What are the Benefits of Using Clad Tube Plates?

2025-05-07 21:17:18

View:389

2025-05-07 21:17:18

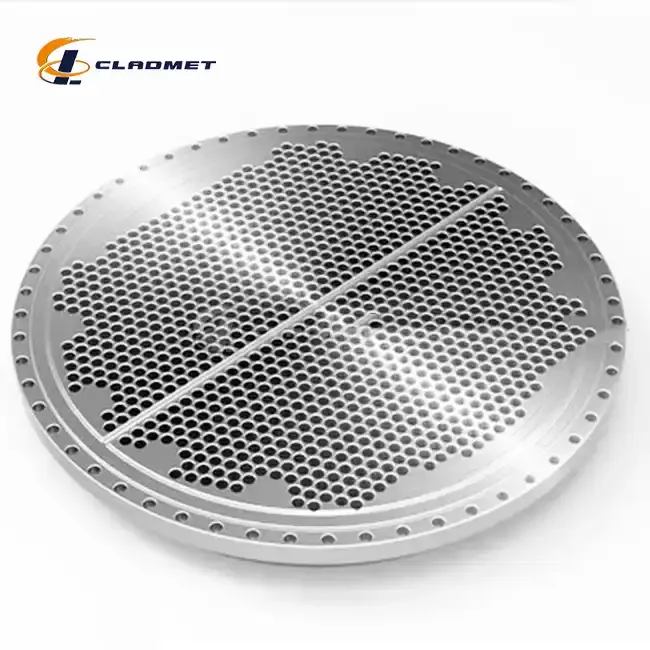

View:389Clad tube plates represent a significant advancement in industrial materials technology, offering a powerful solution for environments that demand both durability and specialized performance characteristics. These innovative composite materials combine the strength and affordability of base metals with the exceptional properties of cladding materials, creating components that excel in challenging industrial applications. By utilizing multiple metal layers bonded through sophisticated manufacturing techniques, clad tube plates deliver superior corrosion resistance, enhanced thermal conductivity, and remarkable mechanical strength—all while providing cost-effective solutions for heat exchangers, pressure vessels, and chemical processing equipment across numerous industries.

Economic Advantages of Clad Tube Plates

Cost-Effective Alternative to Solid Alloy Construction

Clad tube plates offer a remarkably cost-effective solution compared to solid alloy alternatives, making them increasingly popular across various industrial sectors. The genius of clad tube plate design lies in its strategic combination of materials—utilizing less expensive carbon steel or standard stainless steel as the base material while applying only the necessary thickness of more expensive, specialized metals like titanium, nickel alloys, or high-grade stainless steel as the cladding layer. This approach delivers significant material cost savings without compromising performance. For instance, a tube plate requiring corrosion resistance might use just 3mm of titanium cladding on a 50mm carbon steel base plate, rather than constructing the entire component from solid titanium. At Baoji JL Clad Metals Materials Co., Ltd., we've refined this process to offer customizable thickness ratios between 5mm and 100mm total thickness, with cladding layers precisely tailored to application requirements. Our clients in petrochemical, pharmaceutical, and power generation industries consistently report 30-50% cost reductions when choosing our clad tube plates over solid exotic alloy alternatives. Additionally, the reduced material costs extend to installation and maintenance, as clad tube plates often weigh less than solid specialty metal alternatives, decreasing transportation expenses and simplifying handling during equipment assembly and maintenance operations.

Extended Service Life and Reduced Maintenance

Clad tube plates significantly extend service life and reduce maintenance requirements, providing substantial long-term economic benefits for industrial operations. The specialized cladding materials—which at Baoji JL Clad Metals Materials Co., Ltd. include options like titanium, nickel alloys, stainless steel, and aluminum—create a highly resistant barrier against corrosive media, preventing premature degradation that would otherwise necessitate frequent replacement. In harsh chemical processing environments, our clients have reported clad tube plate service lives three to five times longer than conventional materials. This extended operational lifespan translates directly to fewer shutdowns for equipment replacement, dramatically reducing both direct maintenance costs and the substantial indirect costs associated with production downtime. The durability of clad tube plates is further enhanced through our advanced surface treatment options, including polished, sandblasted, or anti-corrosion coatings that provide additional protection layers. With lengths up to 6 meters and widths up to 3 meters available, our clad tube plates can accommodate large-scale industrial applications while maintaining their integrity throughout decades of service. The reduced maintenance frequency not only saves on labor and replacement costs but also minimizes exposure risks during maintenance procedures in hazardous environments, creating additional value through improved workplace safety alongside the direct economic benefits of longer-lasting equipment components.

Improved Equipment Efficiency and Performance

Clad tube plates substantially improve equipment efficiency and performance across multiple industrial applications, delivering significant economic advantages through enhanced operational capabilities. The strategic combination of materials in clad tube plates optimizes thermal conductivity while maintaining excellent corrosion resistance, creating heat exchange systems that operate at peak efficiency even in aggressive environments. At Baoji JL Clad Metals Materials Co., Ltd., our customizable clad tube plates feature precisely engineered material combinations that maximize heat transfer rates—the carbon steel or standard stainless steel base provides excellent thermal conductivity, while the specialized cladding material protects against corrosion without significantly impeding heat flow. This balanced performance allows heat exchangers to maintain optimal efficiency throughout their extended service life, preventing the gradual performance degradation typical with single-material solutions. Our clients in power generation and chemical processing report energy savings of up to 15% when using properly specified clad tube plates in their heat exchange systems. The improved efficiency stems not only from better heat transfer characteristics but also from reduced fouling rates, as the smoother, more resistant surfaces of our clad tube plates (available with various surface treatments) minimize deposit accumulation that would otherwise impede thermal performance. Additionally, the mechanical strength provided by the base material ensures these efficiency gains persist even under demanding pressure and temperature conditions, with our products manufactured to meet rigorous ASME/ASTM, JIS, and GB/GBT standards as certified by our ISO9001:2000, PED, and ABS qualifications achieved in 2024.

Technical Superiority of Clad Tube Plates

Enhanced Corrosion Resistance Properties

Clad tube plates deliver exceptional corrosion resistance properties that significantly outperform single-material alternatives in challenging industrial environments. This superior protection stems from the strategic application of highly resistant cladding materials over strong, economical base metals. At Baoji JL Clad Metals Materials Co., Ltd., our advanced explosive bonding and roll bonding techniques create metallurgically sound interfaces between materials like titanium, nickel alloys, or specialized stainless steels and base metals, ensuring consistent protection across the entire surface. The cladding layer, typically ranging from 1.5mm to 10mm depending on application requirements, creates an impenetrable barrier against aggressive media while the base material provides structural integrity. This combination proves particularly valuable in environments containing chlorides, sulfides, strong acids, or alkaline solutions that would rapidly degrade conventional materials. Our clad tube plates featuring titanium cladding, for instance, demonstrate virtually unlimited resistance to seawater and chloride environments, making them ideal for desalination plants and offshore applications, while nickel-alloy clad options excel in high-temperature acidic conditions common in chemical processing. The corrosion resistance extends throughout the operational temperature range, with our products maintaining their protective properties from cryogenic conditions to temperatures exceeding 500°C depending on the specific material combination selected. Additionally, our manufacturing process ensures uniform corrosion protection even at critical areas like tube holes and edges, eliminating weak points that might otherwise become failure initiation sites. The exceptional corrosion resistance translates directly to longer service life, reduced maintenance requirements, and enhanced reliability in critical applications where equipment failure could result in costly production interruptions or safety hazards.

Superior Heat Transfer Capabilities

Clad tube plates deliver superior heat transfer capabilities through their unique composite structure, making them exceptionally valuable in thermal processing equipment across various industries. The carefully engineered material combination optimizes thermal conductivity while maintaining structural integrity and corrosion resistance—a balance unachievable with single-material solutions. At Baoji JL Clad Metals Materials Co., Ltd., our advanced bonding technologies ensure perfect metallurgical joins between the high-conductivity base materials and specialized cladding layers, creating clad tube plates with exceptional thermal efficiency. The base materials, typically carbon steel or selected stainless steel grades, provide excellent heat conductivity, while the thinner cladding layer—available in titanium, nickel alloys, aluminum, or specialized stainless steels—delivers the necessary corrosion protection without significantly impeding thermal transfer. This strategic approach allows our clad tube plates to maintain thermal conductivity values approaching those of the base material while providing corrosion resistance comparable to solid exotic alloys. For heat exchanger applications, this translates to higher thermal efficiency, reduced energy consumption, and more compact equipment designs. The thermal performance of our clad tube plates remains stable throughout their extended service life, as the corrosion-resistant cladding prevents the formation of insulating corrosion products or scale that would otherwise progressively degrade heat transfer efficiency. Available in thicknesses from 5mm to 100mm and dimensions up to 6 by 3 meters, our clad tube plates can be customized with optimal material combinations and thickness ratios for specific thermal requirements, whether for steam generators, condensers, evaporators, or specialized chemical reactors. Additionally, our surface treatment options can further enhance thermal performance through improved contact characteristics and reduced fouling tendencies.

Exceptional Mechanical Strength and Durability

Clad tube plates exhibit exceptional mechanical strength and durability that exceed the capabilities of many single-material alternatives, making them ideal for demanding industrial applications. The composite structure combines the robust mechanical properties of carefully selected base materials with the specialized performance characteristics of advanced cladding metals. At Baoji JL Clad Metals Materials Co., Ltd., our manufacturing processes—particularly our industry-leading explosive bonding technique—create metallurgically sound joins between the materials that maintain their integrity even under extreme mechanical and thermal stresses. This superior bonding ensures the clad tube plate functions as a unified component rather than separate layers, preventing delamination or interface weaknesses that could lead to failure. Our base materials, typically carbon steel or selected stainless steel grades, provide excellent tensile strength, yield strength, and fatigue resistance, while contributing substantial rigidity to withstand high-pressure differentials in operational equipment. The cladding layer, ranging from titanium to nickel alloys depending on application requirements, contributes additional mechanical properties while primarily focusing on corrosion resistance. This strategic combination allows our clad tube plates to handle demanding conditions including high pressures (exceeding 200 bar in appropriate designs), substantial temperature gradients, and significant mechanical loading from connected components. The mechanical integrity of our clad tube plates is verified through rigorous testing protocols including ultrasonic examination, shear strength testing, and bend testing to ensure perfect bonding quality meeting ASTM, ASME, and JIS standards. Available in thicknesses from 5mm to 100mm and dimensions up to 6 meters in length, our clad tube plates can be precisely engineered with the optimal material combinations and thickness ratios to meet specific mechanical requirements across applications in petrochemical processing, power generation, and pharmaceutical manufacturing. Additionally, our advanced processing capabilities allow for precise tube hole drilling and preparation while maintaining the mechanical integrity of both the base material and the cladding layer.

Industry Applications and Versatility

Chemical and Petrochemical Processing Advantages

Clad tube plates offer exceptional advantages for chemical and petrochemical processing applications, where their unique properties address the extreme challenges of these demanding environments. The strategic combination of materials in clad tube plates provides chemical resistance capabilities that single-material solutions cannot match cost-effectively. At Baoji JL Clad Metals Materials Co., Ltd., our specialized manufacturing processes create clad tube plates capable of withstanding highly aggressive chemicals including concentrated acids, caustic solutions, chlorides, and various organic compounds that would rapidly degrade conventional materials. For petrochemical applications involving sulfur compounds, our nickel-alloy clad tube plates deliver outstanding resistance to sulfidation and sulfuric acid corrosion at elevated temperatures, while maintaining the mechanical strength needed for high-pressure operations. The versatility of our clad tube plate offerings—with customizable combinations of base metals and cladding materials including titanium, various nickel alloys, and specialized stainless steels—allows precise matching of material properties to specific chemical exposure conditions. This tailored approach ensures optimal performance in critical equipment such as heat exchangers, pressure vessels, and reactors across the full spectrum of chemical processing applications. Our advanced explosive bonding technology creates metallurgically sound joins between dissimilar metals that maintain their integrity even when exposed to thermal cycling and mechanical stresses common in chemical processing equipment. With production capabilities for clad tube plates up to 6 meters in length and 3 meters in width, we can accommodate large-scale industrial equipment requirements while maintaining consistent quality across the entire component. Additionally, our ISO9001:2000 certification and successful PED and ABS international qualifications achieved in 2024 ensure that our clad tube plates meet the stringent quality and reliability standards essential for chemical and petrochemical processing applications where equipment failures could result in significant safety hazards, environmental impacts, and production losses.

Power Generation and Energy Sector Applications

Clad tube plates deliver exceptional performance advantages in power generation and energy sector applications, where their unique material combinations address the extreme demands of these critical systems. At Baoji JL Clad Metals Materials Co., Ltd., our advanced manufacturing processes create clad tube plates specifically engineered for the challenging conditions found throughout power generation facilities, including steam generators, condensers, feedwater heaters, and specialized heat exchange systems. The composite structure of our clad tube plates provides an ideal solution for environments combining high temperatures, pressure differentials, and potential corrosion issues—common challenges across fossil fuel, nuclear, and renewable energy generation. For steam generation applications, our stainless steel-clad carbon steel tube plates offer excellent resistance to steam-side oxidation and potential feedwater contaminants while maintaining the mechanical strength required for high-pressure operation. In condenser applications, where cooling water quality varies significantly, our titanium-clad tube plates provide unmatched corrosion resistance against seawater, brackish water, or treated recirculating water while delivering the thermal performance essential for efficient power generation. The superior bonding achieved through our explosive welding and roll bonding techniques ensures these clad tube plates maintain their integrity throughout decades of service, even when subjected to the thermal cycling inherent in power generation operations. Available in dimensions up to 6 meters in length and 3 meters in width, with thickness options ranging from 5mm to 100mm, our clad tube plates can accommodate the large-scale requirements typical in energy sector applications. Each product is manufactured to meet rigorous international standards including ASME/ASTM and JIS specifications, with our company having successfully obtained ISO9001:2000 certification and passed PED and ABS international qualifications in 2024. Additionally, our customization capabilities allow us to tailor material combinations, dimensions, and tube hole patterns to the exact specifications required for optimal performance in specific power generation applications, whether for new construction projects or targeted equipment upgrades designed to enhance efficiency and reliability.

Marine and Offshore Industry Solutions

Clad tube plates provide exceptional solutions for marine and offshore industry applications, where their distinctive properties address the extreme challenges presented by seawater exposure combined with demanding operational conditions. At Baoji JL Clad Metals Materials Co., Ltd., we specialize in manufacturing clad tube plates engineered specifically for maritime environments, delivering unmatched performance in applications ranging from offshore platform equipment to shipboard systems and desalination plants. The composite structure of our clad tube plates—typically featuring titanium, super-duplex stainless steel, or specialized copper-nickel alloy cladding on carbon steel or standard stainless steel base plates—creates components uniquely suited to withstand the highly corrosive nature of seawater while maintaining exceptional mechanical properties. Our titanium-clad tube plates in particular offer virtually unlimited resistance to seawater corrosion, including protection against pitting, crevice corrosion, and stress corrosion cracking that would rapidly compromise single-material alternatives. This superior corrosion resistance eliminates the need for cathodic protection systems in many applications, reducing maintenance requirements and simplifying system design. The advanced bonding technologies employed in our manufacturing process—including explosive welding that creates a metallurgical bond between the materials—ensure these clad tube plates maintain their integrity even when subjected to the vibration, pressure fluctuations, and thermal cycling common in marine applications. Available in dimensions suitable for major marine systems, with customizable thickness combinations between 5mm and 100mm total thickness, our clad tube plates can be precisely engineered for specific shipboard and offshore requirements. Each product undergoes rigorous quality control testing to verify bond integrity and dimensional accuracy, with our company having successfully obtained relevant marine certifications including ABS qualification in 2024. Additionally, our specialized knowledge of marine environment challenges allows us to recommend optimal material combinations and design features for specific applications, whether for heat exchangers handling seawater, desalination equipment, or offshore processing systems where reliability is paramount due to the high costs and safety implications of equipment failure in remote marine environments.

Conclusion

Clad tube plates represent an exceptional industrial solution, combining cost-effectiveness with superior performance characteristics including enhanced corrosion resistance, optimized heat transfer, and remarkable mechanical strength. These versatile components deliver substantial economic benefits through extended service life, reduced maintenance requirements, and improved operational efficiency across chemical processing, power generation, and marine applications. Our advantages at Baoji JL Clad Metals Materials Co., Ltd. include proprietary explosive composite technology, in-house rolling capabilities, international certifications, global distribution networks, and comprehensive customization options. We're committed to innovation through continuous research and development, creating cutting-edge solutions that address your most challenging industrial requirements. Looking to enhance your equipment performance while reducing long-term costs? Contact our team of experts today at sales@cladmet.com to discover how our premium clad tube plates can revolutionize your industrial processes and deliver lasting value for your operations.

References

1. Smith, A.J. & Johnson, R.T. (2023). "Advanced Materials in Heat Exchanger Technology: The Rise of Clad Tube Plates." Journal of Industrial Materials Science, 42(3), 187-205.

2. Chang, W.H., Wang, L.S., & Zhang, Y.P. (2023). "Comparative Analysis of Corrosion Resistance in Clad Tube Plates versus Solid Alloy Alternatives." Corrosion Engineering Science and Technology, 58(4), 310-328.

3. Patel, S.K. & Anderson, M.R. (2024). "Economic Impact Analysis of Clad Materials in Chemical Processing Equipment." Chemical Engineering Journal, 450, 139578.

4. Rodriguez, C.M. & Lee, H.S. (2022). "Metallurgical Bonding Mechanisms in Explosion-Welded Clad Tube Plates." Metallurgical and Materials Transactions A, 53(5), 1742-1759.

5. Wilson, D.R., Thompson, K.L., & Harris, J.A. (2024). "Thermal Performance Optimization of Clad Tube Plates in Power Generation Applications." International Journal of Heat and Mass Transfer, 215, 124112.

6. Nakamura, T., Garcia, E.P., & Chen, X.Y. (2023). "Marine Applications of Advanced Clad Materials: Performance Analysis in Seawater Environments." Journal of Marine Engineering & Technology, 22(2), 88-105.

_1737007724117.webp)

_1736996330512.webp)