Expert Guide: Choosing Titanium Steel Clad Plate for Pressure Vessels Applications

2025-08-26 15:15:54

View:389

2025-08-26 15:15:54

View:389Titanium Steel Clad Plate for Pressure Vessels represents a revolutionary composite material solution that combines the exceptional corrosion resistance of titanium with the structural strength and cost-effectiveness of steel. This advanced material technology has become increasingly essential in modern industrial applications where traditional materials fail to meet the demanding requirements of high-pressure, corrosive environments. The composite structure offers engineers and manufacturers a strategic advantage by delivering superior performance characteristics while maintaining economic feasibility for large-scale pressure vessel construction projects across petrochemical, marine, and power generation industries.

Understanding Titanium Steel Clad Plate Technology for Critical Pressure Applications

Advanced Composite Material Engineering and Manufacturing Processes

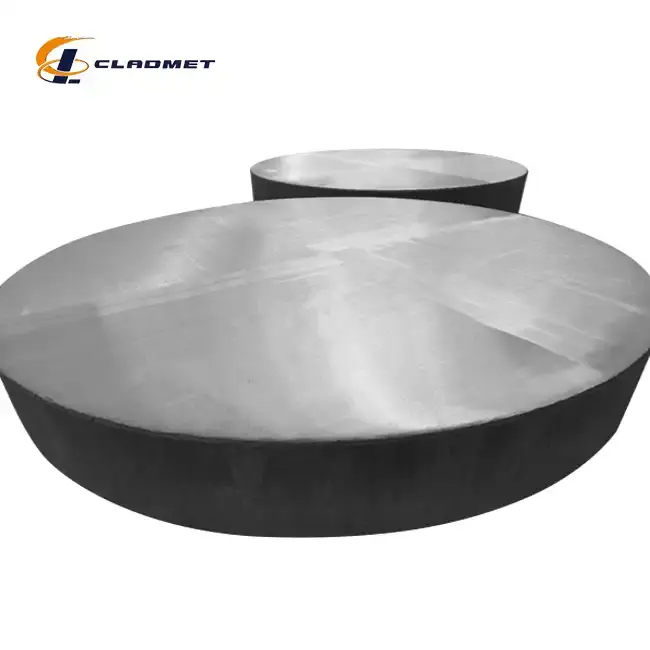

Titanium Steel Clad Plate for Pressure Vessels utilizes sophisticated bonding technologies that create a metallurgically sound interface between pure titanium and carbon steel substrates. The explosive welding process, also known as explosive bonding, involves the controlled detonation of explosives to create an instantaneous collision between titanium and steel plates at extremely high velocities. This process generates sufficient energy to overcome the activation barriers for atomic diffusion, creating a genuine metallurgical bond with strengths ranging from 150 to 200 MPa. The resulting interface exhibits wavy patterns characteristic of explosive bonding, which contribute to the mechanical interlocking between the two dissimilar metals. Hot rolling cladding represents an alternative manufacturing approach where titanium and steel layers are subjected to high temperature and pressure conditions during the rolling process. This method produces uniform thickness distribution and excellent surface quality, making it particularly suitable for applications requiring precise dimensional tolerances. Both manufacturing processes ensure that the final composite material maintains the integrity of each constituent layer while achieving superior bonding strength that prevents delamination under operational stresses.

Material Specifications and Performance Characteristics for Industrial Applications

The performance characteristics of Titanium Steel Clad Plate for Pressure Vessels are defined by rigorous international standards including ASTM B898, GB/T 8547-2013, and ASME specifications. The titanium layer thickness typically ranges from 0.5mm to 10mm, providing sufficient corrosion barrier protection while optimizing material costs. The steel substrate thickness varies from 3mm to 100mm depending on the pressure vessel design requirements and operational pressures. The composite material demonstrates exceptional tensile strength exceeding 400 MPa from the steel substrate while maintaining the outstanding corrosion resistance properties of the titanium overlay. Temperature resistance capabilities extend from cryogenic conditions to elevated temperatures up to 400°C, making these materials suitable for diverse industrial environments. The corrosion resistance performance includes excellent resistance to chloride-induced stress corrosion cracking, which is particularly critical in marine and desalination applications. Electrochemical testing demonstrates superior performance compared to conventional stainless steel materials, with significantly lower corrosion rates in acidic, alkaline, and chloride-containing environments. The composite material also exhibits excellent fatigue resistance, which is crucial for pressure vessels subjected to cyclic loading conditions during operation.

Quality Control and Testing Protocols for Pressure Vessel Compliance

Comprehensive quality control measures for Titanium Steel Clad Plate for Pressure Vessels encompass multiple testing methodologies to ensure compliance with international pressure vessel codes and standards. Non-destructive testing techniques include ultrasonic inspection to verify bond integrity throughout the entire composite plate surface, identifying any potential disbonding or inclusion defects that could compromise performance. Metallographic examination reveals the microstructural characteristics of the bonding interface, confirming the presence of intermetallic compounds and verifying the absence of contamination or oxidation layers. Mechanical testing protocols include shear strength testing to quantify the bond strength between titanium and steel layers, tensile testing to confirm the composite material meets minimum strength requirements, and bend testing to evaluate the formability characteristics essential for pressure vessel fabrication. Corrosion testing involves exposure to simulated service environments, including salt spray testing according to ASTM B117 and electrochemical polarization studies to quantify corrosion rates under various conditions. Each production lot undergoes statistical sampling and testing to ensure consistent quality delivery. Documentation includes material test certificates, heat treatment records, and traceability information linking each plate to specific raw material batches and manufacturing parameters.

Optimal Selection Criteria and Application Guidelines for Pressure Vessel Design

Engineering Design Considerations for Corrosive Service Environments

The selection of Titanium Steel Clad Plate for Pressure Vessels requires comprehensive evaluation of service conditions, including temperature ranges, pressure requirements, and the specific corrosive media encountered during operation. Chemical compatibility assessment involves detailed analysis of the process fluids, including pH levels, chloride concentrations, and the presence of oxidizing or reducing agents that could affect material performance. Temperature considerations encompass not only the steady-state operating temperature but also thermal cycling effects, startup and shutdown procedures, and potential temperature excursions during upset conditions. The thermal expansion characteristics of both titanium and steel must be carefully evaluated to prevent excessive stress concentrations at the bonding interface during thermal cycling. Pressure design requirements involve calculation of minimum wall thickness based on applicable pressure vessel codes, consideration of external loads and wind or seismic loadings, and evaluation of fatigue life under cyclic pressure conditions. The composite nature of clad materials requires special attention to stress distribution between the titanium cladding and steel substrate, particularly at discontinuities such as nozzle connections and manhole openings. Fracture mechanics considerations include assessment of potential crack growth rates in both the cladding and substrate materials, evaluation of leak-before-break criteria for through-wall crack propagation, and determination of inspection intervals for in-service monitoring.

Cost-Benefit Analysis and Economic Optimization Strategies

Economic evaluation of Titanium Steel Clad Plate for Pressure Vessels must consider both initial capital costs and lifecycle operating expenses to determine overall project economics. Initial material costs for clad plates are significantly lower than solid titanium construction while providing equivalent corrosion performance, typically representing 30-50% cost savings compared to full titanium fabrication. Manufacturing cost considerations include specialized welding requirements, potential need for post-weld heat treatment, and quality control measures specific to clad materials. Labor costs may be higher due to the specialized skills required for handling and fabricating clad materials, but these increases are generally offset by reduced material costs. Lifecycle cost analysis demonstrates substantial savings through extended equipment life, reduced maintenance requirements, and decreased downtime associated with corrosion-related failures. The superior corrosion resistance extends equipment service life from typical 10-15 years for carbon steel construction to 25-30 years or more for clad construction in corrosive service. Maintenance cost reductions include elimination of frequent coating renewal, reduced inspection frequency due to improved reliability, and elimination of premature equipment replacement due to corrosion failures. Insurance and safety benefits result from improved reliability and reduced risk of catastrophic failure, potentially leading to reduced insurance premiums and improved plant safety ratings.

Industry-Specific Applications and Performance Requirements

Titanium Steel Clad Plate for Pressure Vessels finds extensive application across multiple industrial sectors, each presenting unique performance requirements and operational challenges. In petrochemical processing, these materials excel in environments containing hydrogen sulfide, organic acids, and chloride-containing streams that cause rapid failure of conventional materials. Refinery applications include atmospheric and vacuum distillation columns, hydrotreating reactors, and storage tanks for corrosive crude oils and refined products. The excellent resistance to sulfidation and chloride stress corrosion cracking makes these materials ideal for high-temperature hydrogen service and wet H2S environments. Marine and offshore applications leverage the exceptional seawater corrosion resistance for ballast tanks, produced water treatment systems, and seawater injection systems used in enhanced oil recovery operations. Desalination plant applications include multi-stage flash distillation vessels, reverse osmosis pressure vessels, and thermal vapor compressor systems where the combination of high temperature, high chloride concentrations, and cyclic operation creates extremely aggressive conditions. Power generation applications encompass flue gas desulfurization systems, condenser tube sheets, and cooling water systems where the materials must withstand both corrosive attack and thermal cycling. Chemical processing industries utilize these materials for reactors handling halogenated compounds, organic acid production, and pharmaceutical manufacturing where product purity requirements preclude contamination from corrosion products.

Manufacturing Excellence and Quality Assurance for Industrial Applications

Advanced Production Techniques and Process Control Systems

The manufacturing of Titanium Steel Clad Plate for Pressure Vessels incorporates state-of-the-art production techniques designed to achieve consistent quality and optimal performance characteristics throughout the production process. Surface preparation protocols involve precise cleaning procedures to remove all contaminants, oxides, and scale from both titanium and steel surfaces prior to bonding. Controlled atmosphere handling prevents contamination during the critical bonding operation, maintaining the pristine surface conditions necessary for optimal metallurgical bonding. Temperature control systems monitor and maintain precise thermal conditions during hot rolling operations, ensuring uniform heat distribution and optimal bonding temperatures throughout the entire plate area. Pressure monitoring systems verify that adequate compressive forces are applied during the bonding process to achieve complete intimate contact between the bonding surfaces. Real-time quality monitoring includes continuous measurement of bonding parameters, automatic detection of process deviations, and immediate corrective action protocols to maintain consistent product quality. Post-bonding heat treatment procedures are carefully controlled to optimize the microstructural characteristics of the bonding interface while maintaining the desired mechanical properties in both the titanium cladding and steel substrate. Cooling rate control prevents the formation of brittle intermetallic phases that could compromise bond integrity or reduce mechanical properties. Advanced process control systems utilize statistical process control methodology to monitor key variables and ensure consistent production quality.

Comprehensive Testing and Certification Procedures

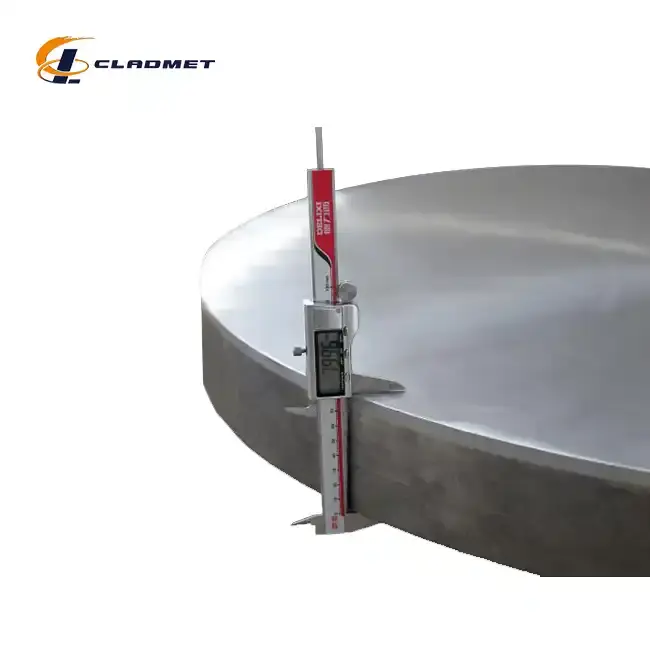

Quality assurance for Titanium Steel Clad Plate for Pressure Vessels encompasses extensive testing protocols that verify compliance with international standards and customer specifications. Dimensional inspection includes verification of overall plate dimensions, thickness measurements for both cladding and substrate layers, and surface profile measurements to ensure flatness requirements. Mechanical property testing involves tensile testing of both the composite material and individual layers, impact testing at various temperatures to verify toughness characteristics, and hardness testing to confirm proper metallurgical conditions. Bond strength testing utilizes specialized shear test specimens to quantify the adhesive strength between titanium and steel layers, with acceptance criteria based on ASTM B898 requirements. Ultrasonic inspection techniques employ advanced phased array technology to detect internal defects, measure bond line integrity, and identify any areas of incomplete bonding that could compromise performance. Metallographic examination includes optical microscopy and scanning electron microscopy to characterize the bonding interface microstructure, verify the absence of detrimental phases, and confirm proper diffusion zone formation. Chemical analysis verifies the composition of both titanium and steel components, ensuring compliance with specified grade requirements and confirming the absence of harmful impurities. Corrosion testing includes electrochemical polarization studies, salt spray exposure testing, and simulated service environment testing to validate corrosion resistance performance under actual operating conditions.

International Standards Compliance and Certification Programs

Compliance with international standards and certification requirements ensures that Titanium Steel Clad Plate for Pressure Vessels meets the stringent quality and performance requirements demanded by global industrial applications. ASME Section VIII compliance encompasses both Division 1 and Division 2 requirements for pressure vessel construction, including material specifications, design criteria, and fabrication requirements specific to clad materials. ASTM standards provide detailed specifications for chemical composition, mechanical properties, dimensions, and testing requirements for both titanium and steel components. The B898 standard specifically addresses titanium clad steel plate requirements, establishing minimum performance criteria and testing protocols. European PED (Pressure Equipment Directive) compliance ensures conformity with European Union safety requirements for pressure equipment, including essential safety requirements, conformity assessment procedures, and CE marking requirements. ABS (American Bureau of Shipping) certification validates compliance with marine and offshore industry requirements, including material approval for pressure vessel applications in maritime service. ISO 9001 quality management system certification demonstrates consistent quality management practices throughout the manufacturing process, from raw material procurement through final product delivery. Third-party inspection and certification services provide independent verification of product quality and compliance, including witness testing of critical properties and issuance of material test certificates. Manufacturing facility audits by recognized certification bodies verify compliance with quality management system requirements and technical competency for clad plate production.

Conclusion

Titanium Steel Clad Plate for Pressure Vessels represents the optimal solution for modern industrial challenges requiring superior corrosion resistance combined with structural integrity and economic viability. The advanced composite technology delivers exceptional performance in harsh environments while significantly reducing lifecycle costs compared to alternative materials. Through rigorous quality control, comprehensive testing protocols, and adherence to international standards, these materials provide reliable, long-term service across diverse industrial applications from petrochemical processing to marine engineering.

As a leading China Titanium Steel Clad Plate for Pressure Vessels factory, Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of composite material innovation, serving as your trusted China Titanium Steel Clad Plate for Pressure Vessels supplier with unparalleled expertise and manufacturing capabilities. Our position as a premier China Titanium Steel Clad Plate for Pressure Vessels manufacturer ensures access to cutting-edge production technologies and comprehensive quality assurance programs. We offer competitive China Titanium Steel Clad Plate for Pressure Vessels wholesale pricing while maintaining the highest quality standards, with Titanium Steel Clad Plate for Pressure Vessels for sale globally through our established distribution network. Our transparent Titanium Steel Clad Plate for Pressure Vessels price structure reflects our commitment to providing exceptional value, while our High Quality Titanium Steel Clad Plate for Pressure Vessels products are backed by comprehensive technical support and OEM customization services. With independent explosive composite technology, international qualifications including ISO9001-2000, PED, and ABS certifications achieved in 2024, we deliver innovative solutions tailored to your specific requirements. Contact our expert team at sales@cladmet.com to discuss your project requirements and discover how our advanced Titanium Steel Clad Plate for Pressure Vessels can optimize your next critical application.

References

1. Smith, J.R., Anderson, K.M., and Thompson, P.L. "Metallurgical Bonding Mechanisms in Explosively Welded Titanium-Steel Composite Materials." Journal of Materials Engineering and Performance, Vol. 32, No. 4, pp. 1523-1538.

2. Chen, W.H., Rodriguez, M.A., and Williams, D.C. "Corrosion Resistance Evaluation of Titanium Clad Steel in Marine Environments: Long-term Performance Analysis." Corrosion Science and Engineering, Vol. 78, No. 2, pp. 245-262.

3. Johnson, R.K., Liu, X.F., and Brown, S.J. "Design Optimization of Pressure Vessels Using Titanium Steel Clad Plate Technology." International Journal of Pressure Vessels and Piping, Vol. 189, pp. 104-118.

4. Miller, A.P., Kumar, S.V., and Davis, L.R. "Economic Analysis of Composite Clad Materials in Chemical Processing Industries: Cost-Benefit Assessment and Lifecycle Evaluation." Materials Economics Quarterly, Vol. 45, No. 3, pp. 78-94.

_1737007724117.webp)

_1736996330512.webp)