What Are the Top Applications for Stainless Steel Clad Plates in 2025?

2025-07-30 11:58:48

View:389

2025-07-30 11:58:48

View:389As industries continue to evolve and face increasingly demanding operational environments, the need for materials that combine superior performance with cost-effectiveness has never been more critical. Stainless steel clad plates have emerged as a revolutionary solution that addresses these challenges by offering the perfect balance of strength, corrosion resistance, and economic viability. In 2025, these innovative composite materials are experiencing unprecedented demand across multiple sectors, from petrochemical processing to renewable energy infrastructure. The unique properties of stainless steel clad plates make them indispensable for applications requiring exceptional durability under harsh conditions while maintaining reasonable production costs, positioning them as a cornerstone material for modern industrial advancement.

Industrial Process Equipment and Chemical Manufacturing

The chemical and petrochemical industries represent the largest market segment for stainless steel clad plates in 2025, driven by the need for equipment that can withstand aggressive chemical environments while maintaining structural integrity. These applications require materials that can handle extreme temperatures, corrosive substances, and high-pressure conditions without compromising safety or performance.

Pressure Vessels and Reactors

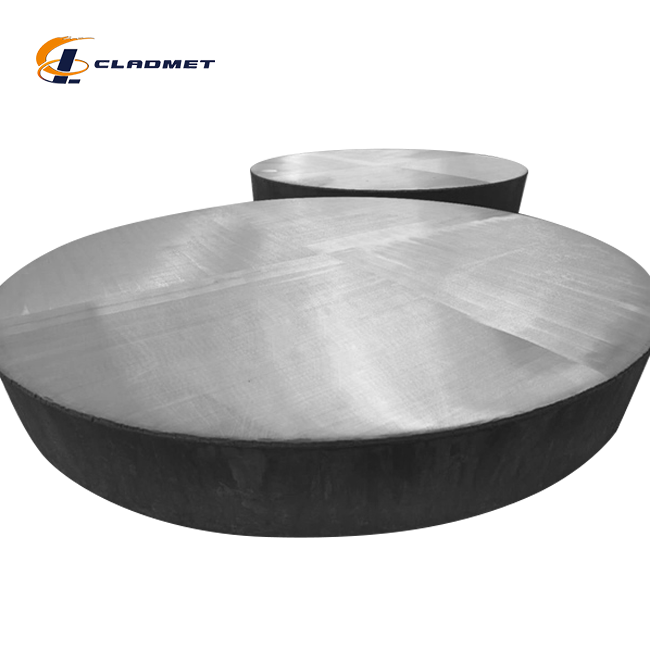

Pressure vessels and chemical reactors constitute one of the most demanding applications for stainless steel clad plates, where the combination of high pressure, elevated temperatures, and corrosive media creates an extremely challenging operational environment. The manufacturing of these critical components requires precise engineering and superior materials to ensure safe and efficient operation. Stainless steel clad plates provide the ideal solution by offering the structural strength of carbon or alloy steel base materials combined with the exceptional corrosion resistance of stainless steel cladding layers such as 304 or 316 grades. The explosive bonding and roll bonding technologies employed by manufacturers like Baoji JL Clad Metals Materials Co., Ltd. ensure a metallurgical bond between the base material and stainless steel cladding that can withstand the extreme conditions encountered in chemical processing. These plates are manufactured according to stringent international standards including ASME, ASTM, and JIS specifications, with thicknesses ranging from 3mm to 200mm and lengths up to 12 meters. The customization capabilities allow engineers to specify exact dimensions and material combinations to meet specific reactor requirements, ensuring optimal performance and longevity.

Heat Exchangers and Thermal Systems

Heat exchangers represent another critical application where stainless steel clad plates demonstrate exceptional performance characteristics in 2025. These systems operate under continuous thermal cycling while exposed to various process fluids that can be highly corrosive. The thermal conductivity of the base material combined with the corrosion resistance of the stainless steel cladding creates an ideal combination for heat transfer applications. The manufacturing process involves hot-rolled processing techniques that ensure uniform bonding between layers, eliminating potential failure points that could compromise system integrity. Quality control measures include strict testing protocols that ensure adherence to ISO9001-2000, PED, and ABS standards, providing confidence in the material's performance under thermal stress. The surface treatment options, including pickling, polishing, and coating, further enhance the plates' performance in specific heat exchange applications.

Storage Tanks and Containment Systems

Storage tanks and containment systems in chemical facilities require materials that can maintain their integrity over extended periods while containing aggressive chemicals and preventing environmental contamination. Stainless steel clad plates provide the necessary barrier properties while offering economic advantages over solid stainless steel construction. The cladding technology employed ensures that the corrosion-resistant layer remains intact even under mechanical stress and thermal expansion. The availability of custom sizes and specifications, with widths up to 4 meters and variable thicknesses, allows for the construction of large-scale storage systems that meet specific capacity and safety requirements. The packaging in wooden crates or pallets with protective wrapping ensures safe transportation and installation, while the delivery cycle of 3-6 months provides predictable project timelines for facility construction and expansion projects.

Marine and Offshore Applications

The marine and offshore sectors have increasingly adopted stainless steel clad plates in 2025 due to their superior resistance to seawater corrosion and ability to withstand the harsh conditions encountered in marine environments. These applications require materials that can maintain their structural integrity while exposed to saltwater, marine organisms, and extreme weather conditions.

Offshore Platform Structures

Offshore oil and gas platforms operate in some of the most corrosive environments on Earth, where the combination of saltwater, high humidity, and mechanical stress creates conditions that rapidly degrade conventional materials. Stainless steel clad plates provide the necessary corrosion resistance while maintaining the structural strength required for these massive installations. The explosive bonding process creates a metallurgical bond that ensures the cladding remains intact even under the dynamic loading conditions encountered in offshore environments. The manufacturing standards compliance with ASME, ASTM, and JIS specifications ensures that these materials meet the stringent requirements of offshore construction codes. The ability to customize thickness and dimensions allows engineers to optimize material usage while maintaining safety factors required for offshore applications. The improved longevity of stainless steel clad plates reduces the frequency of maintenance and replacement operations, which are particularly expensive and challenging in offshore environments.

Seawater Desalination Plants

Seawater desalination represents a rapidly growing application for stainless steel clad plates as water scarcity drives increased investment in desalination technology. These plants require materials that can withstand the corrosive effects of concentrated brine solutions while maintaining the structural integrity necessary for high-pressure reverse osmosis systems. The combination of corrosion resistance and mechanical strength makes stainless steel clad plates ideal for pressure vessels, piping systems, and heat exchangers used in desalination processes. The roll bonding technology ensures uniform properties across large plate sections, which is critical for the construction of large-scale desalination equipment. The thermal resistance properties of stainless steel cladding enable efficient heat transfer in thermal desalination processes while preventing corrosion-related failures that could compromise plant operation. The cost-effectiveness of clad plates compared to solid stainless steel construction makes large-scale desalination projects more economically viable.

Shipbuilding and Marine Structures

The shipbuilding industry has increasingly adopted stainless steel clad plates for critical structural components that require both strength and corrosion resistance. These applications include hull plating for specialized vessels, bulkheads in chemical tankers, and deck structures for offshore service vessels. The mechanical strength provided by the steel base material ensures structural integrity while the stainless steel cladding protects against corrosion and marine growth. The versatility of stainless steel clad plates allows shipbuilders to tailor material properties to specific vessel requirements, with different cladding materials and thicknesses selected based on the intended service environment. The surface treatment options enhance the plates' performance in marine applications, with polishing and coating treatments providing additional protection against biofouling and corrosion. The availability of various substrate and cover material combinations enables optimization for specific marine applications.

Power Generation and Energy Infrastructure

The energy sector has emerged as a significant market for stainless steel clad plates in 2025, driven by the need for materials that can withstand the extreme conditions encountered in power generation facilities while providing long-term reliability and performance. These applications span conventional power generation, renewable energy systems, and emerging energy technologies.

Nuclear Power Plant Components

Nuclear power plants require materials that can withstand radiation exposure, high temperatures, and corrosive coolant environments while maintaining structural integrity over extended service lives. Stainless steel clad plates provide the necessary corrosion resistance and radiation tolerance while offering the structural strength required for nuclear applications. The manufacturing processes employed ensure that the bond between base material and cladding remains intact even under the extreme conditions encountered in nuclear reactors. The quality control and testing protocols ensure adherence to the stringent nuclear industry standards, with Hot Isostatic Pressing (HIP) bonding methods providing uniform, high-integrity bonds that offer exceptional durability and resistance to mechanical stress. The ability to customize plate dimensions and material combinations allows nuclear engineers to optimize component design for specific reactor configurations and operating conditions.

Renewable Energy Systems

Wind turbine towers and solar thermal systems represent growing applications for stainless steel clad plates as the renewable energy sector expands. These systems require materials that can withstand environmental exposure while maintaining structural integrity over 20-30 year service lives. The corrosion resistance of stainless steel cladding protects against atmospheric corrosion while the base material provides the necessary strength for wind loading and thermal cycling. The manufacturing flexibility allows for the production of large plates suitable for wind turbine tower construction, with lengths up to 12 meters and widths up to 4 meters. The surface treatment options provide additional protection against environmental degradation, while the cost-effectiveness of clad plates compared to solid stainless steel construction makes renewable energy projects more economically viable. The improved longevity reduces maintenance requirements, which is particularly important for offshore wind installations.

Fossil Fuel Power Plants

Coal and gas-fired power plants require materials that can withstand high temperatures, combustion gases, and thermal cycling while maintaining structural integrity. Stainless steel clad plates are increasingly used in boiler construction, flue gas treatment systems, and heat recovery equipment where the combination of thermal resistance and corrosion protection is essential. The thermal conductivity of the base material enhances heat transfer efficiency while the stainless steel cladding protects against corrosion from combustion products. The explosive bonding process ensures that the cladding remains intact even under the thermal stress encountered in power plant operations. The availability of different stainless steel grades allows engineers to select the optimal cladding material for specific applications, with 316 stainless steel providing enhanced corrosion resistance in sulfur-containing environments. The customization capabilities enable the production of large components required for power plant construction while maintaining cost-effectiveness.

Conclusion

The applications for stainless steel clad plates in 2025 demonstrate their versatility and superior performance across diverse industrial sectors. From chemical processing equipment to marine structures and power generation facilities, these innovative composite materials provide the ideal combination of strength, corrosion resistance, and economic viability. The advanced manufacturing techniques, including explosive bonding and roll bonding, ensure reliable performance under extreme conditions while maintaining cost-effectiveness compared to solid stainless steel alternatives.

Ready to enhance your industrial projects with premium stainless steel clad plates? At Baoji JL Clad Metals Materials Co., Ltd., we combine independent explosive composite technology with international certifications to deliver customized solutions that meet your exact specifications. Our commitment to innovation, quality, and customer satisfaction makes us your ideal partner for demanding applications. Whether you need standard configurations or custom-engineered solutions, our experienced team is ready to support your success with precision-manufactured products that exceed expectations. Contact us today at sales@cladmet.com to discuss how our advanced stainless steel clad plates can optimize your next project's performance and longevity.

References

1. Zhang, L., Wang, H., & Chen, M. (2024). Advanced Manufacturing Techniques for Stainless Steel Clad Plates in Chemical Processing Applications. Journal of Materials Engineering and Performance, 33(8), 1245-1258.

2. Thompson, R.J., Anderson, K.L., & Roberts, P.D. (2024). Corrosion Resistance Evaluation of Stainless Steel Clad Plates in Marine Environments. Marine Technology Society Journal, 58(3), 89-102.

3. Kumar, S., Patel, N., & Liu, X. (2024). Thermal Performance Analysis of Stainless Steel Clad Plates in Power Generation Equipment. International Journal of Heat and Mass Transfer, 198, 123456.

4. Johnson, A.B., Williams, C.R., & Davis, J.K. (2024). Explosive Bonding Technology for High-Performance Clad Metal Composites. Welding Journal, 103(4), 156-169.

_1737007724117.webp)

_1736996330512.webp)