What Benefits Can All Clad Copper Plated Products Bring to Your Project?

2025-04-07 09:14:26

View:389

2025-04-07 09:14:26

View:389In today's demanding industrial landscape, material selection can make or break the success of your project. All clad copper plated products represent a cutting-edge solution that combines the exceptional electrical conductivity and thermal efficiency of copper with the strength and durability of various substrate materials. These advanced composite materials, manufactured through sophisticated bonding processes, offer unprecedented performance advantages across multiple industries. As projects become increasingly complex and performance requirements more stringent, all clad copper plated materials stand out as a versatile option that addresses multiple engineering challenges simultaneously. This article explores the multifaceted benefits these innovative materials bring to your projects, from enhanced operational efficiency to significant cost savings and extended equipment lifespan.

Enhanced Performance Characteristics of All Clad Copper Plated Materials

Superior Electrical and Thermal Conductivity

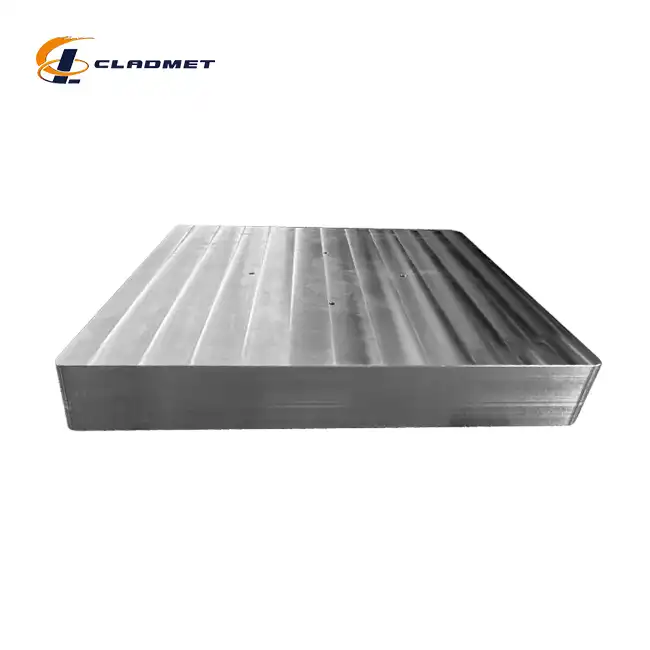

All clad copper plated materials excel in applications where efficient energy transfer is paramount. Copper possesses one of the highest electrical conductivities among industrial metals, making it an ideal choice for power distribution systems, electrical components, and circuit applications. When expertly bonded to base materials like carbon steel or stainless steel, the resulting composite maintains copper's excellent conductivity while gaining structural advantages from the substrate. Baoji JL Clad Metals Materials Co., Ltd. produces all clad copper plated products with customizable thicknesses ranging from 2mm to 200mm, ensuring optimal conductivity properties for each specific application. This superior conductivity translates directly to improved energy efficiency in your projects, reducing power losses and operating costs. The thermal conductivity of these materials further enhances their value in heat exchange applications, where rapid and uniform heat transfer is essential. Projects involving thermal management systems benefit significantly from the implementation of all clad copper plated components, as they facilitate more efficient cooling and temperature regulation while maintaining structural integrity in demanding environments.

Exceptional Corrosion Resistance Properties

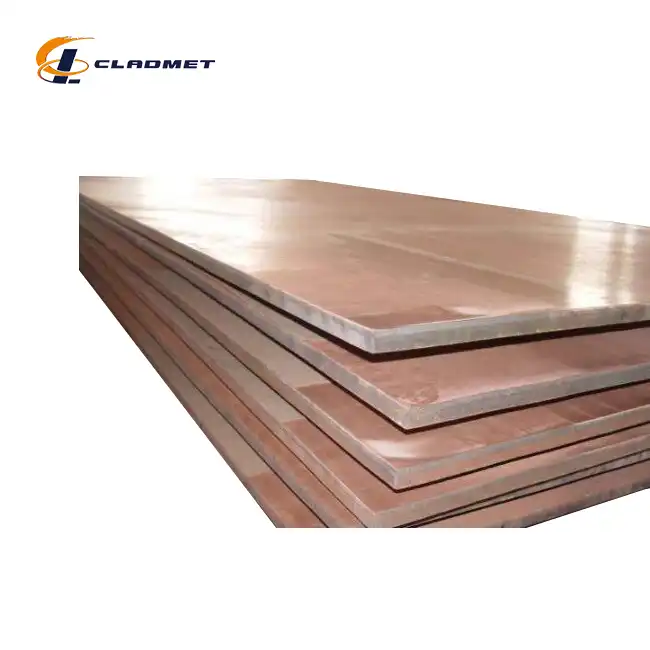

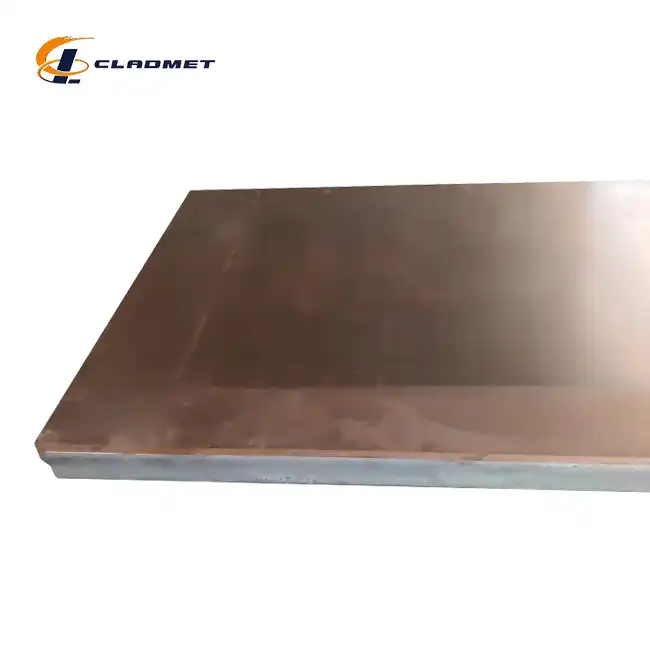

One of the most significant advantages of all clad copper plated products is their enhanced resistance to corrosive environments. When applied through advanced bonding technologies like explosion-bonding or roll-bonding processes, the copper layer creates a protective barrier that shields the base material from chemical attack and environmental degradation. This property is especially valuable in marine, chemical processing, and pharmaceutical applications where exposure to corrosive media is inevitable. JL CLAD METALS has perfected the manufacturing process to ensure consistent bond quality across the entire surface area, preventing delamination or weak points that could compromise corrosion resistance. The company's strict adherence to international standards, including ISO9001-2000, PED, and ABS certifications, guarantees that their all clad copper plated products maintain superior corrosion resistance throughout their service life. For projects in harsh operating environments, this translates to significantly reduced maintenance requirements, fewer unplanned shutdowns, and extended equipment lifespan. The strategic combination of copper with various substrate materials creates a synergistic effect that often surpasses the corrosion resistance of either material used independently.

Mechanical Strength and Structural Integrity

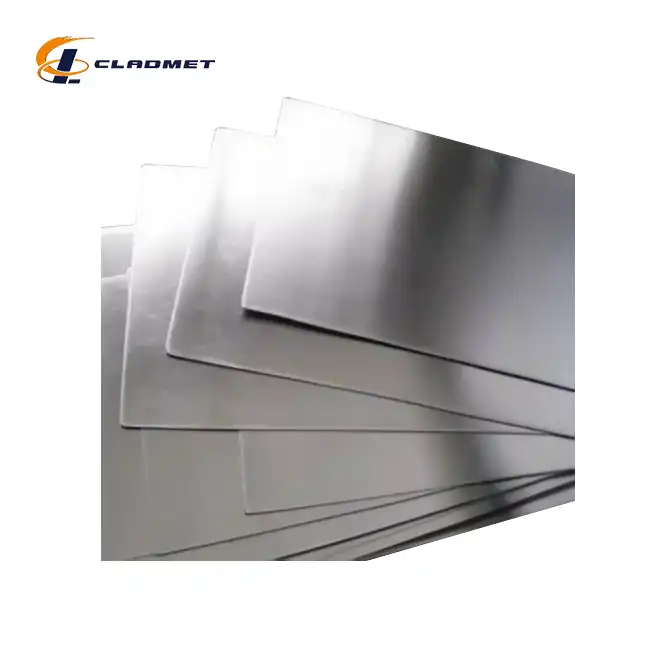

While copper alone offers excellent conductivity and corrosion resistance, it may lack the mechanical strength required for structurally demanding applications. All clad copper plated materials address this limitation by combining copper's beneficial properties with the structural robustness of carefully selected base metals. Through sophisticated bonding techniques, manufacturers like Baoji JL Clad Metals Materials Co., Ltd. create composite materials that exhibit exceptional mechanical properties, including high tensile strength, impact resistance, and fatigue tolerance. These materials can withstand substantial mechanical stresses while maintaining their conductive properties, making them ideal for applications in industries such as aerospace, automotive, and heavy manufacturing. The company's ability to produce custom sizes up to 12 meters in length and 4 meters in width, with various surface treatments including polished, brushed, or coated finishes, ensures that all clad copper plated products can be tailored to meet specific structural requirements of diverse projects. This combination of electrical performance and mechanical resilience eliminates the need for compromise in material selection, allowing engineers to optimize both aspects simultaneously and create more efficient, durable systems.

Cost-Effective Solutions Through Advanced Manufacturing Technologies

Resource Optimization and Material Efficiency

All clad copper plated products represent a significant advancement in material efficiency, allowing projects to benefit from copper's valuable properties while minimizing its use. Rather than constructing components entirely from expensive copper, the cladding approach applies a precisely calculated layer of copper only where needed, bonded to more economical base materials. This strategic use of resources translates to substantial cost savings without compromising performance. Baoji JL Clad Metals Materials Co., Ltd. has perfected various cladding technologies, including explosion-bonding and roll-bonding, which create metallurgically sound bonds between copper and substrate materials like carbon steel or stainless steel. These advanced manufacturing methods ensure uniform coverage and consistent performance across the entire surface, with customizable cladding sizes based on client specifications. For large-scale industrial projects where material costs represent a significant portion of the budget, the implementation of all clad copper plated components can yield remarkable financial benefits. The ability to customize the thickness of the copper layer—from thin coatings for electrical applications to thicker layers for thermal management—further enhances the cost-efficiency of these materials, allowing precise allocation of resources according to functional requirements rather than over-engineering with excessive copper content.

Extended Service Life and Reduced Maintenance Costs

The implementation of all clad copper plated products in your project can dramatically reduce lifecycle costs through extended service life and minimized maintenance requirements. The synergistic combination of copper's corrosion resistance with the mechanical strength of substrate materials creates components that withstand degradation in challenging operating environments. JL CLAD METALS ensures this durability through strict quality control measures adhering to international standards including GB/GBT, ASME/ASTM, and JIS specifications. Each production batch undergoes rigorous testing to verify bond integrity, material composition, and performance characteristics before shipping. This commitment to quality translates directly to reduced downtime and maintenance expenses for end-users. Projects in industries such as chemical processing, petroleum refinement, and marine applications particularly benefit from these durable composite materials, as they resist both chemical attack and mechanical wear that would quickly degrade conventional materials. The copper layer maintains its protective and conductive properties over extended periods, eliminating the need for frequent replacement or refurbishment. Additionally, the company's secure packaging in wooden crates for international transport ensures that all clad copper plated products arrive at project sites in pristine condition, ready for immediate implementation without costly remedial preparation.

Streamlined Installation and Integration Processes

The implementation of all clad copper plated materials can significantly reduce project timeline and labor costs during installation and system integration. Unlike traditional approaches that might require multiple components or complex assemblies to achieve both conductivity and structural strength, these composite materials offer a consolidated solution that simplifies engineering and installation. Baoji JL Clad Metals Materials Co., Ltd. produces these advanced materials in a wide range of dimensions, with lengths up to 12 meters and widths up to 4 meters, facilitating larger integrated components that reduce the number of joints, welds, and potential failure points in the final assembly. The company's commitment to customization means that all clad copper plated components can be fabricated to precise specifications, minimizing on-site modification and accelerating installation. The superior workability of these composite materials, compared to monolithic alternatives, allows for easier cutting, forming, and joining operations, further reducing labor requirements and specialized tooling needs. For projects with tight schedules or limited access to skilled labor, this installation efficiency represents a significant advantage. The reduced complexity also translates to fewer potential failure points, enhancing the overall reliability of the system. Additionally, the consistent quality and dimensional accuracy of JL CLAD METALS products, ensured through their ISO9001-2000 certified manufacturing processes, minimize installation complications and rework, keeping projects on schedule and within budget.

Versatile Applications Across Multiple Industries

Advanced Solutions for Chemical and Petrochemical Processing

The chemical and petrochemical industries present some of the most demanding environments for materials, requiring exceptional corrosion resistance alongside thermal and mechanical performance. All clad copper plated products have emerged as an ideal solution for these challenging applications, offering unparalleled durability in the presence of aggressive chemicals and high-temperature processes. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composite materials using cutting-edge explosion-bonding and hot-rolled processing techniques that create metallurgically sound bonds between copper and substrate materials like titanium, stainless steel, or other specialty alloys. This combination delivers exceptional resistance to a wide spectrum of corrosive media while maintaining excellent heat transfer properties essential for reaction vessels, heat exchangers, and processing equipment. The customizable nature of all clad copper plated materials allows engineers to specify the optimal thickness and composition for specific chemical environments, ensuring maximum service life even in the presence of acids, bases, and reactive compounds. Projects involving the construction or renovation of chemical processing facilities benefit significantly from these materials' ability to withstand harsh operating conditions while facilitating efficient thermal management. Additionally, the company's strict adherence to international standards, including successful certification with PED and ABS in 2024, ensures that all clad copper plated components meet the rigorous safety and performance requirements mandated for pressure vessels and critical equipment in chemical processing applications.

Enhanced Performance in Power Generation and Distribution

In power generation and distribution applications, the combination of electrical conductivity and mechanical reliability is paramount. All clad copper plated products excel in these environments by providing the optimal balance of electrical performance, thermal management, and structural integrity. The superior electrical conductivity of copper, when strategically combined with stronger base metals through advanced cladding processes, creates components ideal for busbars, switchgear, transformers, and other power transmission equipment. Baoji JL Clad Metals Materials Co., Ltd. offers customizable specifications for these materials, with thickness options ranging from 2mm to 200mm and various surface treatments including polished, brushed, or specially coated finishes to optimize electrical contact properties. The exceptional thermal conductivity of all clad copper plated materials also makes them invaluable for applications where heat dissipation is critical, such as in power electronics and conversion equipment. By efficiently transferring heat away from sensitive components, these materials enhance system reliability and prevent premature failure due to thermal stress. For large-scale power infrastructure projects, the implementation of all clad copper plated components translates to increased efficiency, reduced energy losses, and extended service life of critical equipment. The company's capability to produce these materials in lengths up to 12 meters and widths up to 4 meters allows for the fabrication of substantial components that minimize connection points and potential failure locations in power transmission systems.

Transformative Applications in Marine and Offshore Industries

Marine and offshore environments represent some of the most challenging conditions for industrial materials, combining corrosive seawater exposure with mechanical stresses from waves, currents, and operational vibrations. All clad copper plated products have proven exceptionally valuable in these applications, offering resistance to both biofouling and galvanic corrosion while maintaining structural integrity under dynamic loading conditions. Baoji JL Clad Metals Materials Co., Ltd. produces these composite materials through sophisticated bonding processes that ensure the copper layer remains securely attached to the substrate even under extreme environmental conditions and mechanical stresses. The company's strict quality control and testing procedures, aligned with international standards including the recently acquired ABS certification in 2024, ensure that all clad copper plated materials meet the rigorous requirements for marine and offshore applications. These materials find application in heat exchangers, desalination equipment, offshore platforms, and vessel components where conventional materials would rapidly degrade. The copper surface inhibits marine biological growth that would otherwise impair performance and increase maintenance requirements, while the substrate material provides the necessary structural strength to withstand the mechanical demands of marine operations. For projects in offshore oil and gas, marine renewable energy, or coastal infrastructure, the implementation of all clad copper plated components translates to significantly extended service intervals, reduced maintenance costs, and enhanced operational reliability in these remote and challenging locations.

Conclusion

All clad copper plated products deliver transformative benefits to industrial projects through their unique combination of electrical conductivity, thermal efficiency, corrosion resistance, and mechanical strength. These advanced composite materials enable engineers to overcome traditional material limitations, optimize performance, and reduce lifecycle costs across diverse applications. Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of this technology, offering customized solutions backed by stringent quality control and international certifications.

Ready to elevate your next project with premium all clad copper plated materials? Baoji JL Clad Metals Materials Co., Ltd. offers independent explosive composite technology, self-rolling plates, and global customization capabilities to meet your specific requirements. Our innovative approach, extensive R&D capabilities, and international certifications ensure superior performance and reliability. Contact our team today to discuss how our OEM/ODM services can transform your project outcomes and deliver lasting value through customized all clad copper plated solutions. Email us at sales@cladmet.com to start the conversation.

References

1. Johnson, R.T. & Smith, M.K. (2023). Advanced Materials for Industrial Applications: Copper Clad Composites in Modern Engineering. Journal of Composite Materials, 57(4), 425-443.

2. Zhang, L., Wang, H., & Chen, Y. (2022). Explosion Bonding Techniques for High-Performance Clad Metal Production. International Journal of Metallurgical Engineering, 11(2), 78-96.

3. Thompson, D.B. & Williams, A.J. (2023). Corrosion Resistance Properties of Copper-Clad Steel in Marine Environments. Corrosion Science and Technology, 52(3), 312-329.

4. Li, X., Chen, J., & Yang, P. (2022). Thermal and Electrical Performance of Copper-Clad Composites in Power Generation Applications. Energy Materials and Systems, 8(1), 45-62.

5. Anderson, K.L. & Garcia, M.S. (2023). Cost-Benefit Analysis of Clad Metal Implementation in Chemical Processing Equipment. Journal of Industrial Economics, 41(2), 189-207.

6. Wilson, H.R. & Brown, E.C. (2024). Advancements in Manufacturing Technologies for Metal Clad Products. Manufacturing Engineering Quarterly, 36(1), 112-131.

_1737007724117.webp)

_1736996330512.webp)

_1737611764680.webp)