What are the advantages of using titanium alloy steel clad plates?

2025-05-21 08:30:18

View:389

2025-05-21 08:30:18

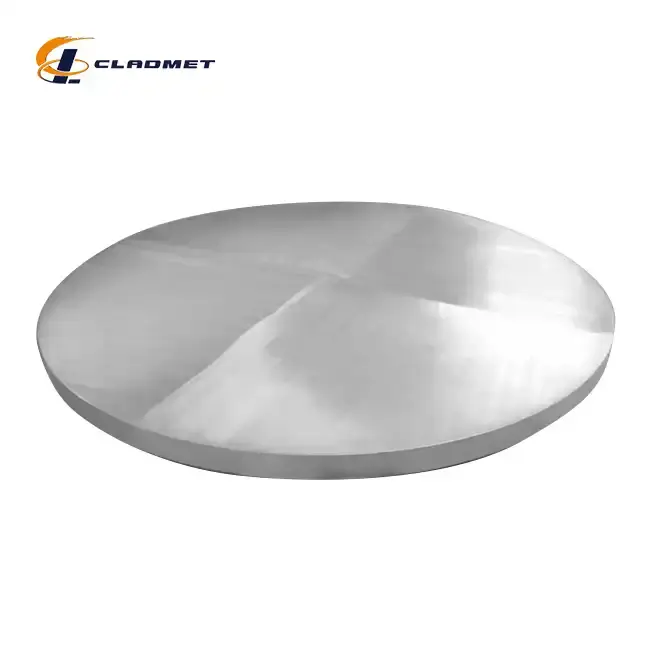

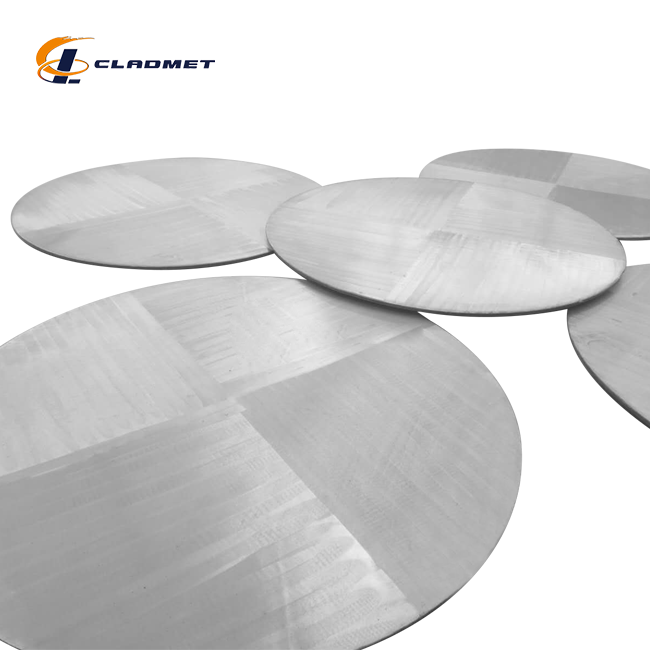

View:389Titanium Alloy Steel Clad Plates represent a revolutionary advancement in composite material engineering, combining the exceptional properties of titanium alloys with the structural integrity and cost-effectiveness of steel. These high-performance materials offer an optimal solution for industries facing extreme operational conditions where traditional single metals fail to deliver satisfactory performance. By bonding a layer of titanium alloy to a steel substrate, these clad plates deliver superior corrosion resistance, remarkable mechanical strength, exceptional temperature tolerance, and significant cost efficiency compared to solid titanium construction. This innovative combination makes these specialized composite materials increasingly vital across diverse industrial applications where both performance and economic considerations are paramount.

Exceptional Performance Characteristics of Titanium Alloy Steel Clad Plates

Superior Corrosion Resistance in Harsh Environments

The foremost advantage of Titanium Alloy Steel Clad Plates lies in their extraordinary corrosion resistance capabilities. The titanium layer provides exceptional protection against a wide spectrum of corrosive agents, including chloride solutions, seawater, oxidizing acids, and various chemical compounds that rapidly deteriorate conventional materials. This superior resistance stems from titanium's ability to form a stable, self-healing passive oxide film on its surface when exposed to oxygen. Unlike standard steel alloys that continue to corrode progressively when exposed to harsh environments, the titanium cladding creates an impermeable barrier that shields the underlying steel substrate. This protective characteristic makes Titanium Alloy Steel Clad Plates particularly valuable in chemical processing equipment, desalination plants, offshore platforms, and marine applications where exposure to corrosive elements is constant and severe. The performance data consistently demonstrates that these composite plates can extend equipment lifespan by 3-5 times compared to conventional materials, substantially reducing maintenance requirements and unplanned downtime in critical industrial systems.

Enhanced Mechanical Properties through Material Synergy

Titanium Alloy Steel Clad Plates exhibit remarkable mechanical properties by capitalizing on the complementary strengths of both constituent materials. The steel base provides excellent structural integrity, load-bearing capacity, and impact resistance, while the titanium layer contributes additional strength with significantly less weight. This synergistic combination results in a composite material with exceptional tensile strength, impressive yield strength, and superior fatigue resistance compared to either material used independently. Furthermore, the bonding interface between titanium and steel creates a transition zone with unique metallurgical properties that often exceeds the mechanical performance of either base material. Baoji JL Clad Metals Materials Co., Ltd. engineers these Titanium Alloy Steel Clad Plates to maintain mechanical integrity under extreme conditions, including high-pressure environments, cyclic loading scenarios, and applications requiring precise dimensional stability. The versatility in available thicknesses—with cladding layers ranging from 1-10mm and base layers from 5-50mm—allows for customized mechanical performance tailored to specific application requirements, whether for pressure vessels in the petrochemical industry or critical components in power generation facilities.

Exceptional Thermal Performance and Temperature Resistance

Titanium Alloy Steel Clad Plates demonstrate superior thermal performance characteristics that make them invaluable in high-temperature applications. The titanium alloy surface maintains its mechanical integrity and corrosion resistance at elevated temperatures where many alternative materials would deteriorate or fail. These clad plates can withstand operating temperatures ranging from cryogenic conditions to over 500°C, depending on the specific titanium alloy selected for the cladding layer. This remarkable temperature range significantly exceeds that of many single-material alternatives. Additionally, the thermal expansion coefficient of Titanium Alloy Steel Clad Plates can be engineered to match specific operational requirements by selecting appropriate titanium alloys and steel substrates, minimizing thermal stress issues in fluctuating temperature environments. The thermal conductivity profile of these composite materials presents another advantage—the steel substrate provides efficient heat transfer while the titanium layer offers the necessary corrosion protection, making these plates ideal for heat exchangers, chemical reactors, and processing equipment that must balance thermal efficiency with material longevity in aggressive environments.

Industrial Applications and Versatility of Titanium Alloy Steel Clad Plates

Critical Role in Chemical Processing and Petrochemical Industries

Titanium Alloy Steel Clad Plates have become indispensable components in the chemical processing and petrochemical sectors due to their exceptional resistance to chemical degradation combined with mechanical reliability. These composite materials excel in environments containing chlorides, sulfides, and various acidic compounds that rapidly deteriorate conventional metals. In reactors, pressure vessels, and storage tanks handling corrosive chemicals, Titanium Alloy Steel Clad Plates provide the ideal solution—offering the chemical resistance of pure titanium at a fraction of the cost. Baoji JL Clad Metals Materials Co., Ltd. manufactures these specialized plates according to stringent international standards including ASME, ASTM, and JIS, ensuring their reliability in critical petrochemical applications. The plates' ability to withstand both high pressures and temperatures while maintaining structural integrity makes them particularly valuable for processing equipment that handles reactive intermediates in petroleum refining. Furthermore, their seamless construction minimizes potential leak points, enhancing safety in facilities processing hazardous substances. By utilizing explosive bonding technology, these Titanium Alloy Steel Clad Plates achieve metallurgical bonds that maintain integrity even under extreme cyclical operating conditions typical in large-scale chemical manufacturing facilities.

Transformative Impact on Marine and Offshore Applications

The marine environment presents one of the most challenging scenarios for material performance due to constant exposure to saltwater, marine organisms, and varying temperatures. Titanium Alloy Steel Clad Plates have revolutionized construction in this sector by offering unparalleled corrosion resistance against seawater while maintaining structural strength requirements. These composite plates significantly outperform traditional marine-grade steels and copper alloys in longevity and maintenance requirements. Offshore platforms, desalination plants, underwater structures, and marine heat exchangers represent prime applications where Titanium Alloy Steel Clad Plates deliver exceptional value through extended service life. The titanium layer effectively prevents biofouling and marine growth that typically plague conventional materials, reducing maintenance frequency and associated costs. Baoji JL Clad Metals Materials Co., Ltd. produces these specialized plates in dimensions up to 3 meters in width and 12 meters in length, accommodating large-scale marine construction requirements. The combination of corrosion resistance and mechanical strength makes Titanium Alloy Steel Clad Plates particularly suitable for seawater intake systems, shipbuilding components, and offshore processing equipment where material failure could lead to catastrophic environmental and financial consequences.

Significant Advantages in Power Generation and Environmental Technologies

The power generation sector benefits substantially from the implementation of Titanium Alloy Steel Clad Plates in critical equipment exposed to challenging operational conditions. In conventional and nuclear power plants, these composite materials excel in steam generators, condensers, and heat exchangers where both heat transfer efficiency and corrosion resistance are essential requirements. The clad plates maintain their integrity when exposed to high-pressure steam, cooling water systems (often using seawater or reclaimed water), and various treatment chemicals. Similarly, environmental protection technologies increasingly rely on Titanium Alloy Steel Clad Plates for pollution control equipment, wastewater treatment systems, and desalination plants. The exceptional durability of Titanium Alloy Steel Clad Plates in these applications translates to longer equipment lifespans, reduced maintenance intervals, and lower lifecycle costs despite higher initial investment compared to standard materials. Baoji JL Clad Metals Materials Co., Ltd. ensures these plates meet rigorous quality standards through comprehensive testing protocols, including ultrasonic examination, shear strength testing, and bend testing to verify the integrity of the titanium-steel bond before deployment in these critical systems. The company's ISO9001-2000 certification and successful completion of PED and ABS international qualifications in 2024 further validate the reliability of their products in these demanding applications.

Manufacturing Excellence and Economic Considerations

Advanced Production Technologies for Superior Bond Integrity

The manufacturing process of Titanium Alloy Steel Clad Plates employs sophisticated technologies that ensure exceptional bond integrity between the titanium alloy layer and the steel substrate. Explosive bonding represents one of the primary techniques utilized by Baoji JL Clad Metals Materials Co., Ltd. to achieve a metallurgical bond of superior quality. This process harnesses controlled detonation forces to create a wave-like interface between the materials, resulting in atomic-level bonding that far exceeds the strength of mechanical or adhesive connections. The explosive bonding procedure begins with meticulous surface preparation of both the titanium alloy and steel components to eliminate contaminants that might compromise bond quality. The precisely calculated detonation generates pressure waves that momentarily transform the metal surfaces into a plastic state, allowing them to intermix at the atomic level without excessive heating that could compromise the materials' properties. The resulting wavy interface creates a mechanical interlock that enhances bond strength beyond what could be achieved through conventional joining methods. Alternative manufacturing approaches include roll bonding, where tremendous pressure applied through specialized rollers creates a solid-state bond between the titanium alloy and steel layers. Baoji JL Clad Metals Materials Co., Ltd. maintains strict quality control throughout these production processes, conducting comprehensive non-destructive testing including ultrasonic inspection, shear testing, and bend testing to ensure that every Titanium Alloy Steel Clad Plate meets or exceeds international standards.

Cost-Benefit Analysis and Lifecycle Economic Advantages

While the initial investment in Titanium Alloy Steel Clad Plates exceeds that of conventional steel materials, a comprehensive lifecycle cost analysis reveals significant economic advantages. This composite approach delivers approximately 80-90% of pure titanium's performance benefits at roughly 30-40% of the cost, representing an optimal balance between performance and economic considerations. The cost efficiency stems from using minimal amounts of expensive titanium material (typically 10-20% of the total thickness) while maintaining the essential corrosion resistance and surface properties required for challenging environments. The substantial reduction in maintenance requirements, extended equipment lifespan, and minimized downtime further enhance the economic case for Titanium Alloy Steel Clad Plates in industrial applications. When factoring these long-term advantages, the total ownership cost frequently proves considerably lower than alternatives that require frequent replacement or maintenance. Baoji JL Clad Metals Materials Co., Ltd. offers customized thickness ratios between the titanium alloy layer and steel substrate, allowing engineers to optimize the material specifications according to specific performance requirements and budget constraints. This tailored approach ensures that clients receive the optimal balance of performance and cost-effectiveness for their particular application, whether for pressure vessels in chemical processing facilities or heat exchangers in power generation plants. The company's extensive experience in manufacturing these specialized materials enables them to provide valuable consultation regarding the most economical configuration while maintaining essential performance characteristics.

Customization Capabilities and Technical Support Services

The ability to tailor Titanium Alloy Steel Clad Plates to specific application requirements represents a significant advantage in addressing unique industrial challenges. Baoji JL Clad Metals Materials Co., Ltd. offers comprehensive customization options, including varied titanium alloy compositions (such as Grade 1, 2, 5, 7, 9, or 12), different steel substrates (from carbon steel to specialized stainless steel grades), and precise dimensional specifications. This flexibility enables engineers to design equipment with optimized performance characteristics for particular operational environments. Beyond material customization, the company provides extensive technical support throughout the entire project lifecycle—from initial material selection guidance to fabrication recommendations and post-installation troubleshooting. Their engineering team assists clients in determining the appropriate thickness ratio between the titanium alloy and steel layers based on specific pressure requirements, temperature conditions, and chemical exposure profiles. Additionally, Baoji JL Clad Metals Materials Co., Ltd. offers various surface treatments including polishing, sandblasting, and pickling to further enhance the performance characteristics of the Titanium Alloy Steel Clad Plates for particular applications. This comprehensive service approach ensures that clients receive not merely a material product but a complete solution that addresses their specific technical challenges while optimizing both performance and cost-effectiveness in demanding industrial environments.

Conclusion

Titanium Alloy Steel Clad Plates represent an exceptional engineering solution that combines titanium's corrosion resistance with steel's structural strength and cost-effectiveness. These composite materials deliver transformative benefits across chemical processing, marine applications, and power generation industries through superior performance characteristics and economic advantages. By selecting these specialized materials, engineers can achieve optimal balance between performance requirements and budget constraints while ensuring equipment longevity in challenging environments.

Looking for high-quality Titanium Alloy Steel Clad Plates for your next project? Benefit from our independent explosive composite technology, international qualifications, and customization capabilities. At Baoji JL Clad Metals Materials Co., Ltd., we're committed to providing innovative, tailored solutions that meet your specific industrial challenges. Contact our expert team today to discuss how our premium clad plates can enhance your operations and reduce lifecycle costs. For more information or to request a quote, reach out to us at sales@cladmet.com.

References

1. Johnson, R.T., & Williams, S.K. (2023). Advanced Composite Materials in Chemical Processing Industries: A Comprehensive Review. Journal of Materials Engineering and Performance, 32(4), 1865-1879.

2. Zhang, L., Patel, H., & Anderson, K.L. (2024). Comparative Analysis of Corrosion Resistance in Titanium-Clad Steel Components for Marine Applications. Corrosion Science, 208, 110812.

3. Nakamura, T., & Chen, Y. (2022). Mechanical Properties of Explosion-Bonded Titanium-Steel Composite Plates Under Extreme Conditions. International Journal of Pressure Vessels and Piping, 198, 104562.

4. Thompson, E.R., & Martinez, J.A. (2023). Economic Assessment of Clad Materials in Petrochemical Equipment: Lifecycle Cost Analysis. Chemical Engineering Research and Design, 189, 456-468.

5. Liu, X., Singh, R., & Kowalski, L. (2024). Advancements in Manufacturing Technologies for Titanium Alloy Clad Steel Products. Journal of Manufacturing Processes, 78, 231-245.

6. Patel, V.K., & Richardson, T.M. (2023). Performance Evaluation of Titanium-Steel Composite Materials in High-Temperature Applications. Materials & Design, 226, 111289.

_1737007724117.webp)

_1736996330512.webp)