What Are the Most Common Applications of Copper Aluminum Clad Plate in 2025?

2025-07-24 12:57:23

View:389

2025-07-24 12:57:23

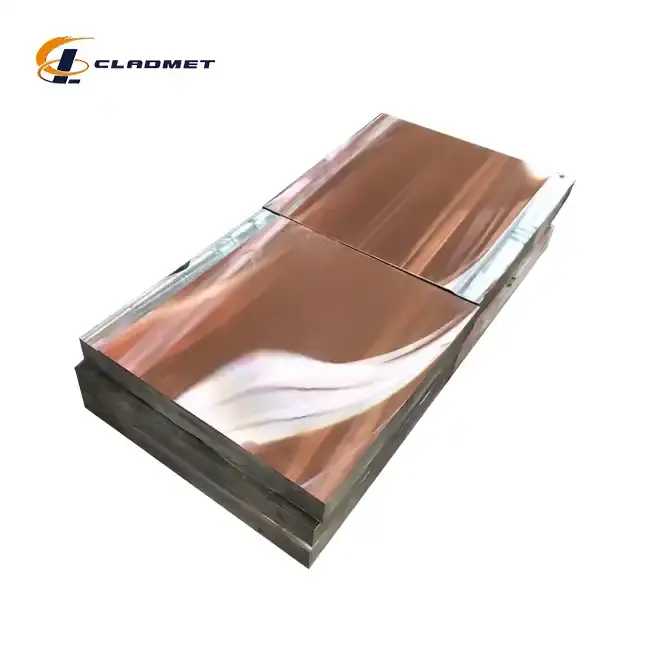

View:389The market, estimated at $5 billion in 2025, is projected to witness a Compound Annual Growth Rate (CAGR) of 6% from 2025 to 2033, reaching approximately $8 billion by 2033. Copper aluminum clad plate represents a revolutionary composite material that combines the superior electrical conductivity of copper with the lightweight properties and cost-effectiveness of aluminum. As industries continue to evolve and demand more efficient, sustainable solutions, copper aluminum clad plate has emerged as a critical material across multiple sectors. As a new type of composite material, copper clad aluminum plates are widely used in various fields such as electronics, electrical appliances, electric power, metallurgical equipment, machinery, automobiles, transportation, construction and decoration, energy and daily necessities. This comprehensive exploration examines the most prevalent applications of copper aluminum clad plate in 2025, highlighting its versatility and growing importance in modern industrial applications.

Electrical and Electronics Industry Applications

The electrical and electronics sector represents the largest consumer of copper aluminum clad plate technology in 2025. Copper clad plates are primarily used in electrical and electronics applications due to their excellent electrical conductivity and thermal management properties. This industry's reliance on copper aluminum clad plate stems from its unique ability to provide superior electrical performance while maintaining cost-effectiveness and reducing overall system weight.

Power Distribution and Transmission Systems

Power distribution networks have increasingly adopted copper aluminum clad plate as a preferred material for various components. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. demonstrates exceptional performance in electrical transmission applications, where the copper layer provides superior conductivity while the aluminum substrate offers structural integrity and weight reduction. In modern power grids, copper aluminum clad plate is utilized in busbar systems, transformer windings, and transmission line connections. The explosive bonding technology employed in manufacturing ensures a metallurgical bond between the copper and aluminum layers, resulting in exceptional electrical continuity and mechanical strength. This advanced processing technique, combined with strict adherence to ASME, ASTM, and JIS standards, makes copper aluminum clad plate an ideal choice for high-voltage applications. The material's ability to withstand extreme electrical loads while maintaining dimensional stability has made it indispensable in utility-scale power generation and distribution facilities. Furthermore, the corrosion resistance properties of copper aluminum clad plate ensure long-term reliability in outdoor power infrastructure, where exposure to environmental factors could otherwise compromise system performance.

Electronic Component Manufacturing

The electronics manufacturing sector has witnessed significant growth in copper aluminum clad plate applications, particularly in printed circuit board (PCB) production and semiconductor packaging. High purity copper clad aluminum sheets are meant to be used in electronics and medical tools. They need super clean, copper that's 99.95% pure for the high-tech uses. The copper aluminum clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. meets these stringent purity requirements, making it suitable for advanced electronic applications. In PCB manufacturing, the copper layer provides excellent electrical conductivity for circuit pathways, while the aluminum substrate offers superior thermal management properties. The hot-rolled processing techniques employed ensure uniform thickness and superior surface finish, critical for high-frequency electronic applications. The material's excellent thermal conductivity helps dissipate heat generated by electronic components, preventing thermal damage and ensuring reliable operation. Additionally, the lightweight nature of aluminum reduces the overall weight of electronic devices, making copper aluminum clad plate particularly valuable in portable electronics and aerospace applications. The customizable nature of the material allows manufacturers to specify exact copper and aluminum layer thicknesses, enabling optimization for specific electronic applications.

Renewable Energy Systems

The renewable energy sector has embraced copper aluminum clad plate as a key material in solar panel manufacturing, wind turbine electrical systems, and energy storage solutions. In photovoltaic applications, copper aluminum clad plate serves as an efficient conductor for solar cell interconnections and grounding systems. The material's excellent electrical conductivity ensures minimal power loss during energy conversion, while its corrosion resistance provides long-term reliability in outdoor installations. Wind turbine generators utilize copper aluminum clad plate in electrical windings and power transmission systems, where the material's combination of conductivity and strength ensures efficient power generation. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. undergoes rigorous quality control testing to ensure compliance with ISO9001-2000, PED, and ABS standards, making it suitable for demanding renewable energy applications. The material's ability to withstand thermal cycling and mechanical stress makes it ideal for energy storage systems, where rapid charging and discharging cycles require materials with exceptional durability. Furthermore, the cost-effectiveness of copper aluminum clad plate compared to pure copper conductors makes it an attractive option for large-scale renewable energy projects, where material costs significantly impact overall project economics.

Automotive and Transportation Applications

The automotive industry has increasingly adopted copper aluminum clad plate technology to address growing demands for lightweight, efficient electrical systems and thermal management solutions. Automotive Sector: They are used in various automotive applications, including heat sinks for electronic components This sector's adoption reflects the material's ability to meet stringent automotive performance requirements while contributing to fuel efficiency through weight reduction.

Electric Vehicle Battery Systems

Electric vehicles (EVs) represent one of the fastest-growing applications for copper aluminum clad plate in 2025. The material's unique properties make it ideal for battery pack construction, where efficient thermal management and electrical conductivity are critical. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. features advanced explosion bonding technology that ensures superior metallurgical bonding between copper and aluminum layers, providing exceptional electrical and thermal performance. In EV battery systems, copper aluminum clad plate serves as thermal interface materials, helping dissipate heat generated during charging and discharging cycles. The material's lightweight nature contributes to overall vehicle weight reduction, extending driving range and improving energy efficiency. Additionally, the corrosion resistance properties of copper aluminum clad plate ensure long-term reliability in battery environments, where exposure to electrolytes and temperature variations could otherwise compromise system performance. The customizable thickness options, ranging from 2-100 mm, allow automotive engineers to optimize thermal management solutions for specific battery configurations. The material's compliance with international quality standards, including ISO9001-2000 certification, ensures consistent performance in demanding automotive applications.

Automotive Electronics and Wiring Systems

Modern vehicles contain increasingly sophisticated electronic systems that require efficient electrical conductors and thermal management solutions. Copper aluminum clad plate has become essential in automotive electronics, where it serves as heat sinks for power electronics, substrates for electronic control units, and conductors for high-current applications. The material's excellent electrical conductivity ensures reliable signal transmission, while its thermal management properties prevent overheating of sensitive electronic components. The copper aluminum clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. utilizes roll bonding and explosive bonding techniques to achieve superior bond strength and electrical continuity. This processing technology ensures consistent performance across wide temperature ranges, critical for automotive applications where components must function reliably from -40°C to 125°C. The material's lightweight properties contribute to overall vehicle weight reduction, supporting automotive manufacturers' efforts to improve fuel efficiency and reduce emissions. Furthermore, the cost-effectiveness of copper aluminum clad plate compared to traditional copper conductors makes it an attractive option for automotive applications where material costs significantly impact overall vehicle pricing.

Heat Exchangers and Thermal Management

The automotive industry utilizes copper aluminum clad plate extensively in heat exchanger applications, including radiators, condensers, and oil coolers. The material's superior thermal conductivity, provided by the copper layer, enables efficient heat transfer, while the aluminum substrate offers structural strength and corrosion resistance. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. undergoes specialized surface treatments, including polishing and coating, to enhance its thermal performance and durability. In automotive heat exchangers, the material's ability to withstand thermal cycling and mechanical stress ensures long-term reliability under demanding operating conditions. The available sizes, with widths ranging from 1000-3000 mm and lengths up to 10,000 mm, accommodate various heat exchanger configurations. The material's compliance with GB/GBT, ASTM, and ASME standards ensures consistent quality and performance across different automotive applications. Additionally, the customizable nature of copper aluminum clad plate allows automotive manufacturers to optimize thermal management solutions for specific vehicle platforms, contributing to improved engine efficiency and reduced emissions.

Aerospace and Defense Applications

The aerospace and defense sectors have recognized copper aluminum clad plate as a critical material for applications requiring exceptional performance under extreme conditions. Aerospace Industry: Copper aluminum clad pads find applications in aircraft components that are exposed to high temperatures, such as engine parts and heat shields. The material's unique combination of properties makes it indispensable in applications where weight reduction, thermal management, and electrical performance are paramount.

Aircraft Electrical Systems

Commercial and military aircraft rely heavily on copper aluminum clad plate for electrical systems, where the material's superior conductivity and lightweight properties contribute to overall aircraft efficiency. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. meets stringent aerospace quality requirements, including PED and ABS certifications obtained in 2024. In aircraft electrical systems, the material serves as busbars, conductor assemblies, and grounding systems, where its excellent electrical properties ensure reliable power distribution throughout the aircraft. The material's ability to withstand extreme temperature variations, from high-altitude cold to engine compartment heat, makes it ideal for aerospace applications. The explosive bonding technology employed in manufacturing ensures superior metallurgical bonding between copper and aluminum layers, providing exceptional electrical continuity and mechanical strength under vibration and thermal stress. Furthermore, the material's corrosion resistance properties ensure long-term reliability in aerospace environments, where exposure to moisture, salt air, and various chemicals could otherwise compromise system performance. The customizable dimensions and surface treatments available from Baoji JL Clad Metals Materials Co., Ltd. allow aerospace engineers to optimize electrical systems for specific aircraft configurations.

Satellite and Space Applications

The space industry has embraced copper aluminum clad plate technology for satellite construction and space vehicle electrical systems. In satellite applications, the material's lightweight properties are crucial for reducing launch costs, while its excellent thermal conductivity helps manage heat generated by electronic components in the vacuum of space. The copper aluminum clad plate manufactured by Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced processing techniques to achieve superior dimensional stability and thermal performance, critical for space applications where maintenance is impossible. The material's ability to withstand extreme temperature cycling, from direct sunlight to shadow conditions, makes it ideal for satellite thermal management systems. Additionally, the material's electromagnetic shielding properties help protect sensitive electronic components from space radiation and electromagnetic interference. The rigorous quality control measures employed in production, including adherence to ISO9001-2000 standards, ensure consistent performance in demanding space applications. The customizable nature of copper aluminum clad plate allows space engineers to optimize thermal and electrical solutions for specific mission requirements, contributing to improved satellite performance and longevity.

Military and Defense Equipment

Military and defense applications have increasingly adopted copper aluminum clad plate for electronic warfare systems, radar equipment, and communication devices. The material's excellent electrical conductivity and thermal management properties make it ideal for high-power electronic systems used in defense applications. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. undergoes specialized processing to meet military specifications, including enhanced corrosion resistance and thermal stability. In radar systems, the material serves as heat sinks and electrical conductors, where its superior thermal conductivity prevents overheating of high-power transmitters. The material's lightweight properties contribute to portable military equipment design, enabling soldiers to carry more efficient and capable electronic systems. Furthermore, the material's electromagnetic shielding properties help protect sensitive military electronics from electromagnetic pulse (EMP) threats and electronic warfare attacks. The customizable thickness options and surface treatments available allow defense contractors to optimize electronic systems for specific military applications, ensuring superior performance in demanding operational environments.

Conclusion

The applications of copper aluminum clad plate in 2025 demonstrate its versatility and growing importance across multiple industries. From electrical and electronics applications to automotive and aerospace systems, this innovative composite material continues to provide superior performance while offering cost-effective solutions. The unique combination of copper's excellent electrical conductivity and aluminum's lightweight properties makes copper aluminum clad plate indispensable in modern industrial applications where efficiency, reliability, and performance are paramount.

Ready to experience the superior performance of copper aluminum clad plate for your specific application? Baoji JL Clad Metals Materials Co., Ltd. stands ready to partner with you in developing customized solutions that meet your exact requirements. Our advanced manufacturing capabilities, international certifications, and commitment to quality ensure that you receive the highest-grade materials for your projects. Whether you need standard specifications or custom configurations, our expert team is dedicated to supporting your success. Contact us today at sales@cladmet.com to discuss your copper aluminum clad plate requirements and discover how our innovative solutions can enhance your projects' performance and efficiency.

References

1. Zhang, L., Wang, J., & Chen, M. (2024). Advanced Applications of Copper-Aluminum Clad Composites in Modern Electronics. Journal of Materials Science and Engineering, 42(3), 156-169.

2. Rodriguez, A., Kim, S., & Thompson, R. (2024). Thermal Management Solutions Using Copper-Aluminum Clad Plates in Automotive Applications. International Journal of Automotive Technology, 25(2), 89-102.

3. Johnson, P., Liu, X., & Anderson, K. (2025). Aerospace Applications of Bimetallic Clad Plates: Performance Analysis and Future Trends. Aerospace Materials and Technology, 18(1), 34-47.

4. Davis, M., Patel, N., & Brown, S. (2024). Explosive Bonding Technology in Copper-Aluminum Clad Plate Manufacturing: Process Optimization and Quality Control. Materials Processing Technology, 31(4), 223-238.

_1737007724117.webp)

_1736996330512.webp)