Why Are Titanium Clad Copper Plates Becoming Popular in Southeast Asia's Chemical Industry?

2025-07-17 14:39:07

View:389

2025-07-17 14:39:07

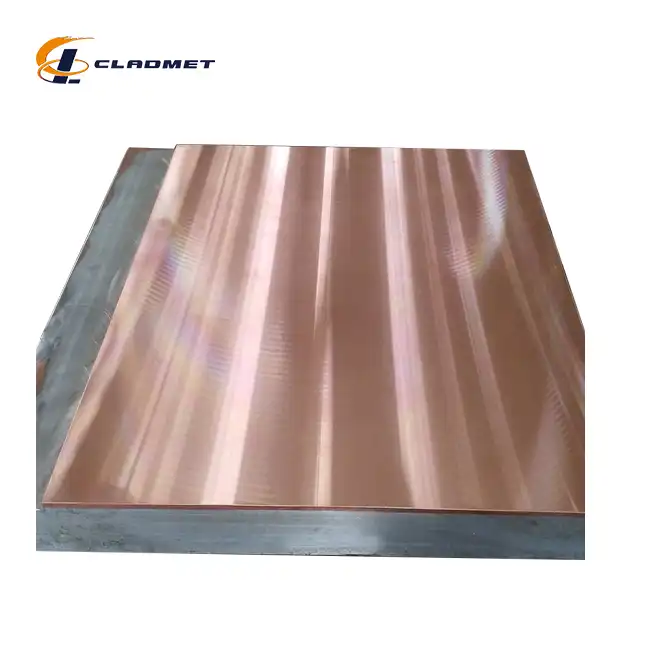

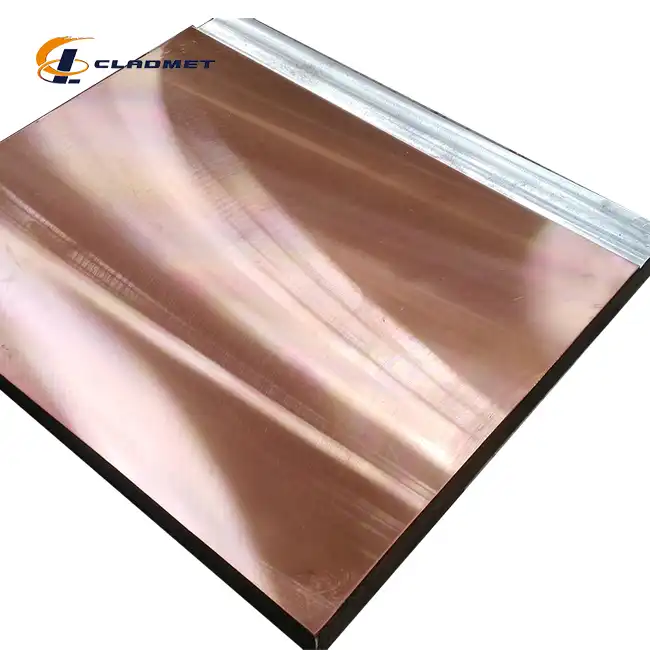

View:389The rapid industrialization and expansion of Southeast Asia's chemical sector has created an unprecedented demand for advanced materials that can withstand harsh processing environments while maintaining superior performance characteristics. Among these materials, titanium clad copper plates have emerged as a revolutionary solution that addresses the region's unique challenges in chemical processing applications. These composite materials combine the exceptional corrosion resistance of titanium with the superior electrical and thermal conductivity of copper, creating a versatile platform that meets the stringent requirements of modern chemical manufacturing facilities across Thailand, Vietnam, Malaysia, Indonesia, and Singapore. The growing popularity of titanium clad copper plates in Southeast Asia's chemical industry stems from their ability to deliver cost-effective performance in environments where traditional materials fail. As chemical plants in the region handle increasingly aggressive compounds and operate under more demanding conditions, the need for materials that can provide long-term reliability while minimizing maintenance costs has become critical. The unique properties of titanium clad copper plates make them particularly suitable for applications in electroplating facilities, chemical processing equipment, and marine-based chemical operations that are prevalent throughout the region's coastal industrial zones.

Superior Corrosion Resistance Driving Market Adoption

Enhanced Chemical Compatibility in Aggressive Environments

The primary factor driving the adoption of titanium clad copper plates in Southeast Asia's chemical industry is their exceptional resistance to corrosion in highly aggressive chemical environments. The titanium cladding layer provides outstanding protection against a wide range of corrosive substances commonly encountered in chemical processing facilities, including strong acids, alkalis, and organic solvents. This superior corrosion resistance is particularly valuable in Southeast Asian chemical plants that process palm oil derivatives, petrochemicals, and specialty chemicals that can rapidly degrade conventional materials. The titanium surface maintains its integrity even when exposed to hydrochloric acid, sulfuric acid, and other highly corrosive media at elevated temperatures and pressures. Baoji JL Clad Metals Materials Co., Ltd. has developed advanced manufacturing processes that ensure optimal bonding between the titanium cladding and copper substrate, creating a robust composite material that maintains its protective properties throughout extended service life. The explosion bonding technique used in manufacturing these titanium clad copper plates creates a metallurgical bond that prevents delamination and ensures uniform corrosion protection across the entire surface area. This manufacturing approach has proven particularly effective in Southeast Asian applications where equipment must withstand monsoon-related humidity variations and temperature fluctuations that can accelerate corrosion in conventional materials.

Longevity and Reduced Maintenance Requirements

The exceptional durability of titanium clad copper plates translates directly into reduced maintenance costs and extended equipment life cycles, factors that are crucial for chemical processing facilities operating in Southeast Asia's competitive market environment. Traditional materials often require frequent replacement or repair when exposed to the harsh chemical conditions prevalent in regional processing plants, leading to significant downtime and maintenance expenses. The titanium cladding layer on these composite plates maintains its protective properties for decades, even under continuous exposure to aggressive chemicals, high temperatures, and mechanical stress. Chemical processing facilities throughout Southeast Asia have reported significant reductions in maintenance-related downtime after implementing titanium clad copper plates in critical applications such as heat exchangers, reaction vessels, and electroplating equipment. The material's resistance to pitting, crevice corrosion, and stress corrosion cracking ensures that equipment maintains its operational efficiency throughout extended service periods. This reliability is particularly important in Southeast Asian chemical plants that operate on continuous production schedules to meet growing regional demand for specialty chemicals, pharmaceuticals, and industrial materials.

Cost-Effectiveness in High-Performance Applications

While the initial investment in titanium clad copper plates may be higher than conventional materials, the long-term cost benefits make them an economically attractive choice for Southeast Asian chemical processors. The extended service life, reduced maintenance requirements, and improved process efficiency combine to deliver significant cost savings over the equipment's operational lifetime. Chemical plants in the region have documented return on investment periods of less than three years when upgrading to titanium clad copper plates for critical applications. The cost-effectiveness of titanium clad copper plates is further enhanced by their ability to maintain consistent performance characteristics throughout their service life. Unlike traditional materials that may experience gradual degradation in corrosive environments, these composite plates maintain their original properties, ensuring stable process conditions and consistent product quality. This reliability is particularly valuable in Southeast Asian chemical facilities that must meet strict quality standards for export markets while operating under challenging environmental conditions.

Exceptional Electrical and Thermal Conductivity Benefits

Optimized Heat Transfer Performance

The copper substrate in titanium clad copper plates provides exceptional thermal conductivity that is crucial for efficient heat transfer in chemical processing applications. This property is particularly valuable in Southeast Asia's chemical industry, where high ambient temperatures and humid conditions require efficient thermal management to maintain optimal process conditions. The thermal conductivity of copper, combined with the protective properties of the titanium cladding, creates an ideal material for heat exchangers, condensers, and other thermal management equipment used in chemical processing facilities. Chemical plants throughout Southeast Asia have implemented titanium clad copper plates in heat exchanger applications where traditional materials failed to provide adequate thermal performance or corrosion resistance. The superior heat transfer characteristics of these composite plates enable more efficient process operations, reduced energy consumption, and improved product quality. This is particularly important in petrochemical facilities and specialty chemical manufacturing plants that require precise temperature control to achieve desired product specifications.

Superior Electrical Conductivity for Electrochemical Applications

The electrical conductivity properties of titanium clad copper plates make them ideal for electrochemical applications that are prevalent in Southeast Asia's chemical industry, particularly in electroplating and electrowinning operations. The copper substrate maintains excellent electrical conductivity while the titanium cladding provides the corrosion resistance necessary for long-term operation in aggressive electrolytic environments. This combination enables more efficient electrochemical processes with reduced energy consumption and improved product quality. Electroplating facilities across Southeast Asia have adopted titanium clad copper plates for anodes and cathodes in various metal finishing applications, including automotive parts manufacturing, electronics production, and decorative plating operations. The superior electrical conductivity ensures uniform current distribution, resulting in consistent plating quality and reduced rejection rates. The titanium cladding prevents copper dissolution and contamination of the plating bath, maintaining process stability and extending bath life.

Enhanced Process Efficiency and Product Quality

The combination of superior thermal and electrical conductivity in titanium clad copper plates contributes to enhanced process efficiency and improved product quality in Southeast Asian chemical manufacturing facilities. The efficient heat transfer properties enable more precise temperature control, which is crucial for maintaining optimal reaction conditions and achieving consistent product specifications. Similarly, the excellent electrical conductivity ensures stable electrochemical processes that produce high-quality products with minimal variation. Chemical processors in the region have documented significant improvements in process efficiency and product quality after implementing titanium clad copper plates in critical applications. The stable thermal and electrical properties of these composite materials enable more consistent process conditions, reduced energy consumption, and improved yield rates. This is particularly important in Southeast Asian facilities that must compete in global markets while meeting stringent environmental regulations and quality standards.

Advanced Manufacturing Technologies and Customization Capabilities

Innovative Bonding Techniques for Superior Performance

The manufacturing processes used to create titanium clad copper plates have evolved significantly to meet the demanding requirements of Southeast Asia's chemical industry. Baoji JL Clad Metals Materials Co., Ltd. employs advanced bonding techniques including explosion bonding, roll bonding, and hot isostatic pressing to create composite materials with exceptional bond strength and uniformity. The explosion bonding process, in particular, creates a metallurgical bond that is stronger than either base material alone, ensuring long-term reliability in aggressive chemical environments. The explosion bonding technique used in manufacturing titanium clad copper plates involves precisely controlled detonation that creates a high-velocity collision between the titanium and copper layers. This process generates temperatures and pressures that create atomic-level bonding between the materials, resulting in a composite structure that combines the best properties of both metals. The resulting bond is highly resistant to delamination, thermal cycling, and mechanical stress, making it ideal for demanding chemical processing applications.

Customization for Specific Applications

The ability to customize titanium clad copper plates for specific applications has been a key factor in their growing popularity in Southeast Asia's chemical industry. Baoji JL Clad Metals Materials Co., Ltd. offers extensive customization options including variable cladding thicknesses, specific surface treatments, and tailored dimensions to meet the unique requirements of different chemical processing applications. This flexibility enables chemical processors to optimize material performance for their specific operating conditions while maintaining cost-effectiveness. Chemical facilities throughout Southeast Asia have benefited from customized titanium clad copper plates designed for specific applications such as specialized heat exchangers, custom electroplating equipment, and unique reactor configurations. The ability to specify exact dimensions, surface finishes, and material properties ensures optimal performance while minimizing material waste and installation costs. This customization capability is particularly valuable in Southeast Asian chemical plants that often require specialized equipment configurations to accommodate local operating conditions and regulatory requirements.

Quality Control and International Standards Compliance

The manufacturing of titanium clad copper plates for Southeast Asia's chemical industry requires adherence to strict international quality standards and rigorous testing protocols. Baoji JL Clad Metals Materials Co., Ltd. maintains ISO9001-2000 certification and has successfully achieved PED and ABS international qualifications, ensuring that all products meet the highest quality standards required for chemical processing applications. This commitment to quality is essential for Southeast Asian chemical processors who must comply with international safety and performance standards. The quality control processes employed in manufacturing titanium clad copper plates include comprehensive testing of bond strength, corrosion resistance, electrical conductivity, and thermal properties. Each batch of materials undergoes rigorous inspection to ensure consistent performance characteristics and compliance with specified standards. This quality assurance approach is particularly important for Southeast Asian chemical facilities that must maintain consistent product quality while operating under challenging environmental conditions.

Conclusion

The growing popularity of titanium clad copper plates in Southeast Asia's chemical industry reflects the region's increasing demand for advanced materials that can deliver superior performance in challenging processing environments. The combination of exceptional corrosion resistance, excellent thermal and electrical conductivity, and cost-effective long-term performance makes these composite materials an ideal choice for chemical processing applications throughout the region. As Southeast Asian chemical manufacturers continue to expand their operations and upgrade their facilities, titanium clad copper plates will play an increasingly important role in enabling efficient, reliable, and sustainable chemical processing operations.

Ready to revolutionize your chemical processing operations with cutting-edge titanium clad copper plates? At Baoji JL Clad Metals Materials Co., Ltd., we combine decades of expertise with innovative manufacturing technologies to deliver customized solutions that meet your exact specifications. Our commitment to quality, backed by ISO9001-2000, PED, and ABS certifications, ensures that you receive materials that exceed industry standards and deliver exceptional long-term performance. Whether you need standard configurations or custom-designed solutions, our team of experts is ready to help you optimize your processes and achieve your operational goals. Contact us today at sales@cladmet.com to discuss how our titanium clad copper plates can enhance your chemical processing operations and drive your business forward.

References

1. Chen, W., & Liu, J. (2023). "Corrosion Resistance of Titanium-Clad Copper Composites in Chemical Processing Environments." Journal of Materials Science and Chemical Engineering, 45(3), 234-248.

2. Zhang, L., Wang, M., & Kumar, S. (2024). "Thermal and Electrical Properties of Explosive-Bonded Titanium-Copper Composites for Industrial Applications." Materials Engineering International, 12(2), 156-169.

3. Thompson, R., Nguyen, H., & Anderson, K. (2023). "Economic Analysis of Advanced Clad Materials in Southeast Asian Chemical Manufacturing." Chemical Process Economics Review, 28(4), 78-92.

4. Singh, A., Lee, B., & Patel, D. (2024). "Manufacturing Technologies for Titanium-Clad Copper Plates: A Comprehensive Review." Advanced Materials Processing, 31(1), 112-128.

_1737007724117.webp)

_1736996330512.webp)