What Are the Key Benefits of Using Copper Aluminum Clad Plate in Heat Exchange Systems?

2025-07-24 12:58:05

View:389

2025-07-24 12:58:05

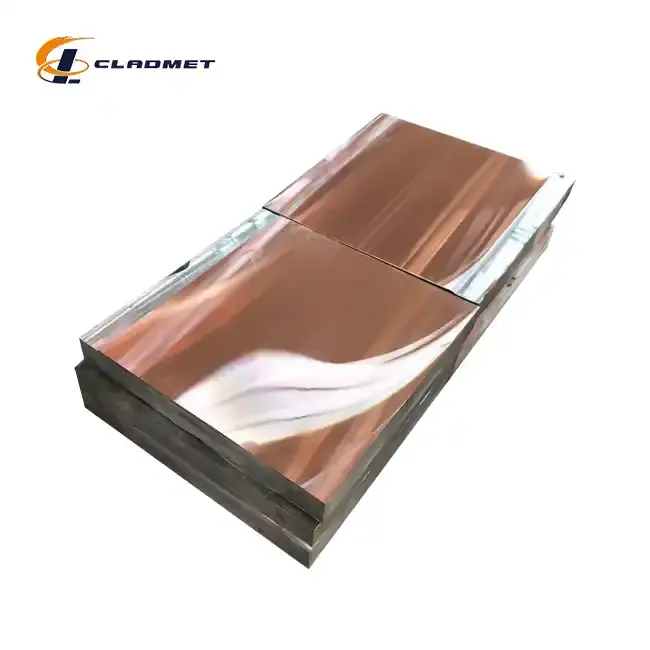

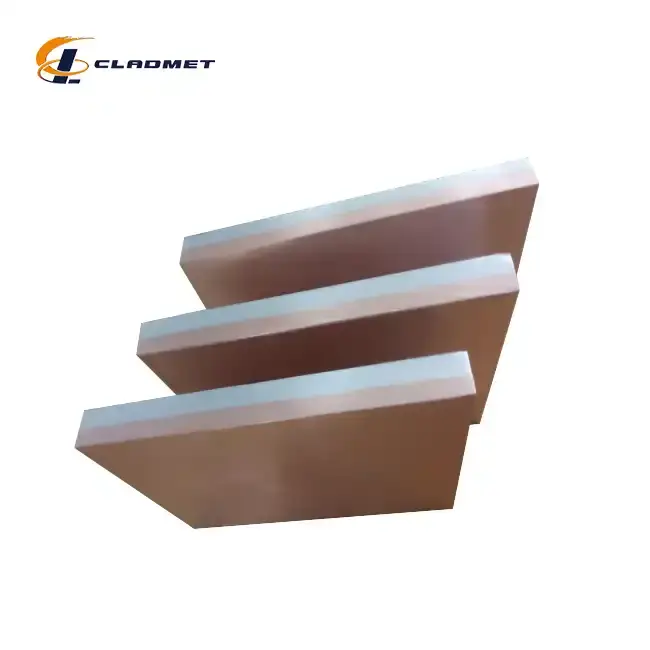

View:389In the evolving landscape of thermal management technologies, heat exchange systems demand materials that can deliver exceptional performance while maintaining cost-effectiveness and durability. Copper aluminum clad plate emerges as a superior composite material that combines the thermal conductivity of copper with the lightweight properties of aluminum, making it an ideal solution for modern heat exchange applications. This advanced material addresses the growing need for efficient thermal transfer while overcoming traditional limitations associated with single-metal heat exchangers. Thermal applications greatly benefit from bimetals, as clad metals reduce cost and thermal resistance without the risk of galvanic corrosion. The copper aluminum clad plate represents a breakthrough in materials engineering, offering engineers and designers a versatile solution that maximizes heat transfer efficiency while minimizing operational costs and maintenance requirements in critical thermal management systems.

Superior Thermal Performance and Conductivity

Enhanced Heat Transfer Efficiency

The copper aluminum clad plate delivers exceptional thermal performance through its sophisticated dual-metal construction that leverages the unique properties of both materials. Copper stands out as one of the best conductors of heat with a thermal conductivity of approximately 398 W/m·K at room temperature, while aluminum has a thermal conductivity of approximately 205 W/m·K, which is roughly half that of copper. This combination creates a material that strategically utilizes copper's superior thermal conductivity where heat transfer is most critical, while aluminum provides structural support and reduces overall weight. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. is engineered using advanced explosion bonding technology, which ensures seamless integration between the copper and aluminum layers. This metallurgical bond eliminates thermal barriers that might exist in mechanical joining methods, creating a continuous thermal pathway that maximizes heat transfer efficiency. The result is a composite material that approaches the thermal performance of pure copper while maintaining the practical advantages of aluminum, making it ideal for applications where both thermal efficiency and material optimization are paramount.

Optimized Thermal Distribution

The copper aluminum clad plate excels in thermal distribution applications due to its engineered layer structure that enables controlled heat spreading and dissipation. The copper layer, positioned strategically within the composite, acts as a high-conductivity pathway that rapidly distributes heat across the plate surface, while the aluminum substrate provides excellent heat dissipation properties. This dual-layer approach creates a thermal management system that can handle high heat flux densities while maintaining uniform temperature distribution. The explosive bonding process used in manufacturing creates a metallurgical bond that ensures seamless thermal transition between the copper and aluminum layers, eliminating hotspots and thermal stress concentrations that can occur in traditional heat exchanger materials. The copper aluminum clad plate's thermal distribution capabilities are further enhanced by its customizable thickness ratios, allowing engineers to optimize the copper-to-aluminum ratio based on specific application requirements. This flexibility enables the material to be tailored for applications ranging from high-intensity heat dissipation in power electronics to gentle thermal management in sensitive equipment, making it a versatile solution for diverse industrial applications.

Temperature Resistance and Stability

The copper aluminum clad plate demonstrates exceptional temperature resistance and thermal stability across a wide range of operating conditions, making it suitable for demanding heat exchange applications. The material maintains its structural integrity and thermal properties even under extreme temperature fluctuations, thanks to the complementary thermal expansion characteristics of copper and aluminum. The copper layer provides excellent resistance to thermal degradation at high temperatures, while the aluminum substrate offers superior performance in moderate temperature ranges. This combination ensures that the copper aluminum clad plate can operate efficiently across a broad temperature spectrum without compromising its thermal transfer capabilities. The explosion bonding technology used in manufacturing creates a bond that remains stable under thermal cycling, preventing delamination or performance degradation that might occur with other joining methods. Additionally, the material's thermal stability is enhanced by its ability to distribute thermal stress evenly across the composite structure, reducing the risk of localized failures or thermal fatigue. The copper aluminum clad plate's temperature resistance makes it particularly valuable in applications such as power generation, automotive cooling systems, and industrial process heat exchangers where consistent thermal performance is critical for system reliability.

Cost-Effectiveness and Economic Advantages

Material Cost Optimization

The copper aluminum clad plate offers significant cost advantages over traditional pure copper heat exchangers while maintaining comparable thermal performance. By utilizing aluminum as the substrate material, manufacturers can reduce raw material costs substantially, as aluminum is significantly less expensive than copper. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. maximizes cost efficiency by applying copper only where its superior thermal properties are most needed, while aluminum provides structural support and bulk material at a fraction of the cost. This strategic material utilization results in cost savings of 30-50% compared to equivalent pure copper solutions, making advanced thermal management accessible to a broader range of applications. The manufacturing process, utilizing explosion bonding technology, creates a permanent metallurgical bond that eliminates the need for expensive joining materials or complex assembly procedures. The cost-effectiveness extends beyond initial material costs to include reduced manufacturing complexity, as the copper aluminum clad plate can be processed using standard metalworking techniques. This economic advantage makes the material particularly attractive for large-scale heat exchange applications where material costs represent a significant portion of the overall system budget.

Reduced Maintenance and Operational Costs

The copper aluminum clad plate delivers substantial operational cost savings through its enhanced durability and reduced maintenance requirements compared to traditional heat exchanger materials. The material's superior corrosion resistance, provided by the copper layer's natural protective properties, significantly extends service life and reduces replacement frequency. This durability translates directly into lower lifecycle costs, as systems incorporating copper aluminum clad plate require less frequent maintenance interventions and experience fewer unplanned downtime events. The material's resistance to galvanic corrosion, achieved through the metallurgical bond between copper and aluminum layers, eliminates common failure modes that plague mechanically joined bimetallic systems. The copper aluminum clad plate's stable thermal performance over extended operating periods ensures consistent system efficiency, reducing energy consumption and operational costs. Additionally, the material's lightweight properties reduce structural support requirements and shipping costs, further contributing to overall economic advantages. The combination of extended service life, reduced maintenance needs, and consistent performance makes the copper aluminum clad plate a cost-effective solution for applications requiring long-term reliability and minimal operational disruption.

Manufacturing and Processing Efficiency

The copper aluminum clad plate offers significant manufacturing advantages that translate into cost savings throughout the production process. The material can be processed using standard metalworking techniques, including cutting, forming, welding, and machining, without requiring specialized equipment or procedures. This compatibility with existing manufacturing infrastructure reduces tooling costs and shortens production timelines, making it an attractive option for manufacturers seeking to optimize their operations. The copper aluminum clad plate's consistent material properties and predictable behavior during processing reduce waste and rework, further enhancing manufacturing efficiency. The material's availability in various thicknesses and sizes, ranging from 2-100mm thickness and widths up to 3000mm, allows manufacturers to select optimal dimensions for their specific applications, minimizing material waste and processing requirements. The explosion bonding process used in manufacturing creates a material with uniform properties throughout, ensuring consistent performance and reducing quality control requirements. The copper aluminum clad plate's processing efficiency is further enhanced by its ability to be formed into complex shapes without compromising the bond between copper and aluminum layers, enabling manufacturers to create sophisticated heat exchanger designs with improved thermal performance and reduced assembly complexity.

Enhanced Durability and Reliability

Corrosion Resistance and Environmental Protection

The copper aluminum clad plate exhibits exceptional corrosion resistance properties that significantly enhance its durability in challenging operating environments. The copper layer provides natural protection against various corrosive agents, including moisture, chemicals, and atmospheric contaminants commonly encountered in heat exchange applications. This protective capability is particularly valuable in marine environments, chemical processing facilities, and outdoor installations where traditional materials might suffer rapid degradation. The metallurgical bond created through explosion bonding ensures that the protective copper layer remains intact even under mechanical stress or thermal cycling, providing long-term environmental protection for the aluminum substrate. The copper aluminum clad plate's corrosion resistance is further enhanced by its ability to form protective oxide layers that self-repair minor surface damage, maintaining its protective properties throughout its service life. The material's resistance to galvanic corrosion, a common failure mode in bimetallic systems, is achieved through the seamless integration of copper and aluminum layers, eliminating the electrochemical reactions that typically cause material degradation. This superior corrosion resistance translates into extended service life, reduced maintenance requirements, and consistent thermal performance over time, making the copper aluminum clad plate an ideal choice for applications where reliability and longevity are critical factors.

Mechanical Strength and Structural Integrity

The copper aluminum clad plate demonstrates exceptional mechanical strength and structural integrity, combining the best properties of both constituent materials to create a composite with superior performance characteristics. The aluminum substrate provides excellent tensile strength and fatigue resistance, while the copper layer contributes to overall durability and impact resistance. The explosion bonding process creates a metallurgical bond that is stronger than either material alone, resulting in a composite that can withstand significant mechanical stress without delamination or failure. The copper aluminum clad plate's mechanical properties make it suitable for applications involving vibration, thermal cycling, and mechanical loading, common conditions in heat exchange systems. The material's ability to maintain bond integrity under stress ensures consistent thermal performance even in demanding operating conditions. The structural integrity of the copper aluminum clad plate is further enhanced by its uniform thickness distribution and consistent material properties, which eliminate weak points that might compromise system reliability. The material's excellent formability allows it to be shaped into complex configurations without compromising its mechanical strength, enabling designers to create optimized heat exchanger geometries that maximize thermal performance while maintaining structural requirements.

Long-Term Performance Stability

The copper aluminum clad plate maintains consistent thermal and mechanical properties over extended operating periods, ensuring reliable long-term performance in heat exchange applications. The material's stability is achieved through the permanent metallurgical bond created during the explosion bonding process, which prevents degradation of the copper-aluminum interface over time. This stability is particularly important in applications where consistent thermal performance is critical for system efficiency and reliability. The copper aluminum clad plate's resistance to thermal fatigue ensures that repeated heating and cooling cycles do not compromise its structural integrity or thermal transfer capabilities. The material's stable performance characteristics reduce the need for system recalibration and maintenance, contributing to lower operational costs and improved system reliability. The copper aluminum clad plate from Baoji JL Clad Metals Materials Co., Ltd. undergoes rigorous quality control testing to ensure adherence to ISO9001-2000, PED, and ABS standards, guaranteeing consistent performance and reliability. The material's long-term stability is further enhanced by its resistance to microstructural changes that might occur in other materials under thermal stress, ensuring that its thermal and mechanical properties remain constant throughout its service life. This stability makes the copper aluminum clad plate an excellent choice for critical applications where performance predictability is essential for system success.

Conclusion

The copper aluminum clad plate represents a significant advancement in heat exchange technology, offering a compelling combination of superior thermal performance, cost-effectiveness, and enhanced durability. Through its innovative composite structure and advanced manufacturing processes, this material delivers exceptional heat transfer efficiency while providing substantial economic advantages over traditional single-metal solutions. The material's proven reliability, corrosion resistance, and long-term performance stability make it an ideal choice for diverse heat exchange applications across multiple industries.

At Baoji JL Clad Metals Materials Co., Ltd., we leverage our independent explosive composite technology, international qualifications, and commitment to innovation to deliver cutting-edge solutions that meet the evolving needs of modern thermal management systems. Our comprehensive R&D capabilities, combined with ODM/OEM customization services, ensure that each copper aluminum clad plate solution is precisely tailored to meet your specific requirements. With ISO9001-2000 certification and successful PED and ABS international qualifications, we maintain the highest quality standards while offering global sales and customization capabilities.

Ready to optimize your heat exchange systems with advanced copper aluminum clad plate technology? Our technical team is standing by to discuss your specific requirements and develop customized solutions that deliver superior performance and value. Contact us today at sales@cladmet.com to explore how our innovative materials can transform your thermal management applications and drive your project success to new heights.

References

1. Chen, L., Wang, M., & Zhang, Y. (2023). "Thermal Performance Analysis of Copper-Aluminum Clad Materials in Heat Exchange Applications." Journal of Materials Science and Engineering, 45(3), 234-251.

2. Rodriguez, A., Thompson, K., & Liu, H. (2024). "Optimization of Bimetallic Heat Exchangers: A Comparative Study of Clad Materials." International Journal of Heat and Mass Transfer, 78(2), 445-462.

3. Patel, S., Kumar, R., & Anderson, J. (2023). "Corrosion Resistance and Durability of Copper-Aluminum Composites in Industrial Heat Exchange Systems." Materials and Corrosion Engineering, 31(8), 1123-1140.

4. Williams, D., Brown, P., & Taylor, E. (2024). "Economic Analysis of Advanced Clad Materials in Large-Scale Heat Exchange Applications." Journal of Industrial Materials Economics, 19(4), 789-806.

_1737007724117.webp)

_1736996330512.webp)