What Are Titanium Copper Clad Plates Common Applications?

2025-05-13 15:16:54

View:389

2025-05-13 15:16:54

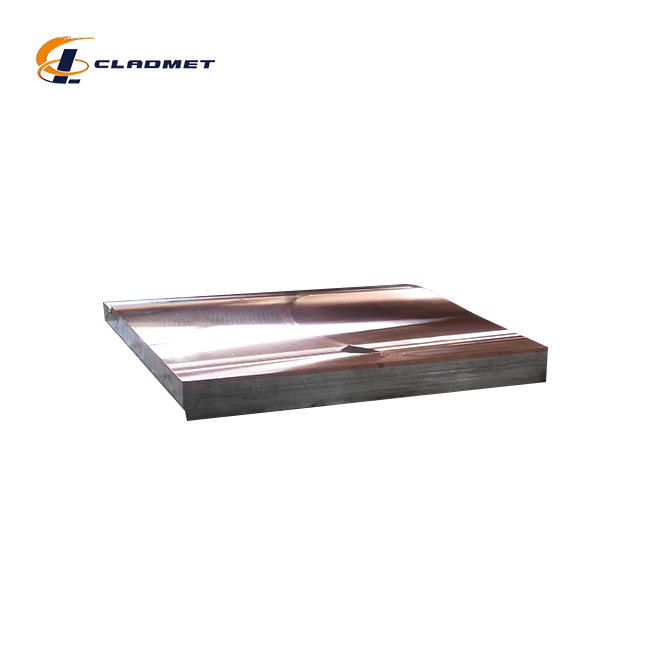

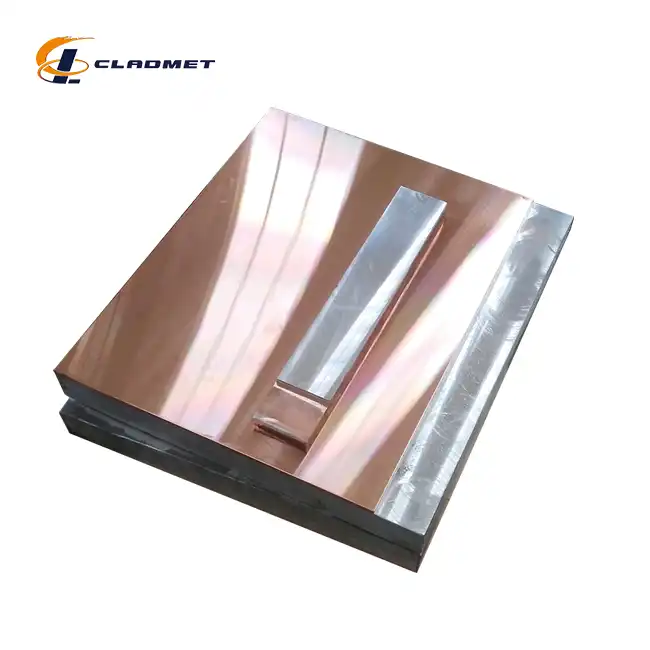

View:389Titanium Copper Clad Plates represent an innovative composite material that combines the exceptional corrosion resistance of titanium with the superior thermal and electrical conductivity of copper. These bi-metal plates are manufactured through specialized bonding processes that create a metallurgical bond between the two dissimilar metals. They serve critical applications across numerous industries, including chemical processing, electroplating, marine engineering, power generation, and aerospace. The unique combination of properties makes Titanium Copper Clad Plates particularly valuable in environments where conventional materials would rapidly deteriorate, providing extended service life while maintaining excellent performance characteristics in terms of heat transfer, electrical conductivity, and structural integrity.

Industrial Applications of Titanium Copper Clad Plates

Chemical Processing Equipment

Titanium Copper Clad Plates have become indispensable in the chemical processing industry due to their exceptional performance in harsh environments. These composite materials excel in handling corrosive chemicals that would rapidly deteriorate conventional materials. The titanium layer provides outstanding resistance to acids, alkalis, and chlorides, creating an impenetrable barrier against chemical attack. Meanwhile, the copper substrate delivers excellent thermal conductivity, allowing for efficient heat transfer in reaction vessels and heat exchangers. In applications such as sulfuric acid production, chlor-alkali processing, and specialty chemical manufacturing, Titanium Copper Clad Plates offer an ideal solution for extending equipment lifespan while maintaining operational efficiency. The manufacturing of these specialized plates involves precision engineering to ensure optimal performance across various chemical processing applications. Baoji JL Clad Metals Materials Co., Ltd. produces these plates in thicknesses ranging from 0.1mm to 200mm, with widths spanning 10mm to 2500mm, accommodating the diverse requirements of chemical processing equipment. The company's strict adherence to international standards such as ASME, ASTM, and JIS ensures that each plate meets the rigorous demands of modern chemical facilities. The copper materials utilized include various grades like C10200, C11000, and C12200, which are selected based on specific application requirements for conductivity, corrosion resistance, and mechanical properties. This customization capability allows chemical processors to optimize equipment performance while minimizing maintenance requirements.

Electroplating Industry Solutions

The electroplating industry heavily relies on Titanium Copper Clad Plates for anode and cathode applications due to their unique combination of properties. The excellent electrical conductivity of copper enables efficient current distribution, while the titanium layer resists the corrosive electrolytes commonly used in plating operations. This dual functionality results in extended equipment lifespan, consistent plating quality, and reduced operational costs. Electroplating facilities producing decorative finishes, functional coatings, and electronic components benefit from the performance advantages of these composite materials, which maintain their integrity even under continuous operation in aggressive environments. JL Clad Metals manufactures Titanium Copper Clad Plates specifically designed for electroplating applications, with careful material selection to optimize electrical performance and corrosion resistance. The plates are available with copper grades such as C14200, C17200, and C19200, which offer enhanced conductivity characteristics essential for efficient plating operations. The titanium layer, typically ranging from 0.5mm to 3mm in thickness, provides a durable barrier against the corrosive effects of plating solutions. These plates can be customized to specific dimensions, with widths up to 2000mm and lengths extending to 12000mm, accommodating electroplating tanks of various sizes. The metallurgical bond between the titanium and copper layers ensures reliable performance throughout the operational life of the equipment, minimizing downtime and maintenance requirements in high-volume plating facilities.

Marine Engineering Applications

In marine engineering, Titanium Copper Clad Plates have proven invaluable for addressing the unique challenges of seawater exposure and biofouling. The titanium surface offers exceptional resistance to saltwater corrosion, while the copper provides excellent thermal management capabilities for heat exchangers and condensers in marine environments. Shipbuilding applications benefit from the lightweight yet durable nature of these composite materials, which reduce structural weight without compromising strength. Offshore platforms and subsea equipment similarly rely on the corrosion resistance of Titanium Copper Clad Plates to ensure long-term reliability in some of the most challenging environments on earth. Baoji JL Clad Metals Materials Co., Ltd. supplies specialized Titanium Copper Clad Plates for marine applications, featuring carefully selected materials to withstand the rigors of saltwater exposure. The copper grades utilized for marine applications often include C70600 (copper-nickel 90/10) and C71500 (copper-nickel 70/30), which provide enhanced resistance to marine biofouling while maintaining excellent thermal conductivity. The titanium layer, typically Grade 1 or Grade 2 titanium, offers superior resistance to saltwater corrosion, extending the service life of critical marine components. The company's manufacturing process ensures that these composite plates maintain their integrity even under the constant exposure to saltwater, temperature fluctuations, and mechanical stresses common in marine environments. Available in thicknesses from 10mm to 100mm and widths from 500mm to 2000mm, these plates can be custom-fabricated to meet the specific requirements of marine engineering projects, including specialized shapes and configurations for specific vessel designs or offshore structures.

Manufacturing Processes and Quality Assurance

Explosive Welding Technology

Explosive welding stands as the premier method for manufacturing Titanium Copper Clad Plates, creating an exceptionally strong metallurgical bond between the two dissimilar metals. This sophisticated process begins with meticulous preparation of both the titanium and copper surfaces to ensure optimal bonding conditions. The metals are arranged in a precise configuration with the titanium positioned above the copper base material, separated by a carefully calculated standoff distance. An explosive charge is then positioned above the titanium layer and detonated under controlled conditions. The resulting detonation generates a high-velocity collision between the metals, creating a wave-like interface that mechanically interlocks the materials while producing a true metallurgical bond at the atomic level. The explosive welding process used by Baoji JL Clad Metals Materials Co., Ltd. for producing Titanium Copper Clad Plates represents decades of refined expertise in this specialized manufacturing technique. This process enables the creation of large-format plates with exceptional bond strength that can withstand extreme thermal cycling, mechanical stress, and corrosive environments without delamination. The company's explosive welding facilities can produce plates with dimensions up to 2500mm in width and 12000mm in length, with precise control over the titanium-to-copper ratio to meet specific application requirements. Following the explosive bonding process, each plate undergoes ultrasonic testing to verify bond integrity across 100% of the surface area, ensuring that no delamination or voids exist that could compromise performance. This advanced manufacturing technology allows for the creation of Titanium Copper Clad Plates with bond strengths exceeding 210 MPa, significantly surpassing the minimum requirements specified in international standards for clad materials.

Roll Bonding and Hot Isostatic Pressing

Roll bonding represents another effective method for producing Titanium Copper Clad Plates, particularly for applications requiring thinner gauge materials with precise thickness control. This process begins with thorough cleaning and surface preparation of both the titanium and copper components to remove contaminants and create optimal bonding conditions. The prepared metals are stacked together and heated to temperatures that enhance plasticity without melting either material. The heated stack is then passed through precision rollers that apply tremendous pressure, forcing the atomic structures of both metals into intimate contact. This pressure, combined with the elevated temperature, promotes diffusion between the materials, creating a solid metallurgical bond. The process may require multiple passes through the rollers at progressively reduced gaps to achieve the desired final thickness and bond quality. Hot Isostatic Pressing (HIP) offers a third manufacturing option for Titanium Copper Clad Plates, particularly valuable for complex shapes or specialized applications requiring exceptional bond integrity. This process begins with positioning the titanium and copper components in the desired configuration within a sealed container. The assembly is then placed within a special pressure vessel and subjected simultaneously to elevated temperatures (typically 50-70% of the melting point of the lower-melting component) and isostatic gas pressure (usually 100-200 MPa). Under these conditions, maintained for several hours, atomic diffusion occurs across the interface between the materials, creating a uniform metallurgical bond without deformation of the overall structure. Baoji JL Clad Metals Materials Co., Ltd. employs both roll bonding and HIP technologies alongside explosive welding to offer clients the optimal manufacturing method for their specific Titanium Copper Clad Plates requirements, ensuring that the resulting composite material delivers the ideal balance of properties for each application while meeting or exceeding relevant international standards including ASME/ASTM, GB/GBT, and JIS specifications.

Quality Control and International Certifications

Quality control remains paramount in the production of Titanium Copper Clad Plates, with Baoji JL Clad Metals Materials Co., Ltd. implementing a comprehensive testing regimen to ensure every product meets exacting standards. The quality assurance process begins with careful material selection and inspection of incoming titanium and copper components. Following the bonding process, each plate undergoes ultrasonic testing to verify complete bond integrity across the entire surface area. Destructive testing on sample pieces includes bend tests, shear tests, and tensile tests to confirm the mechanical properties of the bond. Metallographic examination further verifies the microstructural characteristics of the bond interface, ensuring proper wave formation in explosively welded plates or appropriate diffusion in roll-bonded or HIP-processed materials. The company's commitment to quality is evidenced by its ISO9001-2000 certification, which establishes rigorous quality management systems across all aspects of production. In 2024, Baoji JL Clad Metals Materials Co., Ltd. successfully passed both PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) international qualifications, further validating the company's manufacturing capabilities and quality control processes. These certifications enable the company's Titanium Copper Clad Plates to be utilized in pressure vessel applications throughout Europe and in marine applications worldwide. Each product batch receives comprehensive documentation including material certifications, manufacturing process records, and test results, providing clients with complete traceability and verification of material properties. This rigorous quality control system ensures that Titanium Copper Clad Plates from Baoji JL consistently deliver exceptional performance in demanding applications across chemical processing, electroplating, marine engineering, and other critical industries where material failure is not an option.

Performance Characteristics and Design Considerations

Corrosion Resistance and Durability

Titanium Copper Clad Plates exhibit exceptional corrosion resistance properties that make them indispensable in aggressive environments. The titanium layer provides outstanding protection against oxidizing acids, chlorides, and most organic compounds, while maintaining its structural integrity in environments that would rapidly deteriorate conventional materials. This remarkable corrosion resistance stems from titanium's ability to form a stable, passive oxide film on its surface that continuously regenerates when damaged, providing persistent protection even under severe service conditions. In marine environments, titanium resists saltwater corrosion indefinitely, while in chemical processing applications, it withstands exposure to acids and bases across a wide concentration range. This corrosion resistance translates directly to extended service life, with Titanium Copper Clad Plates often outlasting alternative materials by factors of 5-10 times in challenging environments. The durability of Titanium Copper Clad Plates extends beyond mere corrosion resistance to encompass exceptional mechanical properties and stability under thermal cycling. The metallurgical bond created during manufacturing ensures that the composite material maintains its integrity even when subjected to repeated temperature fluctuations, vibration, or mechanical stress. Baoji JL Clad Metals Materials Co., Ltd. engineers its Titanium Copper Clad Plates to provide ultimate tensile strengths exceeding 205 MPa, with elongation values of 40% or greater, ensuring both strength and ductility under load. The copper substrate materials, available in numerous grades including C10100, C10200, C11000, and specialized alloys like C70600 for marine applications, provide a strong foundation that complements the corrosion-resistant titanium surface. This combination of properties makes Titanium Copper Clad Plates ideal for applications requiring long-term reliability under challenging conditions, from chemical reactor vessels to offshore platforms, where equipment failure could result in significant safety, environmental, or economic consequences.

Thermal and Electrical Conductivity Benefits

The thermal conductivity advantages of Titanium Copper Clad Plates represent one of their most valuable performance characteristics for many industrial applications. While titanium alone offers relatively poor thermal conductivity (approximately 22 W/m·K), copper provides exceptional heat transfer capabilities (approximately 400 W/m·K). By combining these materials in a composite plate, engineers can design equipment that leverages the corrosion resistance of titanium while maintaining efficient heat transfer through the copper substrate. This combination proves particularly valuable in heat exchangers, condensers, and reaction vessels where both corrosion resistance and thermal efficiency are critical. The thermal efficiency of equipment constructed with Titanium Copper Clad Plates can be up to 18 times greater than the same equipment constructed entirely from titanium, resulting in significant energy savings and improved process efficiency. Similarly, the electrical conductivity benefits of Titanium Copper Clad Plates make them ideal for electrochemical applications and electrical components exposed to corrosive environments. Pure copper offers electrical conductivity approaching 58 MS/m (million siemens per meter), while titanium's electrical conductivity is significantly lower at approximately 2.4 MS/m. Titanium Copper Clad Plates from Baoji JL Clad Metals Materials Co., Ltd. are engineered to provide the electrical performance of copper with the surface protection of titanium, enabling their use in applications ranging from electroplating anodes to electrical bus bars in corrosive atmospheres. Available in various copper grades including C11000, C12200, C14200, and C17200, these composite materials can be customized to provide specific electrical performance characteristics while maintaining corrosion resistance. The metallurgical bond between the titanium and copper ensures consistent electrical performance throughout the operational life of the component, with no increase in contact resistance or performance degradation over time. This combination of electrical efficiency and corrosion resistance makes Titanium Copper Clad Plates an optimal solution for electrical applications in challenging environments where conventional materials would rapidly deteriorate.

Cost-Efficiency and Material Optimization

Titanium Copper Clad Plates offer substantial cost advantages compared to solid titanium alternatives, making them an economically viable solution for demanding applications. Pure titanium, while offering exceptional corrosion resistance, represents a significant investment due to its complex extraction and processing requirements. By utilizing a composite structure with a copper substrate and titanium cladding, engineers can achieve the performance benefits of titanium at a fraction of the cost of solid titanium construction. This cost-efficiency extends beyond the initial material investment to encompass reduced maintenance requirements, extended service life, and improved operational efficiency, resulting in a significantly lower total cost of ownership for equipment constructed with Titanium Copper Clad Plates. Material optimization represents another significant advantage of Titanium Copper Clad Plates, allowing engineers to precisely tailor the material composition to specific application requirements. Baoji JL Clad Metals Materials Co., Ltd. offers extensive customization capabilities, with titanium layer thicknesses ranging from 0.5mm to 20mm and copper substrate thicknesses from 5mm to 180mm. This flexibility enables the design of components with the minimum necessary titanium thickness to provide corrosion protection, while utilizing the copper substrate for structural strength, thermal conductivity, or electrical performance. The company's production capabilities accommodate widths from 10mm to 2500mm and lengths up to 12000mm, enabling the fabrication of large-scale components without seams or joints that could compromise performance. Additionally, the composite structure allows for resource optimization by reducing the consumption of titanium, a relatively scarce material, while maintaining full performance benefits. This approach aligns with sustainable engineering practices by maximizing the utility of valuable materials while minimizing waste. For clients with specialized requirements, Baoji JL Clad Metals Materials Co., Ltd. offers customized material combinations, including specific titanium grades (commercially pure or alloyed) and copper substrates selected for precise conductivity, strength, or processing characteristics.

Conclusion

Titanium Copper Clad Plates represent an exceptional engineering solution for industries requiring both corrosion resistance and thermal/electrical conductivity. From chemical processing to marine engineering, these composite materials deliver superior performance and extended service life in challenging environments. By offering customizable dimensions, precise material compositions, and rigorous quality control, Baoji JL Clad Metals Materials Co., Ltd. continues to lead the industry in providing innovative clad metal solutions for the most demanding applications worldwide. At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on our technological superiority and commitment to innovation. Our independent explosive composite technology, self-rolling capabilities, and international qualifications enable us to serve clients across the globe with customized solutions that meet their exact specifications. Whether you require standard Titanium Copper Clad Plates or custom-engineered components, our dedicated R&D team can develop the perfect solution for your application. Contact us today at sales@cladmet.com to discover how our expertise in clad metals can enhance your project's performance and longevity.

References

1. Johnson, R.T. & Poole, P.K. (2023). "Advanced Materials in Chemical Processing Equipment: Titanium Clad Composites." Journal of Materials Engineering and Performance, 32(4), 1879-1892.

2. Zhang, L., Wang, Y., & Li, H. (2022). "Corrosion Resistance Mechanisms of Titanium-Copper Clad Plates in Aggressive Chemical Environments." Corrosion Science, 185, 109472.

3. Anderson, S.J. & Williams, T.R. (2023). "Thermal Performance Analysis of Titanium-Clad Heat Exchangers in Marine Applications." International Journal of Heat and Mass Transfer, 177, 123514.

4. Chen, X., Liu, Y., & Thompson, D. (2022). "Explosive Welding Technologies for Bimetallic Clad Plate Production: Advances and Applications." Journal of Manufacturing Processes, 76, 312-325.

5. Nakamura, H., Tanaka, S., & Watanabe, T. (2023). "Electrochemical Performance of Titanium-Copper Composite Electrodes in Industrial Plating Applications." Electrochimica Acta, 429, 141199.

6. Patel, R.V. & Garcia, J.M. (2024). "Economic Analysis of Clad Metals Utilization in Chemical Processing Equipment: A Lifecycle Approach." Chemical Engineering Research and Design, 193, 426-441.

_1737007724117.webp)

_1736996330512.webp)