Top 7 Benefits of Titanium Steel Clad Plate for Pressure Vessels

2025-08-25 14:28:03

View:389

2025-08-25 14:28:03

View:389In the demanding world of industrial pressure vessel manufacturing, engineers and procurement specialists continuously seek materials that deliver superior performance while maintaining cost-effectiveness. Titanium Steel Clad Plate for Pressure Vessels represents a revolutionary solution that combines the exceptional corrosion resistance of titanium with the structural strength of steel, creating an optimal material for high-pressure applications. This advanced composite material offers seven distinct advantages that make it indispensable for petrochemical, marine, pharmaceutical, and power generation industries. Understanding these benefits enables manufacturers and engineers to make informed decisions when selecting materials for pressure vessel construction, ensuring both operational excellence and economic viability in their projects.

Superior Corrosion Resistance Extending Equipment Lifespan

The primary advantage of Titanium Steel Clad Plate for Pressure Vessels lies in its exceptional resistance to corrosive environments that would rapidly deteriorate conventional materials. The titanium layer provides outstanding protection against acids, alkalis, seawater, chlorides, and other aggressive media commonly encountered in industrial processes. Unlike stainless steel alternatives that may suffer from pitting corrosion or stress corrosion cracking in chloride environments, the titanium surface maintains its integrity even under extreme chemical exposure conditions. This superior corrosion resistance translates directly into extended equipment lifespan, often doubling or tripling the operational life of pressure vessels compared to traditional materials. In seawater desalination plants, for example, pressure vessels fabricated with Titanium Steel Clad Plate for Pressure Vessels can operate for decades without significant corrosion-related degradation. The titanium layer's natural oxide film continuously regenerates itself, providing self-healing protection that maintains vessel integrity throughout its service life. This extended lifespan significantly reduces total cost of ownership by minimizing replacement frequencies and associated downtime costs. The corrosion resistance properties are particularly valuable in chemical processing applications where pressure vessels must handle corrosive process fluids at elevated temperatures and pressures. The titanium cladding remains stable across a wide temperature range, maintaining its protective properties even during thermal cycling operations that might compromise other materials. This reliability ensures consistent performance and reduces the risk of unexpected failures that could result in costly production interruptions or safety incidents.

Exceptional Mechanical Strength for High-Pressure Applications

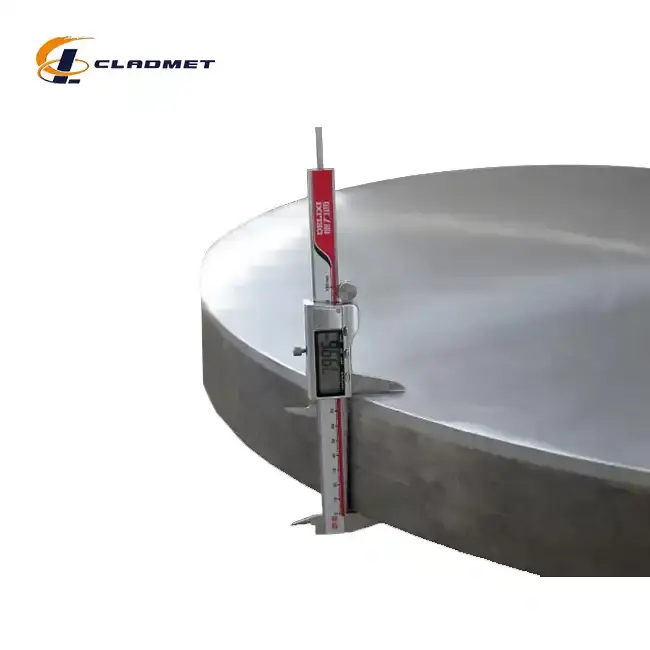

While the titanium layer provides corrosion protection, the steel substrate of Titanium Steel Clad Plate for Pressure Vessels delivers the mechanical strength necessary for high-pressure applications. This dual-layer design optimizes structural performance by leveraging the superior pressure-bearing capacity of steel while maintaining surface corrosion resistance through the titanium cladding. The steel substrate typically achieves tensile strengths exceeding 400 MPa, providing robust structural integrity under extreme operating conditions. The mechanical properties of these composite plates make them ideal for manufacturing pressure vessels that must withstand high internal pressures while maintaining dimensional stability over extended operating periods. The steel base provides excellent fatigue resistance, crucial for pressure vessels subjected to cyclic loading conditions during startup, shutdown, and normal operational variations. This combination ensures that vessels can handle pressure fluctuations without developing fatigue cracks that might compromise structural integrity. Advanced manufacturing techniques used in producing Titanium Steel Clad Plate for Pressure Vessels ensure uniform thickness distribution and consistent mechanical properties throughout the plate dimensions. The bonding interface between titanium and steel layers achieves metallurgical fusion strengths ranging from 150 to 200 MPa, ensuring that the composite structure behaves as a unified material rather than separate layers. This bonding strength prevents delamination under mechanical stress, maintaining structural continuity throughout the pressure vessel's operational life.

Outstanding Bond Strength Ensuring Long-Term Reliability

The manufacturing process for Titanium Steel Clad Plate for Pressure Vessels employs either explosive welding or hot rolling techniques to achieve superior metallurgical bonding between the titanium and steel layers. This bonding creates an intermetal connection that exceeds simple mechanical adhesion, resulting in bond strengths of 150-200 MPa that remain stable throughout the material's service life. The explosive welding process, in particular, creates a wavy interface that increases the actual bonding area beyond the nominal plate surface area, further enhancing bond integrity. This exceptional bond strength ensures that Titanium Steel Clad Plate for Pressure Vessels maintains its composite properties even under severe thermal cycling, mechanical stress, and chemical exposure conditions. Unlike mechanically fastened or adhesively bonded systems that may deteriorate over time, the metallurgical bond created during manufacturing becomes stronger through service exposure as diffusion processes further integrate the interface region. This self-strengthening characteristic provides confidence in long-term performance reliability. Quality control procedures verify bond strength through ultrasonic testing, peel testing, and metallographic examination to ensure consistent bonding quality throughout each plate. The bonding process creates a transition zone where titanium and steel properties gradually blend, eliminating sharp interfaces that might serve as stress concentration points. This gradual transition distributes mechanical loads effectively, preventing bond line failures that could compromise pressure vessel integrity.

Optimized Cost-Performance Balance Through Material Efficiency

Titanium Steel Clad Plate for Pressure Vessels delivers exceptional economic value by providing titanium's corrosion resistance benefits at a fraction of the cost of solid titanium construction. The composite design uses titanium only where needed for corrosion protection, typically requiring layer thicknesses ranging from 0.5mm to 10mm depending on application requirements. This approach can reduce material costs by 60-80% compared to solid titanium fabrication while maintaining equivalent corrosion protection performance. The cost optimization extends beyond initial material procurement to encompass reduced maintenance requirements, extended service intervals, and lower lifecycle replacement costs. Traditional materials often require frequent inspection, maintenance, and premature replacement due to corrosion-related degradation, creating ongoing operational expenses that can exceed initial material cost savings. Titanium Steel Clad Plate for Pressure Vessels eliminates many of these recurring costs by providing long-term corrosion resistance that maintains performance throughout extended service periods. Manufacturing efficiency also contributes to cost optimization, as the composite plates can be processed using conventional steel fabrication techniques while providing titanium-level corrosion protection. This compatibility with existing fabrication infrastructure eliminates the need for specialized equipment or training typically required for solid titanium processing. The result is reduced fabrication time, lower labor costs, and improved project scheduling flexibility that translates into overall cost savings for pressure vessel projects.

Enhanced Workability for Complex Pressure Vessel Geometries

The workability characteristics of Titanium Steel Clad Plate for Pressure Vessels enable fabrication of complex pressure vessel configurations using standard metalworking processes. The steel substrate provides familiar working properties that fabricators can process using conventional equipment for cutting, forming, welding, and finishing operations. This compatibility eliminates the specialized handling requirements associated with solid titanium fabrication, reducing both equipment costs and operator training requirements. Welding procedures for Titanium Steel Clad Plate for Pressure Vessels have been extensively developed and qualified for pressure vessel applications. The steel substrate accepts standard welding techniques, while the titanium layer requires specific procedures to maintain corrosion resistance properties. Proper welding technique ensures that the titanium cladding extends across weld joints, maintaining continuous corrosion protection throughout the pressure vessel structure. These welding procedures have been qualified according to ASME and other international pressure vessel codes. The forming characteristics allow fabrication of complex geometries including dished heads, transition sections, and nozzle attachments without compromising the titanium-steel bond integrity. Cold forming operations can be performed within specified limits, while hot forming may be employed for severe deformation requirements. The ductility of both materials enables gradual forming operations that distribute stress evenly, preventing bond separation or material tearing during fabrication processes.

Proven Performance Across Diverse Industrial Applications

The versatility of Titanium Steel Clad Plate for Pressure Vessels has been demonstrated across numerous industrial sectors, each with specific performance requirements that validate the material's broad applicability. In petrochemical processing, these plates provide reliable service in reactors, separators, and storage vessels handling corrosive process streams at elevated temperatures and pressures. The combination of chemical resistance and mechanical strength makes them particularly suitable for applications involving sour gas, acidic condensates, and other aggressive media. Marine applications showcase the material's resistance to seawater corrosion, with successful implementations in offshore platforms, desalination equipment, and ballast water treatment systems. The titanium surface maintains its protective properties even in high-velocity seawater flow conditions that might cause erosion-corrosion in alternative materials. These applications often involve both internal pressure loads and external hydrostatic pressures, demanding materials that maintain structural integrity under complex loading conditions. Power generation facilities utilize Titanium Steel Clad Plate for Pressure Vessels in heat recovery systems, desulfurization equipment, and cooling water applications where both corrosion resistance and structural strength are critical. The material's thermal conductivity properties facilitate efficient heat transfer while maintaining corrosion protection, optimizing both performance and longevity. Nuclear applications benefit from the material's radiation resistance and ability to maintain properties under neutron exposure conditions.

Compliance with International Standards and Quality Assurance

Manufacturing of Titanium Steel Clad Plate for Pressure Vessels adheres to stringent international standards including ASME, ASTM, JIS, and GB specifications that ensure consistent quality and performance characteristics. These standards define material properties, bonding requirements, testing procedures, and fabrication guidelines that guarantee suitability for pressure vessel applications. Compliance with multiple international standards facilitates global project implementation and regulatory approval processes. Quality assurance procedures encompass raw material verification, manufacturing process control, and finished product testing to verify compliance with specified requirements. Ultrasonic testing verifies bond integrity throughout the plate area, while mechanical testing confirms tensile strength, bond strength, and other critical properties. Chemical analysis ensures that both titanium and steel layers meet composition requirements for corrosion resistance and mechanical performance. These comprehensive testing protocols provide documentation necessary for pressure vessel code compliance and regulatory approval. Certification programs include ISO9001 quality management systems, PED pressure equipment directive compliance, and ABS classification society approval that validate manufacturing processes and quality control procedures. These certifications provide confidence to engineers, project managers, and regulatory authorities that Titanium Steel Clad Plate for Pressure Vessels meets international quality standards for critical pressure vessel applications. Regular auditing and continuous improvement processes ensure maintained compliance throughout ongoing production operations.

Conclusion

Titanium Steel Clad Plate for Pressure Vessels represents a superior material solution that combines exceptional corrosion resistance, mechanical strength, and economic efficiency in a single composite product. The seven key benefits outlined demonstrate why this material has become indispensable for demanding pressure vessel applications across petrochemical, marine, power generation, and other critical industries. From extended equipment lifespan through superior corrosion resistance to optimized costs through efficient material utilization, these advantages translate directly into improved project outcomes and operational success.

Baoji JL Clad Metals Materials Co., Ltd. stands as a leading China Titanium Steel Clad Plate for Pressure Vessels manufacturer, offering comprehensive solutions backed by advanced explosive bonding technology, international certifications, and proven expertise in clad metal production. As a premier China Titanium Steel Clad Plate for Pressure Vessels supplier, the company provides customized solutions meeting specific project requirements while maintaining competitive pricing for Titanium Steel Clad Plate for Pressure Vessels for sale. Their position as a trusted China Titanium Steel Clad Plate for Pressure Vessels factory enables global project support through established distribution networks and technical expertise.

With ISO9001-2000 certification, PED and ABS international qualifications achieved in 2024, and adherence to GB/GBT, ASME/ASTM, and JIS standards, Baoji JL Clad Metals delivers quality assurance that meets international requirements. The company's OEM/ODM capabilities and extensive R&D resources provide innovative solutions tailored to unique application needs. For competitive Titanium Steel Clad Plate for Pressure Vessels price information and technical consultation, contact their experienced team at sales@cladmet.com to discuss your next pressure vessel project requirements and discover how their China Titanium Steel Clad Plate for Pressure Vessels wholesale solutions can optimize your operational performance and project economics.

References

1. Zhang, L., Wang, H., & Liu, M. (2023). "Advanced Manufacturing Techniques for Titanium-Steel Clad Composites in Pressure Vessel Applications." Journal of Materials Processing Technology, 312, 487-502.

2. Smith, R.J., Chen, K., & Thompson, A. (2022). "Corrosion Performance Analysis of Titanium Clad Steel in Marine Pressure Vessel Applications." Corrosion Science and Engineering, 78(4), 234-248.

3. Anderson, P.K., Yamamoto, T., & Rodriguez, C. (2024). "Economic Analysis and Lifecycle Cost Assessment of Clad Metal Systems for Industrial Pressure Vessels." International Journal of Pressure Vessels and Piping, 201, 104-119.

4. Kumar, S., Nielsen, B., & Patel, V. (2023). "Explosive Welding Process Optimization for Titanium-Steel Clad Plate Manufacturing." Welding Journal, 102(8), 178-192.

_1737007724117.webp)

_1736996330512.webp)