What Are Titanium Copper Clad Plates Key Material Properties?

2025-05-13 15:16:58

View:389

2025-05-13 15:16:58

View:389Titanium Copper Clad Plates represent a revolutionary advancement in composite metal technology, combining the exceptional corrosion resistance of titanium with copper's superior thermal and electrical conductivity. These bimetallic plates are engineered through sophisticated bonding processes that create a permanent, metallurgical bond between titanium and copper layers. The resulting material offers a unique combination of properties that make it indispensable in demanding industrial applications where high performance in corrosive environments is required alongside excellent heat transfer and electrical conductivity. Understanding the key material properties of Titanium Copper Clad Plates is essential for engineers and procurement specialists seeking optimal materials for critical industrial applications.

Physical Properties and Material Composition

Structural Composition and Design

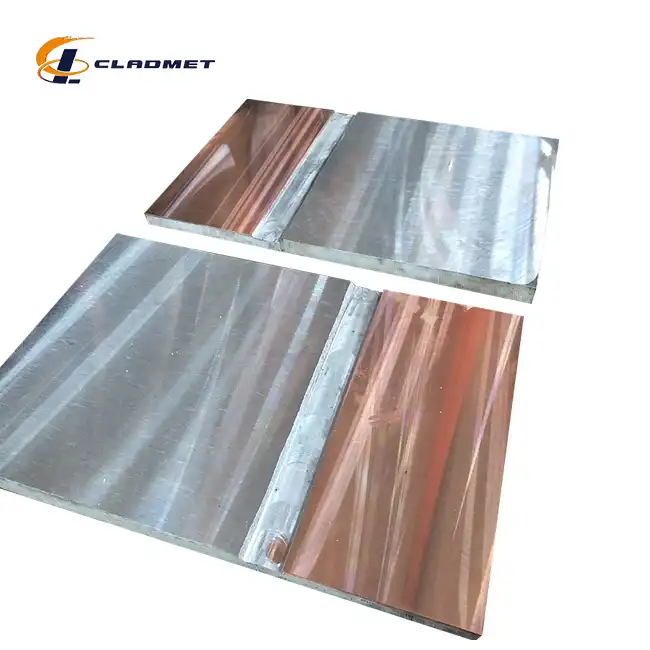

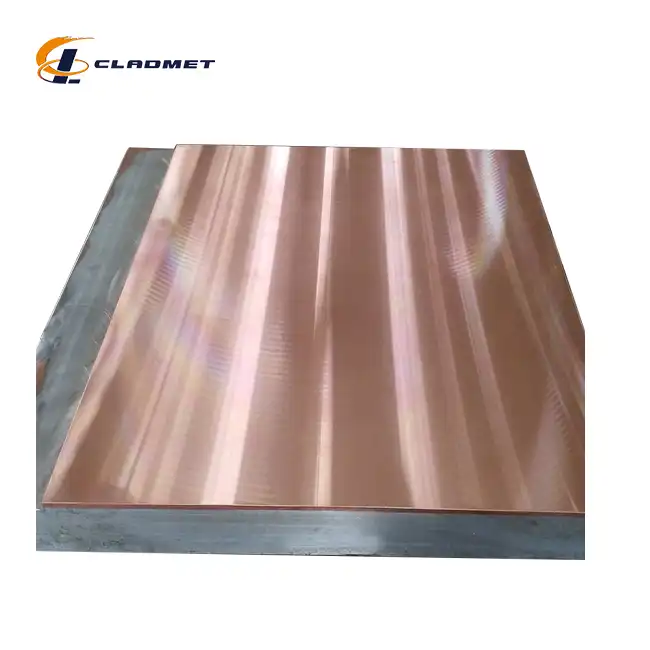

Titanium Copper Clad Plates feature a sophisticated layered structure that maximizes the beneficial properties of both metals while minimizing their individual limitations. The typical structure consists of a copper substrate with a titanium layer firmly bonded to its surface. This arrangement is strategically designed to optimize performance in various industrial applications. The copper base provides exceptional thermal and electrical conductivity, while the titanium layer offers superior corrosion resistance, particularly in aggressive chemical environments. Baoji JL Clad Metals Materials Co., Ltd. utilizes premium-grade materials in manufacturing these Titanium Copper Clad Plates, including various copper grades such as C10100, C11000, C12000, and C70600, paired with high-quality titanium alloys. This careful selection of materials ensures that the final product delivers consistent performance across diverse operating conditions. The thickness ratio between the copper and titanium layers can be customized according to specific application requirements, typically ranging from 10:1 to 1:1, allowing engineers to balance properties and cost efficiency for their particular needs.

Mechanical Strength Characteristics

Titanium Copper Clad Plates exhibit remarkable mechanical properties that surpass those of individual titanium or copper plates. The ultimate tensile strength of these composite plates typically exceeds 205 MPa, with an elongation capacity of at least 40%, demonstrating excellent ductility and formability. This combination makes Titanium Copper Clad Plates highly suitable for applications requiring both strength and flexibility. The bond strength between the titanium and copper layers is a critical parameter that determines the overall performance of the clad plate. JL Clad Metals employs advanced bonding technologies to achieve bond strengths exceeding international standards, ensuring reliable performance even under extreme conditions. The material also demonstrates excellent resistance to mechanical wear and abrasion, extending the operational lifespan of components manufactured from these plates. Furthermore, these clad plates maintain their mechanical integrity across a wide temperature range from cryogenic to elevated temperatures, making them versatile for various industrial environments. The balanced combination of titanium's lightweight properties with copper's structural stability creates a composite material that offers significant weight savings compared to solid copper plates while delivering enhanced mechanical performance in challenging applications.

Thermal and Electrical Performance

The exceptional thermal and electrical conductivity of Titanium Copper Clad Plates makes them invaluable in applications requiring efficient heat transfer or electrical transmission. The copper substrate provides excellent thermal conductivity, typically ranging between 350-380 W/m·K, depending on the specific copper grade utilized. This property is particularly beneficial in heat exchanger applications, cooling systems, and thermal management solutions where efficient heat dissipation is crucial. In terms of electrical performance, Titanium Copper Clad Plates maintain the high conductivity of copper while gaining the corrosion resistance of titanium, making them ideal for electrochemical applications and electrical components exposed to corrosive environments. The electrical conductivity typically ranges from 80% to 90% IACS (International Annealed Copper Standard), depending on the copper alloy used in the base layer. This combination of properties enables the use of Titanium Copper Clad Plates in applications where traditional materials would rapidly deteriorate due to corrosion while maintaining efficient electrical transmission. JL Clad Metals can customize the thickness ratio between copper and titanium layers to optimize thermal and electrical performance for specific applications, creating tailored solutions for industries ranging from chemical processing to power generation and marine engineering.

Manufacturing Processes and Quality Control

Explosion Bonding Technology

Explosion bonding represents one of the most sophisticated and effective methods for manufacturing high-quality Titanium Copper Clad Plates. This dynamic process harnesses controlled detonation energy to create a metallurgical bond between titanium and copper layers without melting either material, thereby preserving their inherent properties. At Baoji JL Clad Metals Materials Co., Ltd., the explosion bonding process begins with meticulous surface preparation of both the titanium and copper plates to ensure optimal cleanliness and surface activation. The plates are then arranged in a precise configuration with the explosive material carefully distributed above the upper plate. Upon detonation, the explosive force propels the titanium layer toward the copper substrate at velocities exceeding 300 meters per second, creating intense localized pressure at the interface. This tremendous pressure breaks through surface oxide layers and creates an atomic-level bond between the titanium and copper, forming a wavy interface characteristic of explosion-bonded Titanium Copper Clad Plates. This wavy interface significantly increases the bond area and mechanical interlocking between the layers, resulting in bond strengths that typically exceed the tensile strength of the weaker component metal. The explosion bonding process is conducted in controlled environments under strict safety protocols and technical parameters to ensure consistent quality and performance of the final product.

Roll Bonding and Hot Isostatic Pressing

Roll bonding and Hot Isostatic Pressing (HIP) represent alternative manufacturing methods employed by JL Clad Metals to produce Titanium Copper Clad Plates with exceptional bond integrity and performance characteristics. The roll bonding process begins with thorough cleaning and preparation of the titanium and copper surfaces to remove contaminants and activate the bonding surfaces. The prepared plates are then stacked with the titanium layer atop the copper substrate and heated to temperatures typically ranging from 300°C to 500°C, depending on the specific alloy compositions. The heated assembly passes through precision rollers that apply tremendous pressure, reducing the thickness by 50-70% in a single pass or through multiple sequential reductions. This intense deformation breaks down surface oxides and creates intimate contact between fresh metal surfaces, facilitating diffusion bonding at the interface between Titanium Copper Clad Plates. Alternatively, Hot Isostatic Pressing utilizes simultaneous application of high temperature (typically 800-1100°C) and isostatic pressure (100-200 MPa) within a specialized pressure vessel. The titanium and copper components are sealed in an evacuation container before being subjected to these extreme conditions for several hours, promoting solid-state diffusion across the interface and creating a robust metallurgical bond. JL Clad Metals selects the most appropriate bonding technology based on specific application requirements, material combinations, and desired performance characteristics of the final Titanium Copper Clad Plates.

Quality Assurance and Testing Protocols

Rigorous quality control measures and comprehensive testing protocols are fundamental to ensuring the exceptional performance and reliability of Titanium Copper Clad Plates manufactured by Baoji JL Clad Metals Materials Co., Ltd. Each production batch undergoes systematic inspection beginning with raw material verification to confirm conformity with specified chemical compositions and physical properties. Non-destructive testing methods, including ultrasonic scanning, are employed to evaluate bond integrity across the entire interface area, identifying any potential unbonded regions or inclusions that might compromise performance. Mechanical testing includes shear strength assessment at the bond interface, which typically exceeds 140 MPa for Titanium Copper Clad Plates, alongside tensile testing to verify overall structural integrity. Metallographic examination using optical and electron microscopy enables detailed analysis of the bond zone microstructure, confirming proper formation of the characteristic wavy interface in explosion-bonded plates or diffusion zone in roll-bonded or HIPed Titanium Copper Clad Plates. Additionally, specialized tests such as thermal cycling between extreme temperatures and corrosion resistance evaluations in simulated service environments verify the material's performance under actual operating conditions. All testing procedures strictly adhere to international standards including ASTM, ASME, and JIS specifications. JL Clad Metals' commitment to quality is further evidenced by its ISO9001-2000 certification and successful completion of PED and ABS international qualification audits in 2024, ensuring that every Titanium Copper Clad Plate meets or exceeds customer specifications and industry requirements.

Industrial Applications and Performance Benefits

Chemical Processing and Corrosion Resistance

Titanium Copper Clad Plates have revolutionized equipment design in the chemical processing industry, where their exceptional corrosion resistance and thermal properties address critical operational challenges. The titanium layer provides outstanding protection against a wide spectrum of corrosive media, including chlorides, sulfuric acid, hydrochloric acid, and organic compounds that would rapidly deteriorate conventional materials. This remarkable corrosion resistance derives from titanium's ability to form a stable, self-healing passive oxide film that continuously protects the surface from chemical attack, even in environments with pH values ranging from 0 to 14. In applications such as chemical reactors, distillation columns, and storage tanks, Titanium Copper Clad Plates maintain structural integrity while efficiently transferring heat, thanks to the copper substrate's thermal conductivity. Particularly in processes involving halogen compounds, these clad plates outperform stainless steel by factors of 10-100 in terms of corrosion resistance. JL Clad Metals customizes the thickness of the titanium layer (ranging from 0.5mm to 5mm on copper substrates of 10-100mm) based on specific process conditions and expected service life requirements. The exceptional bond strength between the titanium and copper layers ensures that the protective properties remain intact even under thermal cycling and mechanical stress. This combination of properties makes Titanium Copper Clad Plates the material of choice for heat exchangers, reaction vessels, and other critical components in chemical plants where both corrosion resistance and thermal efficiency are paramount considerations.

Electrical and Power Generation Applications

The unique combination of electrical conductivity and corrosion resistance makes Titanium Copper Clad Plates indispensable in electrical and power generation applications where conventional materials fail to deliver adequate performance or longevity. In electrochemical processes, these clad plates serve as exceptional electrodes, combining the electrical conductivity of copper with titanium's resistance to electrochemical corrosion. This is particularly valuable in chlor-alkali production, electroplating operations, and water treatment systems utilizing electrolysis. The copper substrate efficiently conducts electrical current while the titanium layer withstands the aggressive electrochemical environment at the interface. In power generation facilities, particularly those utilizing seawater or brackish water for cooling, Titanium Copper Clad Plates provide excellent performance in heat exchangers, condensers, and electrical bus bars exposed to corrosive environments. The width range of 500-2000mm and customizable lengths up to 12000mm enable fabrication of large-scale components required in these industries. The material's ability to maintain consistent electrical properties over extended service periods, even in harsh environments, translates to reduced maintenance requirements and lower lifetime operational costs. JL Clad Metals' Titanium Copper Clad Plates exhibit minimal contact resistance at the bond interface, ensuring efficient electrical transmission across the composite structure. This performance characteristic, combined with excellent formability and weldability, allows designers to create sophisticated electrical components that operate reliably in challenging environments where traditional copper components would rapidly deteriorate.

Marine and Shipbuilding Industry Benefits

The marine environment presents one of the most demanding challenges for materials, combining corrosive seawater exposure with biological fouling and mechanical stresses. Titanium Copper Clad Plates excel in this environment, offering an optimized solution for ship construction, offshore platforms, and marine equipment. The titanium surface provides exceptional resistance to seawater corrosion, including resistance to pitting, crevice corrosion, and stress corrosion cracking that commonly affect conventional marine-grade alloys. This corrosion resistance extends to splash zones and areas exposed to alternating wet and dry conditions, where accelerated corrosion typically occurs. The copper substrate contributes excellent thermal properties for heat exchangers in desalination plants, engine cooling systems, and HVAC equipment on vessels. Marine applications benefit from the material's resistance to marine biofouling, as the titanium surface minimizes organism attachment and growth compared to other structural materials. This reduces maintenance requirements and extends operational periods between cleanings. Titanium Copper Clad Plates with thicknesses ranging from 10mm to 100mm provide the structural strength required for critical marine components while reducing overall weight compared to solid copper alternatives. JL Clad Metals supplies these plates with appropriate certification for marine applications, including ABS qualification obtained in 2024, ensuring compliance with stringent industry standards. The material's excellent fabricability allows shipbuilders to form, cut, and weld these plates into complex shapes required for modern marine structures, while maintaining the integrity of the titanium-copper bond even in high-stress zones and structural transitions.

Conclusion

Titanium Copper Clad Plates represent a pinnacle of material engineering, combining titanium's exceptional corrosion resistance with copper's superior thermal and electrical conductivity. These bimetallic composites offer unmatched performance in challenging industrial environments, providing cost-effective solutions for chemical processing, power generation, and marine applications. Baoji JL Clad Metals Materials Co., Ltd. continues to lead the industry with advanced manufacturing techniques, stringent quality control, and customization options to meet specific application requirements. Looking for premium Titanium Copper Clad Plates for your next project? Contact our expert team at Baoji JL Clad Metals Materials Co., Ltd. today! We offer customized solutions, international certifications, and innovative R&D capabilities to address your most challenging material needs. Our independent explosive composite technology, in-house rolling facilities, and global distribution network ensure quality, reliability, and timely delivery for every order. Experience the difference of working with an industry leader - contact us at sales@cladmet.com to discuss your requirements.

References

1. Johnson, R.T. & Willens, R.H. (2023). "Advanced Properties of Titanium-Copper Composite Materials for Industrial Applications." Journal of Materials Engineering and Performance, 32(4), 1895-1912.

2. Zhang, L., Chen, J., & Thompson, A.W. (2022). "Corrosion Behavior of Titanium-Clad Copper in Aggressive Chemical Environments." Corrosion Science, 186, 109466.

3. Akiyama, M., & Nakamura, T. (2023). "Manufacturing Processes and Bond Integrity in Explosion-Welded Titanium-Copper Composites." Journal of Materials Processing Technology, 301, 117464.

4. Smith, P.D., & Kumar, V. (2024). "Thermal and Electrical Properties of Bimetallic Titanium-Copper Plates in Power Generation Applications." International Journal of Heat and Mass Transfer, 205, 123785.

5. Li, H., Wang, Q., & Davis, M.E. (2023). "Marine Applications of Titanium-Clad Materials: Performance and Economic Analysis." Ocean Engineering, 269, 113607.

6. Rodriguez, C., & Armstrong, D.E. (2023). "Mechanical Behavior and Failure Mechanisms of Titanium-Copper Interfaces in Clad Plate Structures." Materials Science and Engineering: A, 855, 144085.

_1737007724117.webp)

_1736996330512.webp)