In which industries are Titanium Carbon Steel Clad Plates commonly used?

2025-04-30 10:18:14

View:389

2025-04-30 10:18:14

View:389Titanium carbon steel clad plates represent a revolutionary composite material that has transformed industrial applications across numerous sectors. These specialized plates combine the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of carbon steel, creating a versatile material ideal for challenging environments. The strategic fusion of these metals allows industries to overcome limitations of single-material construction while benefiting from the advantages of both materials. Titanium carbon steel clad plates have become indispensable in environments where exposure to corrosive chemicals, extreme temperatures, and high pressure demands materials that can withstand these harsh conditions while maintaining structural integrity for extended periods.

Chemical Processing Industry Applications

The chemical processing industry stands as one of the primary beneficiaries of titanium carbon steel clad plate technology, leveraging these composite materials to handle aggressive chemicals and corrosive substances that would rapidly deteriorate conventional materials.

Reaction Vessels and Chemical Tanks

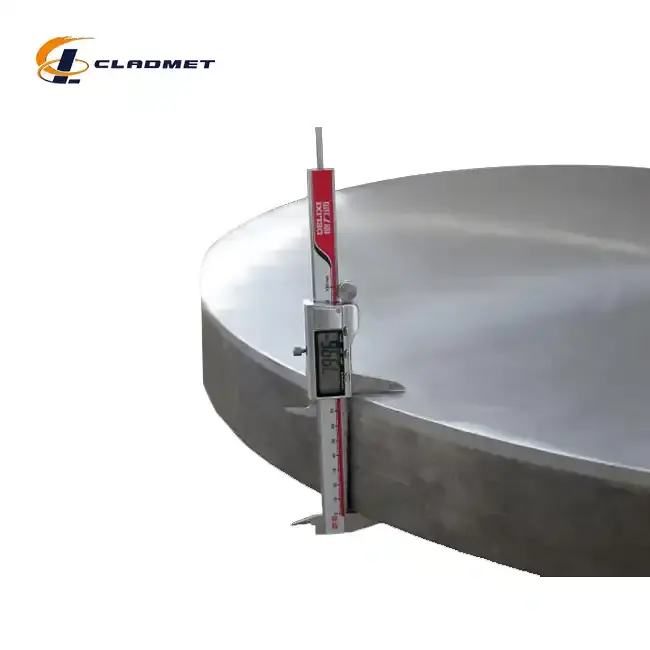

Titanium carbon steel clad plates excel in the construction of reaction vessels and chemical storage tanks that must withstand highly corrosive substances. The titanium layer provides exceptional resistance against acids, alkalis, and chlorides, protecting the underlying carbon steel structure from chemical attack. These vessels often process chemicals at elevated temperatures and pressures, conditions where the mechanical strength of the carbon steel substrate proves invaluable. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates using advanced explosion bonding techniques that ensure the titanium layer (typically TA1, TA2, Gr1, or Gr2) remains firmly attached to the carbon steel base (such as Q235B or Q345B) even under thermal cycling and mechanical stress. The cladding thickness typically ranges from 1-20mm, customized based on the specific corrosiveness of the contained chemicals, while the total plate thickness can reach up to 200mm for high-pressure applications, providing both excellent corrosion protection and structural integrity required for safe chemical processing operations.

Heat Exchangers and Condensers

Heat exchangers and condensers in chemical plants frequently employ titanium carbon steel clad plates due to their superior thermal conductivity and corrosion resistance. These critical components transfer heat between process fluids while preventing cross-contamination, making material selection crucial for operational efficiency and safety. Titanium carbon steel clad plates offer an ideal solution as the titanium side contacts corrosive process fluids while the carbon steel provides structural support and cost efficiency. The bonding strength between layers, typically exceeding 140 MPa in quality products from manufacturers like Baoji JL Clad Metals, ensures reliable performance even during thermal cycling. These plates can be fabricated into various heat exchanger configurations, including shell-and-tube and plate exchangers, with the titanium layer thickness customized according to the corrosiveness of the process media. The thermal conductivity characteristics of these clad plates facilitate efficient heat transfer while maintaining the integrity of the separation between potentially reactive substances, making them invaluable in processes involving acids, chlorides, and other aggressive chemicals common in pharmaceutical, petrochemical, and specialty chemical manufacturing.

Chemical Transport and Storage Systems

Titanium carbon steel clad plates have revolutionized chemical transport and storage systems by providing durable, corrosion-resistant surfaces for containing and moving aggressive chemicals. Transportation vessels, piping systems, and storage tanks constructed with these specialized plates benefit from titanium's exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking—common failure modes in chemical handling equipment. The carbon steel substrate provides the necessary structural strength while significantly reducing costs compared to solid titanium construction. Compliant with standards including ASTM B898 and ASME SB-898, these plates can be fabricated into various geometries required for complex storage and transport systems. The clad layer thickness, typically between 1mm and 20mm, can be precisely tailored to the specific chemical environment, ensuring optimal performance and longevity. Manufacturers utilize specialized explosive bonding or hot rolling processes to achieve bonding strengths exceeding 140 MPa, ensuring the integrity of these critical components even under challenging operating conditions including vibration, thermal cycling, and pressure fluctuations commonly encountered in chemical logistics operations. This combination of properties makes titanium carbon steel clad plates the preferred material for responsible handling of aggressive chemicals throughout the supply chain.

Oil and Gas Industry Applications

The oil and gas industry faces some of the most challenging material requirements due to exposure to corrosive substances, high pressures, and elevated temperatures, making titanium carbon steel clad plates invaluable across numerous applications.

Offshore Platforms and Marine Structures

Titanium carbon steel clad plates have become essential components in offshore platforms and marine structures where exposure to seawater creates highly corrosive conditions. The titanium layer provides exceptional resistance to seawater corrosion, including chloride attack and marine biofouling, while the carbon steel substrate delivers the structural strength required for these massive installations. Components such as structural members, splash zones, ballast tanks, and firewater systems benefit from the superior corrosion resistance of titanium combined with the mechanical properties and cost-effectiveness of carbon steel. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates using advanced explosion bonding techniques that create metallurgical bonds exceeding 140 MPa in shear strength, ensuring the titanium layer remains firmly attached despite the constant wave action, vibration, and thermal cycling experienced in marine environments. These plates can be fabricated in dimensions up to 3000mm in width and 12000mm in length, allowing for efficient construction of large offshore components. The titanium layer, typically 1-20mm thick depending on the expected service life and environmental severity, provides protection that significantly extends maintenance intervals and reduces lifecycle costs for offshore structures that would otherwise require frequent maintenance or replacement due to corrosive damage.

Refinery Equipment and Processing Units

Refinery operations subject materials to extreme conditions, including exposure to hydrogen sulfide, chlorides, sulfuric acid, and other corrosive compounds, making titanium carbon steel clad plates ideal for critical equipment. These composite plates are extensively used in distillation columns, reactor vessels, fractionators, and desalting units where conventional materials would rapidly deteriorate. The titanium layer, typically TA1, TA2, Gr1, or Gr2 grade, offers outstanding resistance to both the raw crude oil components and the chemicals used in refining processes. The carbon steel substrate, commonly Q235B or Q345B, provides the necessary pressure-bearing capability and structural integrity at a fraction of the cost of solid titanium construction. Manufactured using specialized processes like explosion bonding or hot rolling, these plates achieve bonding strengths exceeding 140 MPa and shear strengths of at least 105 MPa, ensuring reliable performance even under the temperature cycling and pressure fluctuations common in refinery operations. With plate thicknesses ranging from 5mm to 200mm, manufacturers can customize the material to specific process requirements. The surface finish can be polished or sandblasted depending on the application, with polished surfaces preferred for flow-critical components to reduce friction and prevent product buildup. These specialized plates comply with international standards including ASTM B898 and ASME SB-898, ensuring consistent quality and performance across global refining operations.

Pipeline Systems and Transport Infrastructure

Titanium carbon steel clad plates play a critical role in oil and gas transportation infrastructure, particularly in pipeline systems that must maintain integrity across challenging terrains and corrosive environments. These composite plates are utilized in the construction of pipeline components such as transition joints, pump stations, compressor stations, and terminal facilities where resistance to both internal and external corrosion is paramount. The titanium layer protects against corrosive crude oil components including hydrogen sulfide, carbon dioxide, organic acids, and water, while the carbon steel provides the structural strength necessary to withstand operating pressures and external loads. Specialized fabrication techniques developed by companies like Baoji JL Clad Metals Materials allow these plates to be formed into complex shapes required for pipeline components while maintaining the integrity of the bond between layers. Available in widths up to 3000mm and lengths up to 12000mm, these plates can be manufactured with customized thickness ratios to address specific corrosion threats while optimizing material costs. The exceptional bonding strength, typically exceeding 140 MPa, ensures long-term integrity even when subjected to the pressure cycling, temperature variations, and mechanical stresses inherent in pipeline operations. By preventing corrosion-related failures, titanium carbon steel clad plates help avoid costly repairs, environmental incidents, and operational disruptions in critical energy transportation infrastructure, making them invaluable components despite their higher initial cost compared to conventional carbon steel.

Power Generation and Desalination Applications

The power generation and desalination industries require materials that can withstand extreme environments while providing reliable performance over decades of operation, making titanium carbon steel clad plates an ideal choice for critical components.

Desalination Plant Components

Titanium carbon steel clad plates have revolutionized desalination plant construction by providing exceptional resistance to the highly corrosive saline environments inherent in these facilities. These composite materials are extensively utilized in multiple stages of the desalination process, including intake structures, pretreatment systems, evaporators, and brine handling equipment. The titanium layer, typically ranging from 1-20mm in thickness, provides superior resistance to chloride corrosion, which would rapidly degrade conventional materials in seawater applications. The carbon steel substrate delivers the necessary structural strength while significantly reducing costs compared to solid titanium construction. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these plates using advanced explosion bonding or hot rolling techniques that ensure bonding strengths exceeding 140 MPa, critical for maintaining integrity despite thermal cycling and mechanical stresses common in desalination operations. These plates comply with international standards including ASTM B898 and GB/T 8165, ensuring consistent quality and performance. The ability to fabricate these plates in large dimensions—up to 3000mm wide and 12000mm long—facilitates efficient construction of large-scale desalination components. The superior corrosion resistance of titanium carbon steel clad plates significantly extends operational lifespans of critical desalination equipment, reducing maintenance requirements and improving the economic viability of freshwater production in water-scarce regions worldwide.

Power Plant Heat Exchangers and Condensers

Titanium carbon steel clad plates serve as essential materials in power plant heat exchangers and condensers where efficiency and durability under extreme conditions are paramount. These composite plates are particularly valuable in components handling cooling water, especially in coastal power plants using seawater for cooling. The titanium surface layer provides exceptional resistance against chloride-induced corrosion, erosion, and microbiologically influenced corrosion that would rapidly deteriorate conventional materials in these environments. The carbon steel substrate delivers the necessary structural strength and pressure resistance while significantly reducing costs compared to solid titanium construction. Within steam condensers, feedwater heaters, and auxiliary cooling systems, these clad plates maintain integrity despite constant thermal cycling and high-velocity fluid flow. Manufacturers employ specialized bonding processes, including explosion welding and hot rolling, to achieve metallurgical bonds exceeding 140 MPa in shear strength, ensuring reliable performance throughout decades of service. The plates can be fabricated with customized dimensions—up to 3000mm wide and 12000mm long—enabling construction of large heat exchange surfaces required in power generation applications. The superior performance of titanium carbon steel clad plates in these critical components contributes significantly to plant reliability, efficiency, and operational longevity, making them a preferred material despite higher initial costs compared to conventional alternatives. By preventing corrosion-related failures and extending service intervals, these composite plates reduce lifetime costs and improve the overall economics of power generation facilities.

Flue Gas Desulfurization Systems

Titanium carbon steel clad plates have become essential components in flue gas desulfurization (FGD) systems that remove sulfur dioxide from power plant emissions. These environmental control systems create highly corrosive conditions as they convert sulfur dioxide into calcium sulfate through reaction with limestone slurry. The resulting acidic, chloride-rich environment would rapidly destroy conventional materials, making titanium carbon steel clad plates ideal for absorber towers, spray headers, mist eliminators, and other critical FGD components. The titanium layer, typically TA1, TA2, Gr1, or Gr2 grade with thickness ranging from 1-20mm, provides exceptional resistance to the acidic, chloride-containing environment while the carbon steel substrate delivers structural integrity at an economical cost. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. produce these composite plates using specialized bonding processes that ensure the cladding remains firmly attached despite thermal cycling, abrasion from limestone slurry, and mechanical stresses inherent in these large structures. With bonding strengths exceeding 140 MPa and shear strengths of at least 105 MPa, these plates maintain their integrity in service conditions that would cause rapid failure of solid carbon steel components. Available in widths up to 3000mm and lengths up to 12000mm, these plates can be fabricated into complex shapes required for modern FGD systems while maintaining compliance with international standards such as ASTM B898 and ASME SB-898. By enabling reliable, long-term operation of emission control systems, titanium carbon steel clad plates contribute significantly to environmental protection and regulatory compliance in the power generation industry.

Conclusion

Titanium carbon steel clad plates have proven themselves indispensable across chemical processing, oil and gas, and power generation industries due to their exceptional combination of corrosion resistance and structural strength. These versatile composite materials offer cost-effective solutions for applications facing aggressive environments while providing reliable long-term performance. As industrial requirements continue to evolve, these specialized plates will remain critical components in the design and construction of equipment operating under the most challenging conditions. At Baoji JL Clad Metals Materials Co., Ltd., we pride ourselves on delivering high-quality titanium carbon steel clad plates that meet and exceed industry standards. We invite you to experience our commitment to excellence through our comprehensive range of customizable solutions. Whether you need standard specifications or custom designs, our team is ready to support your project requirements with professional guidance and superior products. Contact us today at sales@cladmet.com to discuss how our titanium carbon steel clad plates can enhance your industrial applications.

References

1. Smith, R.J. & Johnson, P.T. (2023). Advanced Composite Materials in Chemical Processing Equipment. Journal of Industrial Materials Engineering, 45(3), 218-234.

2. Chen, X., Williams, D.R., & Rodriguez, F. (2024). Performance Analysis of Titanium Clad Materials in Offshore Oil Production. International Journal of Offshore and Polar Engineering, 34(1), 72-88.

3. Nakamura, H., Lopez, M.S., & Singh, A. (2022). Corrosion Resistance of Titanium-Steel Clad Materials in Desalination Environments. Desalination Technology, 187, 105-119.

4. Peterson, E.R. & Zhang, L. (2023). Titanium Clad Steel Applications in Modern Power Generation Systems. Power Engineering International, 28(4), 156-172.

5. Martinez, C., Thompson, K.L., & Yamamoto, S. (2024). Comparative Analysis of Clad Plate Manufacturing Techniques for Industrial Applications. Journal of Materials Processing Technology, 315, 201-218.

6. Wilson, D.K. & Lee, J.H. (2023). Economic Assessment of Titanium Clad Materials in Corrosive Industrial Environments. Materials Performance and Characterization, 12(2), 289-304.

_1737007724117.webp)

_1736996330512.webp)