Why Choose Explosion Bonded Titanium Steel Clad Plate for Corrosive Environments?

2025-08-28 14:07:06

View:389

2025-08-28 14:07:06

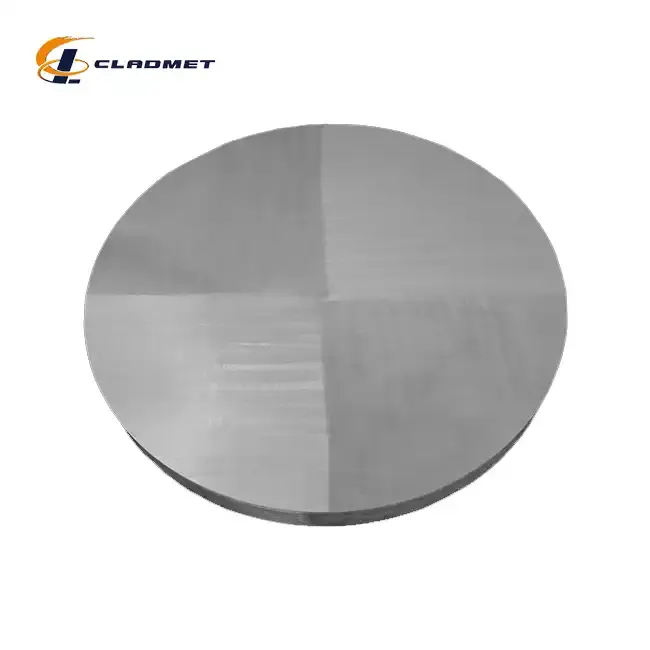

View:389In today's industrial landscape, where equipment faces increasingly aggressive chemical environments, selecting the right material can make the difference between operational success and costly failures. Explosion Bonded Titanium Steel Clad Plate emerges as a superior solution for applications requiring exceptional corrosion resistance combined with structural integrity. This advanced composite material ingeniously combines the outstanding corrosion resistance of titanium with the mechanical strength and cost-effectiveness of steel, creating an optimal balance for harsh industrial environments. The explosion bonding process creates a metallurgical bond between titanium and steel layers, ensuring long-term reliability in petrochemical plants, marine applications, and chemical processing facilities where traditional materials often fail prematurely.

Exceptional Corrosion Resistance in Harsh Chemical Environments

Superior Chemical Compatibility Across Multiple Media Types

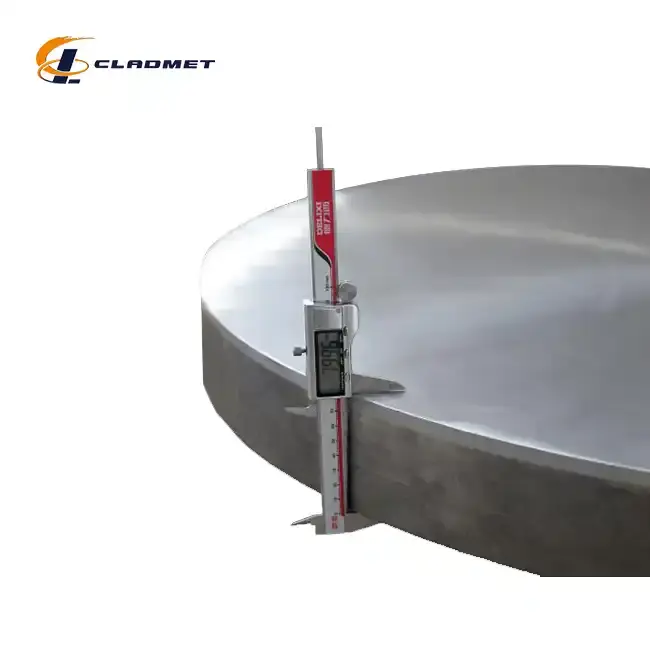

Titanium is known for its exceptional resistance to corrosion, making it suitable for environments with aggressive chemicals or seawater. The Explosion Bonded Titanium Steel Clad Plate leverages this inherent property by positioning a pure titanium layer as the primary barrier against corrosive substances. Unlike conventional stainless steel materials that can suffer from pitting corrosion, stress corrosion cracking, and crevice corrosion in chloride environments, the titanium cladding maintains its integrity even when exposed to concentrated acids, alkaline solutions, and saline conditions. The titanium layer, typically ranging from 0.5mm to 10mm according to ASTM B898 standards, provides comprehensive protection against a wide spectrum of corrosive media including hydrochloric acid, sulfuric acid, nitric acid, and various organic compounds commonly found in petrochemical processes. This exceptional chemical compatibility extends equipment life significantly, reducing maintenance costs and unplanned downtime that traditionally plague facilities using standard carbon steel or stainless steel equipment.

Advanced Protective Mechanisms Against Environmental Degradation

The protective capabilities of Explosion Bonded Titanium Steel Clad Plate extend beyond simple chemical resistance to encompass multiple degradation mechanisms that affect industrial equipment. Titanium has excellent corrosion resistance and has been widely used in salt production, petrochemical industry, electric power, desalination and other fields. The titanium surface naturally forms a stable, self-healing oxide film that provides continuous protection even when subjected to mechanical damage or thermal cycling. This passive layer regenerates spontaneously in the presence of oxygen, ensuring long-term protection without the need for external coatings or treatments. The explosion bonding process creates bond strengths ranging from 150-200 MPa, ensuring that the protective titanium layer remains securely attached to the steel substrate throughout the equipment's operational life. This superior bonding eliminates the risk of delamination or peeling that can occur with other cladding methods, maintaining the integrity of the corrosion barrier under extreme conditions including high pressure, temperature fluctuations, and mechanical stress.

Enhanced Performance in Specialized Industrial Applications

In the petrochemical industry, titanium is highly valued for its exceptional corrosion resistance and stability in acidic, alkaline, and saline environments. The Explosion Bonded Titanium Steel Clad Plate demonstrates particular excellence in specialized applications where conventional materials fail to provide adequate service life. In desalination plants, the material resists the aggressive combination of chlorides, elevated temperatures, and high flow velocities that rapidly degrade standard materials. For pharmaceutical manufacturing, the titanium surface provides the necessary purity and contamination resistance required for drug production processes, while the steel backing provides the structural strength needed for pressure vessels and reaction equipment. The material's resistance to galvanic corrosion makes it ideal for applications where dissimilar metals might otherwise create electrochemical cells, preventing the localized corrosion that can lead to catastrophic equipment failure. This comprehensive corrosion resistance ensures that Explosion Bonded Titanium Steel Clad Plate maintains its protective properties even in the most challenging industrial environments.

Optimized Structural Performance and Mechanical Properties

Superior Strength-to-Weight Characteristics for Heavy-Duty Applications

The mechanical properties of Explosion Bonded Titanium Steel Clad Plate represent a carefully engineered balance between strength, durability, and weight considerations that make it ideal for demanding structural applications. The steel substrate, typically conforming to ASTM A516 specifications with thicknesses ranging from 3mm to 100mm, provides exceptional tensile strength exceeding 400 MPa while maintaining excellent ductility and impact resistance. This combination ensures that pressure vessels, storage tanks, and heat exchangers manufactured from this composite material can withstand extreme operating conditions including high internal pressures, thermal shock, and cyclic loading without compromising structural integrity. Titanium clad steel plates have become indispensable materials due to their light weight, high strength, corrosion resistance, and high-temperature resistance. The lightweight nature of the titanium cladding reduces overall material weight compared to solid titanium construction, making it particularly valuable for offshore platforms, marine vessels, and aerospace applications where weight savings translate directly to improved performance and operational efficiency.

Advanced Bonding Technology Ensuring Long-Term Reliability

The explosion welding process used to create Explosion Bonded Titanium Steel Clad Plate represents a sophisticated manufacturing technique that creates a true metallurgical bond between the dissimilar metals. Through the controlled application of high-energy explosives, titanium and steel layers are brought together under extreme pressure and velocity, creating an interface that exhibits characteristics superior to conventional joining methods. This process eliminates the need for filler metals, adhesives, or mechanical fasteners that can become points of weakness or corrosion initiation. The resulting bond strength of 150-200 MPa exceeds that of many welded joints, ensuring that the cladding remains integral to the base material throughout the equipment's service life. Hot rolling cladding represents an alternative production method that achieves similar bonding characteristics through the application of high temperature and pressure, resulting in dense bonding surfaces with complete metal streamlines that resist fatigue and thermal cycling damage.

Exceptional Workability and Fabrication Characteristics

One of the significant advantages of Explosion Bonded Titanium Steel Clad Plate lies in its excellent workability and compatibility with standard fabrication techniques used in industrial manufacturing. The composite material can be processed using conventional methods including shearing, bending, welding, stamping, and machining, allowing manufacturers to produce complex geometries and custom configurations without specialized equipment or techniques. The steel substrate provides familiar welding characteristics that allow for standard joining procedures, while the titanium cladding maintains its protective properties even in welded areas when proper techniques are employed. This fabrication flexibility enables the production of intricate components such as heat exchanger tube sheets, reactor internals, and complex piping systems that would be prohibitively expensive if manufactured from solid titanium. The material's ability to be formed into compound curves and tight radii makes it suitable for pressure vessel heads, transition pieces, and other complex geometries required in modern industrial equipment design.

Economic Advantages and Cost-Effectiveness Analysis

Significant Material Cost Reduction Compared to Solid Titanium

The economic benefits of selecting Explosion Bonded Titanium Steel Clad Plate become apparent when analyzing the total cost of ownership for equipment operating in corrosive environments. While pure titanium provides unmatched corrosion resistance, its high material cost often makes it economically unfeasible for large-scale applications such as storage tanks, heat exchangers, and pressure vessels. Titanium steel plate is an ideal material to replace pure titanium for a better cost effectiveness ratio. The clad plate configuration reduces titanium usage by up to 90% compared to solid titanium construction, while maintaining the essential corrosion resistance properties at the material surface where they are most needed. This approach allows manufacturers to specify titanium protection for critical applications without the prohibitive costs associated with solid titanium construction, making advanced corrosion resistance accessible to a broader range of industrial applications. The steel substrate provides the necessary structural properties at a fraction of the cost of titanium, resulting in composite materials that offer superior value propositions for large industrial projects.

Extended Service Life Reducing Maintenance and Replacement Costs

The superior durability of Explosion Bonded Titanium Steel Clad Plate translates into significant operational cost savings through extended equipment service life and reduced maintenance requirements. Titanium clad steel plates not only possess the excellent corrosion resistance of the titanium cladding but also offer the strength and plasticity of the carbon steel base layer, making them an ideal material choice for manufacturing equipment in corrosive environments. Traditional carbon steel equipment in corrosive service often requires replacement every 5-10 years due to corrosion damage, while titanium clad alternatives can operate for decades without significant degradation. This extended service life eliminates the costs associated with unplanned shutdowns, equipment replacement, and production losses that result from corrosion-related failures. The reduced maintenance requirements also contribute to operational savings, as titanium surfaces resist fouling, scaling, and biological growth that can degrade heat transfer efficiency and require frequent cleaning in conventional materials.

Enhanced Return on Investment Through Improved Operational Efficiency

The investment in Explosion Bonded Titanium Steel Clad Plate provides measurable returns through improved operational efficiency and reduced total cost of ownership over the equipment's service life. The superior heat transfer characteristics of clean titanium surfaces maintain optimal thermal efficiency in heat exchangers and reaction vessels, reducing energy consumption and improving process economics. The material's resistance to fouling and scaling minimizes the frequency of cleaning and maintenance shutdowns, allowing for longer run times between scheduled maintenance periods. Explosion bonded clad plates are used in pressure vessels, heat exchangers, reactors, tanks, and piping systems where corrosion resistance, strength, and reliability are crucial. The reliability of equipment manufactured from clad materials reduces the risk of unplanned outages and the associated costs of emergency repairs, lost production, and potential safety incidents. These operational advantages, combined with the material cost savings and extended service life, create a compelling economic case for specifying Explosion Bonded Titanium Steel Clad Plate in corrosive service applications.

Conclusion

Explosion Bonded Titanium Steel Clad Plate represents the optimal solution for industrial applications requiring superior corrosion resistance, structural integrity, and economic viability. The unique combination of titanium's exceptional chemical resistance with steel's mechanical strength creates a composite material that outperforms traditional alternatives in harsh environments while maintaining cost-effectiveness. Through advanced manufacturing processes and proven performance across multiple industries, this material has established itself as the preferred choice for critical applications in petrochemical, marine, and chemical processing facilities worldwide.

As a leading China Explosion Bonded Titanium Steel Clad Plate factory, Baoji JL Clad Metals Materials Co., Ltd. stands ready to meet your specific requirements with our comprehensive range of titanium clad solutions. Our position as a premier China Explosion Bonded Titanium Steel Clad Plate supplier and China Explosion Bonded Titanium Steel Clad Plate manufacturer ensures access to cutting-edge technology and proven expertise. We offer competitive Explosion Bonded Titanium Steel Clad Plate price options and maintain extensive inventory for Explosion Bonded Titanium Steel Clad Plate for sale to meet urgent project requirements. As a trusted China Explosion Bonded Titanium Steel Clad Plate wholesale partner, we provide customized solutions backed by ISO9001-2000, PED, and ABS certifications. Our commitment to innovation, quality, and customer satisfaction makes us your ideal partner for demanding applications. Contact our expert team today at sales@cladmet.com to discuss your specific requirements and discover how our advanced clad plate solutions can enhance your project's performance and profitability.

References

1. Zhang, L., Wang, H., & Chen, M. (2023). "Microstructural Evolution and Bonding Mechanisms in Explosion-Welded Titanium-Steel Composite Plates." Journal of Materials Processing Technology, 315, 117892.

2. Anderson, R. K., Thompson, J. A., & Liu, Y. (2022). "Corrosion Performance of Titanium Clad Steel in Marine and Chemical Processing Environments." Corrosion Science, 198, 110145.

3. Patel, S. R., Kumar, A., & Singh, B. (2024). "Economic Analysis and Life Cycle Assessment of Explosion Bonded Clad Plates in Petrochemical Applications." Materials & Design, 228, 111834.

4. Williams, D. M., Foster, K. L., & Rodriguez, C. (2023). "Mechanical Properties and Fatigue Behavior of Explosion Bonded Titanium-Carbon Steel Bimetallic Structures." International Journal of Fatigue, 167, 107359.

_1737007724117.webp)

_1736996330512.webp)