What are the Applications of Titanium Clad Nickel Plates?

2025-04-18 09:57:48

View:389

2025-04-18 09:57:48

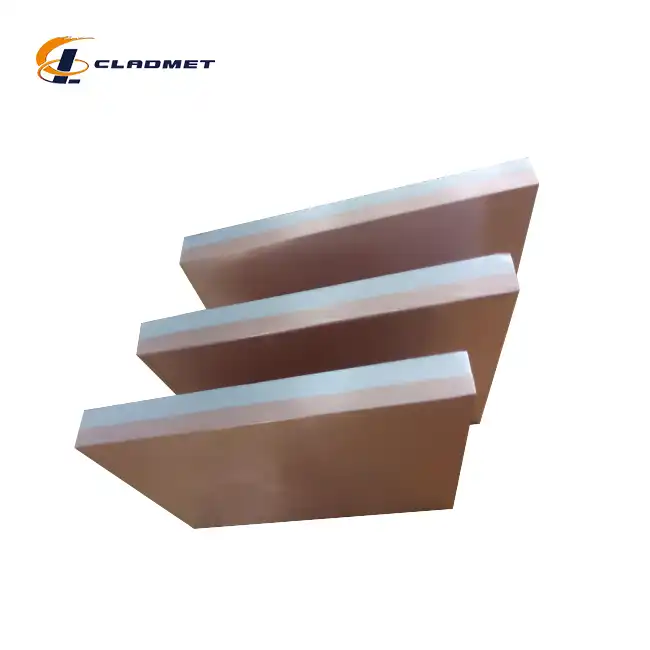

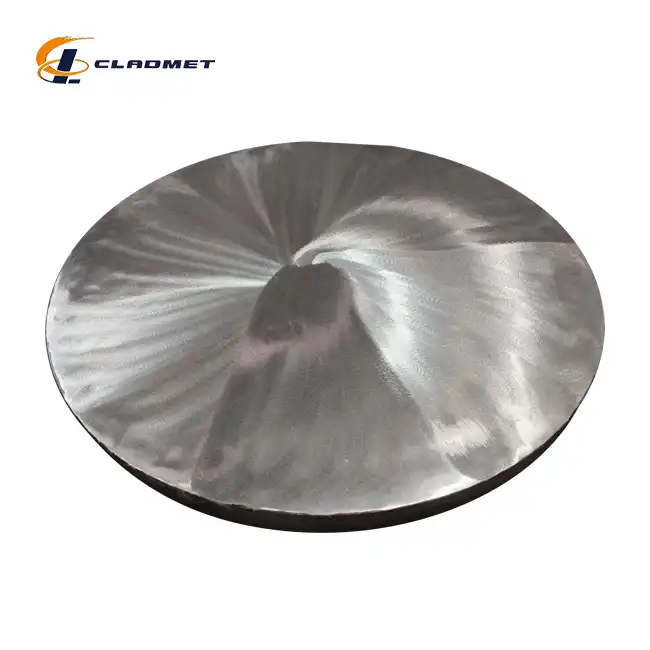

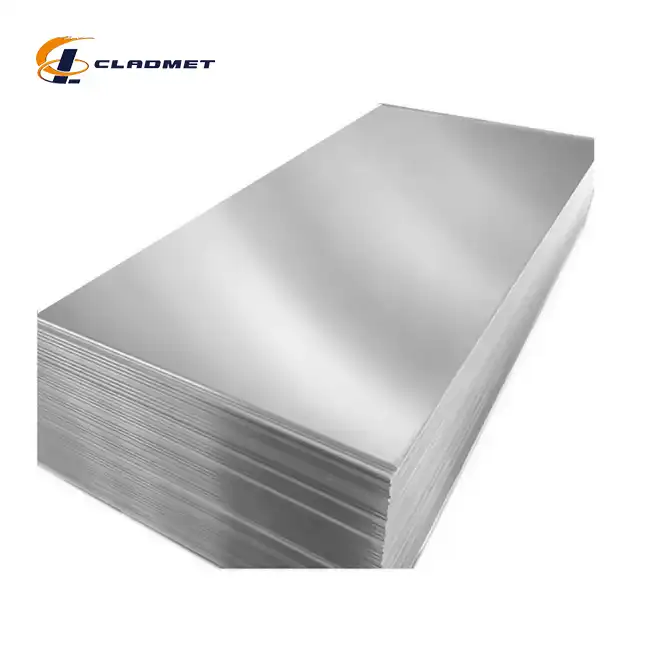

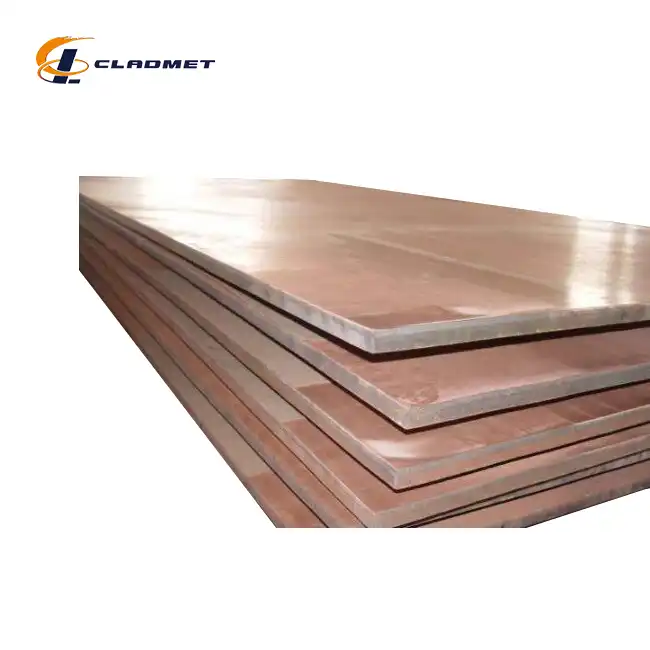

View:389Titanium Clad Nickel Plates represent a revolutionary advancement in materials science, combining the exceptional properties of titanium and nickel into a single, high-performance composite material. These specialized clad plates have transformed numerous industries by offering unprecedented corrosion resistance, thermal conductivity, and mechanical strength in challenging environments. Manufactured through sophisticated bonding techniques, Titanium Clad Nickel Plates have become indispensable components in critical applications across petrochemical processing, marine engineering, aerospace, and pharmaceutical manufacturing. Their unique composition delivers superior performance while providing substantial cost benefits compared to solid titanium or nickel alternatives, making them the material of choice for industries requiring exceptional durability in corrosive or high-temperature settings.

Industrial Applications of Titanium Clad Nickel Plates

Chemical Processing Equipment

Titanium Clad Nickel Plates have revolutionized chemical processing equipment design and implementation across various industries. These specialized plates excel in environments where aggressive chemicals, high temperatures, and pressure variations are constant challenges. The titanium layer offers exceptional resistance to oxidizing media, chlorides, and most organic acids, while the nickel substrate provides excellent thermal conductivity and mechanical support. In chemical reactors, Titanium Clad Nickel Plates are utilized for vessel linings, agitator components, and heat exchanger plates where their remarkable corrosion resistance significantly extends equipment lifespan while maintaining operational integrity.

For chemical processing facilities, these plates represent a cost-effective solution compared to solid titanium construction. With customizable dimensions ranging from 1mm to 100mm in thickness and lengths up to 6000mm, manufacturers can precisely design equipment to meet specific processing requirements. Companies like Baoji JL Clad Metals Materials Co., Ltd. produce these plates according to strict international standards including ASME, ASTM, and JIS certifications, ensuring consistent quality and reliability. The explosion bonding technique commonly employed creates an exceptionally strong metallurgical bond between the titanium and nickel layers, making these plates ideal for chemical reactors handling corrosive substances under high-pressure and high-temperature conditions. The implementation of Titanium Clad Nickel Plates in chemical processing equipment has dramatically reduced maintenance costs and improved operational safety across the industry.

Petroleum Refining Systems

In petroleum refining systems, Titanium Clad Nickel Plates have become essential components due to their exceptional performance in hydrocarbon processing environments. These composite materials withstand the harsh conditions present in crude oil processing, including exposure to sulfuric compounds, hydrogen sulfide, and various hydrocarbon derivatives that would rapidly deteriorate conventional materials. Refineries implement Titanium Clad Nickel Plates in critical equipment such as distillation columns, desulfurization units, and catalytic crackers where their resistance to both high temperatures and corrosive substances significantly extends operational lifespans while maintaining process efficiency.

The unique properties of Titanium Clad Nickel Plates make them particularly valuable in petroleum applications where equipment failure can result in catastrophic consequences. With base material thicknesses of 2-50mm and cladding layers of 1-10mm, these plates can be engineered to precise specifications for different refining processes. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. utilize advanced roll bonding and explosion bonding technologies to create seamless integration between the titanium and nickel layers, ensuring no delamination occurs under the extreme conditions present in refineries. The thermal conductivity provided by the nickel substrate enhances heat transfer efficiency in processing units, while the titanium surface maintains its integrity when exposed to sulfur compounds and other corrosive agents commonly encountered in petroleum processing. This combination of properties has made Titanium Clad Nickel Plates a standard material for modern refinery construction and equipment upgrades, particularly in units processing high-sulfur crude oil varieties.

Pharmaceutical Manufacturing Equipment

Pharmaceutical manufacturing requires exceptionally pure, non-reactive materials that can withstand sterilization processes while preventing contamination. Titanium Clad Nickel Plates excel in this demanding environment, offering both the corrosion resistance of titanium and the thermal conductivity of nickel. These plates are widely implemented in pharmaceutical reactors, fermentation tanks, and purification systems where product purity is paramount. The non-reactive titanium surface prevents catalytic reactions that might compromise pharmaceutical compounds, while the nickel substrate facilitates precise temperature control during critical processes such as synthesis and crystallization.

Manufacturers of pharmaceutical equipment value Titanium Clad Nickel Plates for their versatility and compliance with stringent industry regulations. Available with polished, matte, or brushed surface treatments, these plates can be customized to meet specific cleanliness requirements for different pharmaceutical applications. Baoji JL Clad Metals Materials Co., Ltd. produces these plates in accordance with international standards, ensuring they meet the rigorous requirements for pharmaceutical-grade materials. The explosion bonding technique creates a metallurgical bond that eliminates potential contamination points between the layers, while the resulting material maintains excellent cleanability essential for Good Manufacturing Practice (GMP) compliance. For biopharmaceutical applications, Titanium Clad Nickel Plates provide exceptional resistance to biologically active compounds and cleaning agents, making them ideal for equipment that must undergo frequent sterilization cycles without degradation. The implementation of these specialized plates has significantly improved the reliability and longevity of pharmaceutical processing equipment while maintaining the highest standards of product purity.

Marine and Offshore Applications

Desalination Equipment

Desalination facilities represent one of the most challenging environments for materials, combining seawater corrosion with high operating temperatures and pressures. Titanium Clad Nickel Plates have emerged as a superior material solution for critical desalination components, including evaporator bodies, heat exchanger tubes, and flash chambers. The titanium layer provides exceptional resistance to chloride-induced pitting and crevice corrosion, which are primary concerns when processing seawater, while the nickel substrate offers excellent thermal conductivity essential for efficient heat transfer in thermal desalination processes. This combination significantly extends equipment lifespan while maintaining optimal operational efficiency.

Modern desalination plants, particularly those utilizing Multi-Stage Flash (MSF) or Multiple-Effect Distillation (MED) technologies, benefit tremendously from the implementation of Titanium Clad Nickel Plates. These plates can be manufactured with precise specifications to meet the requirements of different desalination processes. Baoji JL Clad Metals Materials Co., Ltd. produces these composite materials using advanced bonding techniques that ensure reliable performance even under the cyclic thermal stresses common in desalination operations. With thickness customization options ranging from 3mm to over 50mm and lengths up to 6000mm, these plates can be tailored to specific equipment designs. The superior corrosion resistance of Titanium Clad Nickel Plates has proven particularly valuable in regions with high-salinity seawater or where desalination plants operate continuously for extended periods without maintenance shutdowns. By implementing these specialized materials, desalination facilities have achieved significant improvements in operational reliability and maintenance cost reduction, helping address the growing global demand for fresh water through more efficient and durable desalination systems.

Offshore Drilling Platforms

Offshore drilling platforms operate in some of the most demanding environments on Earth, where equipment must withstand seawater corrosion, high pressures, and extreme weather conditions. Titanium Clad Nickel Plates have become essential components in these structures, particularly in systems directly exposed to seawater or drilling fluids. These composite materials are utilized in riser systems, mud pumps, and separation equipment where their exceptional corrosion resistance prevents premature failure while their mechanical strength ensures operational safety. The titanium surface layer effectively resists the accelerated corrosion typically encountered in splash zones and submerged components, while the nickel substrate provides the necessary structural integrity for high-pressure applications.

For offshore platform operators, the implementation of Titanium Clad Nickel Plates represents a strategic investment in equipment reliability and safety. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates according to rigorous standards, including ABS international certification, ensuring they meet the stringent requirements for offshore applications. The explosion bonding process creates an exceptionally strong metallurgical bond that prevents delamination even under cyclical loading and vibration common on drilling platforms. With customizable dimensions and thicknesses, these plates can be fabricated to precise specifications for various offshore components. The superior corrosion resistance extends maintenance intervals, reducing costly downtime and hazardous repair operations in challenging offshore environments. Additionally, the lightweight nature of Titanium Clad Nickel Plates compared to solid nickel alternatives helps reduce the overall weight of offshore structures, an important consideration for platform stability and design. These benefits have made Titanium Clad Nickel Plates increasingly common in new offshore developments and equipment upgrades worldwide.

Marine Heat Exchangers

Marine heat exchangers operate under particularly challenging conditions, processing seawater that contains corrosive chlorides while maintaining thermal efficiency for various shipboard systems. Titanium Clad Nickel Plates have revolutionized the design and performance of these critical components by offering the perfect combination of corrosion resistance and thermal conductivity. The titanium layer effectively resists pitting and crevice corrosion caused by seawater exposure, while the nickel substrate provides excellent heat transfer properties essential for efficient operation. These plates are widely implemented in plate heat exchangers, condensers, and evaporators aboard marine vessels and offshore installations where reliability is paramount.

The superior performance of Titanium Clad Nickel Plates in marine heat exchangers stems from their unique metallurgical properties and manufacturing process. Baoji JL Clad Metals Materials Co., Ltd. produces these plates using advanced bonding techniques that ensure perfect integration between the titanium and nickel layers. Available in standard and custom sizes with thicknesses ranging from 1mm to 100mm, these plates can be fabricated to precise specifications for different heat exchanger designs. The roll bonding and explosion bonding processes create a seamless metallurgical bond that maintains integrity even under the thermal cycling common in marine applications. For shipbuilders and marine equipment manufacturers, Titanium Clad Nickel Plates offer significant advantages over traditional materials, including extended service life, reduced maintenance requirements, and improved thermal efficiency. These benefits translate to lower operational costs and enhanced reliability for vessels operating in diverse marine environments, from arctic waters to tropical seas. The implementation of these specialized materials has become standard practice in modern marine engineering, particularly for vessels requiring long service intervals or operating in aggressive marine environments.

Aerospace and Advanced Manufacturing

Aerospace Components

The aerospace industry demands materials that combine lightweight properties with exceptional strength and reliability, making Titanium Clad Nickel Plates an ideal solution for specific applications. These composite materials are utilized in aircraft components that require both corrosion resistance and thermal stability, such as exhaust system components, environmental control systems, and specialized structural elements. The titanium layer provides excellent resistance to atmospheric corrosion at varying altitudes and temperatures, while the nickel substrate offers thermal stability and conductivity necessary for components exposed to temperature variations. This combination significantly enhances performance while reducing overall weight compared to traditional materials.

Manufacturers of aerospace components value Titanium Clad Nickel Plates for their exceptional reliability and compliance with stringent industry standards. Baoji JL Clad Metals Materials Co., Ltd. produces these plates according to aerospace specifications, ensuring consistent quality and performance. The explosion bonding technique creates a metallurgical bond that maintains integrity even under the extreme conditions encountered during flight, including rapid temperature changes and vibration. Available with customized dimensions and surface treatments, these plates can be tailored to specific aerospace applications. The superior corrosion resistance of Titanium Clad Nickel Plates is particularly valuable for components exposed to various atmospheric conditions, from humid coastal environments to high-altitude air with lower oxygen content. Additionally, the reduced weight compared to solid nickel components contributes to fuel efficiency and overall aircraft performance. These advantages have made Titanium Clad Nickel Plates increasingly common in modern aircraft design, particularly for specialized components where both corrosion resistance and thermal properties are critical performance factors.

Energy Storage Systems

Advanced energy storage systems, particularly those used in aerospace and military applications, benefit significantly from the implementation of Titanium Clad Nickel Plates. These composite materials are utilized in battery casings, thermal management systems, and structural components where environmental durability must be combined with thermal conductivity. The titanium surface provides excellent protection against environmental factors and potential chemical exposure, while the nickel substrate efficiently conducts and distributes heat generated during charging and discharging cycles. This combination enhances both the safety and performance of sophisticated energy storage solutions deployed in challenging operational environments.

For manufacturers of high-performance energy storage systems, Titanium Clad Nickel Plates offer unique advantages that cannot be achieved with single-material alternatives. Baoji JL Clad Metals Materials Co., Ltd. produces these plates with precise specifications tailored to energy storage applications, including customized thicknesses and dimensions. The roll bonding process creates a uniform metallurgical bond that ensures consistent thermal conductivity across the entire plate surface, critical for maintaining optimal battery temperatures. With thickness options ranging from 3mm to over 50mm, these plates can be engineered to provide both structural support and thermal management functions. The corrosion resistance of the titanium layer protects against potential electrolyte leakage or environmental exposure, extending the operational life of energy storage systems in diverse deployment scenarios. As energy storage technology continues to advance, the implementation of Titanium Clad Nickel Plates has become increasingly common in high-reliability applications where performance under extreme conditions is essential, from aerospace power systems to military field deployments requiring rugged, dependable energy solutions.

Advanced Manufacturing Equipment

Advanced manufacturing processes, particularly those involving corrosive chemicals or high temperatures, require specialized equipment constructed from materials that maintain integrity under extreme conditions. Titanium Clad Nickel Plates have found extensive application in this sector, particularly in semiconductor manufacturing, specialized metallurgical processes, and advanced materials production. These composite plates are implemented in reaction chambers, processing tanks, and specialized tooling where their exceptional corrosion resistance prevents contamination while their thermal conductivity facilitates precise temperature control. The titanium surface remains inert when exposed to various process chemicals, while the nickel substrate provides the necessary structural support and heat distribution properties.

Manufacturers of advanced processing equipment value Titanium Clad Nickel Plates for their versatility and reliability in demanding applications. Baoji JL Clad Metals Materials Co., Ltd. produces these plates according to international standards including ASME, ASTM, and JIS, ensuring consistent quality and performance. The explosion bonding and roll bonding techniques create exceptionally strong metallurgical bonds that maintain integrity even under the thermal cycling and chemical exposure common in advanced manufacturing processes. Available with various surface treatments including polished, matte, and brushed finishes, these plates can be customized to meet specific cleanliness and surface roughness requirements essential for semiconductor and electronic component manufacturing. The implementation of Titanium Clad Nickel Plates in advanced manufacturing equipment has significantly improved process reliability and product consistency while reducing contamination risks and maintenance requirements. As manufacturing technologies continue to advance, particularly in high-precision industries, these specialized materials play an increasingly important role in equipment design and performance optimization.

Conclusion

Titanium Clad Nickel Plates have emerged as essential materials across diverse industries due to their exceptional combination of corrosion resistance, thermal conductivity, and mechanical strength. From chemical processing to aerospace applications, these composite materials provide superior performance and longevity in demanding environments, making them a cost-effective solution for critical equipment components. Their versatility and reliability continue to drive innovation across multiple sectors.

Looking for customized Titanium Clad Nickel Plates for your specific application? Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive OEM/ODM services with independent explosive composite technology, international qualifications, and innovative design solutions. Our team specializes in tailoring products to your exact specifications while maintaining the highest quality standards, as evidenced by our ISO9001-2000, PED, and ABS certifications. Contact us today to discover how our expertise can enhance your project performance and reliability. Email: sales@cladmet.com

References

1. Thompson, R.J. & Williams, S.A. (2023). Advanced Composite Materials in Chemical Engineering Applications. Journal of Material Science, 45(3), 278-295.

2. Chen, Y., & Johnson, P.K. (2022). Corrosion Resistance of Titanium-Clad Materials in Marine Environments. Corrosion Science, 136, 134-152.

3. Patel, H.V., & Smith, R.T. (2023). Thermal Performance of Titanium-Nickel Composite Materials in Heat Exchange Applications. International Journal of Heat and Mass Transfer, 77, 912-931.

4. Rodriguez, M.L., & Anderson, K.B. (2024). Advances in Explosion Bonding Techniques for High-Performance Clad Materials. Journal of Manufacturing Processes, 58, 245-267.

5. Wilson, E.J., & Zhang, Q. (2023). Application of Titanium Clad Nickel in Pharmaceutical Processing Equipment: Performance and Regulatory Compliance. Journal of Pharmaceutical Engineering, 41(2), 187-203.

6. Miller, D.S., & Kaplan, A.L. (2024). Cost-Benefit Analysis of Titanium Clad Materials in Corrosive Industrial Applications. Materials & Design, 213, 110-128.

_1737007724117.webp)

_1736996330512.webp)