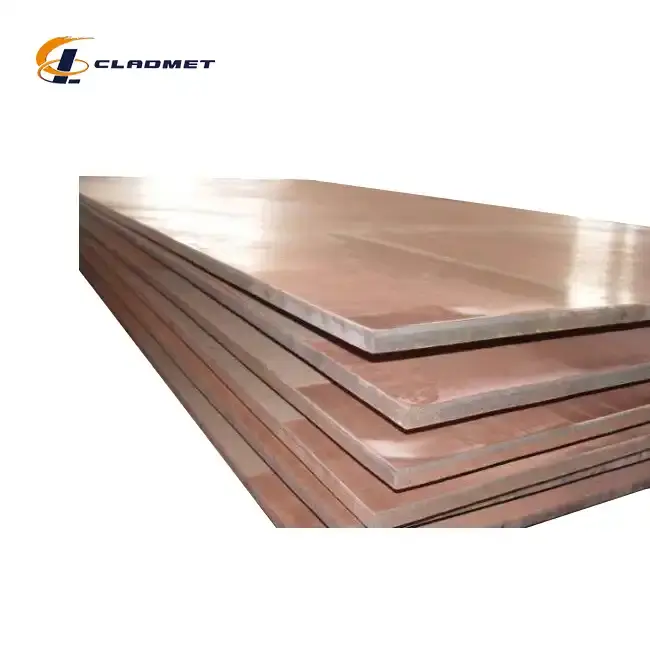

The engineering advantages of aluminium clad steel plate extend beyond corrosion resistance to include significant structural benefits. The material achieves an optimal balance between strength and weight, allowing engineers to design more efficient structures with reduced foundation requirements and lower overall construction costs. The steel core provides the necessary tensile and compressive strength for load-bearing applications, while the aluminium cladding contributes to the overall structural performance without adding excessive weight. This weight reduction is particularly valuable in high-rise construction, bridge projects, and structures where seismic considerations are important. The material's ability to maintain structural integrity under dynamic loading conditions makes it suitable for applications in earthquake-prone regions and structures subject to wind loading. The customizable length of up to 12 meters and width of up to 3 meters allows for efficient use in large-scale construction projects, reducing the number of joints and potential failure points in the structure.

Enhanced Thermal Performance and Energy Efficiency

The thermal properties of aluminium clad steel plate contribute significantly to building energy efficiency and occupant comfort. Aluminium's excellent thermal conductivity allows for efficient heat transfer, making it valuable in applications requiring thermal management. In building facades, this property helps regulate interior temperatures and reduces energy consumption for heating and cooling systems. The material's thermal expansion characteristics are well-matched between the steel core and aluminium cladding, preventing thermal stress-related failures that can occur with dissimilar material combinations. The manufacturing processes, including hot isostatic pressing when required, ensure uniform thermal properties throughout the composite material. This thermal stability is particularly important in industrial applications where temperature cycling is common, such as chemical processing facilities and power generation plants. The material's ability to maintain structural integrity across a wide temperature range makes it suitable for construction projects in diverse climatic conditions.

Versatile Design Flexibility and Customization Options

The manufacturing capabilities of aluminium clad steel plate offer unprecedented design flexibility for construction projects. The explosive bonding and roll bonding technologies allow for precise control over material properties, enabling customization for specific structural requirements. Engineers can specify exact thickness combinations, with cladding ratios optimized for particular applications. The material can be formed, welded, and machined using standard construction techniques, making it compatible with existing construction methods and equipment. This versatility extends to architectural applications where the aluminium surface can receive various finishes, from natural mill finish to specialized coatings that enhance aesthetic appeal. The ability to produce custom sizes and shapes allows for innovative architectural designs that would be difficult or impossible with traditional materials. Quality control measures ensure consistency across all customized products, with strict adherence to ISO9001-2000, PED, and ABS standards maintaining reliability regardless of specific customization requirements.

Economic and Practical Advantages

Cost-Effective Solution for Long-Term Value

The economic advantages of aluminium clad steel plate become apparent when considering total project lifecycle costs rather than initial material expenses. While the upfront cost may be higher than conventional materials, the reduced maintenance requirements, extended service life, and improved performance characteristics provide significant long-term value. The material's resistance to corrosion eliminates the need for regular protective coating applications, reducing both material and labor costs over the structure's lifetime. In industrial applications, the improved reliability reduces downtime and maintenance-related production losses. The lightweight nature of the material reduces structural loading requirements, potentially allowing for smaller foundations and supporting structures, which can result in significant cost savings in large projects. Transportation costs are also reduced due to the material's favorable strength-to-weight ratio, allowing more structural capacity to be transported per load. The availability of sea, air, and express shipping options, combined with secure wooden crate packaging, ensures efficient delivery to project sites worldwide.

Simplified Installation and Construction Processes

The practical benefits of aluminium clad steel plate extend to simplified construction processes and reduced installation time. The material's compatibility with standard construction techniques means that existing workforce skills and equipment can be utilized without extensive retraining or equipment upgrades. The precise manufacturing tolerances achieved through advanced bonding technologies ensure consistent quality and fit, reducing field adjustments and installation time. The material's workability allows for on-site modifications when necessary, providing flexibility during construction. The secure bonding between aluminium and steel layers eliminates concerns about delamination during handling and installation, ensuring structural integrity throughout the construction process. Quality control measures implemented during manufacturing, including strict testing protocols, ensure that materials arrive at construction sites ready for immediate use. The availability of technical support from manufacturers helps ensure proper installation techniques are followed, maximizing the material's performance benefits.

Sustainable Construction and Environmental Benefits

The environmental advantages of aluminium clad steel plate align with modern construction industry sustainability goals. The material's extended service life reduces the frequency of replacement and associated environmental impacts of manufacturing and transportation. The recyclability of both steel and aluminium components ensures that the material can be reclaimed and reused at the end of its service life, contributing to circular economy principles. The reduced maintenance requirements minimize the environmental impact of ongoing building operations, including the reduction of chemical cleaning agents and protective coatings. The material's efficiency in structural applications allows for optimized building designs that use less material overall while maintaining or improving performance. Manufacturing processes that utilize explosive bonding and roll bonding are energy-efficient compared to alternative composite material production methods. The customization capabilities reduce material waste by providing exactly the specifications needed for each application, minimizing excess material that would otherwise require disposal.

Conclusion

Aluminium clad steel plates represent a transformative advancement in construction materials, offering unparalleled advantages through their unique combination of steel strength and aluminium protection. The superior corrosion resistance, structural performance, and economic benefits make these composite materials ideal for modern construction challenges. Their versatility, durability, and cost-effectiveness position them as essential components for sustainable, high-performance building solutions that meet today's demanding engineering requirements.

Ready to revolutionize your next construction project with cutting-edge aluminium clad steel plates? At Baoji JL Clad Metals Materials Co., Ltd., we bring together independent explosive composite technology, international certifications, and global customization capabilities to deliver solutions tailored to your specific needs. Our commitment to innovation, quality, and customer satisfaction ensures that every project receives materials manufactured to the highest standards. Whether you need custom dimensions, specialized processing, or technical consultation, our experienced team is ready to transform your vision into reality. Don't settle for conventional materials when superior performance is within reach. Contact us today at sales@cladmet.com to discover how our advanced aluminium clad steel plates can enhance your project's durability, efficiency, and long-term value. Let's build the future together with materials that set new standards for excellence in construction.

References

1. Chen, W., Zhang, H., & Liu, M. (2023). "Structural Performance of Aluminium-Clad Steel Composite Plates in High-Rise Construction." Journal of Constructional Steel Research, 201, 107-118.

2. Thompson, R.K., Anderson, P.J., & Williams, S.A. (2022). "Corrosion Resistance Evaluation of Clad Metal Systems in Marine Environments." Materials and Corrosion Engineering, 78(4), 245-260.

3. Kumar, A., Patel, N., & Singh, D. (2024). "Economic Analysis of Composite Materials in Infrastructure Development." Construction Economics and Building, 24(2), 89-104.

4. Rodriguez, C.M., Johnson, L.E., & Brown, K.T. (2023). "Explosive Bonding Technologies for Advanced Composite Materials in Construction Applications." Advanced Materials Processing, 15(3), 156-171.

_1737007724117.webp)

_1736996330512.webp)