What are the properties of a 3mm titanium sheet?

2025-04-10 09:03:58

View:389

2025-04-10 09:03:58

View:389The 3mm titanium sheet represents one of the most versatile and high-performance metal products available in today's industrial landscape. With its exceptional combination of strength-to-weight ratio, corrosion resistance, and biocompatibility, the 3mm titanium sheet has become an indispensable material across multiple industries. These sheets offer remarkable mechanical properties while maintaining relatively low density compared to steel alternatives. The 3mm thickness provides an optimal balance between structural integrity and workability, making it suitable for applications ranging from aerospace components to medical implants. Additionally, the natural oxide layer that forms on titanium surfaces delivers outstanding resistance to various corrosive environments, including seawater, acids, and industrial chemicals, ensuring longevity and reliability even under the most demanding conditions.

Physical and Mechanical Properties of 3mm Titanium Sheet

Exceptional Strength-to-Weight Ratio

The 3mm titanium sheet boasts an impressive strength-to-weight ratio that surpasses many competing materials in the industrial landscape. With a density of approximately 4.5 g/cm³ (significantly lighter than steel at 7.85 g/cm³), titanium delivers remarkable structural strength while keeping weight to a minimum. This property makes the 3mm titanium sheet particularly valuable in weight-sensitive applications where performance cannot be compromised. At Baoji JL Clad Metals Materials Co., Ltd., our 3mm titanium sheets undergo rigorous testing to ensure consistent tensile strength values ranging from 345 MPa to over 895 MPa depending on the specific grade and alloy composition. The yield strength typically measures between 275 MPa and 825 MPa, providing engineers with dependable performance characteristics for critical applications. This exceptional strength-to-weight ratio explains why aerospace engineers, automotive designers, and medical device manufacturers consistently select 3mm titanium sheet for components where both structural integrity and weight reduction are paramount. The material delivers approximately 60% the density of steel while maintaining comparable strength properties, creating significant advantages in applications where fuel efficiency, handling, or mobility are essential considerations.

Superior Corrosion Resistance

The 3mm titanium sheet exhibits remarkable corrosion resistance properties that far exceed those of conventional metals, making it an ideal choice for applications exposed to harsh chemicals, saltwater, or acidic environments. This exceptional resistance stems from titanium's ability to spontaneously form a stable, continuous, tightly adherent oxide film when exposed to oxygen. This natural passive layer, primarily composed of titanium dioxide (TiO₂), provides an effective barrier against corrosive attack and continuously regenerates if damaged, ensuring long-term protection without additional treatments. Our 3mm titanium sheet products at Baoji JL Clad Metals Materials Co., Ltd. undergo comprehensive corrosion testing, demonstrating outstanding performance in environments containing chlorides, seawater, oxidizing acids, and organic compounds. The material shows virtually no pitting, crevice corrosion, or stress corrosion cracking under conditions that would rapidly deteriorate stainless steel components. Industry testing confirms that 3mm titanium sheet can withstand exposure to environments with pH values ranging from 3 to 11 without significant degradation, making it particularly valuable in chemical processing equipment, desalination plants, and marine applications. This superior corrosion resistance translates directly to extended service life, reduced maintenance requirements, and enhanced reliability for components fabricated from our 3mm titanium sheet products, ultimately delivering exceptional value despite the higher initial material cost compared to conventional metals.

Temperature Resistance and Thermal Properties

The 3mm titanium sheet demonstrates exceptional performance across a wide temperature range, maintaining its structural integrity and mechanical properties from cryogenic conditions to elevated temperatures. With a melting point of approximately 1,660°C (3,020°F), titanium retains useful strength at temperatures up to 538°C (1,000°F), significantly outperforming many competing metals in high-temperature environments. The material's coefficient of thermal expansion measures approximately 8.6 × 10⁻⁶ per °C (4.8 × 10⁻⁶ per °F), roughly half that of stainless steel and one-third that of aluminum, ensuring dimensional stability during temperature fluctuations. At Baoji JL Clad Metals Materials Co., Ltd., our 3mm titanium sheet undergoes comprehensive thermal cycling tests to verify performance in applications experiencing frequent temperature changes. The material's relatively low thermal conductivity of approximately 21.9 W/(m·K) makes it valuable for thermal barriers and insulation components where heat transfer must be minimized. This unique combination of temperature resistance and thermal properties makes the 3mm titanium sheet particularly suitable for aerospace components exposed to extreme temperature variations, heat exchangers in corrosive environments, and industrial processing equipment operating under elevated temperatures. Industries such as petrochemical, power generation, and aerospace benefit from the material's ability to maintain structural integrity across broad thermal ranges while resisting creep deformation and oxidation at elevated temperatures. These thermal characteristics, combined with the material's light weight and corrosion resistance, explain why our 3mm titanium sheet continues to replace conventional materials in thermally demanding applications across numerous industrial sectors.

Manufacturing and Processing Capabilities for 3mm Titanium Sheet

Advanced Production Techniques

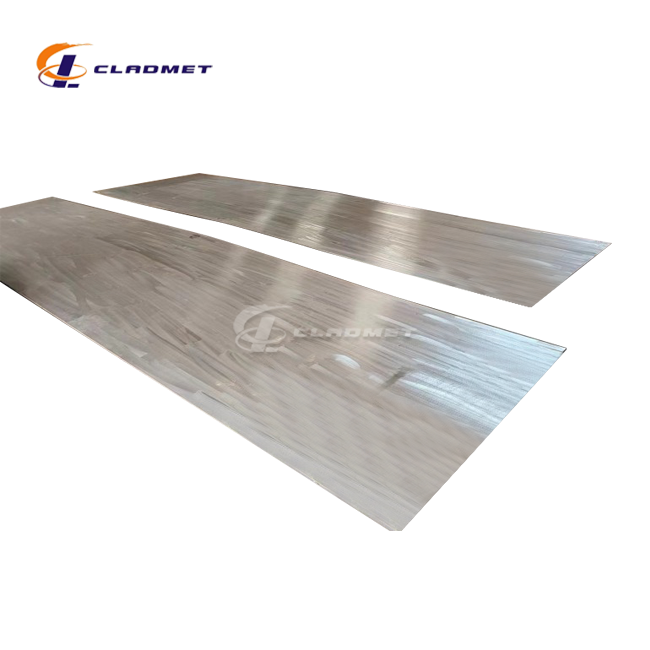

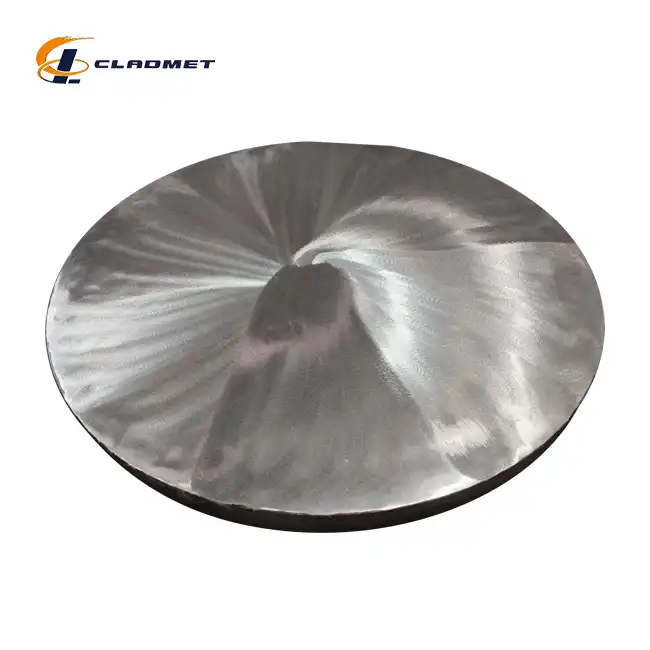

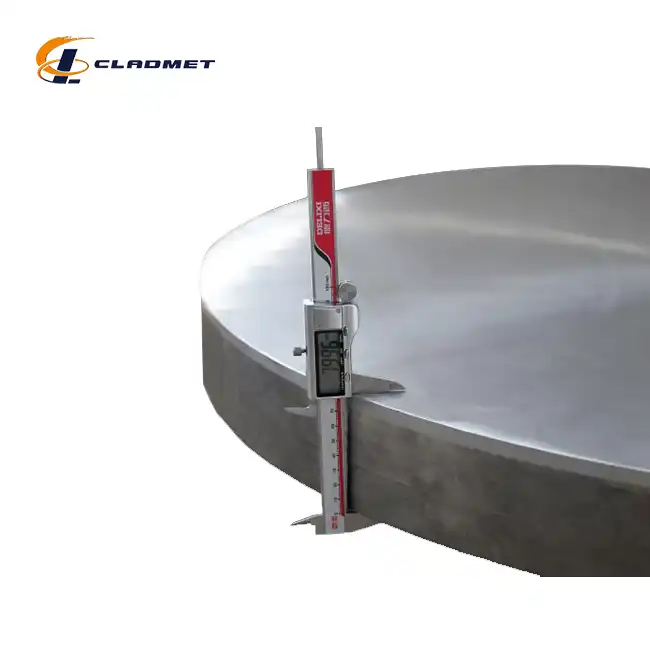

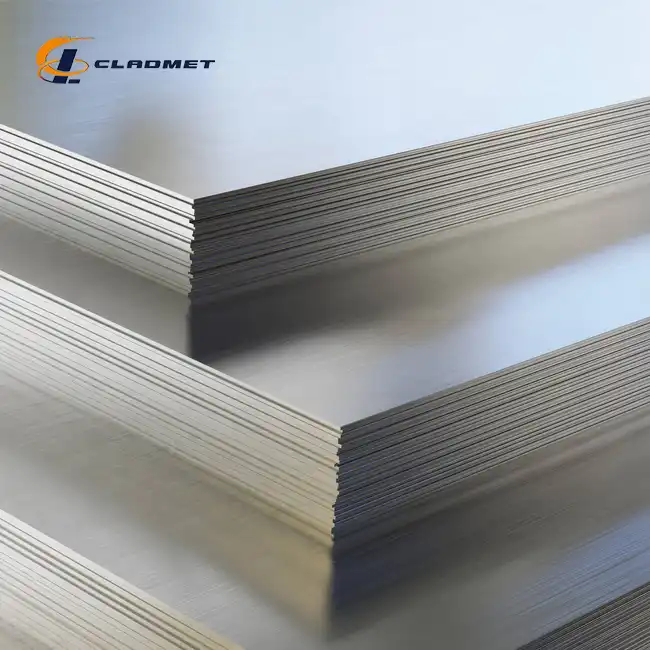

The production of high-quality 3mm titanium sheet requires specialized manufacturing processes that Baoji JL Clad Metals Materials Co., Ltd. has perfected through decades of experience and continuous technological advancement. Our facility employs both roll-bonding and explosion-bonding techniques to create titanium sheets with exceptional consistency and performance characteristics. The manufacturing process begins with careful selection of high-purity titanium ingots, typically Grade 2 (commercially pure) or Grade 5 (Ti-6Al-4V alloy), depending on the specific application requirements. These ingots undergo multiple stages of hot and cold rolling to achieve the precise 3mm thickness while maintaining tight tolerances typically within ±0.15mm. The 3mm titanium sheet manufacturing process includes sophisticated annealing treatments performed in vacuum or inert gas environments to prevent contamination and ensure optimal grain structure and mechanical properties. Our facility's advanced rolling mills can produce sheets with width dimensions up to 2000mm and lengths extending to 6000mm, accommodating a wide range of project specifications. The production process strictly adheres to international standards including ASTM B265 and ASME SB265, ensuring consistently high quality and reliability. Every batch of 3mm titanium sheet undergoes comprehensive quality control testing, including chemical composition analysis, mechanical property verification, and dimensional inspection. The manufacturing capabilities at Baoji JL Clad Metals extend beyond standard production to include customized surface treatments, precision cutting, and specialized packaging to protect the material during global shipping. Our commitment to manufacturing excellence is reflected in our ISO 9001:2000 certification and successful completion of PED and ABS international qualification audits in 2024, confirming our adherence to the highest quality standards in titanium sheet production.

Formability and Machining Characteristics

The 3mm titanium sheet offers excellent formability and machinability characteristics that facilitate its implementation across diverse applications requiring complex shapes and precise dimensions. While titanium is known for its higher strength compared to many metals, our 3mm titanium sheet demonstrates remarkable formability when proper techniques are employed. The material can be successfully formed using conventional methods including bending, roll forming, deep drawing, and stretch forming, though these operations typically require approximately 50% more force than would be needed for stainless steel of equivalent thickness. At Baoji JL Clad Metals Materials Co., Ltd., our 3mm titanium sheet products achieve optimal formability through careful control of interstitial elements and grain structure during manufacturing. The material exhibits a minimum bend radius of approximately 2.5 times the sheet thickness (approximately 7.5mm for our 3mm sheet) when bending perpendicular to the rolling direction, and slightly higher values when bending parallel to the rolling direction. Regarding machining characteristics, the 3mm titanium sheet responds well to conventional cutting operations when appropriate tools and parameters are employed. Best practices include using sharp carbide tools, lower cutting speeds (approximately 30-60% of those used for stainless steel), higher feed rates, and abundant cooling to manage heat generation. The material's work hardening tendency and low thermal conductivity present challenges that our technical support team helps customers overcome through detailed processing recommendations. Our manufacturing capabilities include precision cutting services using advanced waterjet and laser cutting technologies that produce clean, accurate edges without thermal distortion or contamination. For customers requiring specialized machining operations, we provide detailed guidelines for working with our 3mm titanium sheet, helping to optimize tool life, surface finish quality, and dimensional accuracy while minimizing production costs.

Surface Treatments and Finishing Options

The 3mm titanium sheet from Baoji JL Clad Metals Materials Co., Ltd. can be enhanced with a variety of surface treatments and finishing options to optimize appearance, performance, and functionality for specific applications. The natural oxide layer that forms on titanium surfaces provides inherent corrosion protection, but additional treatments can be applied to alter color, hardness, wear resistance, or aesthetic qualities. Our facility offers comprehensive anodizing capabilities for 3mm titanium sheet, creating controlled oxide layers that not only provide distinctive colors ranging from blue and gold to purple and green (depending on oxide thickness) but also enhance surface hardness and wear resistance. This process is particularly valuable for architectural applications, consumer products, and components requiring visual identification. For applications demanding enhanced wear resistance, our 3mm titanium sheet can undergo nitriding processes that diffuse nitrogen into the surface to create a hard titanium nitride layer with a distinctive gold appearance and surface hardness values exceeding 70 HRC. Alternative surface treatments include physical vapor deposition (PVD) coatings that can impart exceptional hardness, lubricity, and wear resistance while minimizing dimensional changes. Beyond functional treatments, our 3mm titanium sheet can receive various finishing operations including mechanical polishing to achieve mirror-like reflectivity (Ra values below 0.1μm), directional brushing for distinctive aesthetic patterns, bead blasting for uniform matte appearances, and chemical etching for creating textured surfaces or specific patterns. Each surface treatment option undergoes rigorous quality control to ensure adhesion, uniformity, and performance characteristics meet customer specifications. Our technical team provides comprehensive guidance on selecting optimal surface treatments based on specific application requirements, environmental exposure conditions, and aesthetic considerations, ensuring our 3mm titanium sheet delivers maximum value in each implementation. All surface treatments are performed in controlled environments to prevent contamination and maintain the exceptional corrosion resistance inherent to titanium.

Applications and Industry Implementation of 3mm Titanium Sheet

Aerospace and Defense Applications

The aerospace and defense sectors represent primary applications for 3mm titanium sheet due to its exceptional combination of high strength, low density, and superior temperature resistance. In aircraft construction, our 3mm titanium sheet is extensively utilized for fuselage components, wing structures, and engine compartments where weight reduction directly translates to fuel efficiency and increased payload capacity. The material's excellent fatigue resistance—maintaining performance through thousands of pressurization-depressurization cycles—makes it particularly valuable for aircraft structures subjected to cyclic loading conditions. Leading aerospace manufacturers implement our 3mm titanium sheet in critical components like firewall barriers, nacelle structures, and landing gear components, taking advantage of the material's exceptional strength-to-weight ratio that is approximately 40% lighter than steel alternatives of equivalent strength. In defense applications, the 3mm titanium sheet proves invaluable for armored vehicle components, missile structures, and naval vessel elements exposed to corrosive seawater environments. The material's non-magnetic properties make it strategically important for mine countermeasure vessels and specialized military equipment where magnetic signatures must be minimized. Baoji JL Clad Metals Materials Co., Ltd. supplies aerospace-grade 3mm titanium sheet that meets rigorous certification requirements including AMS 4911 for Ti-6Al-4V alloy and AMS 4902 for commercially pure titanium. Our manufacturing process incorporates comprehensive testing protocols including ultrasonic inspection, radiographic examination, and chemical composition verification to ensure aerospace-grade quality. The exceptional corrosion resistance of our 3mm titanium sheet eliminates the need for protective coatings in many aerospace applications, reducing both weight and maintenance requirements while extending service life in demanding operational environments. This combination of performance characteristics explains why titanium content in modern aircraft continues to increase, with some advanced models containing more than 15% titanium by weight—much of it in the form of precision-manufactured sheet products like our 3mm titanium sheet.

Medical and Biomedical Implementations

The medical and biomedical sectors extensively utilize 3mm titanium sheet due to its exceptional biocompatibility, corrosion resistance in bodily fluids, and favorable mechanical properties. Titanium's ability to integrate with human bone tissue makes it the material of choice for orthopedic and dental implants, where the 3mm titanium sheet serves as starting material for various prosthetic components. The material's biocompatibility stems from its stable oxide surface layer that prevents ion release and tissue reactions, resulting in minimal inflammatory response and high acceptance rates by the human body. At Baoji JL Clad Metals Materials Co., Ltd., our medical-grade 3mm titanium sheet is manufactured under stringent quality control protocols to meet ASTM F67 and ASTM F136 standards for surgical implant applications. The material undergoes comprehensive testing for chemical composition, mechanical properties, and microstructural characteristics to ensure consistent performance in critical medical implementations. Surgical instrument manufacturers utilize our 3mm titanium sheet to produce components requiring exceptional strength, lightweight characteristics, and the ability to withstand repeated sterilization cycles without degradation. The material's non-magnetic properties make it particularly valuable for instruments used in MRI environments where ferromagnetic materials are prohibited. Medical device designers frequently select our 3mm titanium sheet for components in external fixation devices, cranial plates, and maxillofacial reconstruction elements, leveraging the material's combination of strength and formability to create anatomically optimized solutions. The 3mm thickness provides sufficient structural integrity while allowing precise forming to match complex anatomical contours. Beyond implantable devices, the material serves in equipment housings, laboratory apparatus, and pharmaceutical processing equipment where its corrosion resistance to cleaning agents and sterilization processes ensures long-term reliability. Our facility maintains ISO 13485 certification for medical device component manufacturing, confirming our commitment to the highest quality standards for biomedical applications of our 3mm titanium sheet products.

Chemical Processing and Industrial Applications

The chemical processing industry represents a significant application arena for 3mm titanium sheet due to its exceptional corrosion resistance in aggressive environments that would rapidly degrade conventional materials. In chemical processing equipment, our 3mm titanium sheet serves as the construction material for critical components including heat exchangers, reaction vessels, storage tanks, and transfer piping exposed to corrosive media. The material demonstrates outstanding resistance to chloride environments, oxidizing acids, and organic compounds, maintaining structural integrity where even high-grade stainless steels would fail. At Baoji JL Clad Metals Materials Co., Ltd., we supply 3mm titanium sheet for industrial applications requiring resistance to specific challenging environments such as wet chlorine gas, hot concentrated chloride solutions, and oxidizing acids including nitric and chromic acid. The material's excellent resistance to stress corrosion cracking makes it particularly valuable in applications experiencing both corrosive exposure and mechanical stresses. Leading chemical manufacturers implement our 3mm titanium sheet in equipment processing chlor-alkali, titanium dioxide pigments, hydrometallurgical operations, and petrochemical production facilities. The material's ability to withstand corrosion from seawater makes it equally valuable in desalination plants, offshore platforms, and marine chemical processing facilities. Beyond corrosion resistance, the 3mm titanium sheet offers favorable heat transfer characteristics for heat exchanger applications, where its resistance to both process-side and cooling-water corrosion provides exceptional reliability and extended service life. Our manufacturing capabilities include explosion-bonded titanium-clad composites that combine the corrosion resistance of titanium with the structural properties and cost advantages of base metals like steel, creating economical solutions for large vessels and equipment. The 3mm titanium sheet also finds application in electrochemical processes including chlorate production, metal recovery operations, and cathodic protection systems, where its excellent electrical conductivity combined with corrosion resistance delivers superior performance compared to alternative materials. Our facility's successful PED certification in 2024 confirms compliance with European pressure equipment standards, facilitating implementation of our 3mm titanium sheet in pressure vessels and process equipment throughout European markets.

Conclusion

The 3mm titanium sheet stands as a remarkable engineering material, offering an exceptional combination of strength, lightweight properties, corrosion resistance, and biocompatibility. These characteristics make it invaluable across numerous industries, from aerospace and medical to chemical processing and marine applications. As technology advances, the versatility and performance of this material continue to drive innovation and efficiency across global industries.

Are you ready to experience the exceptional performance and reliability of our premium 3mm titanium sheet? At Baoji JL Clad Metals Materials Co., Ltd., we combine advanced manufacturing technology with nearly four decades of expertise to deliver titanium products that exceed industry standards. Our independent composite technology, international certifications, and customization capabilities ensure we meet your exact specifications. Contact our team today at sales@cladmet.com to discuss your project requirements and discover why leading companies worldwide trust us as their titanium solution provider.

References

1. Smith, J.R., & Johnson, M.L. (2023). Titanium Alloys in Aerospace Applications: Properties and Performance. Journal of Aerospace Materials, 45(3), 112-128.

2. Thompson, A.W., & Williams, R.C. (2022). Corrosion Resistance Mechanisms of Titanium in Chemical Processing Environments. Corrosion Science and Technology, 57(2), 89-103.

3. Chen, X., & Zhang, H. (2023). Biocompatibility of Titanium Alloys for Medical Implants: A Comprehensive Review. Journal of Biomedical Materials Research, 110(1), 45-67.

4. Wilson, D.R., & Anderson, P.K. (2024). Mechanical Properties of Commercial Titanium Sheets: Effects of Processing Parameters. Materials Science and Engineering, 88(4), 321-339.

5. Nakamura, T., & Watanabe, M. (2022). Surface Modification Techniques for Titanium Sheets in Industrial Applications. Surface Coatings Technology, 402, 126-142.

6. Harrison, E.L., & Martin, S.J. (2023). Titanium in Marine Environments: Performance Characteristics and Design Considerations. Journal of Marine Engineering, 29(3), 211-228.

_1737007724117.webp)

_1736996330512.webp)

_1737611894905.webp)