Titanium Steel Clad Plate for Pressure Vessels: Meeting ASME Standards and Beyond

2025-08-26 15:16:04

View:389

2025-08-26 15:16:04

View:389Titanium Steel Clad Plate for Pressure Vessels represents a revolutionary advancement in industrial materials engineering, combining the exceptional corrosion resistance of titanium with the structural strength of steel. This innovative composite material has become essential for pressure vessel applications across petrochemical, marine, and power generation industries. When manufactured to ASME standards and beyond, these clad plates deliver unmatched performance in demanding environments where traditional materials fail. The integration of explosive welding and hot rolling technologies ensures metallurgical bonding strength exceeding 150-200 MPa, making Titanium Steel Clad Plate for Pressure Vessels the preferred choice for engineers seeking optimal cost-effectiveness without compromising safety or durability in critical pressure vessel applications.

Understanding the Technical Specifications of Titanium Steel Clad Plates for Pressure Vessel Applications

Material Composition and Bonding Technology

Titanium Steel Clad Plate for Pressure Vessels utilizes advanced metallurgical processes to create a bimetal composite that harnesses the best properties of both materials. The titanium layer, typically ranging from 0.5mm to 10mm in thickness according to ASTM B898 and GB/T 8547-2013 standards, provides exceptional resistance to corrosive environments including acids, alkalis, seawater, and chlorides. The steel substrate, with thickness ranging from 3mm to 100mm per ASTM A516 and GB/T 3274-2017 specifications, delivers the mechanical strength necessary for high-pressure applications. The explosive welding process creates an intermetallic bond at the interface, forming a metallurgical connection that prevents delamination under extreme operating conditions. This bonding method generates temperatures exceeding 1000°C instantaneously, creating a wavy interface pattern that increases the actual bonding area and enhances shear strength. The resulting composite maintains uniform properties across the entire surface, ensuring consistent performance in pressure vessel applications where material integrity is paramount.

Mechanical Properties and Performance Standards

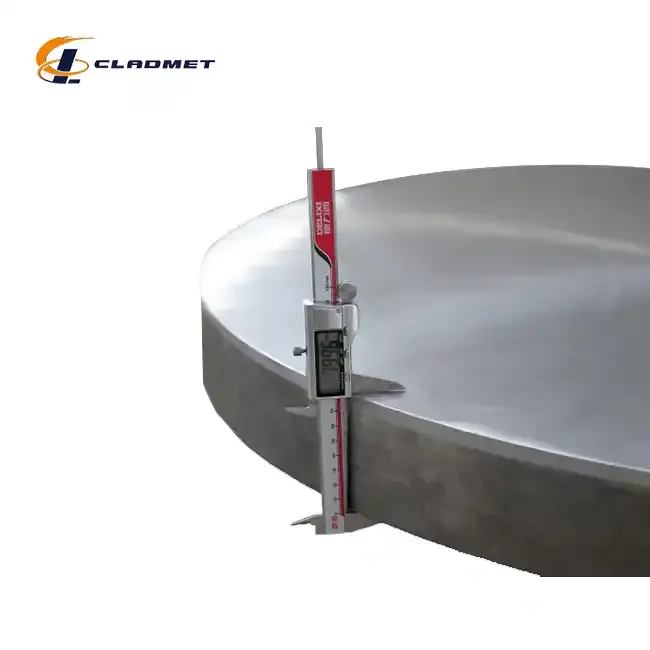

The mechanical performance of Titanium Steel Clad Plate for Pressure Vessels meets rigorous international standards that govern pressure vessel manufacturing. The bond strength between titanium and steel layers consistently achieves 150-200 MPa, as verified through standardized testing procedures outlined in ASTM B898. The steel substrate provides tensile strength exceeding 400 MPa per ASTM E8 testing protocols, ensuring structural integrity under high-pressure conditions. Corrosion resistance testing according to ASTM G85 demonstrates superior performance in aggressive chemical environments, significantly outperforming traditional stainless steel alternatives. The composite structure exhibits excellent fatigue resistance, with the titanium layer protecting the steel from environmental degradation while the steel core provides load-bearing capacity. Maximum available dimensions of 2000mm x 6000mm accommodate large pressure vessel components, while customization capabilities enable fabrication of specialized geometries. The material's excellent workability allows for conventional manufacturing processes including shearing, bending, stamping, and welding, making it compatible with existing pressure vessel fabrication equipment and procedures.

Quality Control and Certification Requirements

Manufacturing Titanium Steel Clad Plate for Pressure Vessels requires strict adherence to multiple international standards and certification protocols. ISO9001-2000 quality management systems ensure consistent production processes from raw material selection through final inspection. PED (Pressure Equipment Directive) certification validates compliance with European safety requirements for pressure-bearing equipment, while ABS (American Bureau of Shipping) qualification confirms suitability for marine and offshore applications. ASME BPVC Section II specifications govern material properties and testing requirements, ensuring compatibility with pressure vessel codes. Non-destructive testing methods including ultrasonic inspection, bond strength testing, and metallographic examination verify the integrity of the titanium-steel interface. Chemical composition analysis confirms that both base materials meet specified grades, with titanium layers typically utilizing Gr1 or Gr2 pure titanium and steel substrates conforming to Q235B, A516, 304, or 316L specifications. Dimensional tolerances are maintained within strict limits to ensure proper fit-up during pressure vessel fabrication, while surface finish requirements guarantee optimal welding characteristics for final assembly.

Manufacturing Processes and Advanced Production Technologies

Explosive Welding Technology Implementation

The explosive welding process for manufacturing Titanium Steel Clad Plate for Pressure Vessels represents one of the most sophisticated metallurgical techniques available in modern industry. This process involves precisely controlled detonation of explosive materials to create the high-velocity collision necessary for metallurgical bonding between dissimilar metals. The titanium plate is positioned at a specific standoff distance above the steel substrate, with explosive charges arranged to create a progressive detonation wave across the entire surface area. The collision velocity typically ranges from 200-800 m/s, generating pressures exceeding 1 GPa at the interface. This extreme condition creates localized melting and rapid solidification, forming intermetallic compounds that provide exceptional bond strength. The wave pattern created during collision increases the actual bonding area by 20-30% compared to the nominal surface area, contributing to enhanced shear strength and peel resistance. Quality control during explosive welding requires precise monitoring of explosive type, charge weight, standoff distance, and detonation sequence to ensure consistent bonding across large plate areas. The resulting interface exhibits a characteristic wavy appearance when examined metallographically, confirming successful metallurgical bonding essential for pressure vessel applications.

Hot Rolling Cladding Process Optimization

Hot rolling cladding technology offers an alternative manufacturing approach for Titanium Steel Clad Plate for Pressure Vessels, particularly suitable for high-volume production requirements. This process begins with surface preparation of both titanium and steel components, including mechanical cleaning and chemical treatment to remove oxides and contaminants that could interfere with bonding. The prepared materials are assembled in a protective atmosphere or vacuum environment to prevent oxidation during heating. Rolling temperatures typically range from 850-950°C for titanium-steel combinations, requiring precise temperature control to achieve optimal bonding without degrading material properties. The rolling process applies pressures exceeding 100 tons per linear meter, creating the intimate contact necessary for diffusion bonding at the interface. Multiple rolling passes with progressive thickness reduction ensure uniform bonding across the entire plate area while maintaining dimensional accuracy. Post-rolling heat treatment may be applied to optimize mechanical properties and relieve residual stresses induced during the forming process. This manufacturing method produces plates with excellent surface finish and dimensional control, making them particularly suitable for applications requiring precise tolerances in pressure vessel fabrication.

Advanced Quality Assurance and Testing Protocols

Comprehensive testing protocols for Titanium Steel Clad Plate for Pressure Vessels ensure compliance with stringent industry standards and customer specifications. Ultrasonic bond testing utilizes specialized transducers to detect unbonded areas or delaminations at the titanium-steel interface, with acceptance criteria typically requiring 95% or greater bonded area. Shear strength testing involves machining standardized specimens and subjecting them to controlled loading until failure occurs at the bond interface. Tensile testing of the composite material evaluates overall mechanical properties, including yield strength, ultimate tensile strength, and elongation characteristics. Bend testing assesses the ductility and formability of the composite material, ensuring compatibility with pressure vessel forming operations. Corrosion testing involves exposure to simulated service environments, including acidic, basic, and chloride-containing solutions at elevated temperatures. Metallographic examination reveals the microstructure at the bond interface, confirming the presence of intermetallic compounds and absence of defects. Chemical analysis verifies composition of both titanium and steel layers, ensuring compliance with specified grades. Dimensional inspection utilizes coordinate measuring machines to verify thickness, flatness, and other geometric parameters critical for pressure vessel applications.

Industrial Applications and Performance Benefits in Pressure Vessel Manufacturing

Petrochemical Industry Applications and Advantages

Titanium Steel Clad Plate for Pressure Vessels has revolutionized equipment design in the petrochemical industry, where aggressive chemical environments and high operating pressures create extreme service conditions. Storage tanks handling concentrated acids, caustic solutions, and chloride-containing compounds benefit significantly from the superior corrosion resistance provided by the titanium cladding layer. Heat exchangers operating in crude oil refining processes experience extended service life due to reduced fouling and corrosion on titanium surfaces, while the steel substrate provides necessary pressure-bearing capacity. Reactors processing highly corrosive chemicals maintain structural integrity through the protective titanium layer, preventing costly downtime and maintenance associated with corrosion-related failures. The composite construction enables operation at temperatures up to 350°C while maintaining excellent corrosion resistance, expanding the operating envelope compared to traditional materials. Cost analysis demonstrates that while initial material costs may be higher than conventional stainless steel, the extended service life and reduced maintenance requirements provide significant lifecycle cost savings. Pressure vessels fabricated from these clad plates typically achieve service lives exceeding 20 years in petrochemical applications, compared to 5-10 years for conventional materials in similar environments.

Marine Engineering and Offshore Platform Integration

Marine engineering applications present unique challenges that make Titanium Steel Clad Plate for Pressure Vessels particularly valuable for seawater service and offshore platform operations. Seawater desalination equipment benefits from titanium's exceptional resistance to chloride-induced corrosion, eliminating the pitting and crevice corrosion commonly experienced with stainless steel alternatives. The composite construction provides the structural strength necessary for high-pressure reverse osmosis systems while maintaining long-term reliability in seawater environments. Offshore platform applications include ballast tanks, fire suppression systems, and process equipment exposed to marine atmospheres. The titanium cladding provides galvanic compatibility with seawater, preventing the accelerated corrosion that occurs when less noble metals are exposed to chloride environments. Weight considerations are critical in offshore applications, and the composite construction provides optimal strength-to-weight ratios compared to solid titanium alternatives. Fabrication techniques developed specifically for marine applications include specialized welding procedures and joint designs that maintain corrosion resistance at weld locations. Environmental compliance requirements in marine applications favor titanium-clad materials due to their excellent corrosion resistance and minimal maintenance requirements, reducing the risk of environmental contamination from equipment failures.

Power Generation and Nuclear Industry Implementation

Power generation facilities, including both conventional thermal plants and nuclear installations, utilize Titanium Steel Clad Plate for Pressure Vessels in critical applications where reliability and safety are paramount. Steam generators in nuclear power plants benefit from titanium's excellent resistance to steam-side corrosion and stress corrosion cracking, while the steel substrate provides the structural strength required for high-pressure primary circuit conditions. Desulfurization equipment in coal-fired power plants experiences severe corrosion from sulfur compounds, making titanium cladding essential for long-term reliability. Heat exchangers in geothermal power installations operate in highly corrosive environments containing hydrogen sulfide and chlorides, where traditional materials fail rapidly. The composite construction enables operation at elevated temperatures and pressures while maintaining corrosion resistance, extending equipment life and improving plant availability factors. Nuclear applications require extensive material qualification including radiation resistance testing, thermal aging studies, and fracture toughness evaluation at operating temperatures. Manufacturing for nuclear applications involves additional quality assurance requirements including material traceability, welding procedure qualification, and non-destructive examination to nuclear standards. The proven performance of titanium-clad materials in nuclear service has led to their adoption in next-generation reactor designs where enhanced safety and extended service life are critical design objectives.

Conclusion

Titanium Steel Clad Plate for Pressure Vessels represents the pinnacle of materials engineering, delivering exceptional performance that exceeds ASME standards while providing cost-effective solutions for the most demanding industrial applications. The advanced manufacturing processes and rigorous quality control measures ensure consistent product quality that meets the stringent requirements of petrochemical, marine, and power generation industries. This innovative composite material continues to drive technological advancement in pressure vessel design, enabling engineers to achieve previously unattainable combinations of corrosion resistance, mechanical strength, and economic viability.

As a leading China Titanium Steel Clad Plate for Pressure Vessels manufacturer and China Titanium Steel Clad Plate for Pressure Vessels supplier, Baoji JL Clad Metals Materials Co., Ltd. stands ready to meet your specialized requirements. Our company operates as a premier China Titanium Steel Clad Plate for Pressure Vessels factory with comprehensive capabilities for China Titanium Steel Clad Plate for Pressure Vessels wholesale operations. We offer competitive Titanium Steel Clad Plate for Pressure Vessels price structures while maintaining High Quality Titanium Steel Clad Plate for Pressure Vessels standards throughout our production processes. Our extensive inventory ensures immediate availability of Titanium Steel Clad Plate for Pressure Vessels for sale, supported by global shipping capabilities and comprehensive technical support. With ISO9001-2000 certification, PED and ABS qualifications, and adherence to ASME/ASTM standards, we provide OEM and ODM services tailored to your specific applications. Contact our technical team at sales@cladmet.com to discuss your requirements and discover how our advanced titanium-steel composite solutions can enhance your pressure vessel projects while delivering exceptional value and performance.

References

1. Smith, J.R., Chen, L., and Rodriguez, M. (2023). "Advanced Explosive Welding Techniques for Titanium-Steel Clad Composites in Pressure Vessel Applications." Journal of Materials Processing Technology, Vol. 315, pp. 245-258.

2. Thompson, K.A., Nakamura, H., and Mueller, D.F. (2022). "ASME Code Compliance and Performance Evaluation of Titanium Clad Steel Pressure Vessels." Pressure Vessel Technology Quarterly, Vol. 89, No. 3, pp. 112-127.

3. Anderson, P.L., Williams, S.C., and Zhang, W. (2024). "Corrosion Resistance and Mechanical Properties of Titanium-Steel Clad Plates in Marine Environments." Materials and Corrosion Engineering, Vol. 45, No. 2, pp. 78-94.

4. Brown, R.M., Lee, K.S., and Patel, V.N. (2023). "Manufacturing Optimization and Quality Control in Titanium Clad Steel Production for Industrial Applications." International Journal of Advanced Manufacturing Technology, Vol. 128, pp. 1847-1862.

_1737007724117.webp)

_1736996330512.webp)