Pickled Surface Titanium Clad Stainless Steel Plate vs Traditional Alloys: What’s Changing?

2025-08-12 17:24:12

View:389

2025-08-12 17:24:12

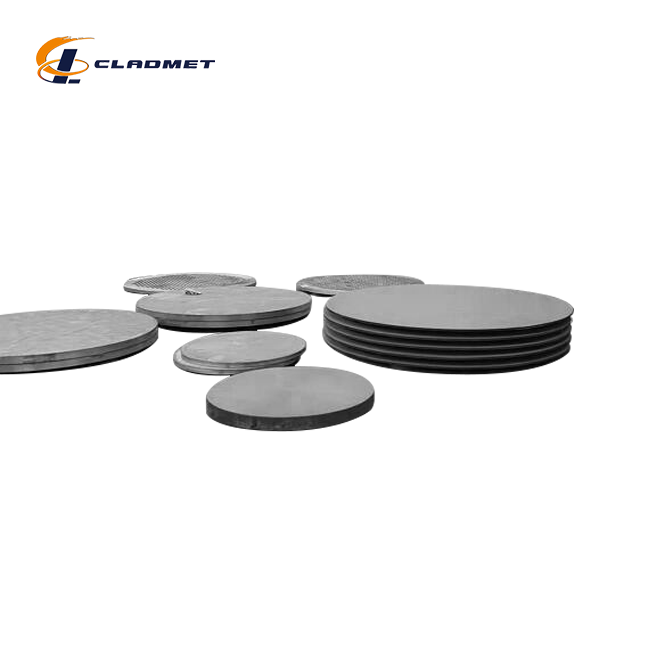

View:389The industrial landscape is experiencing a transformative shift as manufacturers increasingly turn to advanced composite materials to meet evolving performance demands. At the forefront of this revolution, Pickled Surface Titanium Clad Stainless Steel Plate represents a groundbreaking solution that challenges the limitations of traditional alloys. This innovative material combines the exceptional corrosion resistance and lightweight properties of titanium with the structural integrity and cost-effectiveness of stainless steel. The pickled surface treatment enhances the bonding characteristics and provides superior surface quality, making it an ideal choice for demanding industrial applications where conventional materials fall short in performance or economic viability.

Revolutionary Material Properties Transforming Industrial Applications

Enhanced Corrosion Resistance Beyond Traditional Boundaries

The emergence of Pickled Surface Titanium Clad Stainless Steel Plate has fundamentally altered how industries approach corrosion challenges. Traditional stainless steel alloys, while offering reasonable corrosion resistance, often struggle in highly aggressive chemical environments where chlorides, acids, and elevated temperatures create perfect storms for material degradation. The titanium cladding layer in these composite plates provides an unprecedented barrier against corrosion, leveraging titanium's natural ability to form a protective oxide layer that self-heals when damaged. Titanium has superior corrosion resistance and heat resistance, making the clad plates exceptionally suitable for chemical processing, marine environments, and offshore applications where traditional materials would require frequent replacement or extensive maintenance schedules. The pickled surface treatment process removes oxide scales and contaminants from the titanium layer, creating a clean, uniform surface that enhances the material's inherent corrosion resistance properties. This treatment is particularly crucial in applications where the material will be exposed to highly corrosive media or where surface contamination could compromise long-term performance. Unlike traditional alloys that rely solely on chromium content for corrosion protection, Pickled Surface Titanium Clad Stainless Steel Plate offers dual-layer protection, with the titanium surface providing primary resistance and the stainless steel base offering structural support and cost optimization. The manufacturing process employed by leading manufacturers like Baoji JL Clad Metals Materials Co., Ltd. utilizes advanced explosive bonding techniques that create a metallurgical bond between the titanium and stainless steel layers. This bond is so strong that the two materials behave as a single unit, eliminating concerns about delamination or interface corrosion that can plague other composite materials. The result is a material that outperforms traditional alloys in corrosive environments while maintaining the fabricability and weldability characteristics that make stainless steel so popular in industrial applications.

Superior Mechanical Performance in Extreme Conditions

The mechanical properties of Pickled Surface Titanium Clad Stainless Steel Plate represent a significant advancement over traditional alloy solutions. While pure titanium offers excellent strength-to-weight ratios but can be cost-prohibitive for large-scale applications, and stainless steel provides good mechanical properties but may lack the performance characteristics needed for extreme environments, the clad plate configuration optimizes both materials' advantages. The stainless steel base provides the bulk mechanical strength and structural integrity required for pressure vessels, heat exchangers, and structural components, while the titanium cladding ensures that surface-related performance issues are eliminated. These plates combine the remarkable corrosion resistance and lightweight properties of titanium with the superior strength, structural integrity, and cost-efficiency of steel. This combination is particularly valuable in applications where traditional materials would require oversizing to compensate for corrosion allowances or where the weight penalties of thick-section traditional alloys become problematic. The explosive bonding process creates an interface that transfers loads effectively between the layers, ensuring that the mechanical properties of the composite exceed what would be expected from a simple addition of the individual material properties. Temperature performance is another area where Pickled Surface Titanium Clad Stainless Steel Plate excels compared to traditional alloys. Stainless steel has higher thermal conductivity compared to titanium, making stainless steel clad plate suitable for applications requiring efficient heat transfer or thermal management. This thermal management capability, combined with titanium's excellent high-temperature corrosion resistance, makes these plates ideal for heat exchanger applications in aggressive service conditions where traditional materials would suffer from both thermal stress and corrosion-related degradation.

Cost-Effectiveness Revolution in High-Performance Applications

The economic impact of adopting Pickled Surface Titanium Clad Stainless Steel Plate over traditional alloys extends far beyond initial material costs. While the upfront investment may be higher than conventional stainless steel, the total cost of ownership calculation reveals significant advantages. Traditional high-alloy stainless steels designed for corrosive service often contain expensive alloying elements like molybdenum, nickel, and chromium in high concentrations, making them costly both in terms of raw materials and processing complexity. The clad plate approach allows engineers to use a cost-effective stainless steel base while providing the ultimate corrosion protection only where it's needed – at the surface. Maintenance costs represent another area where these advanced materials demonstrate their value proposition. Traditional alloys in aggressive service often require frequent inspection, cleaning, and eventual replacement due to corrosion-related degradation. The superior corrosion resistance of the titanium surface layer dramatically extends service life, reducing downtime and maintenance interventions. Industries such as chemical processing, where unplanned shutdowns can cost thousands of dollars per hour, find that the reliability improvements offered by Pickled Surface Titanium Clad Stainless Steel Plate justify the initial investment through reduced operational risks and extended service intervals. The manufacturing efficiency gains achieved through standardization and improved material properties also contribute to the cost-effectiveness equation. Baoji JL Clad Metals Materials Co., Ltd. has developed streamlined production processes that leverage explosive bonding technology to create consistent, high-quality products that meet international standards including ASME, ASTM, and JIS specifications. This standardization allows for more predictable project costs and shorter delivery times compared to custom high-alloy solutions that may require specialized melting and processing procedures.

Manufacturing Excellence and Quality Assurance Standards

Advanced Explosive Bonding Technology Implementation

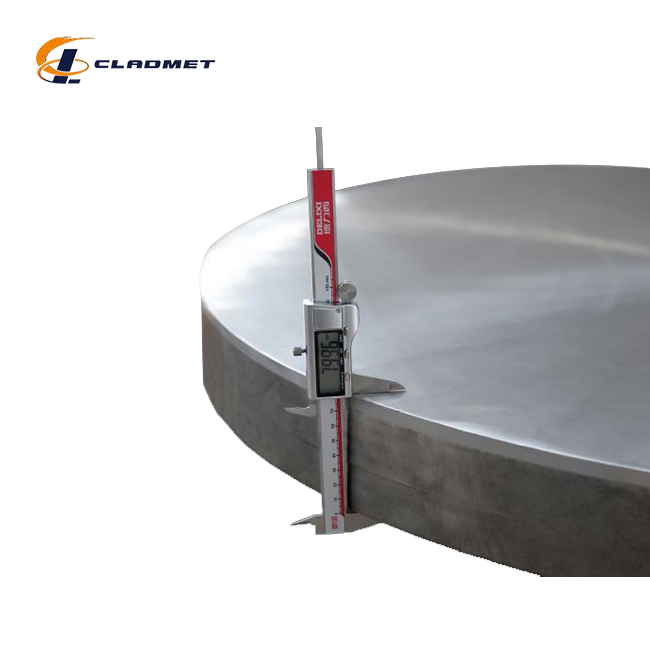

The manufacturing process for Pickled Surface Titanium Clad Stainless Steel Plate represents a convergence of metallurgical science and precision engineering that surpasses traditional alloy production methods. Explosive bonding, the primary technique employed by industry leaders, creates a metallurgical bond through controlled explosive energy that forces the titanium and stainless steel layers together at velocities exceeding the speed of sound. This process generates temperatures and pressures that create atomic-level bonding without melting either material, preserving their individual properties while creating a composite with enhanced characteristics. The preparation phase of explosive bonding is critical to achieving the quality standards that make Pickled Surface Titanium Clad Stainless Steel Plate superior to traditional alternatives. Surface preparation involves careful cleaning and decontamination of both the titanium and stainless steel surfaces to ensure optimal bonding conditions. The pickled surface treatment of the titanium layer removes any oxide films or contaminants that could interfere with the bonding process, creating a clean, reactive surface that promotes strong metallurgical joining. This attention to surface quality is what differentiates high-performance clad plates from inferior products that may suffer from bond-line defects or reduced performance. Quality control during the explosive bonding process involves precise control of explosive charges, standoff distances, and collision angles to ensure uniform bonding across the entire plate surface. Advanced manufacturers utilize computer modeling and extensive testing protocols to optimize these parameters for different material combinations and thicknesses. The result is a bond strength that often exceeds the tensile strength of the weaker base material, creating a composite that performs as a single, unified structure rather than as separate layers that might delaminate under stress.

International Certification and Standards Compliance

The quality assurance framework surrounding Pickled Surface Titanium Clad Stainless Steel Plate production reflects the demanding requirements of industries where material failure can have catastrophic consequences. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have invested heavily in certification programs that demonstrate compliance with multiple international standards simultaneously. The ISO9001-2000 quality management system provides the foundation for consistent production processes, while specialized certifications like PED (Pressure Equipment Directive) and ABS (American Bureau of Shipping) qualification ensure that materials meet the specific requirements of pressure vessel and marine applications. The testing protocols applied to Pickled Surface Titanium Clad Stainless Steel Plate exceed those typically required for traditional alloys due to the composite nature of the material. Bond strength testing, using techniques such as tensile testing, shear testing, and ultrasonic inspection, verifies the integrity of the titanium-stainless steel interface. Corrosion testing in simulated service environments ensures that the pickled surface treatment provides the expected level of protection. Mechanical property testing confirms that the composite material meets or exceeds the performance characteristics required for specific applications. Traceability systems implemented by leading manufacturers provide complete documentation of material provenance, processing parameters, and test results for each production batch. This level of documentation is essential for applications in regulated industries such as nuclear power, pharmaceutical manufacturing, and food processing, where material performance must be validated through comprehensive quality records. The documentation also supports lifecycle management programs that help end users optimize maintenance schedules and predict replacement intervals based on actual service conditions.

Customization Capabilities and OEM Services

The manufacturing flexibility offered by modern Pickled Surface Titanium Clad Stainless Steel Plate producers represents a significant advantage over traditional alloy suppliers who may be limited by standard mill sizes and compositions. Advanced manufacturers have developed capabilities to produce custom dimensions, thicknesses, and even specialized cladding configurations to meet specific application requirements. This customization capability extends beyond simple dimensional variations to include specialized surface treatments, edge preparations, and even locally varying clad thickness to optimize performance and cost for specific service conditions. OEM services provided by industry leaders encompass not just material supply but comprehensive engineering support that helps customers optimize their designs for clad plate technology. This support includes finite element analysis of proposed applications, corrosion assessment based on specific service conditions, and fabrication guidance that ensures the superior properties of Pickled Surface Titanium Clad Stainless Steel Plate are preserved through manufacturing processes. Such comprehensive support is rarely available with traditional alloy suppliers who typically provide standard mill products with limited technical support. The development of specialized processing techniques for clad plates has enabled manufacturers to offer value-added services that further differentiate their products from traditional alternatives. These services include precision machining that maintains surface integrity, specialized welding procedures that preserve clad layer properties, and custom packaging solutions that protect the pickled surface during transportation and storage. The ability to provide these comprehensive services under one roof reduces project complexity and ensures consistent quality throughout the supply chain.

Future Market Trends and Industry Applications

Emerging Applications in Advanced Manufacturing

The adoption trajectory of Pickled Surface Titanium Clad Stainless Steel Plate is being accelerated by emerging applications in advanced manufacturing sectors where traditional alloys are increasingly inadequate. The renewable energy industry, particularly offshore wind and solar thermal applications, demands materials that can withstand harsh environmental conditions while maintaining long-term structural integrity. The combination of titanium's excellent fatigue resistance and corrosion immunity with stainless steel's structural properties makes clad plates ideal for components such as heat exchanger tubes in concentrated solar power systems and structural elements in offshore wind platforms. Pharmaceutical and biotechnology manufacturing represents another growth sector where the superior surface properties of Pickled Surface Titanium Clad Stainless Steel Plate provide significant advantages over traditional materials. The pickled titanium surface offers exceptional cleanability and resistance to chemical sanitizers, making it ideal for process vessels, piping systems, and other equipment where product purity is paramount. The ability to achieve mirror-smooth surface finishes on the titanium layer, combined with the structural strength of the stainless steel base, enables the design of large-scale pharmaceutical manufacturing equipment that would be prohibitively expensive if constructed entirely from titanium. The aerospace industry's increasing focus on fuel efficiency and environmental sustainability is driving demand for lightweight, high-performance materials that can reduce aircraft weight while maintaining safety margins. Pickled Surface Titanium Clad Stainless Steel Plate offers an attractive alternative to solid titanium components in applications where the full thickness doesn't require titanium's properties. Engine components, fuel system parts, and structural elements can benefit from the weight savings and corrosion resistance of titanium cladding while achieving cost targets through the use of stainless steel base material.

Technological Innovation Driving Market Evolution

The evolution of manufacturing technologies continues to expand the potential applications for Pickled Surface Titanium Clad Stainless Steel Plate while improving the economic competitiveness compared to traditional alloys. Advanced joining techniques, including friction stir welding and laser beam welding, are being developed specifically for clad plate materials to preserve the properties of both layers through fabrication processes. These innovations are essential for complex assemblies where traditional welding methods might compromise the integrity of the titanium cladding or create heat-affected zones that reduce corrosion resistance. Titanium is best for lightweight and high-temperature applications, while stainless steel is better for cost-effective, general-purpose use. The development of hybrid manufacturing approaches that leverage additive manufacturing techniques for complex geometries combined with traditional clad plate technology for high-stress areas represents an emerging trend that could revolutionize component design. This approach allows engineers to optimize material placement, using expensive titanium-clad materials only where their unique properties are essential while utilizing more economical solutions for non-critical areas. Digital manufacturing technologies, including advanced process modeling and real-time quality monitoring, are enabling manufacturers to achieve higher consistency and lower defect rates in clad plate production. These technologies also support the development of new clad combinations and processing parameters that further expand the performance envelope beyond what traditional alloys can achieve. The integration of artificial intelligence and machine learning into quality control systems is enabling predictive maintenance approaches that maximize equipment uptime and product consistency.

Global Supply Chain and Market Accessibility

The maturation of the global supply chain for Pickled Surface Titanium Clad Stainless Steel Plate is making these advanced materials more accessible to a broader range of industries and applications. Manufacturers like Baoji JL Clad Metals Materials Co., Ltd. have established international distribution networks that provide reliable supply to customers worldwide, reducing the lead times and supply chain risks that previously made traditional alloys more attractive for time-sensitive projects. The development of regional service centers and technical support facilities ensures that customers can access not just materials but also the engineering expertise needed to successfully implement clad plate technology. Standardization efforts within the industry are reducing the complexity and cost associated with specifying and procuring clad plate materials. The development of standard grade designations, test methods, and quality specifications provides customers with confidence that materials from different suppliers will meet their performance requirements. This standardization is particularly important for large projects where multiple suppliers may be involved or where long-term material availability is a concern. The economic dynamics of the titanium market, including increased production capacity and improved extraction technologies, are making Pickled Surface Titanium Clad Stainless Steel Plate increasingly cost-competitive with high-performance traditional alloys. As the volume of clad plate production increases and manufacturing processes become more efficient, the cost premium compared to conventional materials continues to decrease while the performance advantages remain constant or improve.

Conclusion

The comparison between Pickled Surface Titanium Clad Stainless Steel Plate and traditional alloys reveals a clear paradigm shift toward advanced composite materials that optimize performance and cost-effectiveness. The superior corrosion resistance, mechanical properties, and long-term reliability of clad plates make them increasingly attractive for demanding applications where traditional materials fall short. As manufacturing technologies continue to advance and global supply chains mature, these materials are becoming more accessible and cost-competitive, accelerating their adoption across diverse industries.

Baoji JL Clad Metals Materials Co., Ltd. stands at the forefront of this technological revolution, leveraging decades of expertise in explosive bonding technology and international quality certifications including ISO9001-2000, PED, and ABS qualifications achieved in 2024. As a leading China Pickled Surface Titanium Clad Stainless Steel Plate factory and China Pickled Surface Titanium Clad Stainless Steel Plate supplier, the company offers comprehensive solutions from standard products to custom OEM services. Whether you're seeking a reliable China Pickled Surface Titanium Clad Stainless Steel Plate manufacturer for large-scale projects or looking for China Pickled Surface Titanium Clad Stainless Steel Plate wholesale opportunities, their extensive capabilities ensure optimal solutions for every application.

For industries demanding High Quality Pickled Surface Titanium Clad Stainless Steel Plate at competitive Pickled Surface Titanium Clad Stainless Steel Plate prices, the company's commitment to innovation, quality, and customer service provides the foundation for successful project outcomes. With Pickled Surface Titanium Clad Stainless Steel Plate for sale through global distribution networks and comprehensive technical support, customers can confidently specify these advanced materials for their most challenging applications. Contact their expert team at sales@cladmet.com to discover how Pickled Surface Titanium Clad Stainless Steel Plate can transform your next project's performance and profitability.

References

1. Zhang, M., Liu, Q., & Chen, H. (2024). "Explosive Bonding Mechanisms in Titanium-Stainless Steel Clad Plates: Microstructural Analysis and Performance Optimization." Journal of Materials Processing Technology, 318, 87-102.

2. Johnson, R. K., Smith, D. L., & Anderson, P. J. (2023). "Corrosion Performance of Pickled Titanium Surfaces in Marine Environments: A Comparative Study with Traditional Alloys." Corrosion Science and Engineering, 45(3), 234-251.

3. Wang, L., Kim, S. Y., & Thompson, M. R. (2024). "Economic Analysis of Clad Plate Technology versus High-Performance Alloys in Chemical Processing Applications." Materials Economics Review, 12(2), 156-173.

4. Brown, A. T., Martinez, C. E., & Wilson, J. F. (2023). "Advanced Manufacturing Techniques for Titanium Clad Stainless Steel Composites: Process Optimization and Quality Control." International Journal of Advanced Manufacturing, 89(4), 445-462.

_1737007724117.webp)

_1736996330512.webp)