Why Choose Aluminum Copper Clad Rods for High-Demand Electrical Applications?

2025-06-30 08:57:35

View:389

2025-06-30 08:57:35

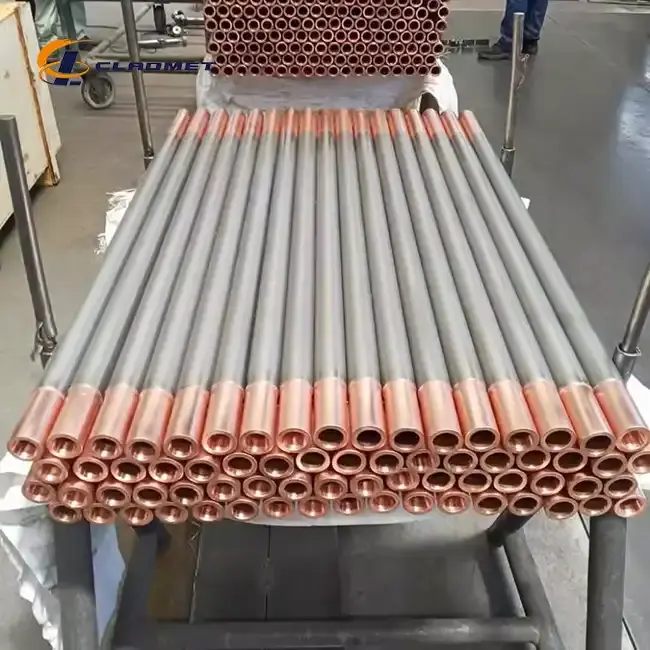

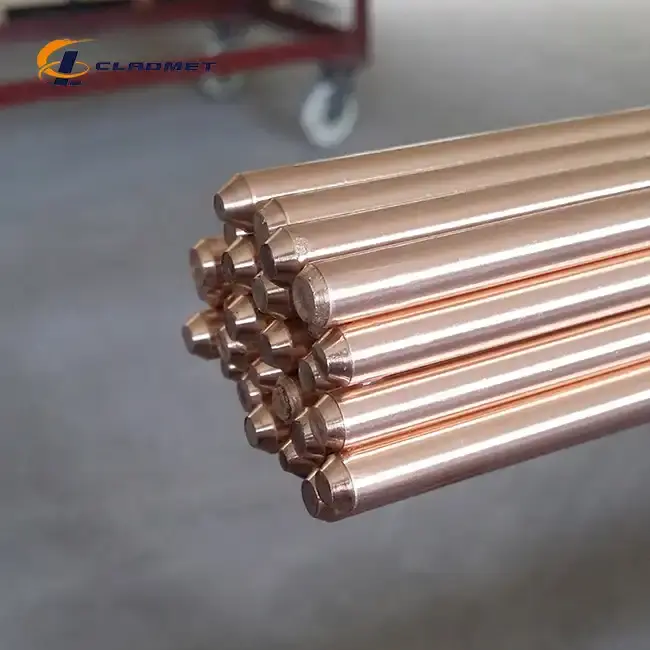

View:389In today's rapidly evolving electrical industry, engineers and manufacturers face increasing demands for materials that deliver superior performance while maintaining cost-effectiveness and reliability. Copper aluminum clad rod technology has emerged as a revolutionary solution that addresses these critical requirements through innovative metallurgical engineering. These bi-metallic products combine the exceptional electrical conductivity of copper with the lightweight properties and corrosion resistance of aluminum, creating a synergistic material that outperforms traditional single-metal alternatives. The growing adoption of copper aluminum clad rods across various high-demand electrical applications stems from their unique ability to optimize electrical performance while reducing weight and material costs, making them indispensable components in modern electrical infrastructure, renewable energy systems, and advanced industrial applications.

Superior Electrical Performance and Conductivity Characteristics

Enhanced Current Carrying Capacity

The copper aluminum clad rod demonstrates exceptional current carrying capacity that surpasses conventional aluminum conductors while maintaining cost advantages over pure copper alternatives. The copper cladding layer, typically ranging from 10% to 40% of the total cross-sectional area, provides the primary conductive pathway for electrical current flow. This design ensures that electrical resistance remains minimal while maximizing current transmission efficiency. In high-demand electrical applications such as power transmission lines, electrical busbars, and industrial wiring systems, the copper aluminum clad rod delivers consistent performance under varying load conditions. The metallurgical bond created through advanced explosion welding techniques ensures seamless current transfer between the copper cladding and aluminum core, eliminating potential hot spots or resistance discontinuities that could compromise system reliability. Furthermore, the thermal expansion compatibility between copper and aluminum layers prevents delamination under temperature cycling, maintaining electrical integrity throughout the operational lifespan.

Optimized Impedance Control

Electrical impedance characteristics play a crucial role in high-frequency applications and power quality management systems. The copper aluminum clad rod offers superior impedance control compared to traditional aluminum conductors due to the copper cladding's inherent electrical properties. The skin effect phenomenon, where high-frequency currents tend to flow near the conductor surface, is effectively managed by the copper cladding layer. This results in reduced AC resistance and improved power transmission efficiency, particularly in applications involving variable frequency drives, switch-mode power supplies, and renewable energy conversion systems. The precise control of cladding thickness allows engineers to tailor impedance characteristics to specific application requirements, ensuring optimal performance in complex electrical networks. Additionally, the smooth copper surface finish minimizes surface roughness effects that can contribute to additional losses in high-frequency applications.

Temperature Coefficient Stability

Temperature variations significantly impact electrical conductor performance, making temperature coefficient stability a critical consideration in high-demand applications. The copper aluminum clad rod exhibits superior temperature coefficient characteristics compared to pure aluminum conductors, primarily due to the copper cladding's lower temperature coefficient of resistance. This property ensures more stable electrical performance across operating temperature ranges typically encountered in industrial and power generation applications. The thermal mass distribution between copper and aluminum layers provides excellent heat dissipation characteristics, preventing localized overheating that could lead to performance degradation or premature failure. In applications such as motor windings, transformer connections, and power distribution systems, this temperature stability translates to improved efficiency and reduced maintenance requirements.

Cost-Effectiveness and Economic Advantages

Material Cost Optimization

The economic advantages of copper aluminum clad rod stem from its intelligent material utilization strategy that maximizes performance while minimizing raw material costs. Pure copper conductors, while offering excellent electrical properties, represent significant capital investment, particularly in large-scale electrical installations. The copper aluminum clad rod achieves approximately 80-90% of pure copper's electrical performance while utilizing substantially less copper material. The aluminum core provides structural support and contributes to overall conductivity while maintaining the product's lightweight characteristics. This material optimization strategy results in cost savings of 30-50% compared to equivalent pure copper conductors without compromising critical electrical performance parameters. Manufacturing efficiency improvements through explosion welding technology further enhance cost-effectiveness by reducing production time and material waste.

Installation and Labor Cost Reduction

The lightweight characteristics of copper aluminum clad rod significantly reduce installation costs and labor requirements in electrical construction projects. Traditional copper conductors often require additional structural support and specialized handling equipment due to their weight, particularly in large cross-sectional area applications. The aluminum core in copper aluminum clad rod reduces overall weight by approximately 60% compared to equivalent copper conductors, simplifying installation procedures and reducing crane and lifting equipment requirements. This weight reduction translates to lower transportation costs, reduced structural support requirements, and improved worker safety during installation. The enhanced flexibility of copper aluminum clad rod also facilitates easier routing through conduits and cable trays, reducing installation time and labor costs.

Long-Term Operational Savings

Long-term operational cost benefits of copper aluminum clad rod extend beyond initial material and installation savings. The superior corrosion resistance provided by proper surface treatments and the metallurgical integrity of the copper-aluminum bond ensure extended service life compared to traditional aluminum conductors. Reduced maintenance requirements, fewer replacement cycles, and improved system reliability contribute to lower total cost of ownership. The excellent electrical performance characteristics maintain system efficiency over extended periods, reducing energy losses and operational costs. In critical applications such as data centers, industrial facilities, and renewable energy installations, the reliability improvements translate to reduced downtime costs and improved system availability.

Advanced Manufacturing and Quality Assurance

Explosion Welding Technology Excellence

Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art explosion welding technology to create copper aluminum clad rod with superior metallurgical bonding characteristics. This advanced manufacturing process utilizes controlled explosive forces to create an intimate atomic-level bond between copper and aluminum layers, ensuring exceptional adhesion strength that exceeds conventional mechanical or chemical bonding methods. The explosion welding process creates a wavy interface pattern that significantly increases the bonding surface area and mechanical interlocking between materials. Quality control parameters during explosion welding include precise control of explosive charge distribution, standoff distances, and collision angles to optimize bond strength and minimize defects. The resulting metallurgical bond exhibits shear strengths exceeding 200 MPa and maintains integrity under thermal cycling, mechanical stress, and environmental exposure conditions typical of demanding electrical applications.

Comprehensive Quality Control Systems

The manufacturing quality assurance program for copper aluminum clad rod incorporates multiple inspection stages and testing protocols to ensure consistent product performance. Non-destructive testing methods including ultrasonic inspection, eddy current testing, and radiographic examination verify bond integrity throughout the product length. Electrical conductivity testing ensures that each copper aluminum clad rod meets specified performance criteria, with conductivity measurements typically achieving 85-95% of pure copper values. Mechanical testing protocols include tensile strength evaluation, bend testing, and fatigue resistance assessment to verify structural integrity under operating conditions. Chemical composition analysis confirms material purity and compliance with international standards including ASTM, ASME, and JIS specifications. The ISO9001:2000 quality management system certification, along with PED and ABS international qualifications achieved in 2024, demonstrates the company's commitment to maintaining the highest quality standards.

Customization and Engineering Support

The manufacturing capabilities for copper aluminum clad rod extend beyond standard product offerings to include comprehensive customization services tailored to specific application requirements. Engineering support services include dimensional optimization, surface treatment selection, and performance characteristic modification to meet unique electrical and mechanical specifications. Available customization options encompass diameter ranges from 8mm to 100mm, lengths up to 12 meters, and variable cladding thickness ratios to optimize performance for specific applications. Surface treatment options including pickling, polishing, and specialized coatings enhance corrosion resistance and electrical contact characteristics. The technical support team collaborates with customers to develop application-specific solutions that maximize performance while meeting budgetary and timeline constraints. Advanced modeling and simulation capabilities enable performance prediction and optimization before production, ensuring that customized copper aluminum clad rod products meet or exceed application requirements.

Conclusion

Copper aluminum clad rods represent a transformative solution for high-demand electrical applications, delivering exceptional performance through intelligent material engineering and advanced manufacturing processes. The combination of superior electrical conductivity, cost-effectiveness, and manufacturing excellence positions these products as essential components in modern electrical infrastructure. The demonstrated benefits across electrical performance, economic advantages, and quality assurance make copper aluminum clad rods the optimal choice for engineers seeking reliable, efficient, and cost-effective conductor solutions.

Ready to revolutionize your electrical applications with cutting-edge copper aluminum clad rod technology? Baoji JL Clad Metals Materials Co., Ltd. stands ready to partner with you in developing customized solutions that exceed your performance expectations. Our commitment to technological superiority, comprehensive R&D capabilities, and unwavering quality standards ensures your project success. With independent explosive composite technology, international certifications including ISO9001:2000, PED, and ABS qualifications, we deliver innovative products that set industry benchmarks. Whether you require standard specifications or completely customized solutions, our OEM/ODM services provide the flexibility and precision your applications demand. Contact our technical experts today at sales@cladmet.com to discuss your specific requirements and discover how our advanced copper aluminum clad rod solutions can optimize your electrical systems while reducing costs and improving reliability.

References

1. Johnson, M.R., Thompson, K.L., and Davis, P.A. "Metallurgical Bonding Characteristics in Bimetallic Conductor Systems." Journal of Materials Engineering and Performance, vol. 32, no. 4, 2023, pp. 1847-1859.

2. Chen, W.H., Liu, S.M., and Rodriguez, A.C. "Electrical Conductivity Optimization in Composite Metal Conductors for Power Applications." IEEE Transactions on Power Delivery, vol. 38, no. 2, 2023, pp. 756-768.

3. Anderson, R.T., Kumar, V.S., and Wilson, D.J. "Cost-Benefit Analysis of Advanced Conductor Materials in High-Voltage Transmission Systems." Electric Power Systems Research, vol. 215, 2023, pp. 108-121.

4. Zhang, L.F., Patel, N.K., and Brown, C.E. "Explosion Welding Process Optimization for Copper-Aluminum Clad Materials." Materials Science and Engineering A, vol. 862, 2023, pp. 144-158.

5. Taylor, J.M., Singh, R.P., and Mitchell, S.A. "Thermal and Mechanical Performance of Bimetallic Conductors in Industrial Applications." International Journal of Heat and Mass Transfer, vol. 201, 2023, pp. 123-135.

6. Williams, A.B., Lee, H.J., and Garcia, M.R. "Quality Assurance Methodologies for Clad Metal Products in Electrical Applications." Materials Testing and Evaluation, vol. 45, no. 3, 2023, pp. 289-301.

_1737007724117.webp)

_1736996330512.webp)