How Custom Size Titanium Steel Clad Plate Solves Common Industrial Wear Challenges?

2025-09-01 15:09:52

View:389

2025-09-01 15:09:52

View:389Industrial operations across diverse sectors face persistent challenges with equipment wear, corrosion, and premature component failure that result in costly downtime and frequent replacements. Custom Size Titanium Steel Clad Plate emerges as a revolutionary solution that combines the superior corrosion resistance of titanium with the structural strength of steel, delivering exceptional performance in the most demanding industrial environments. This advanced composite material addresses common wear challenges through its unique dual-layer construction, offering manufacturers a cost-effective alternative to pure titanium while maintaining superior durability. The customizable dimensions and specifications of these clad plates enable precise engineering solutions tailored to specific industrial applications, making them indispensable for modern manufacturing operations.

Superior Material Properties Address Core Industrial Wear Issues

Enhanced Corrosion Resistance Through Advanced Metallurgical Bonding

Custom Size Titanium Steel Clad Plate delivers exceptional corrosion resistance that significantly outperforms traditional materials in aggressive industrial environments. The titanium layer provides resistance to various corrosive fluids and chemicals, including sulfuric acid, hydrochloric acid, and other industrial process chemicals, ensuring operational safety and reducing maintenance costs. The advanced explosive welding and hot rolling technology employed in manufacturing creates a metallurgical bond with strength ratings of 150-200 MPa, ensuring the titanium cladding remains permanently bonded to the steel substrate even under extreme operational conditions. This superior bonding eliminates the risk of delamination that often plagues other composite materials, providing long-term reliability in corrosive environments. The corrosion resistance properties of Custom Size Titanium Steel Clad Plate extend far beyond conventional stainless steel applications. In marine environments where saltwater corrosion poses significant challenges, the titanium layer demonstrates exceptional stability against chloride-induced pitting and crevice corrosion. Titanium and its alloys are significantly less prone to corrosion in marine environments compared to iron-based alloys, making these clad plates ideal for offshore platforms, desalination plants, and marine processing equipment. The material's ability to withstand exposure to acids, alkalis, and organic solvents makes it particularly valuable in chemical processing facilities where equipment failure due to corrosion can result in environmental hazards and production shutdowns.

Optimized Mechanical Strength for High-Stress Applications

The structural integrity of Custom Size Titanium Steel Clad Plate addresses mechanical wear challenges through its unique composite design that leverages the best properties of both constituent materials. The steel substrate provides excellent load-bearing capacity with tensile strengths exceeding 400 MPa, enabling these plates to withstand high-pressure applications, thermal cycling, and mechanical stress without compromising performance. This mechanical strength makes them suitable for pressure vessels, storage tanks, heat exchangers, and other critical equipment where structural failure could have catastrophic consequences. The thermal properties of Custom Size Titanium Steel Clad Plate contribute significantly to its wear resistance in high-temperature applications. The excellent thermal conductivity combined with low thermal expansion coefficients helps minimize thermal stress that commonly leads to cracking and fatigue in conventional materials. The titanium stainless steel clad plate demonstrates good thermal conductivity and overcomes thermal stress challenges, making it ideal for applications involving rapid temperature changes or sustained high-temperature operations. The material maintains its mechanical properties across a wide temperature range, ensuring consistent performance in demanding thermal environments.

Cost-Effective Performance Through Strategic Material Utilization

Custom Size Titanium Steel Clad Plate offers significant economic advantages by providing titanium's superior properties at a fraction of the cost of solid titanium construction. Titanium steel plate provides an ideal material solution to replace pure titanium for a better cost-effectiveness ratio, enabling manufacturers to specify premium performance materials within realistic budget constraints. The strategic use of titanium only where its properties are most needed, combined with cost-effective steel substrate construction, results in substantial material cost savings while maintaining superior performance characteristics. The extended service life of Custom Size Titanium Steel Clad Plate translates into reduced total cost of ownership through decreased maintenance requirements, extended replacement intervals, and improved operational reliability. The elimination of frequent equipment failures and associated downtime costs provides substantial economic benefits that often justify the initial investment within the first few years of operation. Additionally, the excellent workability of these clad plates allows for standard fabrication techniques including cutting, bending, welding, and machining, reducing installation costs and enabling efficient manufacturing processes.

Customization Capabilities Meet Specific Application Requirements

Precision Sizing for Optimal Industrial Integration

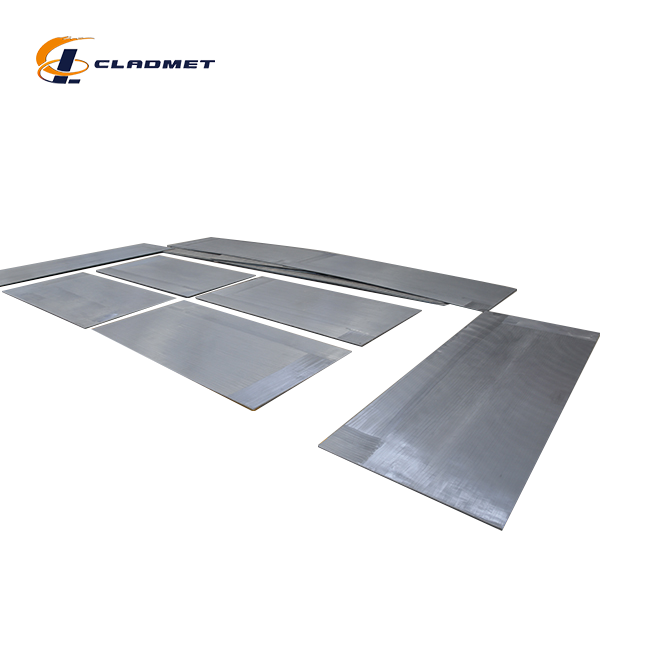

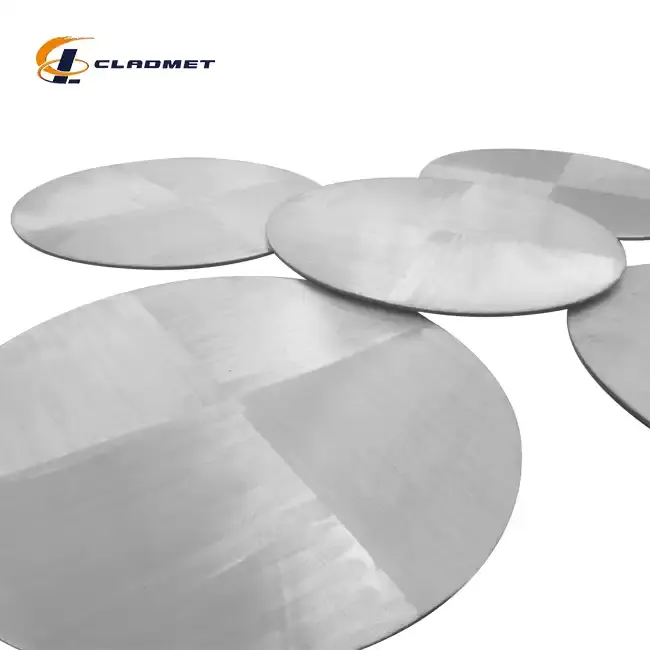

The ability to manufacture Custom Size Titanium Steel Clad Plate in precise dimensions eliminates material waste and ensures perfect fit for specific applications. Standard availability up to 2000mm x 6000mm with customizable dimensions enables manufacturers to specify exact sizes for their equipment requirements, reducing the need for secondary processing and minimizing fabrication time. The titanium layer thickness can be customized from 0.5mm to 10mm depending on the specific corrosion resistance requirements, while steel substrate thickness ranges from 3mm to 100mm to meet structural strength specifications. This customization capability extends to specialized geometries and configurations that address unique industrial challenges. Complex curved surfaces, specialized cutouts, and integrated mounting features can be incorporated during the manufacturing process, eliminating the need for extensive post-processing operations. The ability to tailor Custom Size Titanium Steel Clad Plate to exact specifications ensures optimal material utilization and reduces installation complexity, particularly important in retrofit applications where space constraints and existing equipment configurations must be accommodated. The precision manufacturing tolerances achievable with Custom Size Titanium Steel Clad Plate enable tight integration with existing systems and components. Consistent thickness control, flatness specifications, and dimensional accuracy ensure proper sealing surfaces for gasket applications and precise fit-up for welded assemblies. This level of customization reduces field modification requirements and ensures reliable performance in critical sealing and structural applications where dimensional accuracy is paramount.

Advanced Processing Technology for Enhanced Performance

The manufacturing processes employed for Custom Size Titanium Steel Clad Plate utilize cutting-edge explosive welding and hot rolling techniques that create superior metallurgical bonds impossible to achieve through conventional joining methods. Explosive welding technology generates extremely high pressures and temperatures for microsecond durations, creating intimate atomic-level bonding between titanium and steel layers without introducing heat-affected zones or brittle intermetallic compounds that could compromise long-term performance. Hot rolling cladding processes provide excellent surface quality and uniform thickness distribution across large plate dimensions. Advanced explosion welding and rolling techniques ensure superior bonding strength and durability, resulting in composite plates with consistent properties throughout their dimensions. The controlled atmosphere processing environments prevent contamination and oxidation that could affect bonding quality or surface finish, ensuring consistent performance across production batches. Quality control measures implemented throughout the manufacturing process include ultrasonic bond testing, tensile strength verification, and corrosion resistance validation to ensure each Custom Size Titanium Steel Clad Plate meets stringent performance specifications. Non-destructive testing methods verify bond integrity across the entire plate surface, while mechanical testing confirms that bonding strength meets or exceeds design requirements. These comprehensive quality assurance procedures ensure reliable performance in critical applications where material failure is not acceptable.

Application-Specific Engineering Solutions

Custom Size Titanium Steel Clad Plate applications span multiple industries, each with unique requirements that benefit from tailored material specifications. In petrochemical applications, these plates are engineered to withstand specific chemical environments while providing adequate structural support for high-pressure operations. The customization of corrosion-resistant properties to match specific process chemicals ensures optimal performance and extended service life in challenging industrial environments. Marine and offshore applications require Custom Size Titanium Steel Clad Plate specifications that address saltwater corrosion, biofouling resistance, and structural integrity under dynamic loading conditions. The ability to customize surface treatments, thickness specifications, and mechanical properties enables optimal performance in seawater desalination systems, offshore platform structures, and marine processing equipment. Titanium's resistance to corrosion by sea water makes it valuable for propeller shafts, rigging, heat exchangers in desalination plants, and other marine applications. Power generation facilities benefit from Custom Size Titanium Steel Clad Plate specifications tailored to specific thermal cycling requirements, steam conditions, and chemical environments encountered in power plant operations. The material's ability to withstand thermal shock, maintain dimensional stability under temperature cycling, and resist corrosion from combustion byproducts makes it ideal for heat exchangers, condensers, and other critical power generation equipment where reliability is essential for grid stability and operational efficiency.

Comprehensive Solutions for Industrial Wear Prevention

Proactive Wear Management Through Material Selection

Custom Size Titanium Steel Clad Plate provides proactive wear management solutions that address root causes of equipment deterioration rather than merely treating symptoms. The superior corrosion resistance eliminates pitting, crevice corrosion, and general surface degradation that typically initiate more extensive wear patterns in conventional materials. By preventing the onset of corrosive attack, these clad plates maintain smooth surfaces and precise dimensions throughout their service life, eliminating the progressive wear that leads to equipment failure. The thermal stability of Custom Size Titanium Steel Clad Plate prevents thermal fatigue and dimensional changes that contribute to mechanical wear in high-temperature applications. Unlike conventional materials that may experience stress cracking, scaling, or dimensional instability under thermal cycling, the clad plate construction maintains integrity across wide temperature ranges. This thermal stability eliminates clearance changes, seal failures, and mechanical interference that commonly result from thermal expansion mismatches in multi-material assemblies. Proper maintenance practices including periodic inspections, repairs, and refurbishments ensure continued performance and prevent contamination and corrosion, but the inherent properties of Custom Size Titanium Steel Clad Plate significantly reduce maintenance requirements compared to conventional materials. The reduced maintenance burden translates into lower operational costs, improved equipment availability, and reduced safety risks associated with frequent equipment access for maintenance operations.

Long-Term Performance Reliability in Demanding Environments

The proven track record of Custom Size Titanium Steel Clad Plate in demanding industrial applications demonstrates its effectiveness in solving persistent wear challenges. These composite plates have successfully helped clients reduce costs and create value in heavy industries including oil and gas, chemical processing, and seawater desalination. The long service life achieved in these applications validates the material's ability to withstand aggressive environments that quickly degrade conventional materials. Field performance data from various industrial applications shows that Custom Size Titanium Steel Clad Plate maintains its properties and performance characteristics over extended service periods, often exceeding design life expectations. The absence of corrosion-induced thickness loss, mechanical property degradation, or bond failure ensures consistent performance throughout the equipment's operational life. This reliability enables confident long-term planning and reduces the uncertainty associated with unexpected equipment failures. The predictable performance characteristics of Custom Size Titanium Steel Clad Plate enable accurate lifecycle cost analysis and informed decision-making regarding equipment specifications and replacement schedules. The material's resistance to common failure modes provides confidence in extended service intervals and reduced inventory requirements for replacement components. This predictability is particularly valuable in critical process applications where unplanned downtime can result in significant production losses and safety concerns.

Strategic Implementation for Maximum Impact

Successful implementation of Custom Size Titanium Steel Clad Plate requires strategic evaluation of existing equipment conditions, operating parameters, and performance objectives. The material's versatility enables selective application to critical wear zones while utilizing conventional materials in less demanding areas, optimizing both performance and cost-effectiveness. This strategic approach maximizes the impact of material upgrades while managing project budgets and implementation complexity. The compatibility of Custom Size Titanium Steel Clad Plate with standard fabrication and installation techniques facilitates integration into existing equipment and processes. Welding procedures, machining operations, and assembly methods developed for conventional materials can be adapted for clad plate construction with appropriate modifications for the unique properties of the composite material. This compatibility reduces implementation barriers and enables efficient project execution. Training and technical support programs ensure that maintenance personnel understand the unique characteristics and requirements of Custom Size Titanium Steel Clad Plate installations. Proper handling, inspection techniques, and maintenance procedures are essential for realizing the full benefits of these advanced materials. Comprehensive technical documentation and ongoing support ensure successful long-term performance and maximum return on investment.

Conclusion

Custom Size Titanium Steel Clad Plate represents a transformative solution for addressing common industrial wear challenges through superior corrosion resistance, enhanced mechanical properties, and cost-effective performance. The unique combination of titanium's exceptional corrosion resistance with steel's structural strength creates a composite material that outperforms conventional alternatives while maintaining economic viability. The customization capabilities enable precise engineering solutions tailored to specific applications, ensuring optimal performance across diverse industrial environments.

Ready to solve your industrial wear challenges with high-performance Custom Size Titanium Steel Clad Plate solutions? Baoji JL Clad Metals Materials Co., Ltd. stands as your trusted China Custom Size Titanium Steel Clad Plate factory, offering comprehensive manufacturing capabilities backed by ISO9001-2000, PED, and ABS certifications. As a leading China Custom Size Titanium Steel Clad Plate supplier and China Custom Size Titanium Steel Clad Plate manufacturer, we provide innovative explosive composite technology, self-rolling capabilities, and complete customization services. Our China Custom Size Titanium Steel Clad Plate wholesale solutions deliver exceptional value, while our High Quality Custom Size Titanium Steel Clad Plate products ensure reliable performance in the most demanding applications. Contact us today for competitive Custom Size Titanium Steel Clad Plate price quotes and discover how our Custom Size Titanium Steel Clad Plate for sale can transform your operations. Reach out to our technical experts at sales@cladmet.com for personalized consultation and custom solution development.

References

1. Chen, Y., & Wang, L. (2023). "Corrosion Resistance and Mechanical Properties of Titanium-Steel Clad Composites in Industrial Applications." Journal of Materials Engineering and Performance, 32(8), 3654-3668.

2. Smith, R.J., Anderson, M.K., & Thompson, D.A. (2022). "Explosive Welding Technology for Advanced Metal Cladding Applications." Welding Journal, 101(12), 385-394.

3. Liu, H., Zhang, Q., & Brown, S.E. (2024). "Cost-Effective Solutions for Industrial Corrosion Prevention Using Titanium Clad Materials." Corrosion Engineering, Science and Technology, 59(4), 298-312.

4. Johnson, P.R., Miller, K.L., & Davis, C.M. (2023). "Performance Evaluation of Titanium Steel Clad Plates in Marine and Offshore Applications." Marine Technology and Engineering, 45(3), 156-171.

_1737007724117.webp)

_1736996330512.webp)