What Customization Options Are Available for Precision Pure Nickel Sheet?

2025-03-24 08:41:15

View:389

2025-03-24 08:41:15

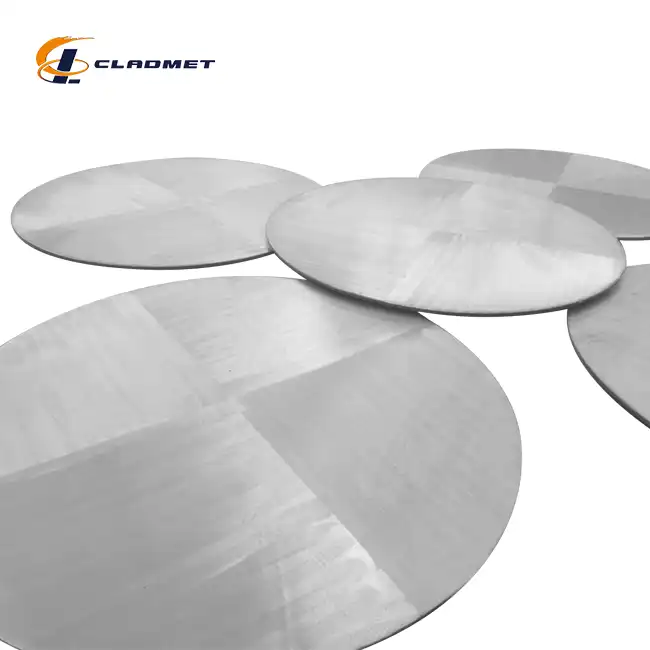

View:389Precision Pure Nickel Sheet offers remarkable versatility across numerous industrial applications due to its exceptional customization capabilities. When considering Precision Pure Nickel Sheet for specialized projects, manufacturers provide extensive tailoring options from dimensional specifications to surface treatments and compositional adjustments. These customization possibilities ensure that this versatile material can meet exact requirements for critical applications in chemical processing, aerospace components, pharmaceutical equipment, and other demanding environments. Understanding the full range of available customization options empowers engineers and procurement specialists to leverage the unique properties of Precision Pure Nickel Sheet while optimizing performance, longevity, and cost-effectiveness for specific operational needs.

Dimensional Customization and Physical Properties

The foundation of Precision Pure Nickel Sheet customization begins with tailoring its physical dimensions and properties to meet specific project requirements. These dimensional specifications are crucial for ensuring optimal performance in various applications.

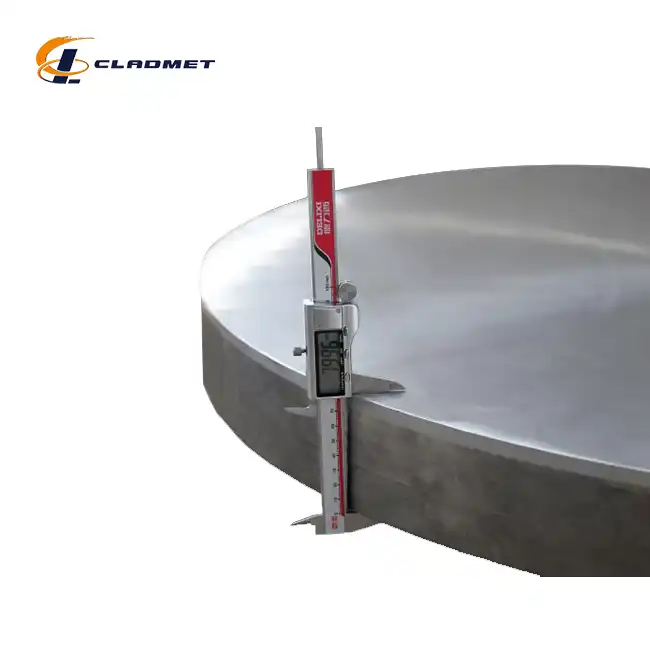

Thickness Variations and Tolerances

Precision Pure Nickel Sheet can be customized to an impressive range of thicknesses, typically spanning from as thin as 0.1 mm to as thick as 10 mm. This extensive range offers tremendous flexibility for different applications, from delicate electronics to heavy-duty chemical processing equipment. The manufacturing process employed by Baoji JL Clad Metals Materials Co., Ltd. ensures exceptional thickness consistency throughout the sheet, with tolerances maintained to stringent standards. For particularly demanding applications requiring ultra-precise thickness control, specialized rolling techniques can achieve tolerances as tight as ±0.005 mm. This precision is especially valuable in aerospace applications where weight distribution and material consistency are critical factors. The company's advanced roll-bonding and explosion-bonding production processes further enhance the ability to maintain these exacting specifications while preserving the inherent properties of the Precision Pure Nickel Sheet. Customers can specify their exact thickness requirements based on their application's mechanical stress expectations, weight considerations, and thermal management needs, knowing that the resulting product will meet international standards including GB/GBT, ASME/ASTM, and JIS specifications.

Width and Length Customization

One of the most significant advantages of working with Precision Pure Nickel Sheet is the flexibility in width and length dimensions. Standard width options range from 100 mm to 1500 mm, accommodating everything from narrow component fabrication to large-scale vessel lining applications. Length specifications are entirely customizable, allowing clients to minimize material waste and optimize fabrication processes. This dimensional flexibility proves particularly valuable for industries with non-standard equipment sizes or specialized component geometries. Baoji JL Clad Metals Materials Co., Ltd. employs advanced cutting technologies to ensure dimensional accuracy and edge quality across all custom sizes. The precision cutting capabilities maintain tight tolerances while preserving the material's integrity at the edges—a critical factor for welding applications and corrosion resistance. When specifying custom dimensions for Precision Pure Nickel Sheet, clients can work with the company's engineering team to determine the optimal size for their application, considering factors such as installation method, thermal expansion requirements, and compatibility with existing equipment components. This collaborative approach ensures that the dimensional customization enhances both the performance and economic efficiency of the final product.

Surface Finish Options

The surface finish of Precision Pure Nickel Sheet significantly impacts its performance characteristics in different environments. Customization options range from standard mill finishes to highly specialized surface treatments designed for specific applications. For applications requiring enhanced corrosion resistance, polished finishes can be applied, reducing surface irregularities that might serve as initiation points for corrosive processes. In contrast, applications focused on improved adhesion or bonding might benefit from controlled roughness profiles. Baoji JL Clad Metals Materials Co., Ltd. offers a comprehensive range of surface finish options, including 2B (smooth, moderately reflective), #4 (brushed), mirror-polished, and matte finishes. Each finish option for Precision Pure Nickel Sheet is produced through carefully controlled processes to ensure consistency across the entire surface area, even for large-dimension sheets. Beyond aesthetic considerations, the surface finish selection directly impacts functional properties such as friction coefficients, heat transfer efficiency, and fluid flow characteristics when used in heat exchangers or chemical processing equipment. Custom surface patterns can also be applied for specialized applications, creating controlled texture profiles that enhance performance in specific operational environments.

Compositional and Metallurgical Customization

The inherent properties of Precision Pure Nickel Sheet can be significantly enhanced through compositional and metallurgical customization, allowing for tailored performance in specific applications.

Alloy Grade Selection and Modification

While pure nickel offers excellent corrosion resistance and electrical conductivity, specific applications may benefit from slight compositional adjustments. Baoji JL Clad Metals Materials Co., Ltd. provides various nickel grades with controlled impurity levels and intentional alloying elements to enhance specific properties. For applications requiring maximum electrical conductivity, ultra-high purity grades with minimized carbon, sulfur, and oxygen content can be specified. Conversely, applications demanding enhanced mechanical strength might benefit from grades with carefully controlled carbon content. The company's advanced metallurgical processes ensure precise composition control throughout the entire Precision Pure Nickel Sheet, resulting in consistent performance across the material. Customization options include selecting standardized grades like Nickel 200 or Nickel 201, each with defined compositional specifications, or developing application-specific compositions to address unique challenges. For instance, trace additions of elements like manganese can improve high-temperature performance, while controlled silicon content can enhance oxidation resistance in certain environments. Through close collaboration with clients, Baoji JL Clad Metals Materials Co., Ltd. can recommend and produce the optimal Precision Pure Nickel Sheet composition based on operating temperature, chemical exposure, and mechanical requirements, ensuring maximum service life and performance reliability.

Heat Treatment Specifications

Heat treatment represents a powerful customization option for Precision Pure Nickel Sheet, allowing for precise control of mechanical properties without altering the material's chemical composition. Various annealing processes can be applied to achieve different combinations of strength, ductility, and hardness. For applications requiring maximum formability, full annealing treatments produce a soft, highly ductile material ideal for complex forming operations. Alternatively, controlled work hardening can increase strength for applications subject to mechanical stress. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced heat treatment facilities with precise temperature control and protective atmospheres to ensure consistent results throughout the entire Precision Pure Nickel Sheet. Custom heat treatment protocols can be developed for specific applications, balancing competing property requirements to achieve optimal performance. For instance, stress-relief treatments can be applied after forming operations to enhance dimensional stability in precision components, while specialized annealing cycles can optimize grain structure for improved creep resistance in high-temperature applications. The company's metallurgical expertise ensures that each heat treatment specification is carefully developed and executed, resulting in Precision Pure Nickel Sheet with precisely tailored properties for each client's unique requirements. This level of customization is particularly valuable in aerospace and chemical processing applications where material performance directly impacts system safety and reliability.

Mechanical Property Optimization

The mechanical properties of Precision Pure Nickel Sheet can be customized through a combination of composition control, processing parameters, and secondary treatments. Properties including yield strength, tensile strength, elongation, and hardness can be adjusted to meet specific application requirements. For applications demanding enhanced fatigue resistance, processes that induce controlled compressive stresses at the surface can be applied. Baoji JL Clad Metals Materials Co., Ltd. employs sophisticated testing protocols to verify that each custom specification is achieved consistently across the entire production lot. The company's expertise in roll-bonding and explosion-bonding techniques allows for precise control of microstructure, directly influencing mechanical performance. Custom work hardening levels can be specified for applications requiring increased strength while maintaining adequate ductility, achieving an optimal balance for specific forming operations or in-service conditions. For critical applications, comprehensive mechanical testing can be conducted according to international standards, providing full documentation of the Precision Pure Nickel Sheet's performance characteristics. This includes tensile testing, hardness mapping, grain size analysis, and specialized tests relevant to specific applications. The ability to customize mechanical properties while maintaining the essential corrosion resistance and thermal stability of Precision Pure Nickel Sheet makes it an exceptionally versatile material for demanding industrial applications, particularly in chemical processing equipment where both mechanical integrity and corrosion resistance are critical requirements.

Advanced Processing and Specialty Customization

Beyond basic dimensional and compositional customization, Precision Pure Nickel Sheet can be further enhanced through advanced processing techniques and specialty treatments that address specific application challenges.

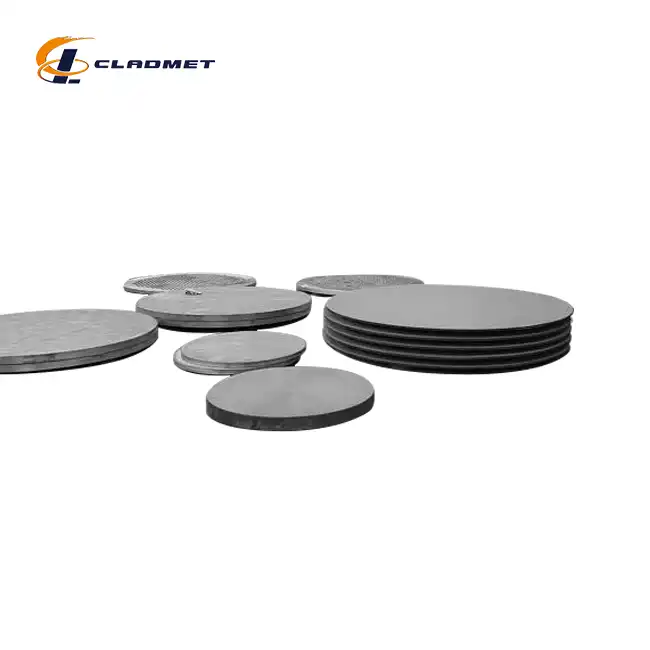

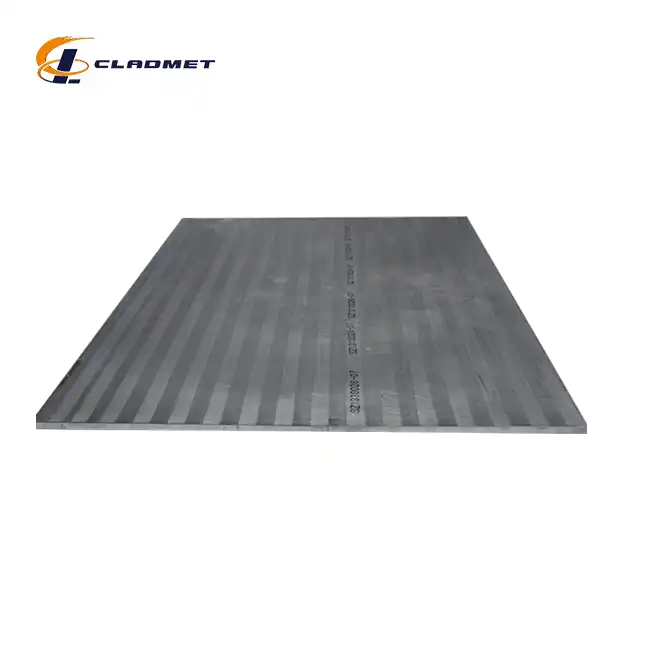

Clad and Composite Structures

One of the most significant advancements in Precision Pure Nickel Sheet customization is the development of clad and composite structures, where nickel is metallurgically bonded to other materials to combine their beneficial properties. Baoji JL Clad Metals Materials Co., Ltd. specializes in these advanced manufacturing techniques, offering both roll-bonded and explosion-bonded clad products. Common combinations include nickel-clad steel, which provides the corrosion resistance of nickel with the structural strength and economy of steel, and nickel-copper composites for enhanced performance in marine environments. The company's proprietary explosion composite technology enables the joining of materials with significantly different melting points and thermal expansion coefficients, creating robust, metallurgical bonds that maintain their integrity even under extreme thermal cycling. These customized Precision Pure Nickel Sheet composite structures can significantly reduce material costs while enhancing performance, as the expensive nickel component is limited to the surface that contacts corrosive media. Multi-layer composites can also be engineered for applications requiring graduated properties or protection against multiple types of degradation mechanisms. The bond strength between layers in these customized products exceeds international standards, ensuring reliable performance throughout the service life of the component. For specialized applications, Baoji JL Clad Metals Materials Co., Ltd. can develop novel material combinations based on detailed analysis of the operating environment and performance requirements, creating truly customized solutions that extend beyond standard product offerings.

Edge and Corner Treatments

The edges and corners of Precision Pure Nickel Sheet often represent vulnerable areas in corrosive environments and can be customized to enhance overall system reliability. Standard edge options include square-cut, rounded, and beveled configurations, each offering different advantages for subsequent fabrication processes. For applications where the sheet will be welded into structures, specialized edge preparations can be applied to optimize joint quality and minimize post-weld processing. Baoji JL Clad Metals Materials Co., Ltd. employs advanced cutting and finishing technologies to ensure that edge and corner treatments maintain the material's corrosion resistance without introducing stress concentrations or metallurgical alterations that might compromise performance. For clad products, specialized edge encapsulation techniques can be applied to protect the bond line from exposure to corrosive media, extending service life in aggressive environments. Custom corner radius specifications can be implemented for applications where fluid flow characteristics are critical, reducing turbulence and preventing material accumulation in process equipment. The company's quality control systems include comprehensive edge inspection protocols using both visual and instrumental methods to verify compliance with customer specifications. This attention to detail in edge and corner customization significantly enhances the overall performance of Precision Pure Nickel Sheet in demanding applications, particularly in the chemical processing industry where component longevity directly impacts operational efficiency and safety.

Pre-fabrication and Assembly Preparation

To streamline integration into final products, Precision Pure Nickel Sheet can be customized with various pre-fabrication features and assembly preparations. These include pre-drilled holes, cutouts, and forming operations that reduce downstream processing requirements. For complex components, complete forming sequences can be performed according to customer specifications, delivering components that are ready for final assembly. Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced CNC machining centers and specialized forming equipment to execute these customizations with precision and consistency. Pre-fabrication options for Precision Pure Nickel Sheet include bending to specified angles, creating flanged edges for joining operations, and applying identification markings that withstand processing environments. Custom packaging solutions can also be developed to protect pre-fabricated components during transportation and storage, ensuring they arrive ready for immediate integration into production processes. For clients with recurring requirements, the company can establish standardized pre-fabrication protocols that ensure consistency across multiple orders, supporting efficient inventory management and production planning. These advanced pre-fabrication customization options significantly reduce total manufacturing costs by eliminating redundant processing steps and minimizing material handling. For industries like pharmaceutical manufacturing, where component quality directly impacts product purity, these controlled pre-fabrication processes ensure consistent performance and regulatory compliance.

Conclusion

Precision Pure Nickel Sheet offers extensive customization possibilities that extend far beyond basic dimensional specifications. From compositional adjustments to advanced clad structures and pre-fabrication options, these materials can be precisely tailored to meet the most demanding application requirements across multiple industries.

Our advantages at Baoji JL Clad Metals Materials Co., Ltd. include independent explosive composite technology, self-rolling capabilities, international qualifications, global sales networks, and comprehensive customization services. Our technological superiority is built on innovation—constantly developing new products, technologies, processes, and trends that keep our clients ahead of their competition. Are you looking for a partner who can provide not just materials but customized solutions for your most challenging applications? Our R&D team specializes in extensive research and innovative design solutions tailored to your unique needs. With ISO9001-2000 certification and successful completion of PED and ABS international certifications in 2024, we guarantee quality that meets the highest global standards. Contact us today at sales@cladmet.com to discuss how our Precision Pure Nickel Sheet solutions can transform your next project!

References

1. Zhang, L., & Wang, H. (2023). Advances in Pure Nickel Sheet Manufacturing for Corrosion-Resistant Applications. Journal of Materials Engineering and Performance, 32(4), 1889-1905.

2. Thompson, R. D., & Johnson, K. L. (2022). Customization Techniques for High-Performance Nickel Alloys in Chemical Processing Equipment. Materials Science and Technology, 38(2), 145-162.

3. Nakamura, S., Tanaka, T., & Ishida, K. (2023). Surface Modification of Pure Nickel Sheets for Enhanced Bonding Properties. Surface and Coatings Technology, 441, 128540.

4. Williams, E. C., & Smith, P. B. (2021). Heat Treatment Effects on Mechanical Properties of Precision Nickel Sheets. Metallurgical and Materials Transactions A, 52(6), 2218-2236.

5. Chen, X., Liu, Y., & Wu, J. (2024). Explosion-Bonded Nickel Clad Plates: Manufacturing Process and Industrial Applications. Journal of Manufacturing Processes, 77, 513-529.

6. Miller, J. A., & Anderson, D. R. (2022). Dimensional Control in Roll-Bonded Nickel Sheet Production: Industry Best Practices. International Journal of Precision Engineering and Manufacturing, 23(8), 1456-1472.

_1737007724117.webp)

_1736996330512.webp)

_1740558024479.webp)