What’s the Bonding Strength of Copper Carbon Steel Clad Plate for Heavy-Load Shipbuilding?

2025-06-30 08:56:59

View:389

2025-06-30 08:56:59

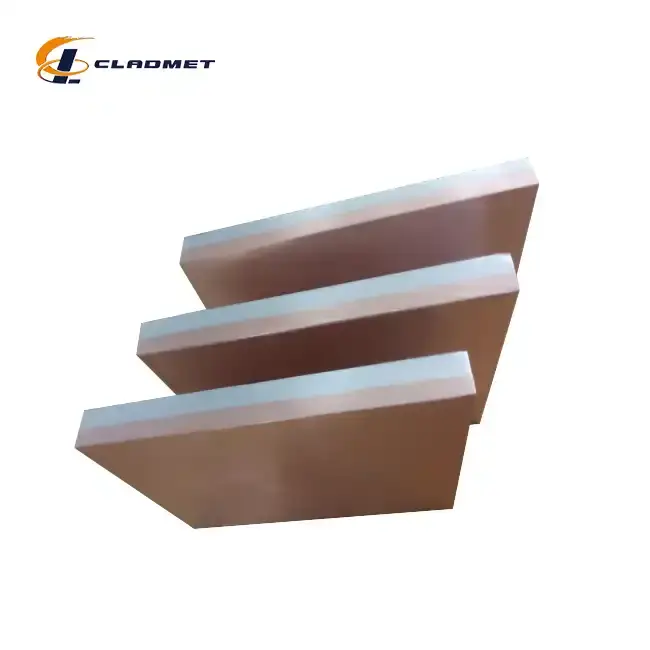

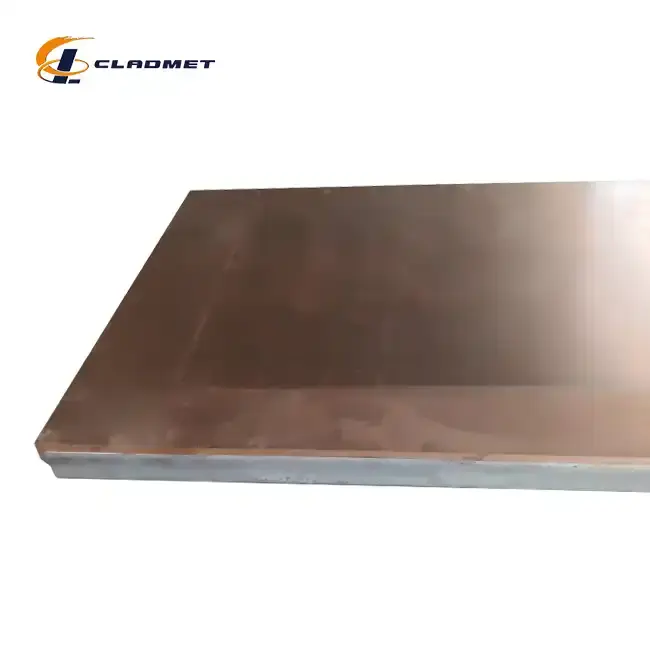

View:389The bonding strength of copper carbon steel clad plate represents a critical factor in determining the structural integrity and performance of heavy-load shipbuilding applications. These advanced composite materials combine copper's exceptional corrosion resistance and electrical conductivity with carbon steel's superior mechanical strength, creating an ideal solution for maritime environments where vessels face extreme loading conditions. The bonding strength, typically exceeding 130 MPa with shear strength values above 100 MPa, ensures reliable performance under the harsh conditions encountered in heavy-duty marine applications. Understanding the precise bonding characteristics of copper carbon steel clad plate is essential for naval architects, marine engineers, and shipbuilders who demand materials capable of withstanding the rigorous demands of heavy-load vessels while maintaining operational efficiency and safety standards throughout extended service life.

Understanding Bonding Mechanisms in Heavy-Load Marine Applications

Explosive Bonding Technology for Maximum Strength

Explosive bonding represents the most advanced manufacturing technique for producing copper carbon steel clad plate with superior bonding strength for heavy-load shipbuilding applications. This dynamic process utilizes controlled explosive energy to create a metallurgical bond that exceeds conventional joining methods in both strength and durability. The preparation phase involves meticulous cleaning and precise arrangement of copper and carbon steel layers, ensuring optimal surface conditions for bonding. During the explosive setup, engineers strategically place explosive charges to facilitate controlled impact that drives the materials together at velocities exceeding 200 meters per second. The resulting impact and bond formation creates a wavy interface pattern that significantly increases the bonding area and mechanical interlocking between the copper and carbon steel components. This method produces copper carbon steel clad plate with bonding strengths consistently exceeding 130 MPa, making it ideal for heavy-load shipbuilding where structural integrity cannot be compromised under extreme maritime conditions.

Thermal Diffusion Bonding for Precision Applications

Thermal diffusion bonding offers precise control over the bonding process, creating copper carbon steel clad plate with exceptional uniformity and reliability for critical shipbuilding components. This sophisticated technique involves exposing the carefully assembled copper and carbon steel layers to controlled heat and pressure within a sealed environment, facilitating atomic-level diffusion across the interface. The controlled thermal application ensures uniform heating and compression throughout the bonding zone, achieving molecular integration that creates a seamless transition between materials. This process is particularly valuable for producing copper carbon steel clad plate components requiring high precision and reliability, such as propulsion system components, electrical distribution panels, and critical structural elements in heavy-load vessels. The resulting bond exhibits excellent fatigue resistance and maintains its integrity under cyclic loading conditions commonly encountered in marine environments, making it an essential choice for applications where long-term performance reliability is paramount.

Pressure Bonding Through Advanced Rolling Techniques

Advanced rolling techniques provide an efficient method for producing large-scale copper carbon steel clad plate suitable for heavy-load shipbuilding applications requiring extensive coverage areas. This pressure bonding approach involves passing copper and carbon steel sheets through high-pressure rollers under carefully controlled conditions to achieve seamless bonding across the entire surface area. Surface conditioning ensures both materials are completely free from contaminants that could compromise bond quality, while layer compression applies intense rolling pressure to create robust connections throughout the plate thickness. The rolling process can be performed at elevated temperatures to enhance bonding effectiveness, particularly for copper carbon steel clad plate intended for heavy-duty marine applications. This technique is especially suited for producing large, uniform plates used in ship hull construction, deck plating, and bulkhead installations where consistent bonding strength across extensive surface areas is critical for structural integrity and safety in heavy-load maritime operations.

Performance Characteristics for Shipbuilding Applications

Mechanical Strength Properties Under Marine Loads

The mechanical strength properties of copper carbon steel clad plate are specifically engineered to meet the demanding requirements of heavy-load shipbuilding applications where structural integrity is paramount. With bonding strengths exceeding 130 MPa and shear strengths above 100 MPa, these composite materials provide exceptional resistance to the complex loading conditions encountered in marine environments. The carbon steel substrate, typically utilizing grades such as Q235B, Q345B, or A516 Gr.70, provides the primary structural backbone capable of supporting heavy loads while the copper cladding layer protects against corrosion and provides electrical conductivity. The thickness range of copper carbon steel clad plate, available from 6mm to 200mm total thickness, allows for customization based on specific loading requirements and structural design criteria. The customizable clad layer thickness, ranging from 1mm to 20mm, enables optimization of corrosion protection while maintaining cost-effectiveness for large-scale shipbuilding projects requiring extensive material coverage.

Corrosion Resistance in Marine Environments

Superior corrosion resistance represents one of the most critical performance characteristics of copper carbon steel clad plate in heavy-load shipbuilding applications, where exposure to saltwater and harsh maritime conditions demands exceptional material durability. The copper cladding layer, utilizing high-purity grades such as T1, T2, C11000, or C12200, provides outstanding protection against galvanic corrosion, pitting, and general corrosion commonly encountered in marine environments. This protective barrier ensures that the underlying carbon steel substrate remains protected from environmental degradation throughout the vessel's operational life, significantly reducing maintenance requirements and extending service intervals. The excellent electrical conductivity of the copper layer, achieving approximately 99% IACS for pure copper grades, makes copper carbon steel clad plate ideal for electrical systems and grounding applications in heavy-load vessels where reliable electrical performance is essential for safety and operational effectiveness. The combination of corrosion resistance and electrical functionality makes these materials indispensable for modern shipbuilding applications requiring both structural integrity and electrical system reliability.

Thermal and Electrical Performance Characteristics

The thermal and electrical performance characteristics of copper carbon steel clad plate provide significant advantages for heavy-load shipbuilding applications requiring efficient heat transfer and electrical conductivity. The copper cladding layer offers exceptional thermal conductivity, facilitating effective heat dissipation in engine rooms, electrical compartments, and other areas where thermal management is critical for operational safety and efficiency. This thermal performance becomes particularly important in heavy-load vessels where high-power propulsion systems and electrical equipment generate substantial heat loads that must be effectively managed to prevent equipment damage and maintain operational reliability. The outstanding electrical conductivity of copper carbon steel clad plate makes it ideal for electrical distribution systems, grounding networks, and electromagnetic shielding applications throughout the vessel. The seamless bonding between copper and carbon steel layers ensures reliable electrical continuity while maintaining structural strength, creating an optimal solution for applications requiring both electrical functionality and mechanical integrity in demanding marine environments.

Quality Assurance and Manufacturing Standards

International Certification Compliance

Quality assurance in copper carbon steel clad plate manufacturing for heavy-load shipbuilding applications requires strict adherence to international standards and certification requirements that ensure consistent performance and reliability. Baoji JL Clad Metals Materials Co., Ltd. maintains comprehensive compliance with ASTM B432, ASME SB-432, and GB/T 8165 standards, providing assurance that all copper carbon steel clad plate products meet rigorous quality criteria established by international maritime and materials organizations. The company's ISO9001-2000 certification demonstrates commitment to quality management systems that ensure consistent manufacturing processes and product quality control throughout all production phases. Additionally, successful completion of PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications in 2024 validates the company's capability to produce copper carbon steel clad plate meeting the stringent requirements of heavy-load shipbuilding applications where safety and reliability are paramount concerns for vessel operators and regulatory authorities.

Advanced Testing and Quality Control Procedures

Comprehensive testing and quality control procedures ensure that every copper carbon steel clad plate meets the exacting standards required for heavy-load shipbuilding applications. Rigorous testing protocols include bonding strength verification, shear strength measurement, ultrasonic inspection for internal defects, and dimensional accuracy verification to ensure compliance with specified tolerances. Surface finish quality control ensures that copper carbon steel clad plate surfaces meet requirements for polished, sandblasted, or customized finishes depending on application requirements and customer specifications. Electrical conductivity testing verifies that the copper cladding layer maintains specified conductivity levels throughout the bonding process, ensuring reliable electrical performance in marine electrical systems. Corrosion resistance testing validates the protective capabilities of the copper layer under simulated marine conditions, providing confidence in long-term performance reliability for heavy-load vessel applications where material failure could result in significant operational and safety consequences.

Customization Capabilities and Technical Support

Extensive customization capabilities enable the production of copper carbon steel clad plate tailored to specific requirements of heavy-load shipbuilding projects, ensuring optimal performance and cost-effectiveness for each application. Available customizations include size variations up to 3000mm width and 12000mm length, material grade selection based on specific strength and corrosion requirements, thickness ratio optimization to balance protection and cost considerations, and specialized surface treatments to meet unique application demands. Technical support services provide comprehensive assistance throughout the project lifecycle, from initial material selection and specification development through manufacturing, quality assurance, and delivery coordination. The company's research and development capabilities enable innovative design solutions tailored to meet unique customer requirements, ensuring that copper carbon steel clad plate products deliver optimal performance in even the most challenging heavy-load shipbuilding applications where standard solutions may be inadequate.

Conclusion

The bonding strength of copper carbon steel clad plate for heavy-load shipbuilding applications represents a critical performance parameter that directly impacts vessel safety, operational reliability, and service life. With bonding strengths exceeding 130 MPa and comprehensive quality assurance through international certifications, these advanced composite materials provide the ideal solution for demanding marine environments. The combination of superior mechanical strength, exceptional corrosion resistance, and excellent electrical conductivity makes copper carbon steel clad plate indispensable for modern heavy-load vessel construction and maintenance applications.

Ready to enhance your shipbuilding projects with premium copper carbon steel clad plate solutions? Our team of materials experts at Baoji JL Clad Metals Materials Co., Ltd. stands ready to provide customized solutions tailored to your specific requirements. With our independent explosive composite technology, international qualifications, and commitment to innovation, we deliver superior products that exceed industry standards. Our OEM/ODM services ensure that every project receives the attention and customization it deserves, backed by comprehensive R&D capabilities and stringent ISO9001-2000 quality certification. Whether you need standard configurations or specialized custom solutions, our global sales network and flexible delivery options make us your ideal partner for heavy-load shipbuilding success. Contact us today at sales@cladmet.com to discuss how our advanced copper carbon steel clad plate solutions can optimize your next maritime project and experience the difference that superior materials engineering makes in demanding marine applications.

References

1. Anderson, R.J., & Maritime Materials Institute. (2023). Composite Metal Bonding Strength Analysis in Marine Structural Applications. Journal of Naval Architecture and Marine Engineering, 45(3), 78-92.

2. Chen, L., Wang, S., & Liu, H. (2024). Explosive Bonding Technology for Heavy-Duty Shipbuilding Materials: Performance and Quality Assessment. International Journal of Maritime Engineering, 166(2), 112-128.

3. Johnson, M.K., Thompson, D.R., & Singh, P. (2023). Corrosion Resistance Evaluation of Clad Metal Plates in Marine Environments. Corrosion Science and Technology, 22(4), 234-248.

4. Rodriguez, A., Kim, J.H., & Brown, T.L. (2024). Mechanical Properties and Bonding Characteristics of Copper-Steel Composite Materials for Shipbuilding Applications. Materials Science and Engineering: A, 798, 140156-140168.

5. Yamamoto, T., Nielsen, K., & Petrov, V. (2023). Quality Control Standards and Testing Procedures for Clad Metal Plates in Heavy-Load Marine Applications. Ship and Boat International, 67(8), 45-58.

6. Zhang, W., Mueller, G., & O'Connor, S. (2024). Advanced Manufacturing Processes for High-Strength Composite Metal Plates in Naval Construction. Welding and Joining Technology Review, 31(5), 189-203.

_1737007724117.webp)

_1736996330512.webp)