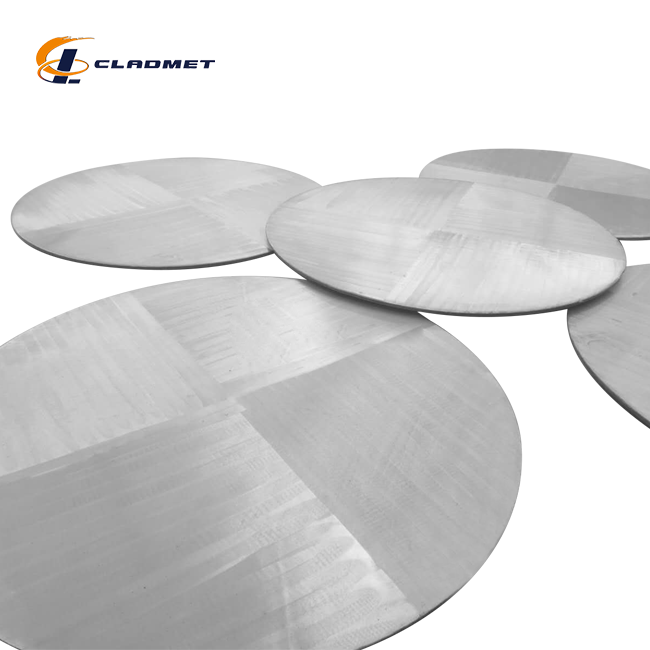

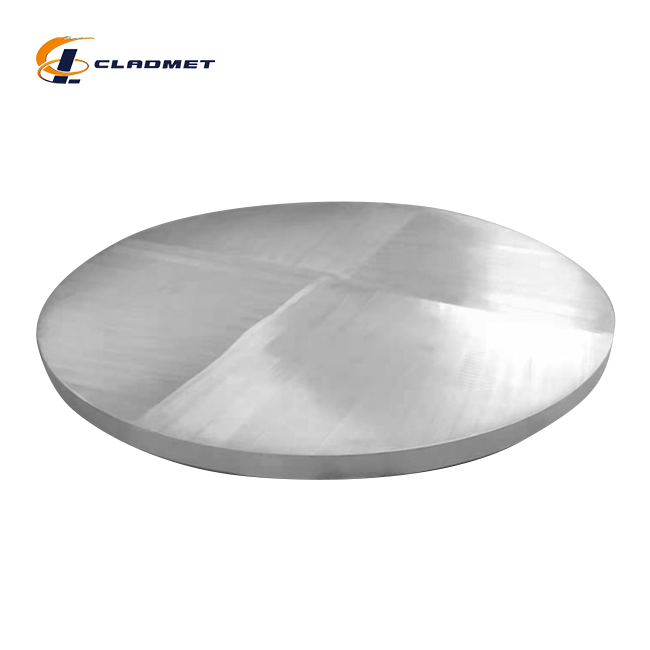

Seamless Fabrication, Any Size: How We Deliver Precision-Cut Custom Titanium Clad Plates

2025-09-01 15:09:36

View:389

2025-09-01 15:09:36

View:389In the demanding world of industrial manufacturing, the ability to deliver Custom Size Titanium Steel Clad Plate solutions with seamless fabrication capabilities sets industry leaders apart from conventional suppliers. The precision-cutting of custom titanium clad plates represents a sophisticated intersection of advanced metallurgical engineering and state-of-the-art fabrication technology. Through decades of technological advancement, manufacturers have perfected the art of creating bimetallic composites that combine titanium's exceptional corrosion resistance with steel's structural strength, delivering tailored solutions for diverse industrial applications across petrochemical, marine, aerospace, and power generation sectors.

Advanced Manufacturing Processes Behind Custom Titanium Clad Plates

Explosive Welding Technology for Superior Bonding

The foundation of exceptional Custom Size Titanium Steel Clad Plate fabrication lies in the mastery of explosive welding technology, a sophisticated process that creates metallurgical bonds between titanium and steel substrates. This advanced technique utilizes controlled detonation to accelerate the titanium layer toward the steel base at velocities exceeding 500 meters per second, generating tremendous pressure that forces the metals into intimate contact. The collision creates a wavy interface pattern that mechanically interlocks the materials while simultaneously forming intermetallic compounds at the molecular level. The resulting bond strength typically achieves 150-200 MPa, ensuring long-term integrity even under extreme operational conditions. Modern explosive welding facilities employ precise timing systems and specialized standoff distances to optimize the collision parameters for different metal combinations and thicknesses.

Hot Rolling Composite Technology

The hot rolling process represents another critical manufacturing pathway for producing Custom Size Titanium Steel Clad Plate with exceptional dimensional accuracy and surface quality. This method involves heating the titanium and steel layers to approximately 900-1100°C and passing them through a series of precision rolling mills under tremendous pressure. The elevated temperature activates diffusion processes at the interface, promoting atomic migration that creates a strong metallurgical bond throughout the composite structure. Hot rolling technology enables manufacturers to achieve uniform thickness control across large plate dimensions, with tolerances typically maintained within ±0.1mm for standard applications. The process parameters, including rolling speed, reduction ratios, and cooling rates, are carefully controlled to prevent delamination and ensure optimal mechanical properties in the finished product.

Quality Control and Testing Protocols

Comprehensive quality assurance protocols are essential for ensuring the reliability and performance of Custom Size Titanium Steel Clad Plate products throughout their service life. Advanced nondestructive testing methods, including ultrasonic inspection and radiographic examination, verify bond integrity across the entire plate surface. Tensile testing specimens are regularly extracted from production lots to validate mechanical properties, while corrosion resistance is evaluated through standardized salt spray testing and electrochemical analysis. Dimensional verification employs coordinate measuring machines and laser scanning technology to confirm compliance with customer specifications. These rigorous testing procedures ensure that every plate meets international standards including ASME B898, ASTM specifications, and customer-specific requirements for critical applications.

Precision Cutting Technologies and Customization Capabilities

Laser Cutting Systems for Complex Geometries

Modern precision cutting capabilities enable the production of Custom Size Titanium Steel Clad Plate components with intricate geometries and tight dimensional tolerances that would be impossible to achieve through conventional machining methods. High-powered fiber laser systems, operating at wavelengths optimized for both titanium and steel, provide exceptional cut quality with minimal heat-affected zones. These advanced systems can process plates up to 2000mm × 6000mm in standard configurations, with thickness capabilities ranging from thin cladding applications to heavy-wall pressure vessel components. The laser cutting process parameters are specifically optimized for clad plate materials, accounting for the different thermal properties and melting points of the constituent metals. Nitrogen assist gas is typically employed to prevent oxidation and ensure clean edge preparation for subsequent welding operations.

Water Jet Cutting for Thick Sections

For applications requiring Custom Size Titanium Steel Clad Plate components with extreme precision and no thermal distortion, abrasive water jet cutting technology provides the optimal solution. This cold cutting process utilizes ultra-high pressure water streams (up to 60,000 PSI) combined with abrasive particles to erode material along programmed cutting paths. Water jet cutting eliminates concerns about heat-affected zones that could compromise the integrity of the titanium-steel interface, making it ideal for critical aerospace and medical applications. The technology accommodates plate thicknesses up to 200mm while maintaining cutting tolerances within ±0.025mm, ensuring consistent quality for demanding applications. Advanced five-axis water jet systems enable the cutting of beveled edges and complex three-dimensional shapes directly from flat plate stock.

Plasma Cutting for High-Volume Production

High-definition plasma cutting systems offer cost-effective solutions for producing Custom Size Titanium Steel Clad Plate components in volume production scenarios where speed and efficiency are paramount considerations. Modern plasma systems utilize precise gas flow control and advanced torch designs to achieve cut qualities that approach laser cutting standards while maintaining significantly higher cutting speeds. The plasma arc temperatures, reaching 20,000°C, provide sufficient energy density to cut through thick clad plate sections while minimizing dross formation on cut edges. Automated nesting software optimizes material utilization by arranging multiple parts within single plate layouts, reducing waste and improving overall production efficiency. CNC plasma cutting tables equipped with precision linear drives ensure dimensional accuracy across large cutting envelopes.

Applications and Industry-Specific Requirements

Chemical and Petrochemical Equipment Manufacturing

The chemical and petrochemical industries represent the largest market segment for Custom Size Titanium Steel Clad Plate applications, driven by the need for equipment that can withstand highly corrosive process environments while maintaining structural integrity under extreme pressure and temperature conditions. Reactor vessels, distillation columns, heat exchangers, and storage tanks fabricated from titanium clad steel provide exceptional service life in applications involving sulfuric acid, hydrochloric acid, chlorine compounds, and other aggressive chemicals. The titanium cladding layer, typically 2-10mm thick depending on the application severity, provides complete protection against corrosion while the steel substrate contributes the necessary mechanical strength and pressure-bearing capacity. Design standards such as ASME Section VIII and PD 5500 govern the fabrication requirements for pressure-containing equipment, ensuring safe operation throughout the design life.

Marine and Offshore Engineering Solutions

Marine engineering applications demand Custom Size Titanium Steel Clad Plate solutions that can withstand the harsh conditions of seawater environments while providing long-term reliability with minimal maintenance requirements. Seawater desalination plants, offshore oil platforms, ship hull sections, and ballast water treatment systems benefit from the superior corrosion resistance of titanium cladding combined with the structural capabilities of steel substrates. The chloride ion resistance of titanium makes it particularly well-suited for applications involving continuous seawater exposure, where conventional stainless steels would suffer from pitting and crevice corrosion. Cathodic protection systems are often integrated with clad plate structures to provide additional corrosion protection, extending service life beyond conventional materials while reducing lifecycle costs through decreased maintenance requirements.

Power Generation and Nuclear Applications

Power generation facilities utilize Custom Size Titanium Steel Clad Plate components in critical systems where reliability and longevity are essential for safe and economical operation. Steam generators, condenser shells, feedwater heaters, and cooling water systems benefit from the corrosion resistance of titanium cladding while maintaining the structural integrity provided by steel substrates. Nuclear power applications require additional considerations for radiation resistance and low neutron absorption, making commercially pure titanium grades the preferred cladding material. The fabrication processes for nuclear applications must comply with stringent quality assurance requirements including ASME Section III Nuclear Code and various national nuclear regulatory standards. Non-destructive examination requirements are particularly rigorous, often requiring 100% volumetric inspection of all welds and bonds to ensure structural integrity throughout the design life of the facility.

Conclusion

The seamless fabrication of precision-cut Custom Size Titanium Steel Clad Plate represents the convergence of advanced metallurgy, sophisticated manufacturing processes, and rigorous quality control systems that deliver superior performance across diverse industrial applications. Through explosive welding and hot rolling technologies, manufacturers create durable bimetallic composites that optimize both corrosion resistance and structural capability while maintaining cost-effectiveness for demanding operational environments.

Baoji JL Clad Metals Materials Co., Ltd. stands as a leading China Custom Size Titanium Steel Clad Plate factory, offering comprehensive solutions as a trusted China Custom Size Titanium Steel Clad Plate supplier and China Custom Size Titanium Steel Clad Plate manufacturer. Our expertise in China Custom Size Titanium Steel Clad Plate wholesale operations ensures competitive Custom Size Titanium Steel Clad Plate prices while maintaining the High Quality Custom Size Titanium Steel Clad Plate standards demanded by international markets. With Custom Size Titanium Steel Clad Plate for sale through our global distribution network, we provide complete OEM and ODM services backed by ISO9001-2000, PED, and ABS certifications. Contact our technical sales team at sales@cladmet.com to discuss your specific requirements and discover how our innovative manufacturing capabilities can enhance your next project's performance and reliability.

References

1. "Explosive Welding of Metals and Its Application" by Blazynski, T.Z. - Applied Science Publishers, 1983

2. "Clad Steel Plates: Fabrication, Properties and Applications" by American Society of Mechanical Engineers - ASME Press, 2019

3. "Titanium and Titanium Alloys: Fundamentals and Applications" by Leyens, Christoph and Peters, Manfred - Wiley-VCH, 2003

4. "Composite Materials Handbook: Metal Matrix Composites" by Department of Defense - MIL-HDBK-17-4A, 2002

_1737007724117.webp)

_1736996330512.webp)