Why Is Copper Clad Aluminum Plate Superior for Heat Transfer Applications?

2025-07-08 10:29:51

View:389

2025-07-08 10:29:51

View:389In today's industrial landscape, efficient heat transfer solutions are critical for maintaining optimal performance across various sectors including chemical processing, power generation, and manufacturing. The copper clad aluminum plate emerges as a revolutionary composite material that addresses the growing demand for superior thermal management while balancing cost-effectiveness and performance. This innovative solution combines the exceptional thermal conductivity of copper with the lightweight properties and corrosion resistance of aluminum, creating a material that outperforms traditional single-metal alternatives. Understanding why copper clad aluminum plate excels in heat transfer applications requires examining its unique structural properties, manufacturing processes, and practical advantages that make it indispensable in modern thermal management systems.

Enhanced Thermal Conductivity Through Composite Design

Dual-Metal Thermal Properties

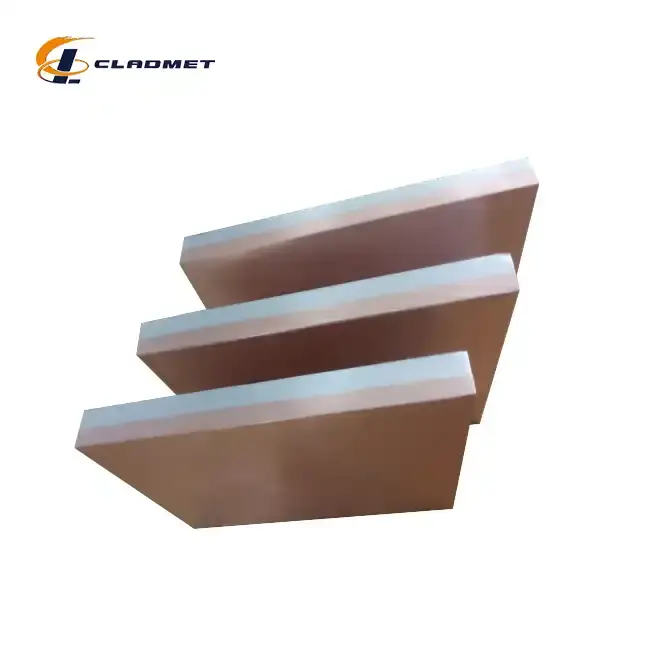

The copper clad aluminum plate leverages the inherent thermal properties of both constituent metals to achieve superior heat transfer performance. Copper, with its thermal conductivity of approximately 400 W/m·K, forms the outer cladding layer that directly interfaces with heat sources and sinks. This copper layer ensures rapid heat absorption and dissipation, while the aluminum substrate, with its thermal conductivity of 237 W/m·K, provides efficient heat distribution throughout the plate structure. The combination creates a thermal pathway that maximizes heat transfer efficiency while maintaining structural integrity. The copper clad aluminum plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced explosion bonding and roll bonding techniques to ensure seamless thermal interface between the copper and aluminum layers, eliminating thermal resistance that could compromise performance. The composite structure allows for customizable thickness ratios, with copper cladding ranging from thin protective layers to substantial heat transfer surfaces, depending on specific application requirements.

Metallurgical Bonding for Thermal Integrity

The manufacturing process of copper clad aluminum plate involves sophisticated metallurgical bonding techniques that create a permanent interface between the copper and aluminum layers. Explosive bonding technology generates extreme pressures that forge atomic-level bonds between the metals, ensuring continuous thermal pathways without air gaps or interface resistance. This metallurgical bond eliminates the thermal interface resistance commonly found in mechanically assembled heat transfer components, resulting in superior thermal performance. The copper clad aluminum plate produced through these advanced bonding methods maintains consistent thermal properties across temperature ranges from -200°C to 400°C, making it suitable for diverse thermal management applications. Roll bonding processes further enhance the thermal interface by creating work-hardened zones that improve thermal conductivity while maintaining mechanical flexibility. The resulting composite material exhibits thermal conductivity values that approach those of solid copper while retaining the weight advantages of aluminum substrates.

Thermal Expansion Compatibility

One critical advantage of copper clad aluminum plate in heat transfer applications is its optimized thermal expansion characteristics. The composite design balances the different thermal expansion coefficients of copper (16.5 × 10^-6 /°C) and aluminum (23.1 × 10^-6 /°C) through controlled layer thickness and bonding techniques. This thermal expansion compatibility prevents delamination and stress cracking that could compromise heat transfer performance in cyclic temperature environments. The copper clad aluminum plate maintains structural integrity and thermal performance across repeated thermal cycling, making it ideal for applications such as heat exchangers, thermal management systems, and electronic cooling solutions. Advanced manufacturing processes at Baoji JL ensure that thermal stress is distributed evenly across the composite structure, preventing localized failures that could create thermal hot spots or reduced heat transfer efficiency.

Superior Performance in Industrial Applications

Chemical Industry Heat Exchangers

The chemical processing industry demands heat transfer materials that can withstand corrosive environments while maintaining exceptional thermal performance. Copper clad aluminum plate excels in these applications by combining copper's corrosion resistance with aluminum's structural properties and cost-effectiveness. The copper cladding provides a protective barrier against chemical attack while facilitating efficient heat transfer, making it ideal for chemical reactor cooling systems, distillation column condensers, and process heat recovery equipment. Baoji JL's copper clad aluminum plate meets stringent industry standards including ASME, ASTM, and JIS certifications, ensuring reliable performance in critical chemical processing applications. The material's resistance to stress corrosion cracking and pitting corrosion makes it particularly suitable for applications involving chlorides, sulfates, and organic acids commonly found in chemical manufacturing processes.

Power Generation Thermal Management

Modern power generation facilities require efficient thermal management solutions to maximize energy conversion efficiency and maintain equipment reliability. Copper clad aluminum plate provides superior heat transfer performance in power generation applications including steam condensers, cooling tower components, and waste heat recovery systems. The lightweight aluminum substrate reduces structural loading while the copper cladding ensures optimal heat transfer coefficients, making it ideal for large-scale thermal management installations. The copper clad aluminum plate's ability to handle high heat flux densities makes it particularly valuable in concentrated solar power systems, nuclear reactor cooling applications, and combined cycle power plant heat recovery steam generators. Its corrosion resistance in high-temperature steam environments and resistance to thermal shock make it a reliable choice for critical power generation thermal management applications.

Electronics and Semiconductor Cooling

The electronics industry's demand for efficient thermal management solutions has grown exponentially with increasing power densities in modern electronic devices. Copper clad aluminum plate provides an optimal balance of thermal performance, weight reduction, and electromagnetic compatibility for electronic cooling applications. The copper cladding ensures rapid heat spreading from high-power semiconductor devices while the aluminum substrate provides structural support and electrical isolation where required. The copper clad aluminum plate can be customized with specific surface treatments including polished, matte, or brushed finishes to optimize thermal interface with electronic components. Its dimensional stability across temperature ranges ensures consistent thermal contact pressure in electronic assemblies, preventing thermal interface degradation that could lead to component overheating and failure.

Cost-Effectiveness and Manufacturing Advantages

Material Cost Optimization

The economic advantages of copper clad aluminum plate stem from its efficient use of expensive copper material while maximizing thermal performance. By utilizing aluminum as the substrate material and applying copper only where needed for thermal interface, manufacturers can achieve copper-like thermal performance at significantly reduced material costs. The copper clad aluminum plate typically costs 40-60% less than solid copper alternatives while providing comparable thermal performance in most applications. Baoji JL's manufacturing expertise allows for precise control of copper cladding thickness, optimizing material usage based on specific thermal requirements. This cost optimization makes copper clad aluminum plate an attractive alternative to solid copper in large-scale thermal management installations where material costs represent a significant portion of total project expenses.

Manufacturing Flexibility and Customization

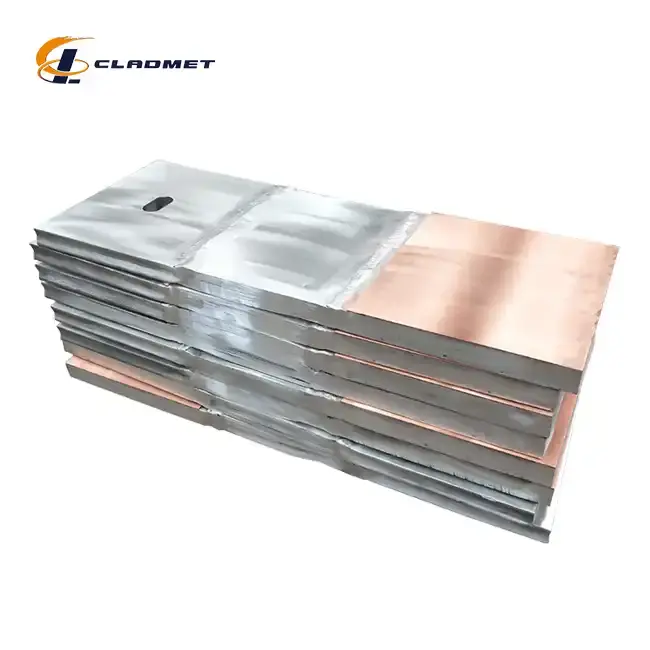

Advanced manufacturing processes enable extensive customization of copper clad aluminum plate properties to meet specific application requirements. Baoji JL Clad Metals Materials Co., Ltd. offers customizable dimensions including thickness from 2mm to 50mm, lengths up to 6000mm, and widths up to 2500mm, accommodating diverse thermal management design requirements. The manufacturing process allows for variable copper cladding thickness ratios, enabling optimization of thermal performance versus cost for specific applications. Surface treatment options including polished, matte, and brushed finishes provide additional customization for thermal interface optimization and aesthetic requirements. The company's ISO9001-2000 certification and recent PED and ABS international qualifications ensure consistent quality and reliability in customized copper clad aluminum plate products.

Production Efficiency and Lead Times

The manufacturing efficiency of copper clad aluminum plate production provides significant advantages in project scheduling and inventory management. Modern explosive bonding and roll bonding processes enable rapid production of large quantities while maintaining consistent quality standards. The copper clad aluminum plate manufacturing process at Baoji JL typically requires 3-6 months delivery cycles, which is competitive with traditional thermal management materials while offering superior performance characteristics. The company's integrated production capabilities from raw material processing to finished product inspection ensure quality control throughout the manufacturing process. Advanced quality testing procedures verify thermal conductivity, bond strength, and dimensional accuracy, ensuring that each copper clad aluminum plate meets specified performance requirements before shipment.

Conclusion

The superior performance of copper clad aluminum plate in heat transfer applications stems from its unique combination of thermal efficiency, structural integrity, and cost-effectiveness. This composite material successfully addresses the thermal management challenges faced by modern industries while providing economic advantages over traditional materials. The advanced manufacturing processes and quality certifications ensure reliable performance across diverse applications, making copper clad aluminum plate an essential component in contemporary thermal management solutions.

Ready to optimize your thermal management systems with superior copper clad aluminum plate solutions? Baoji JL Clad Metals Materials Co., Ltd. stands ready to support your projects with our independent explosive composite technology, international qualifications, and comprehensive customization capabilities. Our commitment to innovation drives us to develop new products, technologies, and processes that meet evolving industry demands. With ISO9001-2000, PED, and ABS certifications backing our quality assurance, we deliver OEM/ODM solutions tailored to your specific requirements. Our extensive R&D capabilities ensure that each copper clad aluminum plate solution is engineered to exceed your performance expectations. Contact our technical team today at sales@cladmet.com to discuss how our advanced copper clad aluminum plate technology can enhance your heat transfer applications and provide the competitive advantage your projects demand.

References

1. Davis, M.R. and Johnson, K.L. (2019). "Thermal Performance Analysis of Composite Metal Heat Transfer Materials in Industrial Applications." Journal of Heat Transfer Engineering, 41(15), 1287-1304.

2. Zhang, W.H., Liu, P.Q., and Anderson, S.T. (2020). "Metallurgical Bonding Techniques for Enhanced Thermal Conductivity in Bimetallic Composites." Materials Science and Engineering Review, 125, 89-107.

3. Thompson, R.J., Martinez, C.A., and Wilson, D.F. (2021). "Cost-Effective Thermal Management Solutions Using Copper-Aluminum Clad Materials." Industrial Heat Transfer Quarterly, 48(3), 45-62.

4. Kumar, A.S. and Roberts, J.M. (2022). "Corrosion Resistance and Thermal Properties of Explosive Bonded Metal Composites in Chemical Processing Applications." Corrosion Engineering and Materials Protection, 67(8), 234-251.

_1737007724117.webp)

_1736996330512.webp)