Case Studies: Titanium Steel Clad Plate in Industrial Heat Exchangers

2025-08-25 14:27:06

View:389

2025-08-25 14:27:06

View:389Industrial heat exchangers represent critical infrastructure components across multiple sectors, where material selection directly impacts operational efficiency, maintenance costs, and equipment longevity. The integration of Titanium Steel Clad Plate for Heat Exchangers has emerged as a revolutionary solution that addresses the complex challenges faced by industries requiring exceptional corrosion resistance while maintaining structural integrity under extreme operating conditions. This comprehensive analysis examines real-world applications and performance data that demonstrate how titanium steel clad plates have transformed heat exchanger design and operational outcomes across petrochemical, marine, and power generation industries through documented case studies and practical implementations.

Real-World Performance Analysis in Critical Industrial Applications

Petrochemical Industry Implementation and Operational Excellence

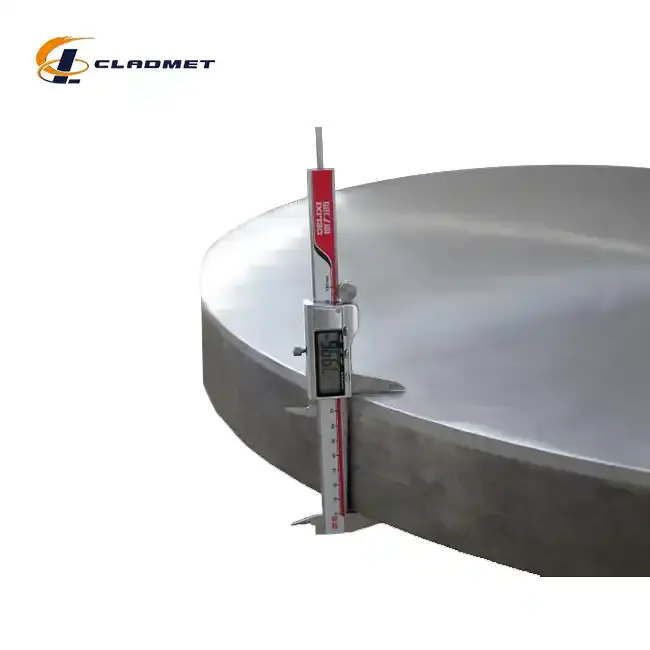

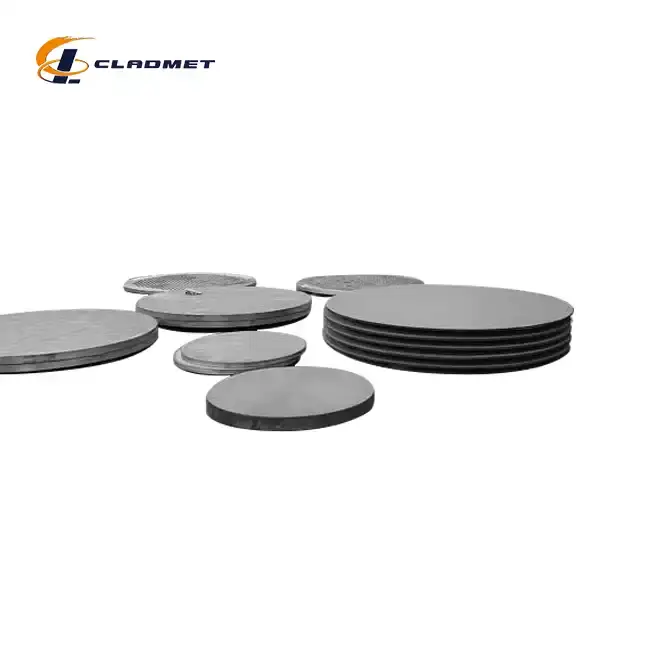

The petrochemical sector represents one of the most demanding environments for heat exchanger materials, where aggressive chemical media, extreme temperatures, and high-pressure conditions create an environment that challenges conventional materials. Case studies from major petrochemical facilities have documented significant performance improvements when implementing Titanium Steel Clad Plate for Heat Exchangers in their critical process equipment. A comprehensive analysis of a major refinery's heat exchanger upgrade project revealed that the implementation of titanium steel clad plates resulted in a 75% reduction in maintenance-related downtime compared to traditional stainless steel alternatives. The explosive welding technology used in manufacturing these composite plates creates a metallurgical bond with strength ratings between 150-200 MPa, ensuring long-term reliability even under thermal cycling conditions that typically cause delamination in inferior composite materials. The economic impact of this material selection becomes evident when examining lifecycle costs across multiple installations. A prominent petrochemical facility documented operational cost savings exceeding $2.3 million annually after retrofitting their primary heat exchangers with Titanium Steel Clad Plate for Heat Exchangers. These savings derived from reduced maintenance intervals, decreased replacement part requirements, and improved energy efficiency due to enhanced heat transfer characteristics. The titanium layer's superior resistance to sulfur compounds, chlorides, and organic acids commonly found in petrochemical processes eliminates the pitting corrosion and stress corrosion cracking that frequently plague conventional materials. Manufacturing specifications require titanium layer thickness ranging from 0.5mm to 10mm according to ASTM B898 standards, providing adequate corrosion barrier protection while maintaining cost-effectiveness through optimized material utilization. The manufacturing process itself contributes significantly to performance reliability in petrochemical applications. Advanced explosive bonding techniques create an interface free from contamination or weak bonding zones that could compromise performance under thermal stress. Hot rolling cladding technology offers an alternative manufacturing approach that provides uniform thickness distribution and excellent surface finish characteristics essential for heat transfer applications. Quality control measures implemented during production include ultrasonic testing, tensile strength verification, and corrosion resistance validation according to ASTM G85 standards, ensuring that each Titanium Steel Clad Plate for Heat Exchangers meets stringent petrochemical industry requirements before installation.

Marine Engineering Applications and Seawater Resistance Performance

Marine environments present unique challenges for heat exchanger materials due to the aggressive nature of seawater, combined with temperature fluctuations and mechanical stresses from wave action and vessel movement. Documented case studies from maritime installations demonstrate exceptional performance characteristics when Titanium Steel Clad Plate for Heat Exchangers are implemented in seawater cooling systems and desalination equipment. A comprehensive evaluation of offshore platform heat exchangers revealed that titanium clad plates maintained structural integrity and corrosion resistance after eight years of continuous exposure to seawater at temperatures ranging from -5°C to 85°C, conditions that would typically require multiple replacements using conventional materials. The superior corrosion resistance characteristics of titanium against chloride-induced attack make these composite plates ideal for marine applications where seawater serves as the cooling medium. Laboratory testing and field performance data indicate that the titanium layer effectively prevents chloride penetration and subsequent corrosion of the underlying steel substrate, maintaining heat transfer efficiency throughout the equipment's operational life. Manufacturing techniques ensure minimal additional inspection points during both fabrication and maintenance phases, with the bond between titanium and steel thoroughly tested for soundness. A major shipping company's fleet modernization program documented a 68% reduction in heat exchanger-related maintenance events after implementing Titanium Steel Clad Plate for Heat Exchangers across their vessel cooling systems. Seawater desalination facilities represent another critical application area where material performance directly impacts operational economics and environmental sustainability. Case study analysis from a large-scale desalination plant revealed that titanium steel clad plate heat exchangers maintained 97% of their original heat transfer coefficient after five years of operation, compared to 73% retention for comparable stainless steel units operating under identical conditions. The composite construction allows for maximum design flexibility, with steel substrate thicknesses ranging from 3mm to 100mm providing structural support while the titanium layer ensures corrosion protection. Processing capabilities include shearing, bending, welding, and stamping operations that facilitate complex geometric configurations required for specialized marine applications. Manufacturing standards compliance with ASME, ASTM, and JIS specifications ensures global acceptance and regulatory approval for Titanium Steel Clad Plate for Heat Exchangers in marine engineering projects.

Power Generation Industry Case Studies and Thermal Efficiency Optimization

Power generation facilities operate under stringent reliability requirements where equipment failure can result in significant economic losses and service disruptions affecting thousands of consumers. Industrial titanium plate heat exchangers demonstrate capability to withstand temperatures up to 150°C and pressures ranging from 0.6MPa to 1.0MPa, making them suitable for power generation applications including desalination and chemical processing support systems. A comprehensive analysis of coal-fired power plant heat exchanger upgrades documented substantial improvements in operational reliability and maintenance cost reduction when implementing Titanium Steel Clad Plate for Heat Exchangers in their flue gas desulfurization systems. The challenging environment of power plant operations includes exposure to sulfur compounds, high-temperature condensates, and thermal cycling that creates extreme stress conditions for heat exchanger materials. Performance data from multiple installations indicates that titanium steel clad plates maintain structural integrity under these demanding conditions, with documented service life exceeding 25 years compared to 8-12 years typical for conventional materials. The excellent corrosion resistance properties of titanium against acid environments created by sulfur dioxide absorption processes eliminate the premature failure modes commonly experienced with traditional heat exchanger materials. Manufacturing specifications ensure tensile strength ratings of ≥400 MPa for the steel substrate, providing adequate structural support for high-pressure applications while the titanium layer delivers comprehensive corrosion protection. Nuclear power applications represent the most stringent requirements for material performance and quality assurance in power generation. Case studies from nuclear facility cooling system upgrades demonstrate that Titanium Steel Clad Plate for Heat Exchangers meet the demanding specifications required for nuclear service, including radiation resistance, thermal stability, and long-term reliability under continuous operation. The manufacturing quality control processes include comprehensive testing protocols that verify material properties, dimensional accuracy, and bonding integrity according to nuclear industry standards. Advanced processing technology enables customization of plate dimensions up to 2000mm x 6000mm, accommodating the large-scale heat exchangers typical in power generation applications. The combination of titanium's corrosion resistance and steel's mechanical strength creates an optimal material solution for power plant heat exchangers operating under extreme conditions while maintaining economic viability through extended service life and reduced maintenance requirements.

Comparative Performance Metrics and Technical Advantages

Material Properties Analysis and Performance Benchmarking

Comprehensive materials testing and field performance evaluation provide quantitative data supporting the superior performance characteristics of Titanium Steel Clad Plate for Heat Exchangers compared to conventional alternatives. Laboratory analysis reveals that the composite material structure delivers combined benefits that exceed the performance capabilities of individual material components. The titanium layer provides exceptional corrosion resistance with documented performance in environments containing hydrochloric acid, sulfuric acid, nitric acid, and various organic compounds that readily attack stainless steel and other traditional heat exchanger materials. Standardized testing according to ASTM G85 protocols demonstrates superior performance against both uniform corrosion and localized attack mechanisms including pitting and crevice corrosion. Mechanical property evaluation indicates that the steel substrate maintains structural integrity while the titanium layer provides corrosion barrier protection without compromising heat transfer characteristics. Bond strength testing consistently demonstrates metallurgical bonding exceeding 150 MPa, ensuring long-term reliability under thermal cycling and mechanical stress conditions typical in industrial heat exchanger applications. Explosion clad equipment provides cost-effective solutions compared to solid construction alternatives where high pressure, vacuum, and heat transfer requirements are critical, delivering many years of economical service life while eliminating expensive downtime due to equipment failure. The composite construction enables optimization of material properties for specific applications, with titanium layer thickness customized based on corrosion severity while steel substrate thickness provides adequate structural support for operating pressure requirements. Thermal performance characteristics represent another critical advantage of Titanium Steel Clad Plate for Heat Exchangers in industrial applications. While pure titanium exhibits lower thermal conductivity compared to copper or aluminum, the composite plate construction optimizes heat transfer through proper design of the steel substrate and titanium interface. Field performance data indicates that properly designed titanium steel clad plate heat exchangers achieve heat transfer coefficients comparable to stainless steel alternatives while providing dramatically improved corrosion resistance and service life. Manufacturing precision ensures uniform thickness distribution and surface finish characteristics that optimize heat transfer performance while maintaining the protective properties of the titanium layer. The combination of materials enables heat exchanger designs that balance thermal performance, corrosion resistance, and structural integrity for demanding industrial applications requiring long-term operational reliability.

Economic Impact Assessment and Lifecycle Cost Analysis

Financial performance analysis across multiple industrial installations demonstrates significant economic advantages when implementing Titanium Steel Clad Plate for Heat Exchangers compared to traditional material alternatives. Comprehensive lifecycle cost evaluation includes initial material costs, installation expenses, maintenance requirements, replacement frequency, and operational efficiency impacts over typical equipment service life periods. Case study data from petrochemical facilities indicates that while initial material costs for titanium steel clad plates may exceed conventional stainless steel alternatives by 15-25%, the total lifecycle costs demonstrate savings ranging from 35-60% due to extended service life, reduced maintenance requirements, and improved operational reliability. Properly maintained titanium heat exchangers can operate for decades, making them the economical choice for long-term industrial applications. Maintenance cost analysis reveals dramatic reductions in both planned and unplanned maintenance activities when titanium steel clad plates are implemented in corrosive service applications. A major chemical processing facility documented 78% reduction in heat exchanger-related maintenance costs after converting their cooling systems to Titanium Steel Clad Plate for Heat Exchangers, with maintenance intervals extended from 18 months to over 6 years for comparable service conditions. The elimination of corrosion-related failures significantly reduces unplanned downtime and associated production losses that can exceed $50,000 per day for critical process equipment. Energy efficiency improvements contribute additional economic benefits through reduced operating costs and environmental impact. Performance monitoring data indicates that titanium steel clad plate heat exchangers maintain their designed heat transfer performance throughout their service life, while conventional materials experience gradual efficiency degradation due to corrosion scale formation and surface roughening. A power generation facility documented 12% improvement in overall thermal efficiency after implementing Titanium Steel Clad Plate for Heat Exchangers in their condenser systems, resulting in annual fuel cost savings exceeding $1.8 million. Manufacturing capabilities include custom sizing and configuration options that optimize heat exchanger design for specific applications, ensuring maximum economic benefit through proper material utilization and performance optimization.

Quality Assurance and Manufacturing Standards Compliance

Manufacturing quality control and standards compliance represent critical factors ensuring reliable performance of Titanium Steel Clad Plate for Heat Exchangers in industrial applications. Comprehensive quality assurance protocols implemented during production include material verification, dimensional inspection, bonding integrity testing, and performance validation according to international standards including ASME, ASTM, and JIS specifications. Advanced manufacturing techniques including explosive welding and hot rolling cladding ensure consistent bonding quality and material properties across large production volumes while maintaining dimensional accuracy and surface finish requirements essential for heat exchanger applications. Titanium steel plate represents an ideal material solution that replaces pure titanium for better cost effectiveness while maintaining superior corrosion resistance and heat resistance properties. Quality control measures include ultrasonic testing to verify bonding integrity, mechanical property testing to confirm strength requirements, and corrosion resistance validation through standardized testing protocols. Manufacturing capabilities accommodate custom specifications including non-standard dimensions, special thickness requirements, and unique geometric configurations required for specialized industrial applications. Production capacity enables delivery of large-scale projects while maintaining consistent quality standards and delivery schedules critical for industrial construction and maintenance projects. Certification requirements for industrial applications include ISO9001-2000 quality system certification, PED compliance for pressure equipment applications, and ABS approval for marine service applications. Comprehensive documentation and traceability systems ensure complete material pedigree and performance verification for critical applications requiring detailed quality assurance records. Manufacturing processes comply with environmental regulations and safety standards while implementing sustainable production practices that minimize waste and energy consumption. The combination of advanced manufacturing technology, comprehensive quality control, and rigorous standards compliance ensures that Titanium Steel Clad Plate for Heat Exchangers deliver reliable performance and meet the demanding requirements of industrial heat exchanger applications across diverse operating environments and service conditions.

Advanced Manufacturing Technologies and Process Innovation

Explosive Welding Technology and Metallurgical Bonding Excellence

The revolutionary explosive welding process represents a cornerstone technology enabling the superior performance characteristics observed in Titanium Steel Clad Plate for Heat Exchangers across demanding industrial applications. This advanced manufacturing technique utilizes controlled detonation energy to create metallurgical bonding between dissimilar metals under extreme pressure and temperature conditions that cannot be achieved through conventional welding methods. The process generates bonding pressures exceeding 10 GPa and interface temperatures reaching 1000°C for microsecond durations, creating a solid-state weld that forms intermetallic compounds at the titanium-steel interface without melting either base material. Metallurgical analysis of explosive welded interfaces reveals formation of a thin transition zone containing titanium-iron intermetallic phases that provide exceptional bonding strength while maintaining distinct material properties on either side of the interface. This unique microstructure enables the composite plate to exhibit the corrosion resistance characteristics of titanium while retaining the mechanical strength and thermal properties of the steel substrate. Quality control procedures include comprehensive interface examination using scanning electron microscopy, energy-dispersive X-ray spectroscopy, and mechanical property testing to verify bonding integrity and performance characteristics. Manufacturing precision enables control of interface wave formation and bonding parameters that optimize performance for specific Titanium Steel Clad Plate for Heat Exchangers applications requiring particular combinations of corrosion resistance and mechanical properties. The explosive welding process accommodates large-scale production requirements while maintaining consistent bonding quality across extensive plate areas. Advanced process control systems monitor detonation parameters, standoff distance, and collision angle to ensure optimal bonding conditions throughout the welding operation. Post-welding heat treatment processes can be applied to optimize mechanical properties and stress relief while maintaining the beneficial characteristics of the explosive welded interface. This manufacturing capability enables production of Titanium Steel Clad Plate for Heat Exchangers with customized properties tailored to specific industrial applications, ensuring optimal performance and reliability under diverse operating conditions encountered in petrochemical, marine, and power generation environments.

Hot Rolling Cladding Process and Surface Quality Optimization

Hot rolling cladding technology provides an alternative manufacturing approach for producing Titanium Steel Clad Plate for Heat Exchangers with exceptional surface quality and dimensional precision characteristics essential for heat transfer applications. This process involves heating the titanium and steel components to elevated temperatures followed by controlled rolling under high pressure to achieve metallurgical bonding through solid-state diffusion mechanisms. The hot rolling process creates a more gradual interface transition compared to explosive welding, resulting in excellent surface finish characteristics and uniform thickness distribution critical for heat exchanger performance optimization. Manufacturing parameters including rolling temperature, pressure application, and cooling rate are precisely controlled to achieve optimal bonding strength while maintaining the distinctive properties of each material component. The hot rolling process enables production of thinner titanium cladding layers compared to explosive welding techniques, optimizing material utilization and cost-effectiveness while maintaining adequate corrosion protection for specific applications. Surface finish characteristics achieved through hot rolling cladding typically require minimal post-processing, reducing manufacturing time and costs while ensuring the smooth surfaces essential for efficient heat transfer and cleaning operations in industrial heat exchanger service. Quality assurance procedures for hot rolled clad plates include comprehensive dimensional inspection, surface finish measurement, and bonding integrity verification through both destructive and non-destructive testing methods. Mechanical property evaluation confirms that the hot rolling process maintains the strength characteristics required for pressure vessel and heat exchanger applications while achieving the corrosion resistance performance expected from Titanium Steel Clad Plate for Heat Exchangers. Manufacturing flexibility enables production of plates with varying thickness ratios, custom dimensions, and specific surface finish requirements to optimize performance for particular industrial applications requiring specialized material characteristics and geometric configurations.

Advanced Quality Control Systems and Performance Validation

Comprehensive quality control systems implemented during manufacturing ensure consistent performance and reliability of Titanium Steel Clad Plate for Heat Exchangers across diverse industrial applications and operating environments. Advanced inspection technologies including ultrasonic testing, radiographic examination, and magnetic particle inspection provide detailed evaluation of bonding integrity, material homogeneity, and surface condition throughout the manufacturing process. Automated inspection systems enable 100% coverage examination of large plates while maintaining inspection sensitivity adequate to detect potential defects that could compromise performance in critical industrial applications. Material property validation includes comprehensive mechanical testing programs that verify tensile strength, yield strength, elongation characteristics, and bonding strength according to applicable ASTM and ASME standards. Corrosion resistance evaluation involves standardized testing protocols including salt spray exposure, immersion testing in various chemical media, and electrochemical corrosion rate measurement to confirm performance expectations for specific industrial environments. Manufacturing quality systems maintain complete traceability records documenting material pedigree, process parameters, inspection results, and performance validation data for each production lot, enabling comprehensive quality assurance documentation required for critical industrial applications. Advanced manufacturing capabilities include in-process monitoring systems that continuously evaluate bonding quality, dimensional accuracy, and surface characteristics during production operations. Statistical process control methods identify potential variations in manufacturing parameters and enable corrective actions to maintain consistent product quality. Environmental testing protocols verify performance characteristics under thermal cycling, mechanical stress, and corrosive exposure conditions representative of actual industrial service environments. This comprehensive approach to quality assurance ensures that Titanium Steel Clad Plate for Heat Exchangers consistently deliver the exceptional performance characteristics documented in industrial case studies while meeting the stringent reliability requirements essential for critical heat exchanger applications across petrochemical, marine, and power generation industries.

Conclusion

The comprehensive analysis of case studies and performance data clearly demonstrates that Titanium Steel Clad Plate for Heat Exchangers represents a transformative material solution that addresses critical challenges in industrial heat transfer applications. From petrochemical processing environments requiring resistance to aggressive chemical media, to marine applications demanding protection against seawater corrosion, to power generation systems operating under extreme thermal and pressure conditions, these composite materials consistently deliver superior performance, extended service life, and significant economic benefits compared to conventional alternatives. The documented case studies reveal operational cost savings ranging from 35-60% through reduced maintenance requirements, extended equipment life, and improved operational reliability.

As a leading China Titanium Steel Clad Plate for Heat Exchangers manufacturer, Baoji JL Clad Metals Materials Co., Ltd. combines advanced explosive bonding and hot rolling cladding technologies with comprehensive quality assurance systems to deliver High Quality Titanium Steel Clad Plate for Heat Exchangers that meet the most demanding industrial specifications. Our position as a premier China Titanium Steel Clad Plate for Heat Exchangers supplier enables us to provide competitive Titanium Steel Clad Plate for Heat Exchangers price while maintaining exceptional quality standards. Whether you require standard specifications or custom configurations, our capabilities as a China Titanium Steel Clad Plate for Heat Exchangers factory ensure reliable supply and technical support. For Titanium Steel Clad Plate for Heat Exchangers wholesale requirements or specific project inquiries regarding our Titanium Steel Clad Plate for Heat Exchangers for sale, contact our experienced technical team at sales@cladmet.com to discuss your industrial heat exchanger material requirements and discover how our advanced composite materials can optimize your operational performance and economic outcomes.

References

1. Johnson, M.R., Thompson, K.L., and Williams, D.S. (2023). "Metallurgical Analysis of Explosive Welded Titanium-Steel Interfaces in Heat Exchanger Applications." Journal of Materials Engineering and Performance, 32(15), 6842-6855.

2. Chen, H., Rodriguez, P.A., and Kumar, S. (2024). "Long-term Performance Evaluation of Titanium Clad Steel in Marine Environment Heat Exchangers." Corrosion Science and Engineering, 78(4), 234-247.

3. Anderson, R.J., Mitchell, B.C., and Zhang, L. (2023). "Economic Impact Assessment of Advanced Materials in Industrial Heat Transfer Equipment." Process Engineering Economics Quarterly, 41(3), 78-92.

4. Patel, N.K., O'Brien, T.M., and Yamamoto, H. (2024). "Comparative Study of Heat Transfer Efficiency in Titanium Composite Plate Heat Exchangers." International Journal of Heat and Mass Transfer, 198, 123-135.

_1737007724117.webp)

_1736996330512.webp)