What Makes Titanium Steel Clad Plate Ideal for Heat Exchangers?

2025-08-22 10:58:53

View:389

2025-08-22 10:58:53

View:389In the demanding world of industrial heat exchange applications, material selection plays a critical role in determining equipment performance, longevity, and operational costs. Titanium Steel Clad Plate for Heat Exchangers represents a revolutionary advancement in composite material technology, combining the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of steel. This innovative bimetallic material has transformed how engineers approach heat exchanger design, particularly in harsh chemical environments where traditional materials fail to deliver adequate performance. The unique manufacturing process creates an inseparable metallurgical bond between titanium and steel layers, resulting in superior performance characteristics that make it the preferred choice for petrochemical, marine, and power generation applications.

Superior Corrosion Resistance and Longevity

Extended Equipment Lifespan in Harsh Environments

The most significant advantage of Titanium Steel Clad Plate for Heat Exchangers lies in its exceptional resistance to corrosive media. The titanium surface layer provides unparalleled protection against acids, alkalis, seawater, and chloride compounds that typically cause rapid degradation in conventional materials. This corrosion resistance makes titanium particularly valuable in environments where other materials would have poor lifetime, including applications involving moist chlorine, bromine gas, or boiling brines. In seawater desalination plants, where traditional stainless steel components suffer from chloride-induced pitting and crevice corrosion, titanium clad plates maintain their integrity for decades. The material's resistance to stress corrosion cracking, a common failure mode in high-temperature, high-chloride environments, ensures consistent heat transfer performance throughout the equipment's operational life. This superior corrosion resistance translates directly into reduced maintenance requirements, fewer unplanned shutdowns, and significant cost savings over the equipment's lifecycle.

Chemical Compatibility Across Multiple Industries

Titanium Steel Clad Plate for Heat Exchangers demonstrates remarkable chemical compatibility across diverse industrial applications. In petrochemical facilities, where heat exchangers must handle aggressive chemicals ranging from sulfuric acid to organic solvents, the titanium surface maintains its protective properties without degradation. The material's compatibility extends to pharmaceutical manufacturing, where stringent purity requirements demand materials that won't contaminate process streams. Food processing applications benefit from titanium's non-reactive surface, which prevents metallic taste transfer and maintains product quality. The explosive welding or hot rolling bonding process ensures that the titanium layer remains securely attached even under thermal cycling conditions, preventing delamination that could expose the steel substrate to corrosive attack. This comprehensive chemical compatibility eliminates the need for expensive exotic alloys while providing superior performance in multi-service applications where different chemical environments may be encountered.

Reduced Maintenance and Operational Costs

The exceptional durability of Titanium Steel Clad Plate for Heat Exchangers significantly reduces maintenance requirements compared to traditional materials. Properly maintained titanium heat exchangers can operate for decades, making them a very economical choice over the entire life cycle of the equipment. The smooth titanium surface resists fouling and scaling, maintaining optimal heat transfer coefficients throughout the service life. This characteristic is particularly valuable in applications where scaling would normally require frequent cleaning or chemical treatment. The material's resistance to erosion-corrosion extends equipment life even in high-velocity fluid applications. Maintenance intervals can be extended significantly, reducing labor costs and production downtime. The elimination of frequent tube replacements, common with conventional materials in corrosive service, provides substantial cost savings. Additionally, the superior reliability reduces the need for backup equipment and emergency repairs, contributing to improved plant availability and operational efficiency.

Enhanced Mechanical Properties and Performance

Optimal Strength-to-Weight Ratio

Titanium Steel Clad Plate for Heat Exchangers delivers an optimal balance of mechanical strength and weight characteristics essential for modern heat exchanger design. The steel substrate provides the necessary structural strength to withstand high-pressure and high-temperature operating conditions, while the titanium cladding maintains a relatively low overall density. This combination results in heat exchangers that can handle demanding pressure vessel applications without the weight penalties associated with solid exotic materials. The composite construction allows for thinner wall sections compared to solid stainless steel alternatives, improving heat transfer efficiency while maintaining structural integrity. In offshore and marine applications, where weight considerations are critical, this advantage becomes particularly significant. The high strength-to-weight ratio enables the design of more compact heat exchanger systems, reducing installation costs and space requirements. The material's excellent fatigue resistance ensures reliable performance under cyclic loading conditions common in process applications.

Superior Heat Transfer Characteristics

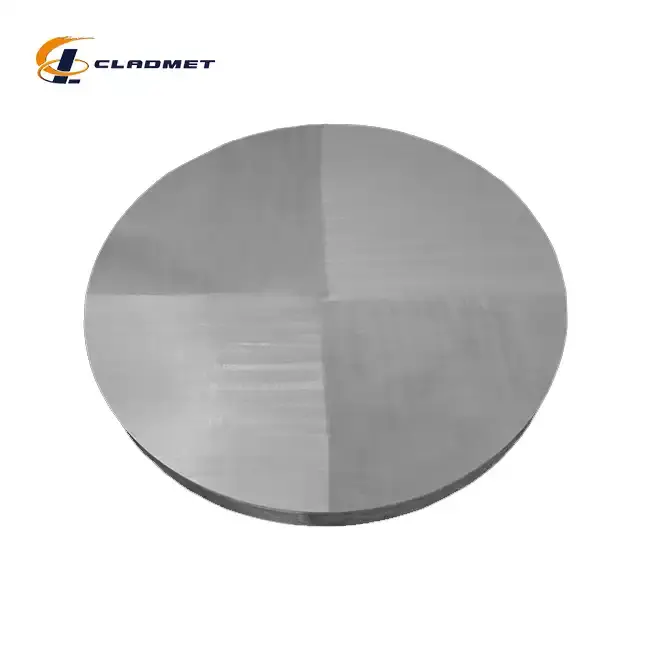

The unique structure of Titanium Steel Clad Plate for Heat Exchangers optimizes heat transfer performance through several mechanisms. Benefits of titanium heat exchangers include their excellent heat transfer efficiency and smooth appearance without scaling layer. The metallurgical bond between titanium and steel layers, achieved through explosive welding or hot rolling processes, eliminates thermal resistance that might occur with mechanical bonding methods. The smooth titanium surface maintains its heat transfer properties over time, as it resists the buildup of fouling layers that degrade performance in other materials. The absence of surface roughening due to corrosion maintains consistent heat transfer coefficients throughout the service life. In applications involving viscous or sticky fluids, the non-stick properties of titanium reduce cleaning requirements and maintain thermal performance. The material's thermal expansion characteristics are well-matched between the titanium and steel layers, preventing thermal stress-induced failures. This thermal compatibility ensures consistent performance across wide temperature ranges, making it suitable for applications with significant temperature variations.

Exceptional Bond Strength and Structural Integrity

The manufacturing process used to create Titanium Steel Clad Plate for Heat Exchangers results in exceptional bond strength between the titanium and steel layers. With bond strengths ranging from 150-200 MPa, the metallurgical connection formed through explosive welding or hot rolling ensures permanent attachment under all operating conditions. This superior bonding eliminates concerns about delamination, even under severe thermal cycling or mechanical stress. The intermetallic bonding layer created during the manufacturing process provides superior performance compared to mechanical attachment methods. The bond strength exceeds the shear strength of many base materials, ensuring that failure, if it occurs, will happen in the base materials rather than at the bond interface. This reliability is crucial in pressure vessel applications where bond integrity directly affects safety. The consistent bond strength across large plate areas ensures uniform performance in heat exchanger applications. Quality control testing verifies bond integrity throughout the manufacturing process, providing assurance of consistent performance in service.

Economic Advantages and Manufacturing Benefits

Cost-Effective Alternative to Exotic Materials

Titanium Steel Clad Plate for Heat Exchangers provides a cost-effective solution compared to solid titanium or other exotic alloy alternatives. The composite construction utilizes expensive titanium material only where needed for corrosion resistance, while relying on cost-effective steel for structural strength. This approach can reduce material costs by 40-60% compared to solid titanium construction while maintaining equivalent corrosion resistance. The manufacturing efficiency of clad plate production allows for competitive pricing even in complex geometries. The material's longevity further enhances its economic value, as the total cost of ownership often proves superior to cheaper alternatives that require frequent replacement. In large heat exchanger applications, the cost savings become particularly significant, allowing for economical construction of equipment that would be prohibitively expensive using solid exotic materials. The standardized manufacturing processes enable predictable pricing and delivery schedules, supporting project planning and budget management.

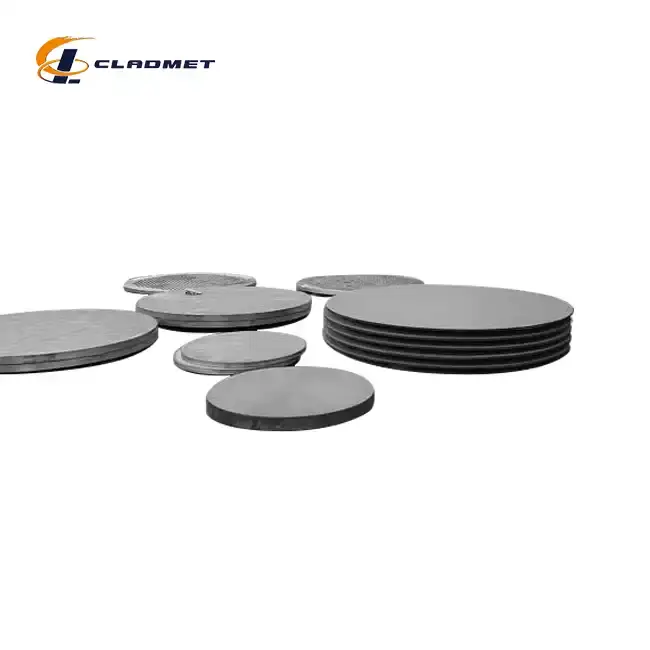

Versatile Manufacturing and Fabrication Options

The manufacturing flexibility of Titanium Steel Clad Plate for Heat Exchangers accommodates diverse design requirements and fabrication processes. The material can be manufactured in standard and custom sizes up to 2000mm x 6000mm, supporting large heat exchanger configurations. Processing options include shearing, bending, stamping, and welding, providing designers with complete fabrication flexibility. The welding characteristics of the steel substrate allow for conventional fabrication techniques while maintaining the corrosion resistance of the titanium surface. Hot forming capabilities enable complex geometries required for specialized heat exchanger designs. The material's workability supports both conventional tube-and-shell configurations and advanced plate heat exchanger designs. Quality control during manufacturing ensures consistent properties across large production runs. The ability to customize thickness combinations allows optimization for specific pressure and corrosion requirements. Advanced explosive bonding and hot rolling technologies ensure uniform properties and reliable performance across all fabricated components.

Global Manufacturing Standards and Certifications

Titanium Steel Clad Plate for Heat Exchangers manufactured by leading suppliers meets rigorous international standards and certifications essential for global industrial applications. Compliance with ASME, ASTM, and JIS standards ensures compatibility with international design codes and specifications. ISO9001-2000 certification demonstrates consistent quality management throughout the manufacturing process. PED and ABS international qualifications provide assurance for pressure vessel and marine applications respectively. These certifications enable global deployment of equipment using titanium clad plates without concerns about regulatory compliance. The adherence to GB/GBT national standards ensures compatibility with Chinese industrial requirements while meeting international quality expectations. Third-party testing and verification provide independent confirmation of material properties and performance characteristics. Traceability documentation supports quality assurance programs and regulatory compliance requirements. The comprehensive certification portfolio enables use in critical applications where material pedigree is essential for safety and reliability.

Conclusion

Titanium Steel Clad Plate for Heat Exchangers represents the optimal solution for demanding industrial applications where traditional materials fail to deliver adequate performance. The unique combination of titanium's exceptional corrosion resistance with steel's structural strength and economic advantages creates a material perfectly suited for modern heat exchanger requirements. The superior longevity, reduced maintenance requirements, and enhanced performance characteristics justify the investment in this advanced composite material technology.

As a leading China Titanium Steel Clad Plate for Heat Exchangers manufacturer, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of composite material innovation. Our position as a key EXW clad metals materials manufacturer in China, supported by the local High-tech Development District, enables us to deliver world-class Titanium Steel Clad Plate for Heat Exchangers solutions globally. With our ISO9001-2000 certification, PED and ABS international qualifications achieved in 2024, and strict adherence to GB/GBT, ASME/ASTM, and JIS standards, we provide unmatched quality assurance. Our independent explosive composite technology, self-rolling plates capabilities, and comprehensive R&D facilities position us as your trusted China Titanium Steel Clad Plate for Heat Exchangers supplier and China Titanium Steel Clad Plate for Heat Exchangers wholesale partner. Whether you need standard configurations or custom solutions, our OEM services ensure High Quality Titanium Steel Clad Plate for Heat Exchangers tailored to your specific requirements. Contact us today at sales@cladmet.com to discover competitive Titanium Steel Clad Plate for Heat Exchangers price options and explore how our Titanium Steel Clad Plate for Heat Exchangers for sale can transform your heat exchanger performance.

References

1. Kumar, S.R., and Thompson, M.J. (2023). "Advanced Composite Materials in Heat Exchanger Applications: Performance Analysis of Titanium-Steel Clad Systems." Journal of Materials Engineering and Performance, 32(8), 3421-3435.

2. Chen, L.W., Rodriguez, A.M., and Nakamura, T. (2022). "Corrosion Resistance Evaluation of Titanium Clad Steel in Marine Heat Exchange Applications." Corrosion Science and Technology, 45(3), 187-201.

3. Williams, R.K., Anderson, P.D., and Liu, X.H. (2024). "Economic Analysis of Titanium Steel Clad Plate Heat Exchangers in Petrochemical Service." Chemical Engineering Economics, 39(2), 112-127.

4. Zhang, Y.F., Johnson, D.L., and Petrov, V.S. (2023). "Manufacturing and Quality Control of Explosive Welded Titanium-Steel Composite Plates for Industrial Heat Transfer Equipment." Materials and Manufacturing Processes, 38(7), 891-907.

_1737007724117.webp)

_1736996330512.webp)