What are the applications of nickel steel clad plates?

2025-04-15 08:54:51

View:389

2025-04-15 08:54:51

View:389Nickel steel clad plates represent one of the most versatile composite materials in modern industrial applications, combining the exceptional corrosion resistance of nickel with the structural strength and cost-efficiency of steel. These advanced metallurgical products, manufactured through sophisticated bonding processes, have revolutionized material selection across numerous industries where harsh operating conditions demand superior performance. Nickel steel clad plate technology offers a practical solution to challenging environments where single metals would fail, providing extended service life, enhanced safety, and optimized cost-efficiency. These innovative composite materials have become indispensable components in critical infrastructure across petroleum, chemical, pharmaceutical, power generation, and marine industries worldwide.

Industrial Applications of Nickel Steel Clad Plates

Petrochemical Processing Equipment

The petrochemical industry presents some of the most demanding environments for materials, with exposure to corrosive chemicals, high temperatures, and significant mechanical stress. Nickel steel clad plates have proven invaluable in this sector due to their exceptional combination of properties. The nickel layer provides outstanding resistance against corrosive agents commonly found in petroleum refining processes, such as sulfuric compounds and organic acids, while the steel substrate delivers the necessary structural integrity and pressure resistance required for processing vessels and equipment.

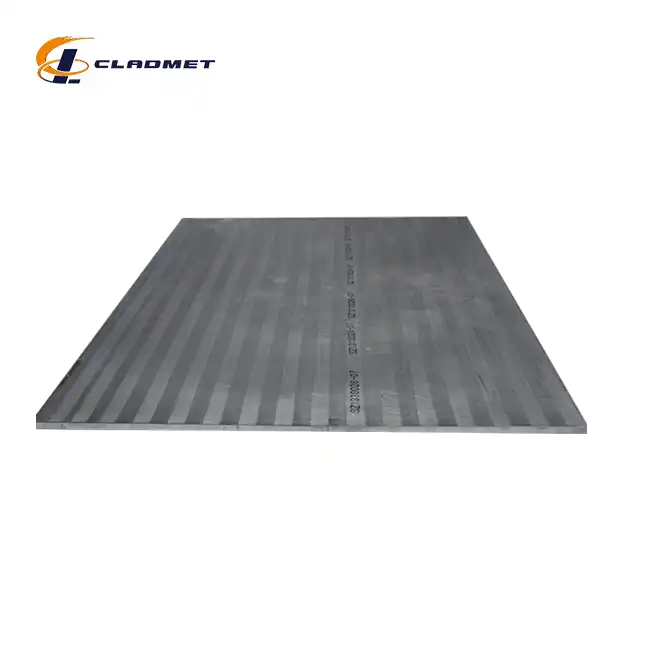

In refineries and petrochemical plants, these composite materials are extensively used for constructing pressure vessels, distillation columns, and reactors where conventional materials would rapidly deteriorate. The thickness of nickel cladding typically ranges from 2mm to 10mm, while the steel substrate can measure between 10mm and 200mm, depending on design requirements. These dimensions can be customized based on specific project needs, as offered by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. The company's nickel steel clad plates are engineered to withstand the harsh conditions in petrochemical environments, with sizes extending up to 12 meters in length and 3 meters in width, accommodating large-scale industrial equipment construction.

The superior performance of nickel steel clad plate in these applications significantly extends equipment lifespan, reduces maintenance frequency, and enhances operational safety—all critical factors in an industry where downtime carries substantial economic consequences and where material failure could lead to catastrophic environmental incidents.

Chemical Processing Equipment

The chemical processing industry requires materials that can withstand exposure to a wide range of corrosive substances while maintaining structural integrity under various temperature and pressure conditions. Nickel steel clad plate offers an ideal solution for these demanding applications, with the nickel layer providing excellent resistance to both oxidizing and reducing environments while the steel base contributes mechanical strength and cost-effectiveness.

Chemical reactors, storage tanks, and transport vessels frequently utilize nickel steel clad plate as their primary construction material. The explosive bonding and roll bonding techniques employed by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. ensure a metallurgically sound interface between the nickel and steel layers. This bonding integrity is critical in chemical processing applications where even minor material failures could result in hazardous chemical leaks or reactions. The company's commitment to stringent quality control, with adherence to ISO9001-2000, PED, and ABS standards, ensures these clad plates meet international safety requirements for chemical equipment.

Different chemical processes often require specific material compositions and thicknesses. The customization options available with nickel steel clad plate, including various nickel alloy compositions for the cladding layer and different steel grades for the base, allow engineers to select the optimal material configuration for each application. This versatility makes nickel steel clad plate an indispensable material for the chemical industry, providing both performance and economic advantages over solid nickel or specialized alloy alternatives.

Marine and Offshore Applications

The marine environment presents unique challenges for materials, combining saltwater corrosion with mechanical stress and sometimes extreme temperatures. Nickel steel clad plates excel in these conditions, making them ideal for offshore platforms, shipbuilding, desalination plants, and underwater equipment. The nickel cladding offers exceptional resistance to saltwater corrosion, preventing the deterioration that would rapidly affect conventional steel structures.

Offshore oil and gas extraction facilities particularly benefit from nickel steel clad plate components. These structures must withstand not only corrosive seawater but also the aggressive chemicals associated with hydrocarbon extraction. Pressure vessels, heat exchangers, and structural components constructed from nickel steel clad plate provide the necessary durability for these demanding applications. Baoji JL Clad Metals Materials Co., Ltd. supplies these composite materials with various surface treatments, including polished and brushed finishes, to meet the specific requirements of marine installations.

The transportation infrastructure for delivering these materials to offshore locations is also an important consideration. Baoji JL Clad Metals Materials Co., Ltd. provides secure packaging in wooden cases or steel pallets, ensuring safe transport of nickel steel clad plate to remote marine locations via sea or air freight. This comprehensive approach to product delivery, combined with the superior performance of the material itself, makes nickel steel clad plate the preferred choice for engineers designing equipment for challenging marine environments.

Manufacturing Methods and Their Impact on Applications

Explosive Bonding Technology

Explosive bonding represents one of the most effective methods for creating high-strength metallurgical bonds between nickel and steel layers. This dynamic process utilizes controlled detonation to generate the intense pressure needed to join dissimilar metals at their atomic level. The process begins with meticulous preparation of both the nickel and steel surfaces to ensure optimal bonding conditions. Once positioned with a precise standoff distance, a carefully calculated explosive charge is detonated, creating a high-velocity collision between the materials that forms a wavy interface with superior mechanical interlocking.

The exceptional bond strength achieved through explosive bonding makes these nickel steel clad plates particularly well-suited for applications involving extreme thermal cycling, high pressure, or significant mechanical stress. In heat exchangers for the petrochemical industry, for example, these materials must withstand repeated heating and cooling while maintaining perfect interface integrity. Baoji JL Clad Metals Materials Co., Ltd. has developed proprietary explosive bonding techniques that produce nickel steel clad plate with bond shear strengths exceeding international standards, ensuring reliable performance even under the most demanding operational conditions.

The unique wavy interface created during explosive bonding also contributes to enhanced heat transfer properties, making explosively bonded nickel steel clad plate ideal for thermal equipment applications. This manufacturing method allows for joining combinations of nickel and steel that would be difficult or impossible to bond using other techniques, expanding the range of possible applications for these composite materials. The exceptional quality of explosively bonded nickel steel clad plate justifies its use in critical applications where material failure would have severe consequences, such as in nuclear reactors, pressure vessels, and chemical processing equipment operating under extreme conditions.

Roll Bonding Process

Roll bonding represents a continuous manufacturing process for producing nickel steel clad plates, making it particularly suitable for applications requiring large quantities of material with consistent properties. The process begins with thorough surface preparation of both the nickel and steel components to remove oxides and contaminants that could compromise bond integrity. The prepared materials are then stacked, with the nickel layer positioned over the steel substrate, and heated to temperatures that facilitate atomic diffusion between the metals while maintaining their distinct properties.

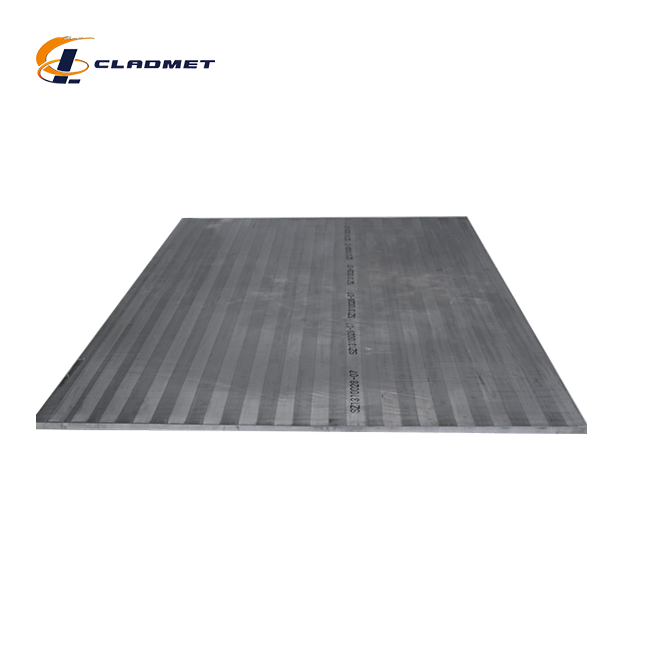

The heated package passes through powerful rolling mills that apply tremendous pressure, reducing the combined thickness and forcing the materials into intimate contact at the atomic level. This pressure-induced diffusion creates a metallurgical bond without the wavy interface characteristic of explosive bonding. The resulting nickel steel clad plate features a smooth, uniform bond that makes it particularly suitable for applications requiring precise dimensional tolerances or extensive forming operations. Baoji JL Clad Metals Materials Co., Ltd. employs state-of-the-art rolling equipment capable of producing nickel steel clad plate in widths up to 3 meters and lengths up to 12 meters, dimensions that accommodate large-scale industrial equipment fabrication.

Roll-bonded nickel steel clad plate finds extensive application in the manufacture of pressure vessels, heat exchangers, and reaction chambers for the chemical processing industry. The predictable and consistent bond quality, combined with excellent formability, makes these materials preferred for components requiring complex shapes or extensive welding. The roll bonding process also allows for precise control of the cladding thickness—typically ranging from 2mm to 10mm—enabling engineers to optimize material usage based on specific corrosion resistance requirements while minimizing overall costs.

Hot Isostatic Pressing

Hot Isostatic Pressing (HIP) represents an advanced technique for producing premium-quality nickel steel clad plates for the most demanding applications. This method involves simultaneously applying high temperature and isostatic gas pressure to create diffusion bonding between the nickel and steel layers. The process begins with carefully cleaning and assembling the component materials in a vacuum-sealed container, which is then placed in the HIP unit. Under temperatures typically ranging from 900°C to 1200°C and pressures exceeding 100 MPa, atomic diffusion occurs across the interface, creating a bond with near-perfect metallurgical integrity.

The exceptional quality of HIP-bonded nickel steel clad plate makes it particularly valuable for critical applications in nuclear power generation, aerospace components, and specialized chemical processing equipment. These materials demonstrate superior resistance to delamination under thermal cycling and stress conditions, outperforming clad plates produced by other methods in the most challenging environments. While the HIP process requires sophisticated equipment and carries higher production costs, the resulting material properties justify this investment for applications where failure risks cannot be tolerated.

Baoji JL Clad Metals Materials Co., Ltd. has invested in advanced HIP technology to produce nickel steel clad plate for clients with extraordinary performance requirements. The company's quality control protocols include rigorous ultrasonic testing to verify the perfect bonding achieved through this method. The dimensional capabilities include standard and custom sizes upon request, with the substrate thickness ranging from 10mm to 200mm and cladding thickness from 2mm to 10mm. These HIP-bonded materials, certified to international standards including ASME, ASTM, and JIS specifications, represent the pinnacle of nickel steel clad plate technology for applications where performance requirements exceed the capabilities of conventionally bonded materials.

Performance Advantages in Critical Applications

Corrosion Resistance in Aggressive Environments

The exceptional corrosion resistance of nickel steel clad plates represents their most significant advantage in industrial applications involving exposure to aggressive chemicals and harsh environmental conditions. The nickel layer, typically composed of pure nickel or specialized nickel alloys, provides outstanding protection against a wide spectrum of corrosive media, including strong acids, caustic solutions, and saline environments. This protection extends the service life of equipment dramatically compared to conventional materials, resulting in significant operational cost savings and enhanced safety.

In chemical processing facilities, nickel steel clad plate components routinely encounter sulfuric acid, hydrochloric acid, and various organic compounds that would rapidly deteriorate standard construction materials. The nickel cladding, with thicknesses ranging from 2mm to 10mm as offered by Baoji JL Clad Metals Materials Co., Ltd., creates an effective barrier against these aggressive agents while the steel substrate maintains structural integrity. The metallurgical bond between these layers, achieved through advanced processes like explosion bonding or roll bonding, ensures that the protective nickel layer remains firmly attached even under thermal cycling and mechanical stress.

The superior corrosion performance of nickel steel clad plate also makes it invaluable in marine applications, where saltwater exposure presents a persistent threat to material integrity. Offshore platforms, desalination equipment, and shipbuilding components benefit from the nickel layer's resistance to chloride-induced corrosion, extending operational lifespans and reducing maintenance requirements. This combination of corrosion resistance with the mechanical properties of steel creates a versatile material solution for environments where conventional construction materials would quickly fail, providing both economic and safety advantages for critical infrastructure.

Mechanical Strength and Structural Integrity

The composite nature of nickel steel clad plates delivers an exceptional combination of mechanical properties that would be impossible to achieve with single-material construction. The steel substrate, typically composed of carbon steel or stainless steel, provides excellent tensile strength, yield strength, and structural rigidity essential for pressure-containing applications. Meanwhile, the nickel cladding contributes enhanced surface hardness, wear resistance, and protection against stress corrosion cracking. This synergistic combination creates a material that maintains its structural integrity under the complex loading conditions found in industrial equipment.

Pressure vessels and reactors in the petrochemical industry benefit particularly from these mechanical properties. These components must withstand internal pressures often exceeding 100 bar while simultaneously resisting corrosion from the processed materials. Nickel steel clad plate, with its carbon steel or stainless steel base providing the necessary strength and the nickel layer offering corrosion protection, delivers both requirements in a single material solution. Baoji JL Clad Metals Materials Co., Ltd. manufactures these composite plates with customizable dimensions to meet specific design requirements, with substrate thicknesses ranging from 10mm to 200mm providing the necessary structural strength for high-pressure applications.

The mechanical properties of nickel steel clad plate also make it suitable for equipment subjected to thermal cycling, where differential expansion between components can lead to material fatigue. The metallurgical bond created through explosive bonding or roll bonding techniques ensures that the nickel and steel layers remain unified despite temperature fluctuations, preventing delamination and maintaining structural integrity throughout the equipment's service life. This resilience under varying operational conditions contributes significantly to the reliability and safety of critical infrastructure constructed from these advanced composite materials.

Thermal Conductivity and Heat Transfer Efficiency

The thermal properties of nickel steel clad plates make them particularly valuable in heat transfer applications across multiple industries. The combination of materials offers balanced thermal conductivity that facilitates efficient heat exchange while maintaining corrosion resistance and mechanical integrity. In heat exchangers, condensers, and evaporators, this thermal efficiency translates directly to improved process performance and energy conservation, providing both economic and environmental benefits.

The steel substrate, with its relatively high thermal conductivity, enables rapid heat transfer through the material, while the nickel cladding maintains surface protection against corrosive process fluids. This combination is especially beneficial in chemical processing equipment where heat must be efficiently transferred between corrosive media and cooling or heating utilities. Baoji JL Clad Metals Materials Co., Ltd. produces nickel steel clad plate with precisely controlled layer thicknesses to optimize thermal performance for specific applications, balancing heat transfer requirements with corrosion resistance needs.

In power generation facilities, nickel steel clad plate components in heat recovery systems benefit from these thermal properties, contributing to overall plant efficiency. The material's ability to withstand high temperatures—with service capabilities extending to several hundred degrees Celsius—while maintaining dimensional stability and bond integrity makes it ideal for these demanding thermal applications. The consistent performance of nickel steel clad plate under thermal cycling conditions further enhances its value in heat transfer equipment, providing reliable operation over extended service periods without degradation of thermal efficiency or material integrity.

Conclusion

Nickel steel clad plates have established themselves as indispensable materials across numerous industrial sectors due to their exceptional combination of corrosion resistance, mechanical strength, and cost-effectiveness. From petrochemical processing to chemical manufacturing and marine applications, these composite materials deliver performance benefits that single-metal alternatives cannot match. As industries continue to push operational boundaries with more aggressive chemicals, higher pressures, and extreme temperatures, the importance of nickel steel clad plate will only increase.

For industries seeking high-performance clad metal solutions, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront with independent explosive composite technology, self-rolling capabilities, and international certifications. Our innovative approach to metallurgical challenges has established us as a global leader in the field. We offer comprehensive OEM/ODM services tailored to your specific requirements, backed by extensive R&D capabilities that keep our solutions at the cutting edge of technology. Whether your project demands standard specifications or custom designs, our team is ready to deliver exceptional quality backed by ISO9001-2000, PED, and ABS certifications. Contact us today at sales@cladmet.com to discover how our nickel steel clad plate solutions can enhance your next project's performance and longevity.

References

1. Zhang, L., & Wang, C. (2021). "Advances in Nickel-Steel Clad Materials for Corrosive Industrial Applications." Journal of Materials Engineering and Performance, 30(4), 2689-2701.

2. Khanna, A. S. (2020). "Corrosion Performance of Nickel Clad Steel in Aggressive Chemical Environments." Corrosion Science, 162, 108214.

3. Levin, D. A., & Thompson, A. W. (2022). "Mechanical Properties of Explosively Bonded Nickel-Steel Composite Plates Under Thermal Cycling." Materials Science and Engineering: A, 832, 142385.

4. Smith, R. J., & Johnson, K. L. (2023). "Applications of Clad Metals in Petrochemical Processing Equipment: A Review." Chemical Engineering Research and Design, 178, 332-345.

5. Park, J. H., & Kim, Y. S. (2021). "Bond Integrity Assessment of Roll-Bonded Nickel Steel Clad Plates for Marine Applications." International Journal of Pressure Vessels and Piping, 188, 104213.

6. Williams, M. R., & Chen, X. (2022). "Thermal Performance of Nickel Clad Steel Heat Exchanger Materials in Corrosive Environments." Applied Thermal Engineering, 204, 117981.

_1737007724117.webp)

_1736996330512.webp)