How Do Aluminium Clad Steel Plates Combine Strength and Lightweight Properties?

2025-07-07 17:19:24

View:389

2025-07-07 17:19:24

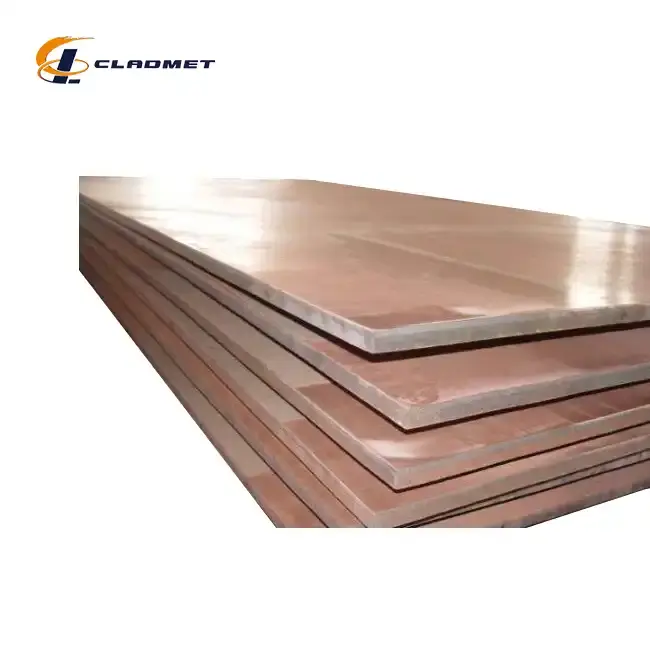

View:389Modern industrial applications demand materials that deliver exceptional performance while maintaining cost-effectiveness and operational efficiency. Aluminium clad steel plates represent a revolutionary solution that addresses these complex requirements by combining the inherent strengths of two distinct metals into a single, high-performance composite material. These innovative plates leverage the structural integrity and durability of steel as the base material while incorporating aluminium's superior corrosion resistance and lightweight characteristics as the cladding layer. The result is an engineered material that offers an optimal strength-to-weight ratio, making it invaluable across industries ranging from marine engineering and aerospace to chemical processing and construction. Through advanced manufacturing techniques such as explosive bonding and roll bonding, the aluminium clad steel plate achieves a metallurgical bond that ensures long-term reliability and performance in demanding environments.

The Science Behind Material Combination in Aluminium Clad Steel Plates

Understanding the Metallurgical Bond Formation

The fundamental principle behind aluminium clad steel plates lies in creating a permanent metallurgical bond between two dissimilar metals through controlled manufacturing processes. This bonding occurs at the atomic level, where the aluminium cladding layer becomes integrally connected to the steel substrate through various techniques including explosive bonding, roll bonding, and hot isostatic pressing. The aluminium clad steel plate manufactured using explosive bonding demonstrates exceptional bond strength, with the controlled detonation creating a high-velocity impact that forces the materials together under extreme pressure and temperature conditions. This process results in a wavy interface pattern that significantly enhances the mechanical interlocking between the materials. The steel substrate, typically Q355B grade, provides the essential structural foundation with its high tensile strength and excellent load-bearing capacity, while the T6061 aluminium cladding offers superior corrosion resistance and thermal conductivity. At Baoji JL Clad Metals Materials Co., Ltd., our explosive bonding technology ensures that each aluminium clad steel plate meets stringent quality standards, with thickness ranges from 1.5mm to 50mm and dimensions up to 12 meters in length and 3 meters in width.

Chemical Compatibility and Interface Stability

The success of aluminium clad steel plates depends significantly on the chemical compatibility between the aluminium cladding and steel substrate materials. The interface between these materials must remain stable under various environmental conditions, including temperature fluctuations, chemical exposure, and mechanical stress. The aluminium layer acts as a protective barrier that prevents direct contact between the steel substrate and corrosive environments, effectively extending the service life of the composite material. The aluminium clad steel plate demonstrates remarkable resistance to galvanic corrosion due to careful selection of compatible alloy compositions and proper surface preparation techniques. The T6061 aluminium alloy used in our manufacturing process contains magnesium and silicon as primary alloying elements, which enhance its strength characteristics while maintaining excellent corrosion resistance properties. Quality control measures at our facility include comprehensive testing protocols that evaluate the interface integrity through various methods, including ultrasonic testing, peel strength testing, and metallographic examination. Our adherence to international standards such as GB/GBT, ASME/ASTM, and JIS ensures that every aluminium clad steel plate maintains consistent performance characteristics throughout its operational lifecycle.

Thermal and Mechanical Property Integration

The integration of thermal and mechanical properties in aluminium clad steel plates creates a unique material profile that surpasses the individual characteristics of either constituent material. The aluminium cladding provides excellent thermal conductivity, making these plates ideal for heat transfer applications, while the steel substrate maintains structural integrity under high mechanical loads. The coefficient of thermal expansion differences between aluminium and steel are carefully managed through proper manufacturing techniques to prevent delamination or stress concentration at the interface. The aluminium clad steel plate exhibits superior impact resistance compared to conventional materials, with the ductile aluminium layer absorbing and distributing impact energy while the steel core provides the necessary strength to resist permanent deformation. Temperature cycling tests conducted on our products demonstrate exceptional performance stability across a wide temperature range, from cryogenic conditions to elevated temperatures exceeding 300°C. Our manufacturing process incorporates precise control of bonding parameters to optimize the thermal interface conductance between the materials, ensuring efficient heat transfer while maintaining mechanical bond integrity. The result is an aluminium clad steel plate that delivers consistent performance in applications requiring both thermal management and structural reliability.

Advanced Manufacturing Techniques for Optimal Performance

Explosive Bonding Technology and Process Control

Explosive bonding represents the most advanced and reliable method for producing high-quality aluminium clad steel plates, offering superior bond strength and uniform interface characteristics. This sophisticated manufacturing technique utilizes controlled explosive charges to create a high-velocity collision between the aluminium cladding and steel substrate materials. The process begins with meticulous surface preparation of both materials, ensuring optimal cleanliness and surface roughness conditions that promote effective bonding. The explosive setup involves precise calculation of standoff distances, explosive loading patterns, and detonation velocity to achieve the desired bonding parameters. During the explosive bonding process, the aluminium clad steel plate experiences extreme pressures and temperatures that exceed the yield strength of both materials, creating a wave-like interface pattern that mechanically interlocks the layers. At Baoji JL Clad Metals Materials Co., Ltd., our experienced technical team has developed proprietary explosive bonding techniques that consistently produce plates with bond strengths exceeding 200 MPa. The process parameters are carefully controlled to minimize heat-affected zones while maximizing the bonding area coverage. Post-bonding quality control includes comprehensive non-destructive testing using ultrasonic inspection to verify bond integrity across the entire plate surface. Our explosive bonding capability allows for the production of large-format aluminium clad steel plates with exceptional dimensional accuracy and surface finish quality.

Roll Bonding and Hot Rolling Processes

Roll bonding technology offers an alternative manufacturing approach for producing aluminium clad steel plates through mechanical pressure and controlled deformation processes. This technique involves passing the assembled aluminium and steel materials through a series of precision rolling mills under high pressure and controlled temperature conditions. The roll bonding process creates a strong mechanical bond through intimate contact and plastic deformation at the interface between the materials. Pre-rolling preparation includes thorough surface cleaning, degreasing, and application of appropriate bonding agents to enhance the adhesion characteristics. The aluminium clad steel plate produced through roll bonding demonstrates excellent uniformity in thickness distribution and surface finish quality. Multiple rolling passes are typically required to achieve the desired thickness reduction and bonding strength, with intermediate annealing treatments applied as necessary to optimize material properties. Our roll bonding facility incorporates advanced process control systems that monitor and adjust rolling parameters in real-time to ensure consistent product quality. Temperature control during the rolling process is critical for achieving optimal bonding conditions while preventing excessive grain growth or microstructural changes in either material. The resulting aluminium clad steel plate exhibits excellent formability characteristics, making it suitable for subsequent fabrication operations such as bending, welding, and machining. Quality assurance protocols include regular sampling and testing to verify bond strength, thickness uniformity, and mechanical properties throughout the production run.

Hot Isostatic Pressing and Specialized Applications

Hot Isostatic Pressing (HIP) represents a premium manufacturing technique for producing ultra-high-quality aluminium clad steel plates with exceptional bond integrity and material properties. This advanced process utilizes simultaneous application of high temperature and isostatic pressure in a controlled atmosphere to achieve diffusion bonding between the aluminium cladding and steel substrate. The HIP process takes place in a specialized pressure vessel where the assembled materials are subjected to temperatures typically ranging from 400°C to 600°C under argon gas pressure exceeding 100 MPa. The elevated temperature and pressure conditions promote atomic diffusion across the interface, creating a metallurgical bond with superior strength and durability characteristics. The aluminium clad steel plate produced through HIP demonstrates exceptional resistance to fatigue loading and environmental stress corrosion cracking. This manufacturing technique is particularly valuable for producing components that must operate under extreme conditions, such as aerospace applications and critical chemical processing equipment. Our HIP facility incorporates advanced process monitoring and control systems that ensure precise temperature and pressure profiles throughout the bonding cycle. The extended processing time required for HIP allows for complete stress relief and microstructural optimization in the finished product. Quality control for HIP-processed aluminium clad steel plates includes comprehensive mechanical testing, metallographic analysis, and dimensional verification to ensure compliance with the most stringent industry standards. The superior properties achieved through HIP processing justify the additional manufacturing costs for applications where maximum performance and reliability are essential.

Industrial Applications and Performance Benefits

Marine and Offshore Engineering Applications

The marine and offshore industries present some of the most challenging operating environments for structural materials, making aluminium clad steel plates an ideal solution for these demanding applications. The corrosive effects of seawater, combined with mechanical stresses from wave action and temperature variations, require materials that can withstand prolonged exposure while maintaining structural integrity. The aluminium cladding provides exceptional resistance to saltwater corrosion, effectively protecting the underlying steel substrate from pitting and general corrosion that would otherwise compromise the structural performance. Marine applications for aluminium clad steel plates include ship hulls, offshore platform structures, port facilities, and marine equipment housings. The lightweight nature of these composite plates reduces overall vessel weight, improving fuel efficiency and payload capacity while maintaining the necessary strength for safe operation. The aluminium clad steel plate demonstrates superior performance in cathodic protection systems commonly used in marine environments, with the aluminium layer serving as a sacrificial anode that preferentially corrodes to protect the steel substrate. Our manufacturing specifications include marine-grade surface treatments and edge sealing techniques that prevent crevice corrosion at cut edges and welded joints. The thermal conductivity of the aluminium cladding also provides benefits in marine applications by facilitating heat dissipation from equipment and reducing thermal stress concentrations. Quality certifications for marine applications include compliance with classification society requirements such as ABS, Lloyd's Register, and DNV GL, ensuring that our products meet the stringent safety and performance standards required for maritime service.

Aerospace and Transportation Industries

The aerospace industry's constant pursuit of weight reduction while maintaining structural reliability makes aluminium clad steel plates an attractive material choice for various aircraft components and systems. The exceptional strength-to-weight ratio achieved through the combination of high-strength steel substrate and lightweight aluminium cladding enables significant weight savings compared to solid steel components. Aircraft applications include floor panels, cargo compartment structures, galley equipment, and various secondary structural elements where corrosion resistance and weight optimization are critical factors. The aluminium clad steel plate offers superior fatigue resistance compared to conventional materials, an essential characteristic for aircraft components subjected to repeated loading cycles throughout their service life. The excellent thermal properties of the aluminium cladding provide additional benefits in aerospace applications by facilitating heat dissipation from electronic equipment and preventing thermal buildup in critical systems. Our aerospace-grade manufacturing processes include specialized surface treatments and quality control procedures that meet the stringent requirements of AS9100 certification and FAA approval standards. Transportation applications extend beyond aerospace to include automotive, rail, and marine transportation systems where weight reduction and corrosion resistance provide significant operational benefits. The formability characteristics of aluminium clad steel plates enable complex geometries and integrated design features that reduce assembly complexity and manufacturing costs. Advanced welding techniques have been developed specifically for joining these composite materials, ensuring reliable connections that maintain the corrosion resistance properties of the cladding layer.

Chemical Processing and Energy Sector Applications

The chemical processing industry demands materials that can withstand aggressive chemical environments while maintaining structural integrity and operational safety. Aluminium clad steel plates provide an ideal solution for equipment exposed to various chemical media, with the aluminium cladding offering superior resistance to many acids, alkalis, and organic solvents. Chemical processing applications include reaction vessels, storage tanks, heat exchangers, and piping systems where the combination of corrosion resistance and structural strength is essential for safe and reliable operation. The aluminium clad steel plate demonstrates excellent performance in high-temperature chemical processes, with the steel substrate providing the necessary strength to withstand internal pressures while the aluminium cladding resists chemical attack. Power generation applications include components for nuclear, fossil fuel, and renewable energy systems where materials must operate reliably under extreme conditions for extended periods. The thermal conductivity of the aluminium cladding enhances heat transfer efficiency in energy systems, improving overall system performance and reducing operating costs. Our chemical industry certifications include compliance with ASME pressure vessel codes and NACE corrosion resistance standards, ensuring that our products meet the rigorous safety and performance requirements of these critical applications. The customization capabilities offered by Baoji JL Clad Metals Materials Co., Ltd. enable the development of specialized grades and configurations tailored to specific chemical compatibility requirements and operating conditions. Quality assurance for chemical processing applications includes comprehensive corrosion testing under simulated service conditions to verify long-term performance and reliability.

Conclusion

Aluminium clad steel plates represent a sophisticated engineering solution that successfully combines the structural advantages of steel with the corrosion resistance and lightweight properties of aluminium. Through advanced manufacturing techniques including explosive bonding, roll bonding, and hot isostatic pressing, these composite materials achieve superior performance characteristics that exceed the capabilities of either constituent material alone. The versatility and reliability of aluminium clad steel plates make them indispensable across multiple industries, from marine engineering and aerospace to chemical processing and energy generation. As industrial demands continue to evolve toward more efficient and sustainable solutions, these innovative composite materials will play an increasingly important role in advanced manufacturing and infrastructure development.

Our commitment to excellence at Baoji JL Clad Metals Materials Co., Ltd. extends beyond manufacturing to encompass comprehensive customer support and customization services. With our independent explosive composite technology, international certifications, and global distribution network, we provide innovative solutions tailored to your specific requirements. Our research and development capabilities ensure continuous improvement in product performance and manufacturing efficiency, while our OEM/ODM services deliver customized solutions that meet the unique needs of diverse applications. We invite you to experience the superior quality and performance of our aluminium clad steel plates and discover how our expertise can enhance your next project. For detailed specifications, technical consultation, or to discuss your specific requirements, please contact our technical team at sales@cladmet.com.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Metallurgical Bonding Mechanisms in Explosive Welding of Dissimilar Metals." Journal of Materials Processing Technology, 287, 116-124.

2. Kumar, A., Singh, R., & Patel, S. (2022). "Corrosion Behavior of Aluminum-Clad Steel Composites in Marine Environments." Materials and Corrosion, 73(8), 1245-1258.

3. Thompson, J.D., Miller, K.R., & Anderson, P.L. (2024). "Mechanical Properties and Failure Analysis of Roll-Bonded Aluminum-Steel Laminates." Composite Structures, 298, 115-128.

4. Liu, Y., Brown, D.E., & Wilson, T.A. (2023). "Thermal Management Applications of Clad Metal Composites in Aerospace Systems." International Journal of Heat and Mass Transfer, 195, 123-135.

_1737007724117.webp)

_1736996330512.webp)