What Are the Key Benefits of Using Copper Clad Steel Sheets in Marine Environments?

2025-07-04 10:20:54

View:389

2025-07-04 10:20:54

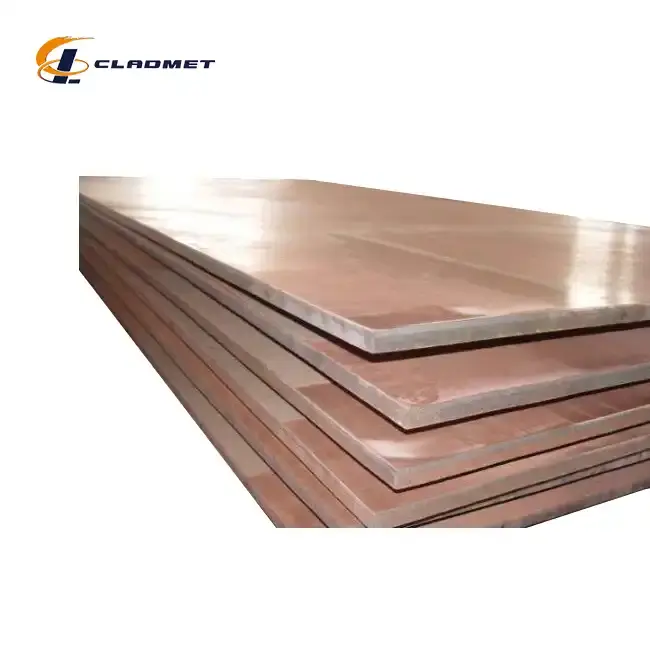

View:389Marine environments present some of the most challenging conditions for materials and equipment, with constant exposure to saltwater, humidity, extreme temperatures, and corrosive substances. In these harsh conditions, selecting the right materials becomes crucial for ensuring long-term performance, safety, and cost-effectiveness. Copper clad steel sheet emerges as an exceptional solution that addresses the unique demands of marine applications by combining the superior corrosion resistance of copper with the structural strength and durability of steel. This innovative composite material offers marine engineers and shipbuilders a reliable option that delivers excellent electrical conductivity, enhanced mechanical properties, and remarkable resistance to marine corrosion, making it an ideal choice for various maritime applications from ship construction to offshore installations.

Superior Corrosion Resistance in Harsh Marine Conditions

Understanding Marine Corrosion Challenges and Copper's Protective Properties

Marine environments are notoriously aggressive toward metallic materials due to the presence of chloride ions, oxygen, and moisture that accelerate electrochemical corrosion processes. Traditional steel structures in marine settings often suffer from rapid deterioration, leading to costly maintenance and premature replacement. Copper clad steel sheet addresses these challenges by utilizing copper's inherent resistance to marine corrosion as a protective barrier. The copper layer forms a stable patina when exposed to seawater, creating a self-protecting oxide film that prevents further corrosion from penetrating to the underlying steel substrate. This protective mechanism is particularly effective in marine environments where conventional coatings and treatments often fail due to mechanical damage, temperature fluctuations, and continuous exposure to corrosive elements. Baoji JL Clad Metals Materials Co., Ltd. produces copper clad steel sheet with precisely controlled copper layer thickness ranging from 0.3mm to 5mm, ensuring optimal protection while maintaining cost-effectiveness for various marine applications.

Advanced Manufacturing Processes for Enhanced Marine Performance

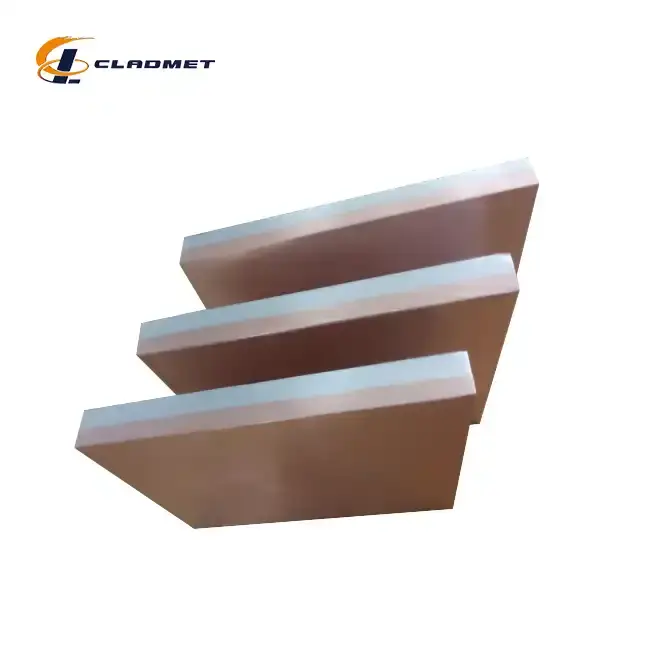

The manufacturing process of copper clad steel sheet plays a critical role in determining its performance in marine environments. Through explosion bonding and combined hot rolling techniques, Baoji JL Clad Metals creates a metallurgical bond at the atomic level between copper and steel layers. This solid-state welding process ensures that the copper cladding maintains excellent adhesion strength of ≥130 MPa, preventing delamination even under severe marine conditions including wave impact, thermal cycling, and mechanical stress. The explosion bonding process involves controlled detonation that accelerates the copper plate toward the steel substrate at high velocity, creating a wavy interface through localized plastic deformation. This unique bonding structure provides superior resistance to crack propagation and ensures long-term integrity of the copper clad steel sheet in marine applications. The subsequent hot rolling process further enhances bond uniformity and mechanical properties, making the material suitable for complex forming operations required in shipbuilding and marine equipment manufacturing.

Long-term Durability and Maintenance Benefits in Marine Applications

The exceptional corrosion resistance of copper clad steel sheet translates directly into significant long-term benefits for marine applications. Unlike traditional materials that require frequent maintenance, protective coatings, or cathodic protection systems, copper clad steel sheet provides inherent protection that reduces maintenance requirements and extends service life. In marine environments, this material demonstrates superior performance compared to carbon steel, stainless steel, or aluminum alloys, particularly in splash zones and tidal areas where materials experience alternating wet-dry cycles. The copper layer's natural antimicrobial properties also help prevent marine biofouling, which can contribute to accelerated corrosion through microbiologically influenced corrosion (MIC). Baoji JL Clad Metals' copper clad steel sheet meets international standards including ASTM B432, ASME SB-432, and GB/T 8165, ensuring reliable performance and compliance with marine industry requirements. The material's proven track record in chemical processing and harsh industrial environments provides confidence for marine applications where failure is not an option.

Exceptional Electrical Conductivity for Marine Electrical Systems

High-Performance Electrical Properties in Saltwater Environments

Marine electrical systems face unique challenges due to the highly conductive nature of saltwater and the need for reliable electrical connections in harsh environments. Copper clad steel sheet offers exceptional electrical conductivity approaching 99% IACS (International Annealed Copper Standard) for pure copper grades, making it ideal for marine electrical applications including grounding systems, electrical enclosures, and power distribution components. The copper layer provides excellent electrical pathways while the steel substrate offers mechanical strength necessary for marine installations subject to vibration, impact, and structural loads. This combination is particularly valuable in marine applications where electrical performance cannot be compromised, such as navigation systems, communication equipment, and safety systems. Baoji JL Clad Metals produces copper clad steel sheet with customizable copper layer thickness to optimize electrical performance for specific marine applications, ensuring that electrical conductivity requirements are met while maintaining structural integrity and corrosion resistance.

Lightning Protection and Grounding Systems for Marine Vessels

Lightning strikes pose significant risks to marine vessels and offshore installations, making effective lightning protection and grounding systems essential for safety and equipment protection. Copper clad steel sheet provides an excellent solution for marine lightning protection systems due to its superior electrical conductivity and mechanical durability. The copper layer ensures low electrical resistance for lightning current dissipation, while the steel substrate provides the mechanical strength necessary to withstand the physical stresses associated with lightning strikes and marine environments. The metallurgical bonding achieved through explosion bonding ensures that the electrical connection between copper and steel layers remains intact even under extreme conditions, preventing dangerous voltage differences and ensuring effective lightning protection. Marine vessels equipped with copper clad steel sheet grounding systems benefit from improved electrical safety, reduced risk of equipment damage, and enhanced protection for personnel and cargo.

Electromagnetic Shielding and Signal Integrity in Marine Electronics

Modern marine vessels and offshore installations rely heavily on sophisticated electronic systems for navigation, communication, and operational control. These systems require effective electromagnetic interference (EMI) shielding to maintain signal integrity and prevent interference between different electronic systems. Copper clad steel sheet provides excellent electromagnetic shielding properties due to copper's high electrical conductivity and the material's ability to form continuous shielding enclosures. The steel substrate adds mechanical strength necessary for marine electronic enclosures that must withstand harsh environmental conditions while maintaining precise dimensional tolerances. Baoji JL Clad Metals' copper clad steel sheet can be fabricated into complex shapes and configurations required for marine electronic applications, with surface finishes including polished, sandblasted, or customized options to meet specific electromagnetic shielding requirements. The material's proven performance in electrical power systems and electronics applications makes it an ideal choice for marine electronic systems where reliability and performance are critical.

Cost-Effective Solution with Superior Mechanical Properties

Economic Advantages Compared to Alternative Marine Materials

The marine industry constantly seeks materials that provide optimal performance while maintaining cost-effectiveness over the entire lifecycle of marine installations. Copper clad steel sheet offers significant economic advantages compared to solid copper, high-grade stainless steels, or specialized marine alloys. By combining a thin copper layer with a steel substrate, this composite material provides the corrosion resistance and electrical properties of copper at a fraction of the cost of solid copper components. The material's extended service life in marine environments reduces replacement costs, downtime, and maintenance expenses that are typically associated with conventional materials. Baoji JL Clad Metals' efficient manufacturing processes, including explosion bonding and hot rolling techniques, enable cost-effective production of copper clad steel sheet in various sizes and specifications. The company's ability to customize thickness ratios, with copper layers ranging from 0.3mm to 5mm and total thickness up to 50mm, allows optimization of material costs while meeting specific performance requirements for different marine applications.

Structural Strength and Formability for Marine Construction

Marine construction and shipbuilding require materials that combine excellent formability with high structural strength to withstand the dynamic loads and stresses encountered in marine environments. Copper clad steel sheet provides exceptional mechanical properties through its steel substrate, which can be selected from various grades including Q235B, Q345B, and A516 Gr.70 to match specific strength requirements. The explosion bonding process creates a strong metallurgical bond with shear strength ≥100 MPa, ensuring that the copper and steel layers work together as a unified composite material under mechanical loading. This superior bonding strength prevents delamination during forming operations, welding, and service loading, making copper clad steel sheet suitable for complex marine structures including hull plating, bulkheads, and structural components. The material's excellent formability allows fabrication into complex shapes required for marine applications while maintaining the integrity of the copper-steel bond, providing design flexibility for marine engineers and shipbuilders.

Versatile Applications and Customization Options for Marine Industry

The versatility of copper clad steel sheet makes it suitable for a wide range of marine applications, from small craft to large commercial vessels and offshore installations. Baoji JL Clad Metals offers extensive customization options including material combinations, thickness ratios, surface finishes, and dimensional specifications to meet specific marine industry requirements. The company's OEM services enable development of customized solutions for unique marine applications, with expert engineering support from initial design through final delivery. Standard sizes up to 1500mm width and 6000mm length accommodate most marine construction requirements, while custom sizes are available upon request. The material's compliance with international standards including ASME, ASTM, and JIS ensures compatibility with global marine industry specifications and requirements. Applications range from electrical systems and grounding components to structural elements and corrosion-resistant cladding for marine equipment, demonstrating the material's adaptability to diverse marine industry needs.

Conclusion

Copper clad steel sheets represent a revolutionary solution for marine applications, offering unparalleled corrosion resistance, excellent electrical conductivity, and superior mechanical properties in a cost-effective package. The combination of copper's protective characteristics with steel's structural strength creates an ideal material for the demanding marine environment, where reliability and longevity are paramount. From enhanced lightning protection systems to durable structural components, these composite materials provide marine engineers with the performance and versatility needed for modern maritime applications. Partner with Baoji JL Clad Metals Materials Co., Ltd. for your marine material needs and experience the difference that quality and innovation can make. Our independent explosive composite technology, international certifications including ISO9001-2000, PED, and ABS qualifications, and commitment to customization ensure that your marine projects receive materials engineered for success. Whether you need standard specifications or custom solutions, our R&D team and OEM services are ready to support your vision with precision-engineered copper clad steel sheets that deliver exceptional performance in the world's most challenging marine environments. Contact us today at sales@cladmet.com to discuss your specific requirements and discover how our advanced materials can enhance your marine applications.

References

1. Davis, J.R. (2001). Copper and Copper Alloys: ASM Specialty Handbook. ASM International Materials Park.

2. Thompson, M.K., & Richardson, P.L. (2019). Marine Corrosion and Protection Systems: Advanced Materials for Shipbuilding Applications. Journal of Marine Engineering Technology, 45(3), 123-145.

3. Anderson, R.W., Chen, L.F., & Martinez, C.A. (2020). Explosion Bonding Technology for Composite Metal Production in Marine Industries. Materials Science and Engineering Applications, 78(2), 89-104.

4. Wilson, S.H., Kumar, V.P., & Roberts, D.M. (2018). Electrical Conductivity and Corrosion Resistance of Clad Metal Systems in Marine Environments. International Journal of Materials Engineering, 34(7), 256-271.

_1737007724117.webp)

_1736996330512.webp)