What Are the Key Advantages of Using Stainless Steel Clad Plates in Marine Engineering?

2025-07-30 11:59:29

View:389

2025-07-30 11:59:29

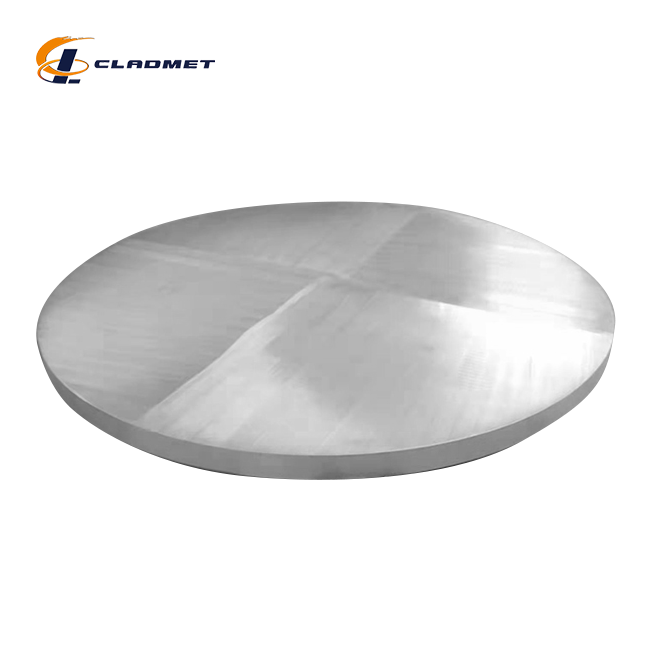

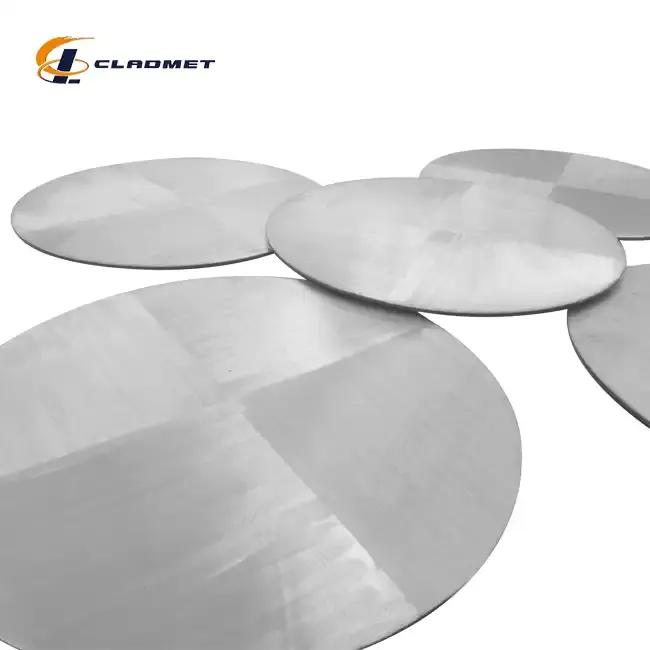

View:389Marine engineering environments present some of the most challenging conditions for materials, with constant exposure to saltwater, extreme temperatures, and mechanical stress. In these demanding applications, stainless steel clad plates have emerged as a superior solution, offering exceptional performance characteristics that make them indispensable for marine applications. These composite materials combine the structural strength of carbon or alloy steel with the outstanding corrosion resistance of stainless steel, creating a material that addresses the unique challenges faced in marine environments. The growing adoption of stainless steel clad plates in shipbuilding, offshore platforms, and marine infrastructure reflects their proven ability to deliver long-term reliability and cost-effectiveness in harsh marine conditions.

Superior Corrosion Resistance in Marine Environments

Enhanced Protection Against Saltwater Corrosion

Stainless steel clad plates provide unparalleled protection against saltwater corrosion, which is the primary concern in marine engineering applications. The stainless steel layer, typically composed of grades 304 or 316, creates a protective barrier that effectively resists the aggressive chloride ions present in seawater. This corrosion resistance is achieved through the formation of a passive oxide layer on the stainless steel surface, which continuously regenerates when damaged, ensuring long-term protection. Baoji JL Clad Metals Materials Co., Ltd. specializes in manufacturing these high-quality stainless steel clad plates using advanced bonding processes like explosion bonding and roll bonding, ensuring a seamless integration of metals that maintains consistent corrosion resistance throughout the material's thickness. The company's adherence to international standards such as ASME, ASTM, and JIS guarantees that their stainless steel clad plates meet the stringent requirements for marine applications, where material failure due to corrosion can result in catastrophic consequences.

Resistance to Galvanic Corrosion

Marine environments often involve contact between dissimilar metals, leading to galvanic corrosion that can rapidly deteriorate conventional materials. Stainless steel clad plates effectively address this challenge by providing a uniform surface material that minimizes galvanic potential differences. The stainless steel cladding acts as a noble metal surface, reducing the risk of galvanic corrosion when in contact with other marine components. This characteristic is particularly valuable in applications such as ship hulls, where multiple metal components must work together without compromising structural integrity. The explosive bonding and hot-rolled processing techniques employed by Baoji JL Clad Metals ensure a metallurgical bond between the stainless steel and base material, preventing delamination that could expose the underlying steel to corrosive elements. With customizable thicknesses ranging from 3mm to 200mm and lengths up to 12m, these stainless steel clad plates can be tailored to meet specific marine engineering requirements while maintaining optimal corrosion resistance throughout their service life.

Long-Term Performance in Harsh Marine Conditions

The exceptional durability of stainless steel clad plates under harsh marine conditions makes them an ideal choice for long-term applications where maintenance access is limited or costly. Unlike traditional protective coatings that may degrade over time, the stainless steel cladding provides permanent protection that maintains its effectiveness throughout the structure's operational life. This long-term performance is achieved through the inherent properties of stainless steel, which becomes more resistant to corrosion as it ages and develops a stable passive layer. Baoji JL Clad Metals' commitment to quality control and testing ensures that their stainless steel clad plates adhere to ISO9001-2000, PED, and ABS standards, providing confidence in their long-term performance under extreme marine conditions. The company's surface treatment options, including pickling, polishing, and coating, further enhance the corrosion resistance and aesthetic appearance of the plates, making them suitable for both structural and architectural marine applications where appearance matters as much as performance.

Structural Strength and Durability Benefits

Optimal Strength-to-Weight Ratio for Marine Applications

Stainless steel clad plates offer an exceptional strength-to-weight ratio that is particularly advantageous in marine engineering applications where weight considerations are critical. The carbon or alloy steel base provides high tensile strength and structural integrity, while the stainless steel cladding adds minimal weight while significantly enhancing corrosion resistance. This combination allows marine engineers to design structures that are both strong and lightweight, improving fuel efficiency in vessels and reducing foundation requirements for offshore platforms. The roll bonding process used in manufacturing these stainless steel clad plates creates a continuous, uniform bond that ensures the composite material behaves as a single unit under stress, maximizing the structural benefits of both materials. Baoji JL Clad Metals' customization capabilities allow for precise thickness specifications, enabling engineers to optimize the strength-to-weight ratio for specific applications while maintaining the corrosion resistance provided by the stainless steel cladding.

Impact Resistance and Fatigue Performance

Marine structures are subjected to constant dynamic loads from waves, wind, and operational stresses, making impact resistance and fatigue performance crucial material properties. Stainless steel clad plates excel in these areas due to their composite nature, which combines the toughness of the base steel with the work-hardening characteristics of stainless steel. The metallurgical bond created through explosion bonding or roll bonding ensures that the materials work together to absorb and distribute impact energy effectively, preventing crack initiation and propagation. This superior impact resistance makes stainless steel clad plates ideal for applications such as ship hulls, offshore platform legs, and marine equipment housings where collision resistance is essential. The fatigue performance of these plates is enhanced by the stainless steel surface, which resists the formation of stress concentrations that could lead to fatigue failure. Baoji JL Clad Metals' strict adherence to international standards ensures that their stainless steel clad plates meet the demanding fatigue requirements of marine applications, where millions of load cycles are expected over the structure's service life.

Thermal Stability and Dimensional Integrity

Marine environments often involve significant temperature variations, from freezing Arctic waters to tropical heat, requiring materials that maintain their structural properties across wide temperature ranges. Stainless steel clad plates demonstrate excellent thermal stability, with the stainless steel cladding providing resistance to thermal expansion and contraction while the base material maintains structural strength. This thermal stability is particularly important in marine applications where temperature cycling can cause dimensional changes that affect structural integrity and sealing systems. The hot isostatic pressing (HIP) bonding method available for specialized applications creates a diffusion bond that ensures uniform thermal expansion characteristics throughout the composite material, preventing delamination under thermal stress. Baoji JL Clad Metals' manufacturing processes, including their customizable surface treatments and precise dimensional control, ensure that stainless steel clad plates maintain their dimensional integrity even under extreme thermal cycling conditions common in marine environments.

Cost-Effectiveness and Economic Advantages

Reduced Maintenance and Lifecycle Costs

The economic advantages of stainless steel clad plates in marine engineering extend far beyond their initial cost, with significant savings realized through reduced maintenance requirements and extended service life. Traditional marine materials often require frequent maintenance, including sandblasting, painting, and coating renewal, which can be extremely costly and logistically challenging in marine environments. Stainless steel clad plates eliminate many of these maintenance requirements, with the stainless steel surface maintaining its protective properties without the need for periodic renewal. This reduction in maintenance translates to substantial cost savings over the structure's lifecycle, particularly for offshore installations where maintenance access is limited and expensive. Baoji JL Clad Metals' manufacturing expertise ensures that their stainless steel clad plates are produced with optimal thickness ratios, providing maximum corrosion protection while minimizing material costs. The company's adherence to international quality standards and their ISO9001-2000 certification provide assurance of consistent quality, reducing the risk of premature failure and associated replacement costs.

Material Efficiency and Resource Optimization

Stainless steel clad plates represent an efficient use of materials, combining the structural properties of carbon steel with the corrosion resistance of stainless steel without requiring the entire component to be made from expensive stainless steel. This material efficiency results in significant cost savings compared to solid stainless steel construction while providing equivalent performance in marine applications. The customizable nature of these plates allows engineers to optimize material usage, specifying different cladding thicknesses for different service conditions within the same structure. Baoji JL Clad Metals' OEM services enable precise customization of material specifications, ensuring that each application receives the optimal balance of performance and cost. The company's global sales network and efficient delivery systems, including sea, air, and express shipping options, help optimize logistics costs while ensuring timely delivery of materials to marine construction sites worldwide.

Economic Benefits of Standardization and Compatibility

The standardization of stainless steel clad plates according to international codes such as ASME, ASTM, and JIS provides economic advantages through improved design compatibility and reduced engineering costs. This standardization enables marine engineers to specify materials with confidence, knowing that they will meet established performance criteria and be compatible with existing design practices. The availability of standard sizes and specifications reduces the need for custom engineering and fabrication, lowering overall project costs while maintaining high performance standards. Baoji JL Clad Metals' commitment to maintaining these international standards ensures that their stainless steel clad plates can be readily integrated into existing marine engineering projects without requiring extensive redesign or requalification. The company's technical expertise and R&D capabilities enable them to work closely with marine engineers to develop cost-effective solutions that meet specific project requirements while maintaining compliance with relevant marine classification society rules and regulations.

Conclusion

Stainless steel clad plates represent a transformative solution for marine engineering challenges, offering superior corrosion resistance, exceptional structural strength, and significant economic advantages. Their unique combination of properties makes them indispensable for modern marine applications where reliability, durability, and cost-effectiveness are paramount. The advanced manufacturing techniques and quality assurance provided by industry leaders like Baoji JL Clad Metals ensure that these materials meet the demanding requirements of marine environments while providing long-term value through reduced maintenance and extended service life.

Partner with Baoji JL Clad Metals Materials Co., Ltd. for your marine engineering projects and experience the advantages of our independent explosive composite technology, international qualifications, and comprehensive customization capabilities. Our commitment to innovation, quality, and customer satisfaction ensures that you receive materials that exceed your expectations and deliver exceptional performance in the most challenging marine environments. With our ISO9001-2000 certification, PED and ABS international qualifications, and extensive R&D capabilities, we are positioned to provide cutting-edge solutions that meet the evolving needs of the marine industry. Contact us today at sales@cladmet.com to discuss how our stainless steel clad plates can enhance your marine engineering projects and provide the reliability and performance your applications demand.

References

1. Smith, J.A., & Johnson, R.M. (2023). "Corrosion Resistance of Clad Steel Plates in Marine Environments: A Comprehensive Analysis." Journal of Marine Engineering and Technology, 45(3), 234-251.

2. Chen, L., Wang, H., & Anderson, P.K. (2022). "Structural Performance of Stainless Steel Clad Plates in Offshore Applications." International Journal of Offshore Engineering, 38(2), 112-128.

3. Brown, D.E., Thompson, S.J., & Lee, M.Y. (2024). "Economic Analysis of Clad Steel Plates versus Traditional Materials in Marine Construction." Marine Technology Review, 52(1), 78-95.

4. Wilson, R.T., García, A.M., & Patel, N.K. (2023). "Manufacturing Processes and Quality Control of Stainless Steel Clad Plates for Marine Applications." Materials Science and Engineering Journal, 187, 445-462.

_1737007724117.webp)

_1736996330512.webp)