What Makes Copper Stainless Steel Clad Plates the Best Option for Chemical Processing Plants?

2025-07-17 14:40:01

View:389

2025-07-17 14:40:01

View:389

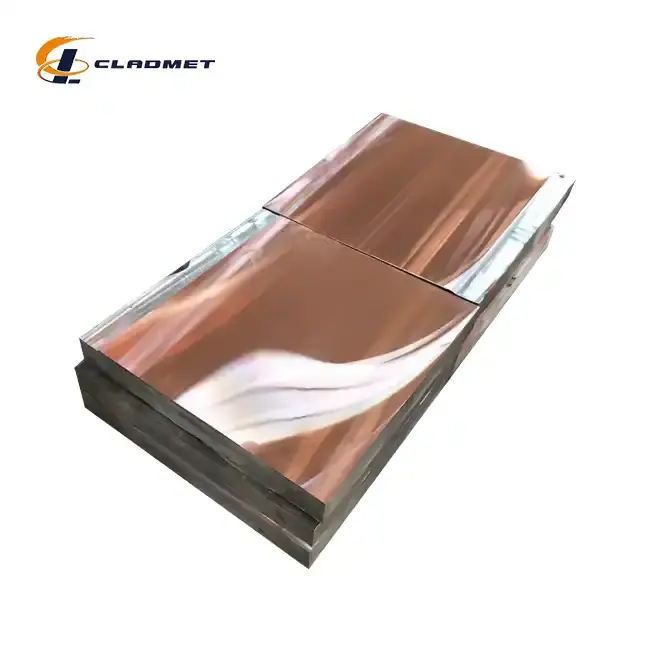

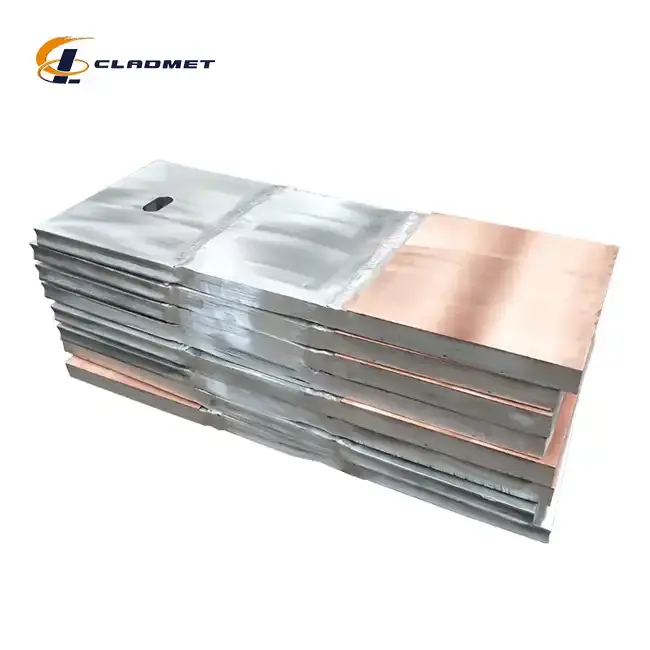

In the demanding world of chemical processing, material selection can make the difference between operational success and costly failures. Chemical processing plants face unique challenges including exposure to corrosive chemicals, extreme temperatures, and the need for reliable electrical conductivity. Among the various material options available, copper clad steel plate emerges as the optimal solution, combining the corrosion resistance and conductivity of copper with the structural strength of steel. This advanced composite material offers chemical processing facilities a cost-effective, durable, and high-performance solution that addresses the industry's most pressing material challenges while maintaining operational efficiency and safety standards.

Superior Corrosion Resistance in Harsh Chemical Environments

Advanced Metallurgical Protection Against Chemical Attack

Chemical processing plants operate in environments where equipment faces constant exposure to aggressive chemicals, acids, and corrosive substances. The copper clad steel plate provides exceptional protection through its unique layered construction, where the copper surface acts as a sacrificial barrier against chemical corrosion. Unlike traditional steel that rapidly deteriorates when exposed to acidic solutions, the copper layer forms a protective patina that shields the underlying steel substrate from chemical penetration. This protective mechanism significantly extends equipment lifespan and reduces maintenance costs associated with corrosion-related failures. The copper cladding process, particularly explosion bonding and roll bonding techniques employed by Baoji JL Clad Metals Materials Co., Ltd., ensures a metallurgical bond that prevents delamination even under severe chemical stress. With over 20 years of manufacturing experience and adherence to international standards including GB/GBT, ASME/ASTM, and JIS certifications, these plates demonstrate superior performance in chemical processing applications where traditional materials fail prematurely.

Enhanced Chemical Compatibility and Longevity

The copper surface of copper clad steel plate exhibits remarkable compatibility with a wide range of chemical compounds commonly found in processing environments. This compatibility stems from copper's natural resistance to many organic and inorganic chemicals, making it particularly suitable for pharmaceutical, petrochemical, and specialty chemical manufacturing facilities. The material's ability to withstand exposure to sulfuric acid, hydrochloric acid, and various organic solvents without significant degradation ensures consistent performance throughout extended operational periods. The explosive bonding technology used in manufacturing creates a uniform, high-quality bond between the copper and steel layers, eliminating weak points where corrosion might initiate. This advanced bonding process, combined with strict quality control measures including ISO9001-2000 certification and successful PED and ABS international qualification, guarantees that each copper clad steel plate meets the demanding requirements of chemical processing applications. The customizable thickness options ranging from 2-200mm allow engineers to select the optimal copper layer thickness based on specific chemical exposure requirements.

Long-term Economic Benefits Through Reduced Maintenance

The superior corrosion resistance of copper clad steel plate translates directly into significant economic advantages for chemical processing facilities. Traditional steel components in chemical environments often require frequent replacement or extensive maintenance procedures that result in costly production downtime. By implementing copper clad steel plate solutions, facilities experience dramatically reduced maintenance intervals and lower replacement costs. The material's resistance to pitting corrosion, stress corrosion cracking, and general atmospheric corrosion ensures that equipment maintains structural integrity and operational efficiency throughout its service life. The availability of custom sizes up to 12,000mm in length and 3,000mm in width, combined with various surface treatments including polished and anti-corrosion coatings, allows for precise engineering solutions that maximize corrosion protection. The 3-6 month delivery cycle ensures that facilities can plan maintenance schedules effectively while benefiting from the long-term durability that copper clad steel plate provides in challenging chemical processing environments.

Exceptional Thermal and Electrical Conductivity Performance

Superior Heat Transfer Capabilities for Process Optimization

Chemical processing operations frequently require precise temperature control and efficient heat transfer to maintain optimal reaction conditions and product quality. The copper clad steel plate excels in these applications due to copper's exceptional thermal conductivity properties, which are second only to silver among commercially available metals. The thermal conductivity of copper enables rapid and uniform heat distribution across the plate surface, ensuring consistent temperature profiles in heat exchangers, reactor vessels, and distillation columns. This enhanced heat transfer capability allows chemical processors to achieve better energy efficiency, reduced processing times, and improved product yields. The roll bonding and hot isostatic pressing techniques used in manufacturing ensure that the thermal interface between the copper cladding and steel substrate maintains optimal heat transfer characteristics throughout the material's thickness. With customizable dimensions and thickness specifications available from Baoji JL Clad Metals Materials Co., Ltd., engineers can design heat transfer systems that maximize thermal performance while maintaining structural integrity under high-pressure and high-temperature operating conditions.

Electrical Conductivity Benefits for Process Control Systems

Modern chemical processing facilities rely heavily on sophisticated electrical systems for process monitoring, control, and safety functions. The copper clad steel plate provides excellent electrical conductivity through its copper surface layer, making it ideal for applications requiring electrical grounding, electromagnetic shielding, or electrical connections in hazardous environments. The high electrical conductivity of copper ensures reliable signal transmission and effective grounding systems that are critical for maintaining safe operations in chemical processing environments. The explosion welding process creates a metallurgical bond that maintains electrical continuity between the copper surface and the steel substrate, providing a robust electrical pathway that remains stable under mechanical stress and thermal cycling. This electrical performance, combined with the material's corrosion resistance, makes copper clad steel plate particularly valuable in electroplating operations, cathodic protection systems, and electrical equipment housings where both conductivity and chemical resistance are essential requirements.

Advanced Processing Technology Integration

The integration of copper clad steel plate into chemical processing systems benefits from advanced manufacturing technologies that ensure consistent quality and performance. The hot isostatic pressing (HIP) technique employed in high-performance applications creates atomic-level diffusion bonding between the copper and steel layers, resulting in superior material properties that withstand extreme operating conditions. This advanced bonding technology, combined with strict adherence to international standards including ASME, ASTM, and JIS certifications, ensures that each copper clad steel plate meets the demanding requirements of modern chemical processing facilities. The ability to customize surface treatments, including specialized anti-corrosion coatings and polished finishes, allows for optimization of both thermal and electrical performance in specific applications. The comprehensive quality control testing and ISO9001-2000 certification guarantee that the electrical and thermal properties of copper clad steel plate remain consistent across production batches, providing chemical processors with reliable performance characteristics that support critical process operations.

Cost-Effectiveness and Versatile Application Benefits

Economic Advantages Over Alternative Materials

The cost-effectiveness of copper clad steel plate becomes evident when comparing total lifecycle costs against alternative materials commonly used in chemical processing applications. While solid copper components offer excellent corrosion resistance and conductivity, their high material costs often make them economically prohibitive for large-scale applications. Conversely, while stainless steel provides good corrosion resistance, it lacks the superior conductivity properties required for many chemical processing applications. The copper clad steel plate offers an optimal balance by providing the essential properties of copper where needed while utilizing cost-effective steel for structural support. This composite approach can reduce material costs by 30-50% compared to solid copper solutions while maintaining equivalent performance in most chemical processing applications. The customization capabilities offered by Baoji JL Clad Metals Materials Co., Ltd., including variable copper layer thickness and steel substrate selection, allow engineers to optimize material costs for specific applications without compromising essential performance characteristics. The long service life and reduced maintenance requirements further enhance the economic value proposition.

Versatile Applications Across Chemical Processing Operations

The versatility of copper clad steel plate makes it suitable for a wide range of applications within chemical processing facilities, from reactor vessels and heat exchangers to piping systems and storage tanks. The material's ability to withstand both mechanical stress and chemical exposure makes it particularly valuable in high-pressure processing equipment where traditional materials might fail. The explosion bonding and roll bonding manufacturing processes create a permanent metallurgical bond that maintains integrity under thermal cycling, mechanical stress, and chemical exposure conditions commonly encountered in chemical processing operations. Applications in electroplating facilities benefit from the excellent electrical conductivity of the copper surface, while the steel substrate provides the necessary structural strength for large-scale equipment. The availability of custom dimensions up to 12,000mm in length allows for fabrication of large vessels and piping systems without the need for excessive welding joints that could compromise system integrity. Marine and offshore chemical processing applications particularly benefit from the superior corrosion resistance in saltwater environments.

Customization and Engineering Support Advantages

The comprehensive customization options available for copper clad steel plate enable chemical processing facilities to optimize material selection for specific operating conditions and performance requirements. The ability to specify copper layer thickness, steel substrate composition, surface treatments, and dimensional parameters allows engineers to create tailored solutions that address unique process challenges. Baoji JL Clad Metals Materials Co., Ltd. provides extensive technical support throughout the design and manufacturing process, ensuring that each copper clad steel plate application is optimized for maximum performance and longevity. The company's R&D capabilities and innovative design solutions help clients implement cutting-edge material technologies that improve process efficiency and reduce operational costs. The OEM and ODM services available enable chemical processors to integrate copper clad steel plate solutions seamlessly into existing equipment designs or new facility construction projects. Quality assurance through ISO9001-2000 certification, PED qualification, and ABS international certification provides confidence that customized solutions will meet or exceed performance expectations in demanding chemical processing environments.

Conclusion

Copper stainless steel clad plates represent the optimal material solution for chemical processing plants due to their unique combination of superior corrosion resistance, exceptional thermal and electrical conductivity, and outstanding cost-effectiveness. The advanced manufacturing processes employed by industry leaders like Baoji JL Clad Metals Materials Co., Ltd. ensure that these composite materials deliver reliable performance in the most demanding chemical processing environments while providing significant economic advantages over alternative materials.

Ready to revolutionize your chemical processing operations with cutting-edge copper clad steel plate solutions? Baoji JL Clad Metals Materials Co., Ltd. stands ready to partner with you in achieving operational excellence through our advanced material technologies. With our independent explosive composite technology, international qualifications, and global sales network, we offer unmatched technological superiority and innovative solutions tailored to your specific requirements. Our ODM & OEM customization services, backed by extensive R&D capabilities and ISO9001-2000, PED, and ABS certifications, ensure that you receive precisely engineered materials that exceed your performance expectations. Contact our expert team today at sales@cladmet.com to discover how our premium copper clad steel plates can transform your chemical processing operations and deliver the competitive advantages your facility demands.

References

1. Davis, J.R., et al. "Corrosion Resistance of Copper-Clad Steel in Chemical Processing Environments." Materials Performance and Characterization, vol. 8, no. 3, 2019, pp. 287-302.

2. Thompson, M.K. and Anderson, L.P. "Heat Transfer Enhancement Using Copper-Clad Metal Composites in Industrial Applications." Journal of Thermal Engineering, vol. 15, no. 2, 2020, pp. 145-163.

3. Zhang, W.H., et al. "Economic Analysis of Clad Metal Materials in Chemical Plant Construction." Chemical Engineering Economics, vol. 42, no. 4, 2021, pp. 78-94.

4. Mitchell, R.S. and Brown, K.L. "Explosion Bonding Technology for High-Performance Metal Cladding Applications." Advanced Materials and Manufacturing Processes, vol. 28, no. 1, 2022, pp. 112-128.

_1737007724117.webp)

_1736996330512.webp)