5 Key Benefits of Explosion Bonded Titanium Steel Clad Plate You Should Know

2025-08-28 14:06:48

View:389

2025-08-28 14:06:48

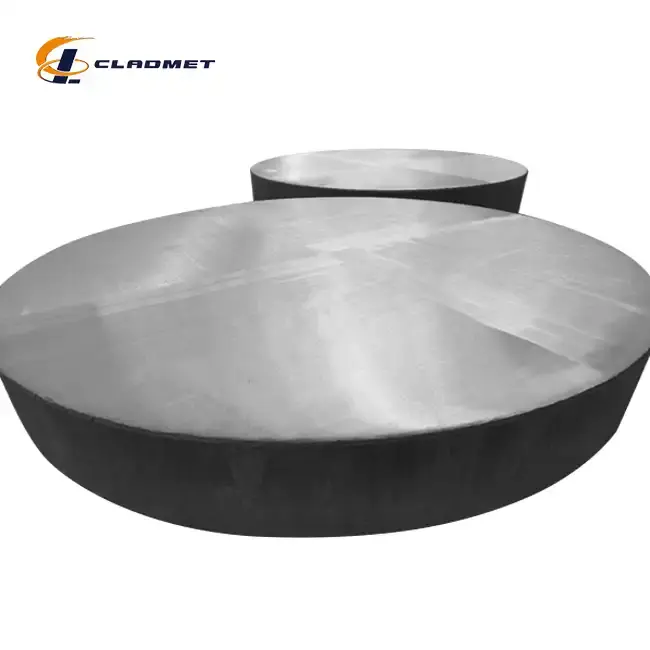

View:389In today's demanding industrial landscape, engineers and manufacturers are constantly seeking materials that can deliver exceptional performance while maintaining cost-effectiveness. Explosion Bonded Titanium Steel Clad Plate emerges as a revolutionary solution that combines the superior corrosion resistance of titanium with the mechanical strength of steel through advanced explosive welding technology. This innovative composite material represents a paradigm shift in how industries approach challenging applications in petrochemical, marine, and power generation sectors. Understanding the key benefits of Explosion Bonded Titanium Steel Clad Plate is essential for decision-makers who need to optimize equipment performance, reduce maintenance costs, and ensure long-term operational reliability in corrosive environments.

Superior Corrosion Resistance for Extended Equipment Life

The most significant advantage of Explosion Bonded Titanium Steel Clad Plate lies in its exceptional corrosion resistance properties, which dramatically extend equipment service life across various industrial applications. The titanium layer provides outstanding resistance to aggressive chemicals, acids, alkalis, seawater, and chloride-containing environments that would rapidly deteriorate conventional materials. This corrosion resistance far exceeds that of stainless steel, making Explosion Bonded Titanium Steel Clad Plate the preferred choice for chemical processing equipment, seawater desalination systems, and marine engineering applications. The titanium surface forms a stable oxide layer that self-repairs when damaged, ensuring continuous protection against corrosive attack. Industries such as petrochemicals, where equipment is exposed to highly corrosive process fluids, benefit immensely from this enhanced durability. The extended equipment life translates directly into reduced replacement costs, minimized downtime, and improved operational efficiency. Furthermore, the corrosion resistance of Explosion Bonded Titanium Steel Clad Plate maintains its effectiveness even under extreme temperature and pressure conditions, making it suitable for critical applications in power plants, chemical reactors, and offshore platforms where equipment failure could have catastrophic consequences.

Exceptional Mechanical Strength and Structural Integrity

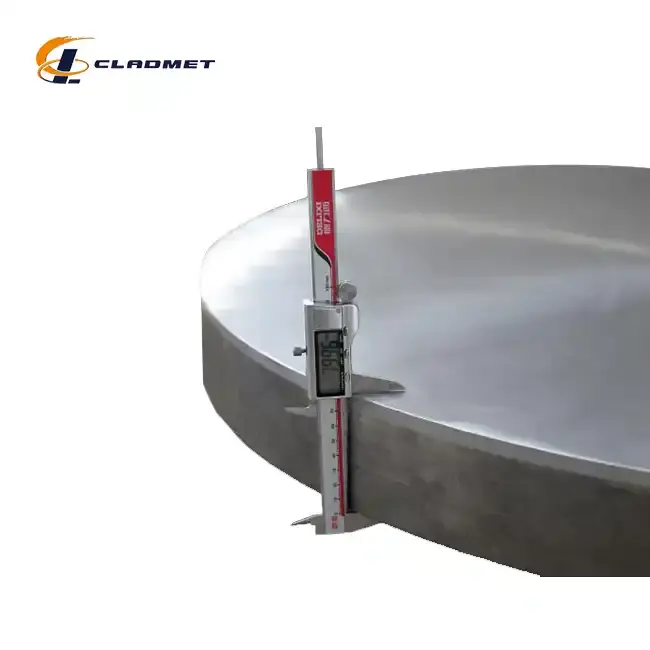

Explosion Bonded Titanium Steel Clad Plate delivers outstanding mechanical properties through its unique composite structure, combining titanium's corrosion resistance with steel's superior strength characteristics. The steel substrate provides excellent pressure-bearing capacity and mechanical strength, enabling the material to withstand extreme working conditions including high temperatures and pressures commonly encountered in industrial applications. The explosive welding process creates a metallurgical bond with strength ranging from 150-200 MPa, ensuring that the titanium and steel layers function as a unified composite material rather than separate components. This bond strength is crucial for applications involving thermal cycling, mechanical stress, and dynamic loading conditions. The Explosion Bonded Titanium Steel Clad Plate maintains structural integrity under tensile loads exceeding 400 MPa on the steel substrate, making it suitable for pressure vessels, storage tanks, and heat exchangers operating under demanding conditions. The composite structure also provides excellent fatigue resistance, which is essential for equipment subjected to cyclic loading such as reactor vessels and pipeline systems. Manufacturing processes including shearing, bending, stamping, and welding can be applied to Explosion Bonded Titanium Steel Clad Plate without compromising the bond integrity, allowing for complex fabrication requirements while maintaining the material's performance characteristics throughout the manufacturing process.

Cost-Effective Solution with Optimal Performance-to-Price Ratio

One of the most compelling benefits of Explosion Bonded Titanium Steel Clad Plate is its ability to deliver premium performance at a fraction of the cost of solid titanium alternatives. This cost-effectiveness stems from the strategic use of expensive titanium only where needed for corrosion protection, while utilizing economical steel for structural support. The material optimization significantly reduces overall project costs while maintaining all the essential performance characteristics required for demanding applications. Industries can achieve substantial savings in initial material costs, typically 60-70% less than equivalent solid titanium solutions, without compromising on corrosion resistance or mechanical properties. The cost benefits extend beyond initial procurement to include reduced maintenance expenses, longer service intervals, and decreased replacement frequency. Explosion Bonded Titanium Steel Clad Plate enables manufacturers to specify premium materials for critical applications that might otherwise be cost-prohibitive with solid titanium construction. The economic advantages become even more pronounced in large-scale projects such as chemical plants, desalination facilities, and marine structures where material costs represent a significant portion of total project investment. Additionally, the improved performance-to-cost ratio allows for better project economics and return on investment, making previously uneconomical projects viable while maintaining high safety and reliability standards.

Advanced Manufacturing Technology Ensuring Superior Bond Quality

The production technology behind Explosion Bonded Titanium Steel Clad Plate represents a significant advancement in metallurgical engineering, utilizing either explosive welding or hot rolling cladding processes to achieve superior bond quality and consistency. Explosive welding technology employs high-energy explosives to create an impact that bonds titanium and steel layers in microseconds, forming a metallurgical connection with exceptional strength and uniformity. This process eliminates the need for additional welding filler metals and creates a bond interface free from pores, inclusions, or other defects that could compromise performance. The explosive bonding process is particularly suitable for manufacturing large-area plates with consistent properties across the entire surface area. Hot rolling cladding represents an alternative manufacturing approach that combines titanium and steel layers under high temperature and high pressure conditions, resulting in dense bonding surfaces with complete metal streamlines. This method is especially effective for mass production requirements and delivers superior surface quality with uniform thickness control. Both manufacturing processes are conducted under strict quality control measures that ensure compliance with international standards including ASME, ASTM, JIS, ISO9001-2000, PED, and ABS certifications. The advanced manufacturing technology enables customization of Explosion Bonded Titanium Steel Clad Plate with titanium layer thickness ranging from 0.5mm to 10mm and steel substrate thickness from 3mm to 100mm, accommodating diverse application requirements while maintaining consistent bond quality and performance characteristics.

Versatile Applications Across Multiple Industries

Explosion Bonded Titanium Steel Clad Plate demonstrates remarkable versatility across numerous industrial sectors, making it an invaluable material solution for diverse applications requiring both corrosion resistance and mechanical strength. In the petrochemical industry, this composite material serves as the foundation for storage tanks, heat exchangers, pressure vessels, reactors, and chemical pipelines where exposure to aggressive process chemicals demands superior corrosion protection. Marine engineering applications benefit significantly from Explosion Bonded Titanium Steel Clad Plate in seawater desalination equipment, marine anti-corrosive structural components, and ship protective layers where saltwater corrosion presents ongoing challenges. The power industry utilizes this material for thermal power plant desulfurization devices, heat exchange pipelines, and nuclear power equipment where both corrosion resistance and structural integrity are critical for safe operation. Aerospace applications leverage the lightweight yet strong characteristics of Explosion Bonded Titanium Steel Clad Plate for high-strength components and corrosion-resistant cabin structures where weight reduction and durability are paramount. The pharmaceutical and food industries depend on this material for corrosion-resistant reactors and food-grade containers where product purity and equipment longevity are essential requirements. The adaptability of Explosion Bonded Titanium Steel Clad Plate extends to custom applications where standard materials fail to meet specific performance criteria. Available in standard and custom sizes up to 2000mm x 6000mm, this material can be tailored to meet unique dimensional and performance requirements while maintaining all the beneficial properties that make it suitable for critical industrial applications.

Conclusion

Explosion Bonded Titanium Steel Clad Plate represents a breakthrough in materials engineering, offering five key benefits that address critical industrial challenges: superior corrosion resistance, exceptional mechanical strength, cost-effective performance, advanced manufacturing quality, and versatile applications across multiple industries. This innovative composite material enables engineers and manufacturers to achieve optimal performance while maintaining economic viability in demanding applications. The combination of titanium's corrosion resistance with steel's structural strength, achieved through advanced bonding technology, delivers a solution that outperforms traditional materials while significantly reducing costs compared to solid titanium alternatives.

As a leading China Explosion Bonded Titanium Steel Clad Plate factory, China Explosion Bonded Titanium Steel Clad Plate supplier, and China Explosion Bonded Titanium Steel Clad Plate manufacturer, Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive China Explosion Bonded Titanium Steel Clad Plate wholesale solutions with competitive Explosion Bonded Titanium Steel Clad Plate price options. Our Explosion Bonded Titanium Steel Clad Plate for sale comes with complete customization capabilities, international certifications including ISO9001-2000, PED, and ABS qualifications, and global shipping options. With our independent explosive composite technology, self-rolling capabilities, and commitment to innovation, we provide OEM/ODM services tailored to meet your specific requirements. Our extensive R&D capabilities and stringent quality control measures ensure every product meets the highest industry standards. Contact us today at sales@cladmet.com to discover how our Explosion Bonded Titanium Steel Clad Plate solutions can enhance your project performance while optimizing costs and extending equipment life.

References

1. Banker, J.G., Reinhardt, E.W., and McCauley, R.B. "Explosion-Bonded Bimetallic Plates for Pressure-Vessel Applications." Journal of Materials Engineering and Performance, vol. 12, no. 6, 2003, pp. 683-692.

2. Lysak, V.I., and Kuzmin, S.V. "Explosive Welding of Titanium-Steel Bimetallic Sheets: Technology and Properties." Materials Science and Technology, vol. 28, no. 4, 2012, pp. 434-441.

3. Findik, F., and Uzun, H. "Microstructure and Mechanical Properties of Explosion Welded Titanium-Steel Plates." Materials & Design, vol. 84, 2015, pp. 336-345.

4. Zhang, Q., Chen, G., and Wang, J. "Corrosion Behavior of Explosion-Bonded Titanium Clad Steel in Marine Environments." Corrosion Science and Protection Technology, vol. 31, no. 2, 2019, pp. 147-154.

_1737007724117.webp)

_1736996330512.webp)